DOI: 10.11817/j.issn.1672-7207.2018.11.001

赤铁矿流化床还原过程中磁铁矿的形成与生长规律

余建文,韩跃新,李艳军,高鹏

(东北大学 资源与土木工程学院,辽宁 沈阳,110819)

摘要:以20% CO-80% CO2(质量分数)为还原流化气体,借助光学显微镜、扫描电镜研究赤铁矿流化床还原过程中磁铁矿的形成与生长规律。研究结果表明:新生磁铁矿晶核呈针状,长度不一且优先在赤铁矿颗粒的边缘处形成;还原温度和焙烧时间对产物磁铁矿层的厚度影响显著,随着还原温度升高和焙烧时间延长,产物磁铁矿层厚度增加;磁铁矿的生长过程可分为2个不同的阶段即诱导期和生长期,且产物磁铁矿层厚度增长与还原时间的关系符合抛物线定律;在诱导期,生长过程的指前因子k0=1.95×105 μm2/min,活化能△Ea=60.86 kJ/mol;在生长期,生长过程的指前因子k0=9.77×104 μm2/min,活化能△Ea=35.71 kJ/mol。

关键词:赤铁矿;悬浮磁化焙烧;磁铁矿;生长动力学

中图分类号:TD924.1;TD925.6 文献标志码:A 文章编号:1672-7207(2018)11-2643-06

Formation and growth mechanism of magnetite during the fluidized reduction of hematite

YU Jianwen, HAN Yuexin, LI Yanjun, GAO Peng

(School of Resources & Civil Engineering, Northeastern University, Shenyang 110819, China)

Abstract: A gas mixture of 20% CO-80% CO2 was used as reducing and fluidizing agent, and the formation and growth mechanism of magnetite phase during the fluidized reduction of hematite was investigated by optical microscopy and scanning electron microscopy(SEM). The results show that the fresh magnetite nucleus are needle-like with different lengths, and are preferentially formed at the edges of original hematite particle. The reduction temperature and roasting time have significant effect on thickness of the magnetite product layer. With the increase of reduction temperature and roasting time, the thickness of magnetite layer increases. The growth process of magnetite phase can be divided into two different stages which includes induction period and growth period, and the growth mechanism of magnetite phase coincides with the parabolic law. In the induction and growth periods, the pre-exponential factor k0 is 1.95×105μm2/min and 9.77×104 μm2/min, the activation energy △Ea is 60.86 kJ/mol and 35.71 kJ/mol, respectively.

Key words: hematite; fluidized magnetization roasting; magnetite; growth kinetics

磁化焙烧是复杂难选赤铁矿石开发利用的重要预处理方法[1-7]。流态化焙烧因具有传热传质效率高、焙烧能耗低等突出优点,成为近年来的研究热点[8-11]。目前,关于赤铁矿、褐铁矿、菱铁矿、混合型红铁矿等难选铁矿石的悬浮态磁化焙烧工艺优化研究较多[12-15],而对于赤铁矿悬浮态还原过程中磁铁矿的形成及其生长机制研究较少。为此,本文作者以20% CO- 80% CO2(质量分数)为还原流化气体,借助光学显微镜、扫描电镜研究赤铁矿流化床还原过程中磁铁矿的形成与生长规律,以便为难选赤铁矿石的悬浮磁化焙烧过程提供参考。

1 实验材料和实验方法

试验原料为赤铁矿单矿物(纯度为93.48%,符合试验要求),另外含有少量的石英等杂质,其化学成分(质量分数)如下:TFe,65.44%;SiO2,4.11%;Al2O3,0.61%;CaO,0.14%;MgO,0.63%,平均粒径为60 μm。试验所用还原剂为CO与CO2的混合气体,质量比为2:8,纯度为99.99%。

