Sound insulation property of Al-Si closed-cell aluminum foam bare board material

YU Hai-jun(尉海军)1, YAO Guang-chun(姚广春)1, WANG Xiao-lin(王晓林)2,

LI Bing(李 兵)1, YIN Yao(尹 銚)2, LIU Ke(刘 克)2

1. School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China;

2. Institute of Acoustics, Chinese Academy of Sciences, Beijing 100080, China

Received 14 April 2006; accepted 25 September 2006

___________________________________________________________

Abstract: Al-Si closed-cell aluminum foam bare boards of 1 240 mm×1 100 mm with different densities and thicknesses were prepared by molten body transitional foaming process. The sound reduction index(R) of Al-Si closed-cell aluminum foam bare boards was investigated experimentally under different frequencies (100-4 000 Hz). It is found that sound reduction index(R) is small under low frequencies, large under high frequencies and is controlled by different mechanisms. The sound insulation property basically conforms with the monolayer board sound insulation theory. The sound reduction index(R) increases with the even growth of thickness and density, but its rising trend is tempered. The single number sound reduction indexes(RW) of specimen with thickness of 20 cm and density of 0.51 g/cm3 are 30.8 dB and 33 dB respectively, which demonstrates good sound insulation property for lightmass materials.

Key words: Al-Si closed-cell aluminum foam; bare board; sound reduction index(R); density; thickness

___________________________________________________________

1 Introduction

The research and development of metal foams started since 1940’s[1]. Compared with traditional materials, aluminum foam materials have the advantages of low density, high stiffness and impact resistance, low thermal conductivity, low magnetic conductivity, and fine damping, so they have become one of the fields in high technology material research all over the world [2-8]. Owing to the limitation of preparing large specimen, the researches in the past focused only on the mechanics and energy absorption of aluminum foam material[9-10] and rarely on the acoustics especially sound insulation property. Because of its special structure, aluminum foam has great potential application in fields such as sound insulation and noise reduction. In this paper, the author researches on the sound insulation property of Al-Si closed-cell aluminum foam bare boards of different densities and thicknesses prepared by molten body transitional foaming process in Northeastern University[11-12], and provides some information for its application in such fields as sound insulation and noise reduction.

2 Experimental

2.1 Preparation of aluminum foam materials

Al-Si closed-cell aluminum foams were produced by molten body transitional foaming process in Northeastern University, China. The materials of different densities and thicknesses will be called below the NEU foams. The process of preparing aluminum foam can be found in Refs.[11-12].

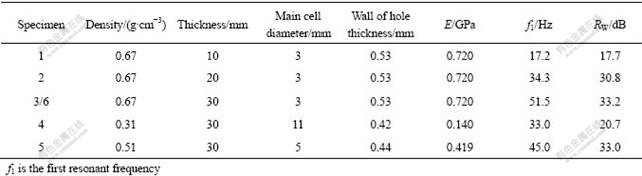

Five bare boards (1 240 mm×1 100 mm) with different thicknesses (ρ=0.67 g/cm3, thickness 10 mm, 20 mm, 30 mm) and different densities (thickness 30 mm, ρ=0.31, 0.51, 0.67 g/cm3) were prepared by utilizing the saw machine, flattener, cleaning machine, etc. The densities of the NEU foams were calculated by weighing the machined specimens on a balance and measuring their dimensions using a digital caliper. The cell and wall of cell for each specimen were measured using the method of arithmetic average. The essential parameters of specimens were systematically recorded before experiments, including the density of specimen, cell diameter, and wall thickness of cells etc (see Table 1). For convenience, the NEU foams above are labeled specimens 1, 2, 3, 4, 5, 6 respectively, among which specimens 3 and 6 are the same specimen.

