DOI: 10.11817/j.issn.1672-7207.2017.04.017

2种形式的液力透平叶轮外特性

杨孙圣1,张慧2,孔繁余1,刘莹莹1

(1. 江苏大学 流体机械研究中心,江苏 镇江,212013;

2. 镇江市自来水公司,江苏 镇江,212013)

摘要:为了提高液力透平的效率,设计前弯和后弯2种形式的叶轮,通过理论分析、数值计算以及实验研究的方法对其进行分析。应用流场分析软件ANSYS CFX分别对具有2种形式叶轮的液力透平进行全流场数值计算与分析,得到2种液力透平外特性曲线的差别,并分析2种液力透平叶轮内部流场流动规律。研究结果表明:前弯形叶轮在最高效率点的流量、扬程、轴功率和效率分别比后弯形叶轮高24.45%,29.80%,68.95%和4.38%;前弯形叶轮高效点以及高效点之后的流量效率(η-Q)曲线高于后弯形叶轮的流量效率曲线,流量扬程(H-Q)曲线低于后弯形叶轮的流量扬程曲线,2种形式的叶轮轴功率相差不大;前弯形叶片叶轮内部速度梯度小于后弯形叶片叶轮的内部速度梯度,前弯形叶片叶轮内部水力损失较少;实验结果与数值预测结果相吻合,验证了数值计算可以用来对液力透平进行优化设计。

关键词:液力透平;前弯形叶轮;后弯形叶轮

中图分类号:TH322 文献标志码:A 文章编号:1672-7207(2017)04-0977-07

Performance of two types of hydraulic turbine impellers

YANG Sunsheng1, ZHANG Hui2, KONG Fanyu1, LIU Yingying1

(1. Research Center of Fluid Machinery Engineering and Technology, Jiangsu University, Zhenjiang 212013, China;

2. Zhenjiang Water Supply Company, Zhenjiang 212013, China)

Abstract: To improve the efficiency of hydraulic turbine, forward and backward-swept impellers were designed. Theoretical analysis, calculation simulation and experimental research were carried out on forward and backward-swept impellers. Performance difference of these two impellers was found by adopting computational fluid dynamic software ANSYS CFX. The internal fluid flow law in impeller was analyzed. The results show that compared with that of backward-swept impeller the flow rate, head, shaft power and efficiency at the best efficiency point (BEP) of forward swept impeller are increased by 24.45%, 29.80%, 68.95% and 4.38%, respectively. After BEP, turbine’s η-Q curve of impeller with forward-swept impeller is higher and H-Q curve is lower than that of backward-swept impeller. The variation of shaft power of these two impellers is small. Internal velocity distribution shows that gradient of velocity in forward-swept impeller is smaller than that in the backward-swept impeller. And hydraulic loss in forward-swept impeller is less than that in the backward one. The coincidence of experimental and numerical results demonstrates that CFD can be used in the performance prediction and optimization of hydraulic turbine.

Key words: hydraulic turbine; forward-swept impeller; backward-swept impeller

泵是可逆式机械,离心泵能反转用作液力透平。液力透平能量回收装置是将高压液体具有的压力能转化为透平转子的旋转机械能,并用于发电或者驱动耗能机械做功,实现对高压液体能量的开发利用。液力透平以其结构简单、体积小、造价低、维修方便、运行可靠等特点,目前在小型水利水电资源的开发利用,化工处理过程中余压液体能量的回收等节能技术领域有着广泛应用[1-2]。目前对液力透平的研究,主要集中在对泵正反转工况的研究。AMELIO等[3]对获得离心泵做透平效率的一维数值编译法进行了研究; DERAKHSHAM等[4]利用实验法对不同比转速的泵作透平的特性曲线进行研究,并寻找出泵作透平最高效率点的性能关联式;WILLIAMS[5]对35台不同型号的泵作透平进行实验研究,推荐一种用于预测泵作透平时透平工况性能的方法;SINGH等[6-8]对离心泵作透平工况选型和性能预测的优化法进行研究,并提出了试验验证平台;CHAPALLAZ等[9]对泵正反转工况进行了多方面研究,并对选择合适的透平工况进行了分析。当液力透平运行时,透平的流动方向与泵的流动方向相反,内部流动规律完全不同,因此,需要新的设计方法使液力透平能够高效运行。杨孙圣等[10-12]主要集中在分流叶片以及叶片包角对泵反转式透平性能影响的研究。DERAKHSHAM等[13-15]对如何提高离心泵反转作透平的效率进行研究,主要采用理论分析、优化数值计算以及实验验证的方法。但所研究的叶轮叶片弯曲形状均是后弯形叶片,这种形式的叶轮在泵和透平工况下都能够稳定运行,前弯形叶片叶轮在泵工况下的效率较低[16],但对其在透平工况下运行情况的研究则鲜有报道。为此,本文作者分别设计2种弯曲形式的叶轮,采用数值计算的方法对2种液力透平叶轮内部流场流动规律进行对比分析,将数值计算和试验验证方法相结合对2种液力透平外特性以及最高效率点的性能参数进行对比,以此来探究叶片弯曲形状对液力透平性能的影响。