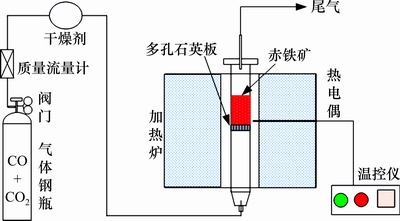

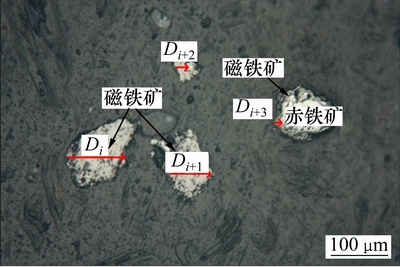

图1所示为微型流化床磁化焙烧装置示意图。前期探索试验结果表明:在还原温度为500~600 ℃,气体流量为1 000 mL/min时,赤铁矿颗粒群(质量为5 g)在多孔(孔径为15 μm)石英板(直径为25 mm)上流化状态良好。在试验过程中,待温度升至设定值(500,525,550,575或600 ℃)后通入流量为1 000 mL/min的 20% CO-80% CO2混合气体并开始计时,待反应到预设时间后,关闭CO/CO2混合气体阀门,并停止加热。待炉温冷却至室温时,将不同焙烧条件下的焙烧矿与树脂固结成直径×高为35 mm×5 mm的圆柱体,经细磨、抛光后采用光学显微镜随机地测量不同焙烧条件下物料光片中产物磁铁矿层的厚度Di,结果如图2所示。

根据测量结果计算出不同焙烧条件下产物磁铁矿层的平均厚度D,对磁铁矿相的生长特性进行定量描述。产物磁铁矿层平均厚度D的计算公式为

(1)

(1)

式中:N为待测量颗粒总数;Di为第i个(1≤i≤100)颗粒中产物磁铁矿层厚度,μm。

图1 微型流化床磁化焙烧装置示意图

Fig. 1 Diagram of micro-fluidized bed magnetization roasting equipment

图2 颗粒中产物磁铁矿层厚度的测量

Fig. 2 Measurement for thickness of magnetite layer in particles

2 结果与讨论

2.1 磁铁矿相形成及生长过程分析

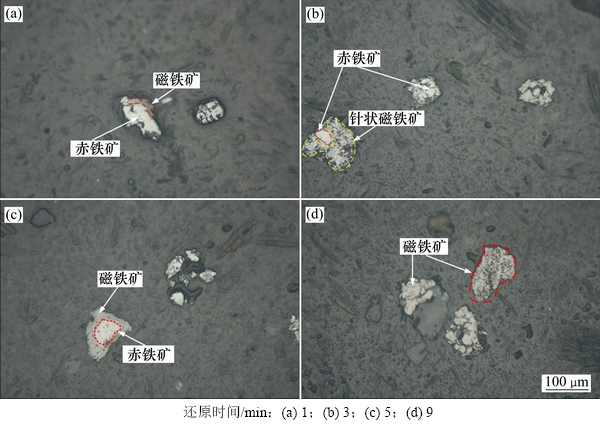

图3所示为反射光下550 ℃时不同焙烧时间下样品抛光截面的显微照片。由图3(a)可见:在反应前期,赤铁矿的还原磁化反应优先在颗粒的边缘(界)处发生;由图3(b)可知:新生磁铁矿呈针状结构,随着反应时间延长,生成的磁铁矿相越来越多,产物层厚度逐渐增大,赤铁矿内核逐渐变小(见图3(c)),并最终完全转变为磁铁矿(见图3(d))。