Table 1 Parameters of Al-Si closed-cell aluminum foam bare boards

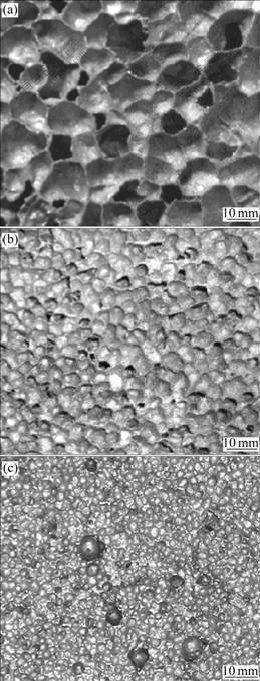

Figs.1(a), (b) and (c) show the macrographs of specimens 4, 5, 3/6 respectively. It can be easily seen that the morphology of the three specimens is distinct from each other; the cell morphology is comparatively in good condition; the main cell diameter gets smaller and smaller, while the wall of cell thicker and thicker.

Fig.1 Macrographs of specimens with different densities: (a) ρ= 0.31 g/cm3; (b) ρ=0.51 g/cm3; (c) ρ=0.67 g/cm3

2.2 Test of sound insulation property

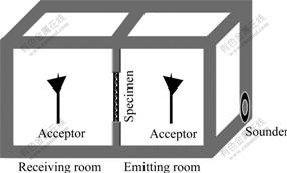

The sound insulation properties of specimens were tested at Institute of Acoustics, Chinese Academy of Sciences. Fig.2 shows the sketch map of sound insulation testing. The shape and volume of the Lab test room were in agreement with the criterion of GBJ 75/84[13]. Clamping the specimen on testing frame, the actual testing area of specimen was only 1 100 mm×1 100 mm. The sound pressure signals of emitting room and receiving room were collected by Real Time Analyzer 840 sound pressure analytical apparatus, and the average sound pressure level in room was calculated by Eqn.(1)[14]:

Fig.2 Sketch map of sound insulation testing

(1)

(1)

where  is the average sound pressure level in the room, dB; Lpi is the sound pressure level of the measuring point i in the room, dB; n is the number of the measuring points.

is the average sound pressure level in the room, dB; Lpi is the sound pressure level of the measuring point i in the room, dB; n is the number of the measuring points.

Because the sound field can diffuse and sound can only pass through specimen, the sound insulation property of random incidence can be calculated by

(2)

(2)

where R is the sound reduction index, dB;  is the average sound pressure level of the emitting room, dB;

is the average sound pressure level of the emitting room, dB;  is the average sound pressure level of receiving room, dB; S is the area of the specimen, m2; A is the sound absorption value, m2.

is the average sound pressure level of receiving room, dB; S is the area of the specimen, m2; A is the sound absorption value, m2.

(3)

(3)

The sound absorption value(A) can be got from Eqn.(3). Microphones were set at five different positions, and for each position the sound reveration time was analyzed at least twice. A is the sound absorption value of the receiving room; V is the volume of the receiving room; T60 is the sound reveration time, s.

3 Results and discussion

3.1 Influence of frequency on sound insulation property

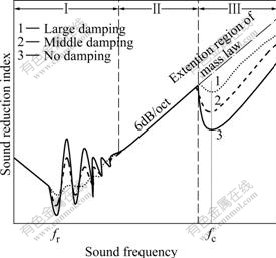

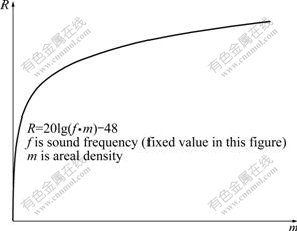

For the given material, the sound reduction index (R) is controlled by different mechanisms in different frequency ranges[15] (Fig.3).

Fig.3 Characteristic curve between sound reduction index and sound frequency of monolayer board (fr is the first resonance frequency; fc is the critical frequency; Ⅰis the stiffness and damping control section; Ⅱis the mass control section; Ⅲ is the coincidence effect section)

The first resonant frequency can be calculated by [16]:

(4)

(4)

where B=10.4; h, a, b, ρ, υ, E are the thickness, length, width, density, Poisson ratio and elastic modulus of specimen, respectively.