1 理论分析

液力透平的理论扬程为

(1)

(1)

式中:u为圆周速度;vu为绝对速度的圆周分量;高压液体用角标2表示,低压液体用角标1表示。

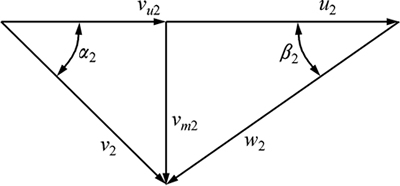

假设透平出口为无预旋出口,即vu1=0。叶轮进口速度三角形见图1。由进口速度三角形得:

(2)

(2)

则

(3)

(3)

式中:β2为液力透平叶轮进口安放角;vm2为叶轮进口轴面速度;Qt为理论流量;F2为叶轮进口面积,ψ2考虑叶片进口边厚度的排挤系数。

图1 叶轮进口速度三角形

Fig. 1 Velocity triangle in impeller inlet

根据式(3)分析,透平进口安放角β2增加时,透平的理论扬程将增加。由于

(4)

(4)

所以,当透平扬程增加时,透平的流量也将相应的增加。常规泵设计时,叶片安放角β2通常取18°~40°[16],因此,提出一种新型前弯形液力透平叶轮,这种形式的叶轮叶片安放角β2取值较大,取值范围也较宽。

2 液力透平的主要设计参数

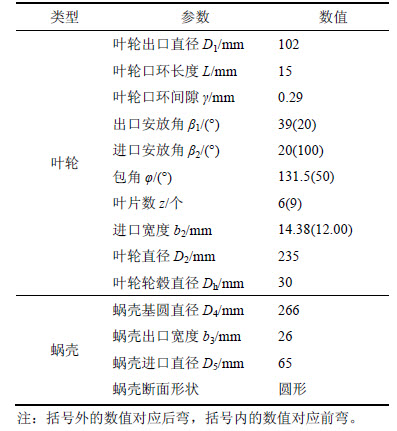

为了研究2种形式叶轮外特性的差异,选用一单级单吸蜗壳式液力透平为研究对象,分别设计2种形式的叶轮,并进行数值与实验研究。液力透平的设计参数为流量Q=80 m3/h,扬程H=30 m,转速n=1 500 r/min,叶轮旋转方向顺时针。表1所示为液力透平的主要几何参数。

3 数值研究

3.1 三维造型

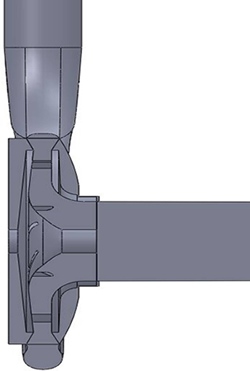

在离心泵数值计算过程中,通常不考虑前后腔内部的流体,此时,数值计算结果不包括容积损失和圆盘摩擦损失,然后通过经验公式估算出容积效率和机械效率,再对计算结果进行修正,这样得到的结果与实验结果相差不大[17]。当液力透平运行时,泵叶轮出口成为透平叶轮进口,这时数值计算若不考虑前后腔内部的流体,则计算结果与实验结果相差较大[18],因此,本文对该模型进行了全流场数值计算。图2所示为液力透平内部流场三维造型。