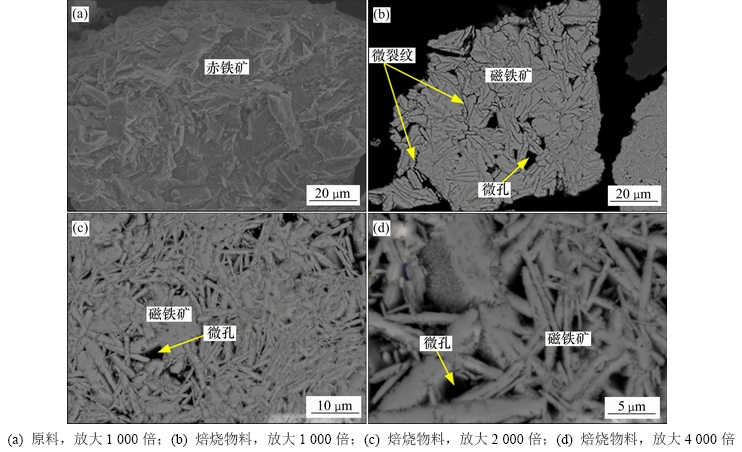

图4所示为原料表面及焙烧样品(还原温度为550 ℃,焙烧时间为9 min)抛光截面的SEM图片。由图4(a)可见:原料赤铁矿颗粒的表面(边缘)粗糙、凹凸不平,这些凹凸表面存在大量不饱和化学键,具有很强的化学反应活性,故赤铁矿的还原磁化反应优先在颗粒的外表面(边缘)发生。由图4(b),(c)和(d)可知:反应生成的磁铁矿颗粒是疏松多孔的,并伴随有大量微裂纹和微孔。由图4(c)和(d)可见:生成的磁铁矿晶核呈致密的针状结构,这些针状结构长度不一,平均长度为10~20 μm,平均直径为0.5~2.0 μm,这些致密针状结构的磁铁矿晶核聚集形成蜂窝多孔状的磁铁矿颗粒。

图3 550 ℃时不同焙烧时间下样品抛光截面的显微照片

Fig. 3 Micrograph of polished section of samples roasted at 550 ℃ and different time

图4 原料表面及焙烧物料抛光截面的SEM图片

Fig. 4 SEM images of raw material surface and polished section of roasted sample

由上述分析可知:新生的磁铁矿晶核优先在原始赤铁矿颗粒边缘处形成,并呈致密针状结构。随着反应进行,反应生成的Fe2+通过扩散作用向针状结构的磁铁矿尖端运输,促使磁铁矿晶核长大。在磁铁矿晶核长大过程中,由于磁铁矿与赤铁矿晶格参数存在差异,反应相变时会引起体积膨胀,容易在磁铁矿与赤铁矿的相界面处产生微裂纹或微孔[16]。若微裂纹发生在针状磁铁矿晶核的尖端,则Fe2+向针状磁铁矿晶核尖端扩散的通道被阻断,针状磁铁矿晶核停止生长;若微裂纹发生在其他磁铁矿-赤铁矿界面处,裸露出的新鲜赤铁矿内表面化学反应活性高,磁铁矿晶核容易在此处形成并长大。由于微裂纹发生位置具有随机性,致使新生的针状磁铁矿晶核长度不一,且多呈树枝状结构随机地分布于磁铁矿颗粒中(见图4(d))。同时,微裂纹的产生进一步促进了反应的进行,直至赤铁矿完全转变为多孔状的磁铁矿。

2.2 产物磁铁矿层的厚度分布规律

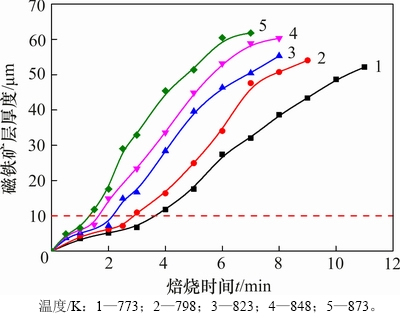

图5所示为不同还原温度下产物磁铁矿层厚度随时间的变化。从图5可见:随着还原温度升高或焙烧时间延长,产物磁铁矿层厚度显著增加。值得一提的是,当产物磁铁矿层厚度Dt小于10 μm时,产物磁铁矿层厚度随时间增长速率比产物磁铁矿层厚度大于10 μm时的增长速率小。这一结果表明产物磁铁矿层厚度增长过程可分为2个不同阶段即诱导期(Dt≤10 μm)和生长期(Dt>10 μm)。诱导期产物磁铁矿层的增长速度明显要比生长期的增长速度慢,且随着还原温度升高,诱导期缩短。这可能是由于诱导期新相磁铁矿成核困难,产物磁铁矿层的厚度增长缓慢;一旦新相磁铁矿核形成(反应进入生长期),其本身就是新的活性中心,对反应起催化作用。同时,新相磁铁矿的形成容易引发微裂纹的产生,加速反应进行,提高Fe2+向反应界面处扩散、迁移的能力,促进新相磁铁矿核的生长过程,即快速地提高产物磁铁矿层厚度增长的速率。