When the frequency is lower than fr, the sound reduction index (R) is mainly controlled by the stiffness of the board[15]. Among this section, the response of the board wall when facing sound pressure is similar to a spring; sound reduction index (R) is proportional to the stiffness of the board wall (for certain frequency, the higher the stiffness, the larger the sound reduction index is). For the same board, sound reduction index (R) gradually drops when the frequency increases. From Table 1, all of the first resonant frequencies of NEU foam bare boards are lower than 100 dB, so there is no stiffness control section in Fig.4.

Fig.4 Characteristic curve between sound reduction index (R) and sound frequency of specimen 5

When the frequency is higher than f1, sound reduction index (R) mainly relies on natural resonance, board size and fix condition of the board[15]. Compared with entity material, aluminum foams have good damping effect; and the loss coefficient (η) is one order of magnitude higher than that of entity material[17]. The consumption of vibration by aluminum foam is mainly through the friction between crack faces in the structure transmitting vibration energy to thermal energy and then dispersing into the surrounding environment. In addition, the wall vibration of cell also has damping effect, and the thinner the wall of cell, the easier the vibration, so it can consume the sound energy more easily. As a result the fluctuations of curves in Fig.4 within this section are smooth, which can be well predicated by the theoretical curve with large damping.

After the damping control comes to the mass control, Eqn.(5) is the formula for mass control[16]:

R0=20lg(m?f)-43 (5)

where R0 is the vertical incidence sound reduction index, dB; m is the surface density of board material, kg·m-2; f is the frequency, Hz. Then, the random incidence sound reduction index (R) can be calculated from the following equation approximately[14]:

R=R0-5=20lg(m?f)-48 (5)

In Fig.4, the sound reduction index (R) in this section climbs straightly when the frequency increases, and the slope coefficient is 4.5 dB/oct, which is close to the theoretical value (6 dB/oct). While the projection of incident sound wave’s wavelength on the board is equal to the wavelength of board when doing flexural vibration, the sound wave of this frequency can completely transfer to the opposite side of the board, and generate a valley, which is called coincidence effect. The frequency is called critical frequency[14]. The result of Fig.4 indicates that the coincident valley of NEU foam bare board is not obvious, and sound reduction index (R) also climbs straightly when the frequency is larger than fc, and the slope coefficient is 8 dB/oct approaching 10 dB/oct.