表1 液力透平的主要几何参数

Table 1 Main geometric parameters of designed turbine

图2 液力透平内部流场三维造型

Fig. 2 3-D model within hydraulic turbine

3.2 网格生成

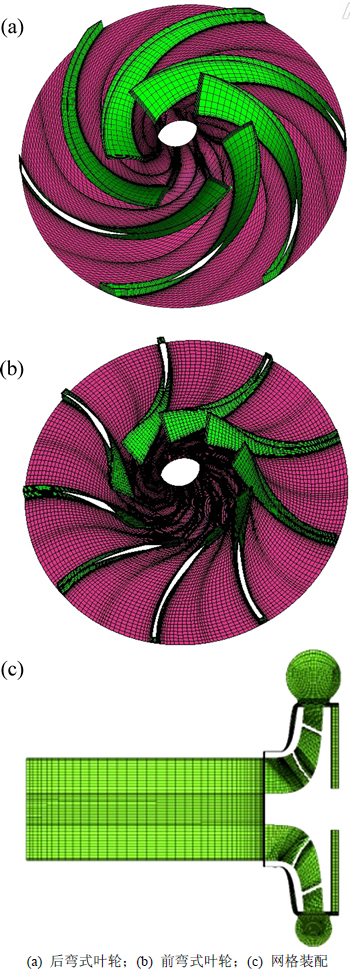

由于叶轮口环存在较小的间隙,非结构网格很难对细小间隙进行较好的处理,因此,本文采用结构化网格技术[19],对过流部件进行六面体结构网格划分,边界层网格y+≥40。图3所示为叶轮流道和全流场网格装配。

图3 叶轮流道及全流场网格装配

Fig. 3 Impeller passages and mesh assembly

对该模型的网格无关性进行了研究,当网格数量在95万以上时,效率的变动范围小于0.5%,因此,网格数量应当在100万以上时较合适。本文用于数值计算具有后弯形叶轮液力透平的蜗壳、叶轮、前腔、后腔、出水管网格数量分别为479 710,378 222,134 956,129 700和174 720,网格总数1 297 308。前弯形叶轮网格数量与该数量相当。

3.3 参数设置

ANSYS-CFX软件采用基于有限元的有限体积法和全隐式算法进行求解,具有收敛速度快、收敛精度高的优点。本文采用ANSYS-CFX流场分析软件对液力透平内部流动进行求解分析。

进口条件设为静压进口,出口设为质量出口[20],通过调节出口的质量流量得到液力透平的外特性曲线。计算收敛标准设为10-6,壁面粗糙度设为50 μm,输送介质选用25 ℃的水,通过k-ε,RNG k-ε和k-ω3种湍流模型对液力透平外特性影响的分析,选用k-ε湍流模型,分析类型为稳态,过流部件动静结合部位用rotor-stator interface 连接,静止过流部件之间用general grid interface连接。

3.4 数值计算结果比较

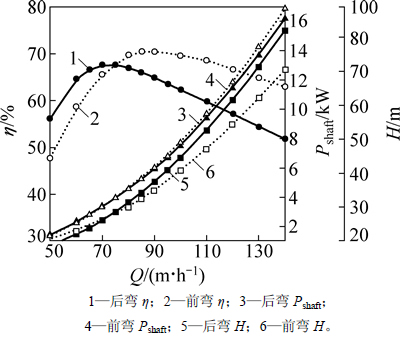

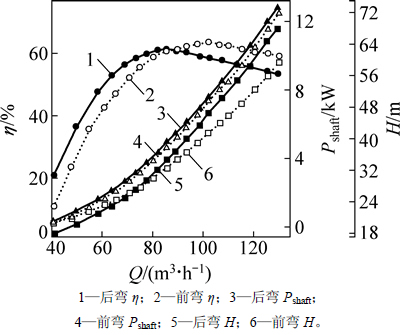

图4所示为2种形式叶轮的液力透平情况外特性曲线,表2所示为2种形式叶轮的最高效率比较。

图4 2种形式透平数值计算结果比较

Fig. 4 Numerical results comparison between two kinds of turbines

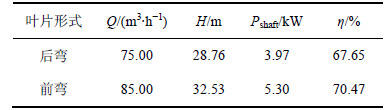

表2 2种形式叶轮最高效率比较

Table 2 BEPs of two kinds of impellers

从图4和表2可以看出:对于相同叶轮外径的2种形式叶轮,具有前弯形叶轮的透平高效点向大流量偏移,高效点以及高效点之后的流量效率曲线高于后弯式叶轮的流量效率曲线,流量扬程曲线低于后弯形叶轮的流量扬程曲线;对于2种形式叶轮,当流量相同时轴功率相差不大。