图5 不同温度下产物磁铁矿层厚度随还原时间的变化

Fig. 5 Change of thickness of the magnetite layer at different temperatures with reduction time

2.3 产物磁铁矿层厚度增长动力学

在固相反应中,产物层厚度增长与反应时间的关系一般遵循抛物线定律,其计算公式如下[12, 17-19]:

(2)

(2)

式中:D0为初始产物层厚度,μm;k为产物层厚度的增长速率常数,μm2/min;t为反应时间,min。

在试验过程中,反应初始时无磁铁矿形成,产物磁铁矿层厚度D0=0,故式(2)可简写为

(3)

(3)

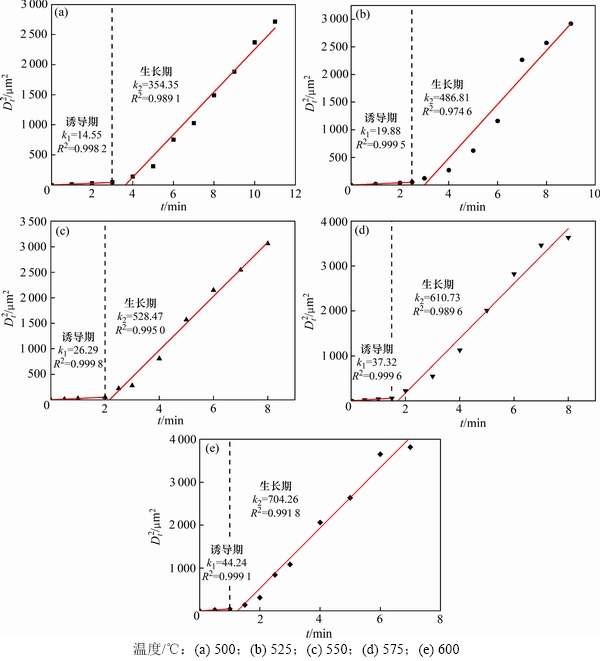

图6所示为产物磁铁矿层厚度的平方( )对反应时间(t)的线性拟合结果。根据不同温度下

)对反应时间(t)的线性拟合结果。根据不同温度下 随反应时间t的变化规律,可将产物磁铁矿层厚度增长过程分为诱导期(Dt≤10 μm)和生长期(Dt>10 μm)这2个阶段分别进行分析,且2个不同阶段内

随反应时间t的变化规律,可将产物磁铁矿层厚度增长过程分为诱导期(Dt≤10 μm)和生长期(Dt>10 μm)这2个阶段分别进行分析,且2个不同阶段内 与t均呈现出良好的线性拟合关系(见图6)。

与t均呈现出良好的线性拟合关系(见图6)。

基于阿伦尼乌斯公式,生长速率常数k与反应温度T之间的关系可表示为

(4)

(4)

式中:k0为指前因子,μm2/min;T为反应热力学温度,K;△Ea为表观活化能,J/mol;R为气体常数,为8.314 J/(mol·K)。

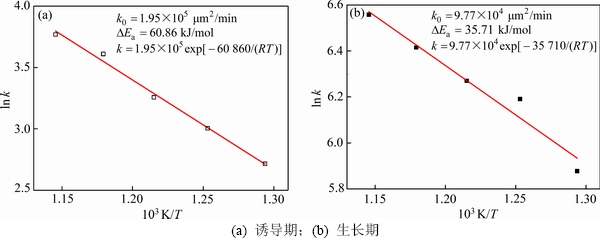

将不同还原温度条件下的生长速率常数k(见图6)代入式(4),并对函数lnk和1/T进行回归计算和线性拟合,结果如图7所示。由图7可分别求得诱导期和生长期的动力学参数:在诱导期,指前因子k0=1.95× 105 μm2/min,活化能△Ea=60.86 kJ/mol;在生长期,指前因子k0=9.77×104 μm2/min,活化能△Ea=35.71 kJ/mol。