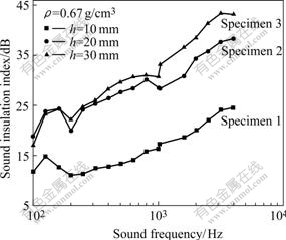

3.2 Influence of thickness on sound insulation property

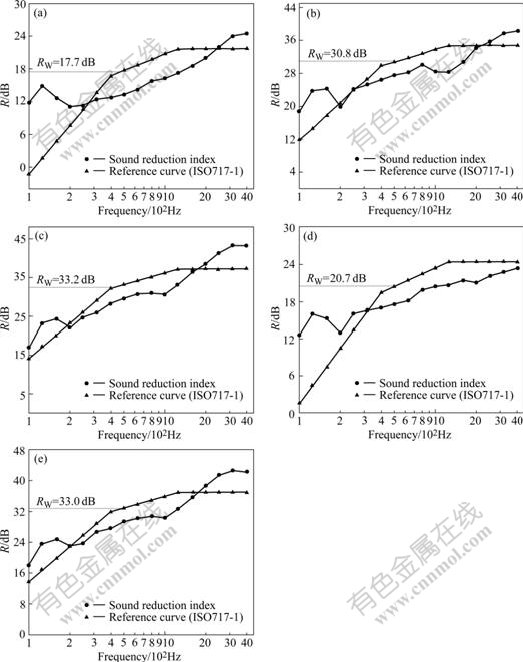

Fig.5 shows the sound insulation property of NEU foam bare boards of different thicknesses, from which it can be concluded that all sound reduction index (R) of the three NEU foam bare boards increases with the frequency accreting from 100 Hz to 4 000 Hz; and sound reduction index (R) at low frequencies is smaller than that at high frequencies regardless of the thickness of the NEU foam bare boards. Sound reduction index (R) of NEU foam bare board of different thicknesses grows with thickness increasing, but does not increase equivalently with the equivalently added thickness. For the convenience of analysis, single number sound reduction index (RW) is gotten according to the international evaluation criterion of sound insulation material[18] in Fig.6. Figs.6(a), (b) and (c) show the single number sound reduction index (RW) of NEU foam bare board of different thicknesses, from which it can be seen that single number sound reduction index (RW) increases by 13.1 dB with thickness increasing from 10 mm to 20 mm, while it grows by 2.4 dB with thickness increasing from 20 mm to 30 mm.

Fig.5 Characteristic curves between sound reduction index (R) and frequency of specimens 1, 2, 3

Fig.6 ISO717-1 sound reduction index (R) vs frequency of various specimens:(a) Specimen 1; (b) Specimen 2; (c) Specimen 3/6; (d) Specimen 4; (e) Specimen 5

Sound reduction index (R) is mainly influenced by the surface density (m) and the frequency, which can be explained by Eqn.(6). Fixing the frequency, sound reduction index (R) increases with the added surface density of board, but the increasing trend becomes flatten (Fig.7), while the surface density (m) is directly proportional to the thickness of boards, so the test result shows that although the thickness of NEU foam bare board increases equivalently, the single number sound reduction index (RW) of it grows unequivalently.

Fig.7 Relation between R and m

Thus adding thickness of NEU foam bare boards can increase the sound reduction index (R) markedly, but the sound insulation property does not increase equivalently with equally adding thickness. The increase of sound insulation property cannot be achieved by adding the thickness of aluminum foam boards. Based on tests, NEU foam bare boards (thickness 20 mm) can commendably satisfy the effective demand when considering material economy.

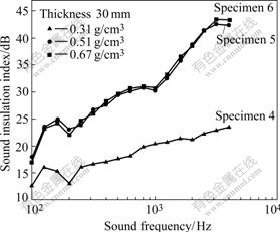

3.3 Influence of density on sound insulation property

Fig.8 shows the sound insulation property of NEU foam bare boards (thickness 30 mm, ρ=0.31, 0.51, 0.67 g/cm3). Sound reduction index (R) also increases with the frequency accreting from 100 Hz to 4 000 Hz. The sound insulation property increases obviously when the density increases from 0.31 g/cm3 to 0.51 g/cm3, but no obvious change occurs when the density increases from 0.51 g/cm3 to 0.67 g/cm3. Figs.6(d), (e) and (c) show that the increasing trend of single number sound reduction index (RW) gradually becomes mitigated.

Fig.8 Characteristic curves between sound reduction index (R) and frequency of specimens 4, 5, 6

Although density has great influence on the sound insulation property of aluminum foam board, when it reaches a definite value, the single number sound reduction index (RW) changes little, that is to say, density does not have positive effect on sound insulation property at this moment, and the reason can also be explained by Eqn.(6). So NEU foam bare boards of 0.51 g/cm3 already has fine sound insulation effect in practical situation, and there is no necessity to enhance the sound insulation of the material by adding the density of board again.

4 Conclusions

1) Frequency has great effect on sound reduction index (R) of NEU foam bare boards, regardless of their thickness and density, and the sound insulation property of board shows the same rule (frequency ranges from 100 Hz to 4 000 Hz). The sound reduction index (R) of NEU foam bare boards under different frequency ranges is controlled by different mechanisms, and sound insulation index (R) under lower frequencies is smaller than that under higher frequencies.