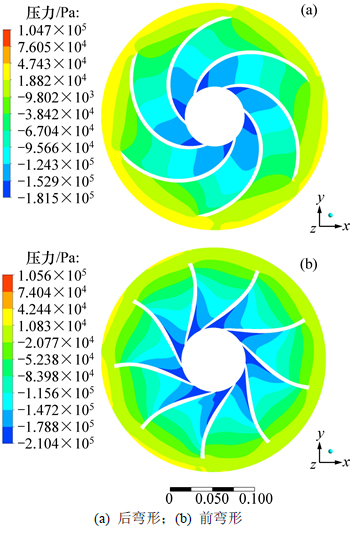

3.5 叶轮内部流场分布

图5所示为叶轮直径为235 mm时,具有2种形式叶轮在同一流量时液力透平中间平面z=0上叶轮内部静压力的分布。从图5可以看出:2种形式的液力透平叶轮内部压力最低点均出现在叶片出口背面处;叶轮内部静压力从叶片的进口沿叶轮流道到叶片出口逐渐减小;2种形式液力透平叶轮内部各流道压力分布不完全一样。

图5 2种形式液力透平叶轮内部压力场分布比较

Fig. 5 Distribution of pressure field comparison between two kinds of hydraulic turbines

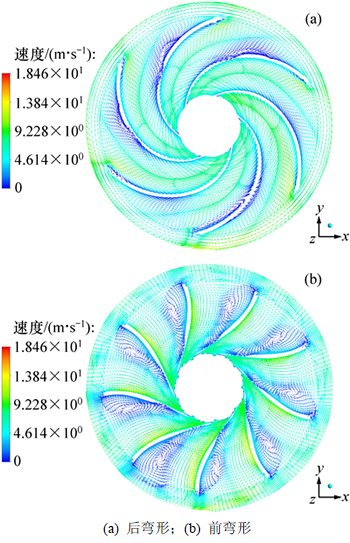

图6所示为叶轮直径为235 mm时,具有2种形式叶轮在同一流量时液力透平叶轮内部速度矢量的分布。从图6可以看出,后弯形叶片叶轮漩涡区域主要分布在叶片吸力面进口位置处,与后弯形叶片叶轮不同,前弯形叶片叶轮漩涡区域主要分布在叶片压力面进口位置处。同时,从图6中2种形式叶轮内部速度分布可以看出前弯形叶片叶轮内部的速度梯度比后弯形叶片叶轮小。

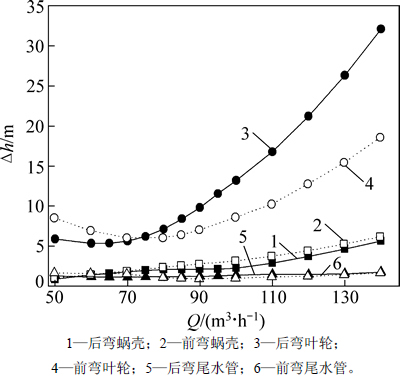

图7所示为2种形式液力透平各部分水力损失比较。由图7可知:叶轮内部的水力损失是液力透平内部主要的水力损失,高效点之后,叶片前弯式叶轮和尾水管内部的水力损失下降,蜗壳内部的水力损失增加,其中叶轮内部的水力损失下降较为明显。由于2种形式的叶轮主要几何参数,只有叶片型线不同,因此,叶片前弯形叶轮内部的水力损失较小。

图6 2种形式液力透平叶轮内部速度场分布比较

Fig. 6 Distribution of velocity field comparison between two kinds of hydraulic turbines

图7 2种形式液力透平各部分水力损失比较

Fig. 7 Hydraulic loss of every section comparison between two kinds of hydraulic turbines