活化能是化学反应发生难易程度的表征。磁铁矿生长过程中诱导期活化能(△Ea=60.86 kJ/mol)明显高于生长期活化能(△Ea=35.71 kJ/mol),说明诱导期磁铁矿晶核生长困难,产物磁铁矿层厚度增长缓慢;生长期磁铁矿晶核生长过程容易,产物磁铁矿层厚度增长速率快。此外,产物磁铁矿层厚度增长动力学分析结果也进一步佐证了上述结论。

图6 不同温度下 与时间t的线性拟合

与时间t的线性拟合

Fig. 6 Linear fitting of  and time at different temperatures

and time at different temperatures

图7 诱导期和生长期ln k与1/T的线性拟合分析

Fig. 7 Linear fitting analysis of ln k and 1/T during the induction and growth period

3 结论

1) 新生磁铁矿晶核呈针状结构、长度不一,且优先在原始赤铁矿颗粒的边缘处形成;随着反应进行,赤铁矿内核逐渐变小,生成的磁铁矿相越来越多,产物层厚度逐渐增大,并最终完全转变为磁铁矿;新生磁铁矿晶核在长大过程中容易随机地引发微裂纹的产生,故新生磁铁矿颗粒通常是疏松多孔的。

2) 还原温度和焙烧时间对产物磁铁矿层厚度影响显著。随着还原温度升高和焙烧时间延长,产物磁铁矿层厚度显著增加;磁铁矿相的生长过程可分为2个不同阶段即诱导期和生长期,且诱导期(Dt≤10 μm) 的产物磁铁矿层增长速率要比生长期(Dt>10 μm)的增长速率小。

3) 产物磁铁矿层厚度的增长过程符合抛物线定律。在诱导期,指前因子k0=1.95×105 μm2/min,活化能△Ea=60.86kJ/mol;在生长期,指前因子k0=9.77×104 μm2/min,活化能△Ea=35.71 kJ/mol。

参考文献:

[1] LI Chao, SUN Henghu, BAI Jing, et al. Innovative methodology for comprehensive utilization of iron ore tailings: Part 1. The recovery of iron from iron ore tailings using magnetic separation after magnetizing roasting[J]. Journal of Hazardous Materials, 2010, 174(1): 71-77.

[2] YANG Huifeng, JING Lili, ZHANG Baogang. Recovery of iron from vanadium tailings with coal-based direct reduction followed by magnetic separation[J]. Journal of Hazardous Materials, 2011, 185(2/3): 1405-1411.

[3] PENG Ning, PENG Bing, CHAI Liyuan, et al. Recovery of iron from zinc calcines by reduction roasting and magnetic separation[J]. Minerals Engineering, 2012, 35: 57-60.

[4] YU Jianwen, HAN Yuexin, LI Yanjun, et al. Separation and recovery of iron from a low-grade carbonate-bearing iron ore using magnetizing roasting followed by magnetic separation[J]. Separation Science and Technology, 2017, 52(10): 1768-1774.

[5] LIU Xing, YU Yongfu, CHEN Wen. Phase change of chlorite in reducing atmosphere[J]. Physicochemical Problems of Mineral Processing, 2014, 50(2): 607-614.

[6] YU Jianwen, HAN Yuexin, LI Yanjun, et al. Beneficiation of an iron ore fines by magnetization roasting and magnetic separation[J]. International Journal of Mineral Processing, 2017, 168: 102-108.