2) Experiments with boards of different thicknesses and densities display that the increasing trend of sound reduction index (R) and single number sound reduction index (RW) becomes mitigated when the thickness and density are added equivalently. So adding thickness and density have their limitations on enhancing sound insulation property of material. Considering practical application, NEU foam bare boards of 0.51 g/cm3 and thickness of 20 mm can demonstrate good sound insulation effect.

References

[1] SOSNICK B. Process for making foamlike mass of metal [P]. US Patent 2434775, 1948.

[2] UENO H, AKIYAMA S. The foaming effect of molten aluminum added calcium metal [J]. J Japan Inst Light Metals, 1987, 37(1): 42-47.

[3] YU Hai-jun, YAO Guang-chun, WANG Xiao-lin, LIU Yi-han, LI Hong-bin. Sound insulation property of Al-Si closed-cell aluminum foam sandwich panels [J]. Applied Acoustics, 2006. (in press)

[4] BAUMG?RTNER F, DUARTE I, BANHART J. Industrialization of powder compact foaming process [J]. Adv Eng Mater, 2000, 2(4): 168-174.

[5] BEALS J T, THOMPSON M S. Density gradient effects on aluminum foam compression behavior [J]. J Mater Sci, 1997, 32: 3595-3600.

[6] BANHART J. Manufacture, characterization and application of cellular metals and metal foams [J]. Progr Mater Sci, 2001, 46: 559-632.

[7] YU Hai-jun, YAO Guang-chun, LIU Yi-han. Research of tensile property of Al-Si closed-cell aluminum foam [J]. Trans Nonferrous Met Soc China, 2006, 16(6): 1335-1340.

[8] IMAGAWA K, AKIYAMA S, UENO H. The development and utilization trend of metal foams [J]. Industrial Mater, 1987, 35(14): 45-46.

[9] ZHOU J, SHROTRIYA P, SOBOYEJO W O. Mechanisms and mechanics of compressive deformation in open-cell Al foams [J]. Mech Mater, 2004, 36: 781-797.

[10] CAO Xiao-qing, WANG Zhi-hua, MA Hong-wei, ZHAO Long-mao, YANG Gui-tong. Effects of heat treatment on dynamic compressive properties and energy absorption characteristics of open-cell aluminum alloy foams [J]. Trans Nonferrous Met Soc China, 2006, 16(1): 159-163.

[11] YU Hai-jun, YAO Guang-chun, LI Bing, GUO Zhi-qiang. Electromagnetic shielding effectiveness of Al-Si closed-cell aluminum foam [J]. J Functional Mater, 2006, 37(8): 1239-1241.(in Chinese)

[12] YU Hai-jun, YAO Guang-chun, LI Bing, WANG Yong. Influence of relative density on compressive behavior of Al-Si closed-cell aluminum foam [J]. Journal of Northeastern University (Natural Science), 2006, 21(6): 1126-1129. (in Chinese)

[13] GBJ75/84. Testing Standard of Sound Insulation in Building [S]. 1984. (in Chinese)

[14] LI Yao-zhong. The Technology of Sound Insulation Controlling [M]. Beijing: Chemical Industry Press, 2004. 18-20. (in Chinese)

[15] WHEELER P D. In Industrial and Machinery Noise Control Practice [M]. UK: University of Sourthampton Press, 1978. 11-13.

[16] MA Da-you, SHEN H. Acoustic Manual [M]. Beijing: Science Press, 2003: 62-65.

[17] HANS-PETER D, BRIGITTE K, ZUO X Q, ZHOU Y. Handbook of Cellular Metals: Production, Processing, Applications [M]. Austria: Wiley-VCH, 2002: 184-195.

[18] ISO 717-1/97. Rating of Sound Insulation in Buildings and of Buildings Elements—Airborne Sound Insulation [S]. 1997.

________________________

Foundation item: Project(2002AA334060) supported by Hi-tech Research and Development Program of China

Corresponding author: YU Hai-jun; Tel: +86-24-83686462; E-mail: yuhaijunneu@163.com

(Edited by YUAN Sai-qian)