4 实验研究

4.1 实验台

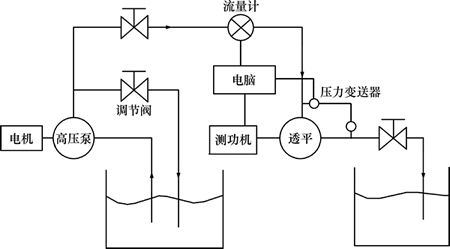

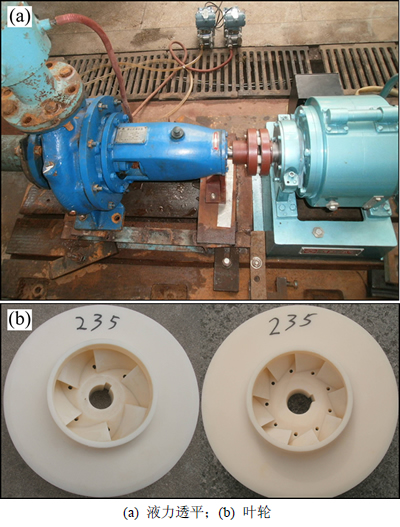

为了验证数值模拟的可靠性,制作液力透平样机,对2种形式的叶轮进行实验研究。图8所示为开式液力透平实验台,高压泵排出的高压液体经流量计进入透平,液力透平将液体具有的压力能转化为轴系的旋转机械能,测功机测量、消耗液力透平产生的轴功率并控制液力透平的转速恒定,压力变送器测量透平进出口位置处的压力。通过测量液力透平进出口压力、扭矩、转速、流量等参数,计算出液力透平的扬程、轴功率和效率等。测功机扭矩测量精度为±0.4%,流量计精度等级为B级,压力变送器精度准确度为0.1%。图9所示为实验现场和实验用叶轮。

图8 开式液力透平实验台

Fig. 8 An open hydraulic turbine test ring

图9 实验现场和叶轮

Fig. 9 Experimental field and impellers

4.2 实验结果分析

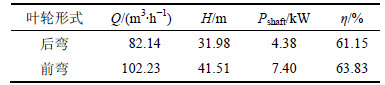

图10所示为2种不同形式叶轮的外特性曲线,表3所示为2种形式叶轮外特性曲线最高效率点参数。从图10和表3可以看出:高效点及高效点之后,前弯形叶轮流量效率曲线高于后弯形叶轮的流量效率曲线;流量扬程曲线低于后弯形叶轮的流量扬程曲线,2种形式的叶轮高效点之后轴功率相差不大。表3表明前弯形叶轮最高效率点的流量、扬程、轴功率和效率分别比后弯形叶轮高24.45%,29.80%,68.95%和4.38%。

图10 2种形式液力透平实验结果比较

Fig. 10 Experimental results comparison between two kinds of turbines

表3 2种形式液力透平最高效率点参数

Table 3 Parameters of two types of hydraulic turbine

5 结论

1) 具有前弯形叶轮的液力透平高效点向大流量偏移,高效点以及高效点之后的流量效率曲线高于后弯形叶轮的流量效率曲线,流量扬程曲线低于后弯形叶轮的流量扬程曲线,2种形式的叶轮轴功率相差不大。前弯形叶轮最高效率点的流量、扬程、轴功率和效率分别比后弯形叶轮高24.45%,29.80%,68.95%和4.38%。

2) 2种液力透平叶轮内部速度分布表明,前弯形叶片叶轮内部速度梯度比后弯形叶片叶轮的小,前弯形叶片叶轮内部水力损失较少。

3) 根据数值与实验结果分析,前弯形叶轮的液力透平,具有体积小、效率高、可靠性高的特点,因此,具有前弯形叶片的叶轮更适合在液力透平工况下运行。

4) 液力透平实验结果与数值的外特性预测结果趋势相吻合,说明CFD可以用来对液力透平内部流动进行性能预测和优化设计。

参考文献:

[1] WILLIAMS A. Pumps as turbines used with induction generations of stand-alone micro-hydroelectric power plants[D]. Nottingham: Nottingham Polytechnic, 1992: 1-3.

[2] RAJA W A, PIAZZA R W. Reverse running centrifugal pumps as hydraulic power recovery turbines for seawater reverse osmosis systems[J]. Desalination, 1981, 38(1/2/3): 123-134.

[3] AMELIO M, BARBARELLI S. A one-dimensional numerical model for calculating the efficiency of pumps as turbines for implication in micro-hydro power plants[C]//Proceeding of ESDA:7th Biennial ASME Conference Engineering Systems Design and Analysis. Manchester, UK, 2004: 19-22.

[4] DERAKHSHAM S, NOURBAKHSH A. Experimental study of characteristic curves of centrifugal pumps working as turbines in different specific speeds[J]. Journal of Experimental Thermal and Fluid Science, 2008, 32: 800-807.

[5] WILLIAMS A A. The turbine performance of centrifugal pumps: a comparison of prediction methods[J]. Proc Instn Mech Engrs, 1994, 208: 59-66.