[7] YU Jianwen, HAN Yuexin, LI Yanjun, et al. Separation and recovery of iron from a low-grade carbonate-bearing iron ore using magnetizing roasting followed by magnetic separation[J]. Separation Science and Technology, 2017, 52(10): 1-7.

[8] 朱庆山, 李洪钟. 难选铁矿流态化磁化焙烧研究进展与发展前景[J]. 化工学报, 2014, 65(7): 2437-2442.

ZHU Qingshan, LI Hongzhong. Status quo and development prospect of magnetizing roasting via fluidized bed for low grade iron ore[J]. CIESC Journal, 2014, 65(7): 2437-2442.

[9] HOU Baolin, ZHANG Haiying, LI Hongzhong, et al. Determination of the intrinsic kinetics of iron oxide reduced by carbon monoxide in an isothermal differential micro-packed bed[J]. Chinese Journal of Chemical Engineering, 2015, 23(6): 974-980.

[10] FENG Zhili, YU Yongfu, LIU Genfan, et al. Kinetics of the thermal decomposition of Wangjiatan siderite[J]. Journal of Wuhan University of Technology(Materials Science Edition), 2011, 26(3): 523-526.

[11] YU Yongfu, QI Chaoying. Magnetizing roasting mechanism and effective ore dressing process for oolitic hematite ore[J]. Journal of Wuhan University of Technology(Materials Science Edition), 2011, 26(2): 176-181.

[12] FEILMAYR C, THURNHOFER A, WINTER F, et al. Reduction behavior of hematite to magnetite under fluidized bed conditions[J]. ISIJ International, 2004, 44(7): 1125-1133.

[13] LI Yuan, ZHU Tong. Recovery of low grade hematite via fluidized bed magnetizing roasting: investigation of magnetic properties and liberation characteristics[J]. Ironmaking & Steelmaking, 2012, 39(2): 112-120.

[14] LI Yanjun, WANG Ru, HAN Yuexin, et al. Phase transformation in suspension roasting of oolitic hematite ore[J]. Journal of Central South University, 2015, 22(12): 4560-4565.

[15] VYAZOVKIN S, BURNHAM A K, CRIADO J M, et al. ICTAC Kinetics committee recommendations for performing kinetic computations on thermal analysis data[J]. Thermochimica Acta, 2011, 520(1): 1-19.

[16] YU Jianwen, HAN Yuexin, LI Yanjun, et al. Mechanism and kinetics of the reduction of hematite to magnetite with CO-CO2 in a micro-fluidized bed[J]. Minerals, 2017, 7(11): 209.

[17] 翟玉春. 铁氧化物还原动力学—用不可逆过程热力学推导抛物线公式[J]. 东北大学学报 (自然科学版), 1982, 3(3): 39-46.

ZHAI Yuchun. Kinetics of reduction process of iron oxides—the parabolic formula derived on the basis of thermodynamics of irreversible process[J]. Journal of Northeastern University (Natural Science), 1982, 3(3): 39-46.

[18] DU Zhan, ZHU Qingshan, YANG Yafeng, et al. The role of MgO powder in preventing defluidization during fluidized bed reduction of fine iron ores with different iron valences[J]. Steel Research International, 2016, 87(12): 1742-1749.

[19] KHAWAM A, FLANAGAN D R. Solid-state kinetic models: basics and mathematical fundamentals[J]. Journal of Physical Chemistry B, 2006, 110(35): 17315-17328.

(编辑 伍锦花)

收稿日期:2017-11-20;修回日期:2018-02-09

基金项目(Foundation item):国家自然科学基金资助项目(51734005,51674064,51674065);中国博士后科学基金资助项目(2018M631812) (Projects(51734005, 51674064, 51674065) supported by the National Natural Science Foundation of China; Project(2018M631812) supported by the National Science Foundation for Postdoctoral Science of China)

通信作者:韩跃新,博士,教授,从事复杂难选矿产资源高效利用研究;E-mail: dongdafulong@mail.neu.edu.cn.