[6] SINGH P, NESTMANN F. Internal hydraulic analysis of impeller rounding in centrifugal pumps as turbines[J]. Experimental Thermal & Fluid Science, 2011, 35(1): 121-134.

[7] SINGH P. Optimization of the internal hydraulic and of system design in pumps as turbines with field implementation and evaluation[D]. Karlsruhe: University of Karlsruhe, 2005: 97-104.

[8] SINGH P, NESTMAN F. An optimization routine on a prediction and selection model for the turbine operation of centrifugal pumps[J]. Experimental Thermal and Fluid Science, 2010, 34: 152-164.

[9] CHAPALLAZ J M, EICHENBERGER P, FISCHER G. Manual on pumps used as turbines[M]. Braunchweig, Germany: Spring Vieweg, 1992: 21-29.

[10] 杨孙圣, 孔繁余, 陈斌. 分流叶片对泵反转式透平性能影响的数值研究[J]. 工程热物理学报, 2010, 31(12): 141-144.

YANG Sunsheng, KONG Fanyu, CHEN Bin. Spitter blades to the performance of pump as turbine using CFD[J]. Journal of Engineering Thermophysics, 2010, 31(12): 141-144.

[11] 杨孙圣, 孔繁余, 陈斌. 叶片包角对可逆式泵性能影响的数值研究[J]. 流体机械, 2011(6): 17-20.

YANG Sunsheng, KONG Fanyu, CHEN Bin. Numerical research of blade wrap angle to the performance of reversible pump[J]. Fluid Machinery, 2011(6): 17-20.

[12] YANG Sunsheng, DAI Tao, XU Rongjun, et al. Numerical research on splitter blades design of centrifugal pump as turbine[J]. International Agricultural Engineering Journal, 2016, 25(4): 179-186.

[13] DERAKHSHAN S, MOHAMMADI B. Efficiency improvement of centrifugal reverse pumps[J]. Journal of Fluids Engineering, 2009, 131: 1-9.

[14] DERAKHSHAN S, MOHAMMADI B. Incomplete sensitivities for 3D radial turbomachinery blade optimization[J]. Computers and Fluids, 2008, 37: 1354-1363.

[15] DERAKHSHAM S, NOURBAKHSH A. Theoretical, numerical and experimental investigation of centrifugal pumps in reverse operation[J]. Experimental Thermal and Fluid Science, 2008, 32: 1620-1627.

[16] 关醒凡. 现代泵技术手册[M]. 北京: 宇航出版社, 1995: 31.

GUAN Xingfan. Pump handbook[M]. Beijing: Yuhang Press, 1995: 31.

[17] 杨孙圣, 孔繁余, 周水清, 等. 离心泵汽蚀性能的数值计算与分析[J]. 华中科技大学学报(自然科学版), 2010, 38(10): 93-95.

YANG Sunsheng, KONG Fanyu, ZHOU Shuiqing, et al. Numerical simulation and analysis of centrifugal pump cavitation characteristics[J]. Journal of Huazhong University of Science and Technology (Natural Science Edition), 2010, 38(10): 93-95.

[18] DERAKHSHAN S, NOURBAKHSH A. Theoretical, numerical and experimental investigation of centrifugal pumps in reverse operation[J]. Experimental Thermal and Fluid, Science, 2008, 32(5): 1620-1627.

[19] 杨孙圣, 孔繁余, 邵飞, 等. 液力透平的数值计算与试验[J]. 江苏大学学报(自然科学版), 2012, 33(3): 165-169.

YANG Sunsheng, KONG Fanyu, SHAO Fei, et al. Numerical calculation and experiment of hydraulic turbine[J]. Journal of Jiangsu University (Natural Science Edition), 2012, 33(3): 165-169.

[20] SPENCE P, AMARAL-TEIXEIRA J. Investigation into pressure pulsations in a centrifugal pump using numerical methods supported by industrial tests[J]. Computer Fluids, 2008, 37(6): 690-704.

(编辑 杨幼平)

收稿日期:2016-04-28;修回日期:2016-07-10

基金项目(Foundation item):国家自然科学基金资助项目(11602097);江苏大学引进人才项目(13JDG081)(Project (11602097) supported by the National Natural Science Foundation of China; Project (13JDG081) supported by the Introduce Talents Project of Jiangsu University)

通信作者:杨孙圣,博士,助理研究员,从事能量回收设计理论与技术应用研究;E-mail:yangsunsheng@126.com