Creep behavior on Ag particle reinforced SnCu based composite solder joints

YAN Yan-fu(闫焉服), ZHU Jin-hong(朱锦洪),

CHEN Fu-xiao(陈拂晓), HE Jun-guang(贺俊光), YANG Di-xin(杨涤心)

School of Materials Science and Engineering, Henan University of Science and Technology, Luoyang 471003, China

Received 1 December 2005; accepted 23 March 2006

Abstract: SnCu solder is one of the most promising substitutes of SnPb solder, but its creep resistance is worse than that of the other lead-free solders. Particle-reinforcement is a way to improve the creep resistance of solder alloys and cause much more attention than before. A novel Ag particles reinforced SnCu based composite solder is formed and the influence of stress on creep behavior of the composite solder is investigated. Results indicate that the creep resistance of solder joints is superior to that of the SnCu solder joints. Creep rupture lifetime of solder joints decreases gradually with stress increasing. And the creep rupture lifetime of the composite solder joints falls down faster than that of the matrix solder joints.

Key words: composite solder; particle-reinforcement; SnCu; creep rupture life; stress

1 Introduction

The EU had issued the WEEE mandate that aimed to prohibit the use of SnPb solders by 2006. Under the pressure of legislation and trade competitions, large electronic manufacturers and research institutes studied substitutes for SnPb solders. SnCu eutectic and near eutectic solder alloys have been regarded as one of the most promising Pb-free substitutes for the SnPb solders for their low cost and good mechanical properties. However, tensile and shear-tensile strengths of SnCu eutectic solder are inferior to SnAg and SnAgCu eutectic solder[1-4]. How to further improve the mechanical properties of SnCu eutectic solder in service brings about more concerns.

An attractive and potentially viable method of enhancing the mechanical properties of a solder is by using composite solders formed by the addition of reinforcement particles to a conventional solder alloy[5-9]. Study of MARSHALL et al[10] showed that the mechanical properties of powdered Cu6Sn5 intermetallics reinforced composite solder were superior to those of SnAg eutectic solder. CLOUGH et al[11] reported that Cu6Sn5 particle-enhanced SnAg composite solders exhibited two-times yield strength without significant ductility loss and nearly an order of magnitude lower creep rate in comparison to the non-composite solders. Studies by MAVOORI and JIN[12] indicated that ultrafine oxide dispersions enhanced 63Sn37Pb composite solder had better creep resistance than 63Sn37Pb eutectic solder. SHI et al[13] studied the creep properties of metal particle enhanced SnCu based composite solder joints under 50 ℃ with a deadload of 16.17 MPa. Results showed that the creep rupture lives of three SnCu based composite solders with 8 μm Cu (3%) particles, 1 μm Ag (3%) particles or 1 μm Ni (3%) particles were improved by 8, 14 and 25 times, respectively.

Creep rupture lifetime is an important index to evaluate the reliability of solder joints. Stress is one of the most important factors to affect the reliability of solder joints. In this paper the influence of stress on creep behavior of Ag particle enhanced 99.3Sn0.7Cu based composite solder joints is investigated so that the composite solder can be evaluated accurately and applied reliably.

2 Experimental

2.1 Solder preparation

Particle enhanced SnCu based composite solder consisted of 43 mm 99.3Sn0.7Cu particles and 1 mm Ag particles. The volume fraction of Ag particles was 5% in the composite solder, which was determined earlier as the most appropriate content[14]. The composite solder paste was made by mixing particles with RMA no-clean flux in a crucible. To achieve a uniform distribution of the enhancing particles in the 99.3Sn0.7Cu eutectic solder matrix, mechanical mixing time of at least 15 min was used. These pastes were sealed immediately after mixing and preserved in a refrigerator at -10 ℃ to avoid oxidation.

2.2 Measurement of creep rupture life

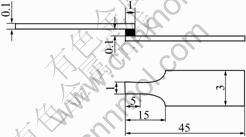

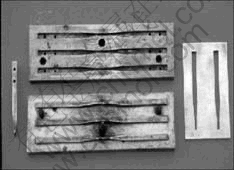

To simulate the size of solder joints on the PCB (Print Circuit Board) in practical assembly, small single lap shear joints were used in the creep rupture life test [15]. The mini joint is shown in Fig.1. Two pieces of “dog-bone” copper sheets were used as soldered substrates. The copper substrates were polished using 400 grit sand paper, followed by rinsing with ethanol. Solder mask IF710 was applied on the surface of the narrow end of the copper substrates to achieve a cross-sectional area of 1 mm2. The composite solder paste was sandwiched between the two copper sheets. Soldering was performed in an aluminum mold, as shown in Fig.2. The solder joints were heated to 260 ℃ for 2 min, then cooled quickly at a rate of 50 ℃/min to room temperature.

Fig.1 Specimen for creep rupture life test

Fig.2 Aluminum mold for soldering

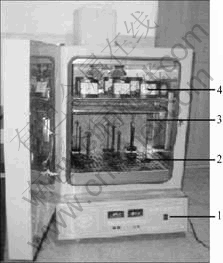

The creep rupture life tests under four different dead loads (11.27, 13.23, 16.1 and 18.13 MPa) were performed at four different temperatures (50, 75, 100 and 125 ℃), respectively. The fluctuation of temperature during the creep tests was maintained within 2 ℃. The creep rupture lives of specimens were recorded automatically by a clock electrically connected in series with the solder joint. The test results were averaged from 12 specimens. Test of 99.3Sn0.7Cu eutectic solder was also performed as a comparison under the above same condition. The equipment of the creep rupture life is shown in Fig.3.

Fig.3 Equipment of creep rupture test: 1 Temperature and humidity controlled chamber; 2 Dead load; 3 Specimen;4 Clock

3 Results and discussion

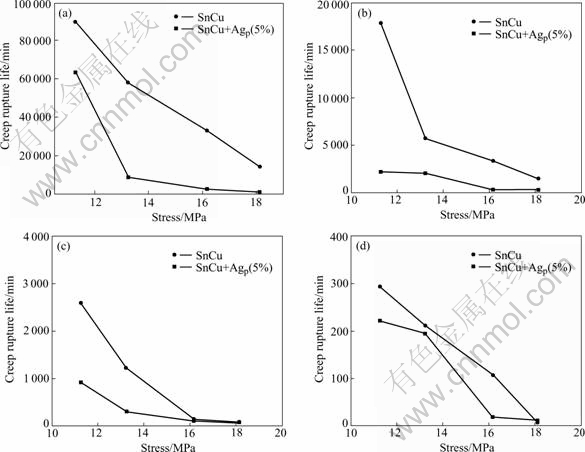

The test results of the creep rupture lives of the composite solder joints and SnCu eutectic solder joints under the above conditions are shown in Fig.4. It can be seen easily that the creep rupture lives of the composite solder joints are superior to those of SnCu eutectic solder joints under the experimental conditions, especially at the low temperatures and low stresses. And at 50 ℃ with a dead load stress of 13.23 MPa, the rupture life of the composite solder joint is more than 6 times longer than that of the SnCu eutectic solder joint. At 75 ℃ with a stress of 11.27 MPa, the rupture life of the composite solder joint is more than 8 times longer than that of the SnCu eutectic solder joint.

The microstructures of the SnCu eutectic solder and Ag particles enhanced composite solder are shown in Fig.5. The microstructure of Ag particle enhanced composite solder consists of SnCu eutectic solder matrix and Ag particles. The light core region is pure Ag. Ag particles are found not only inside the grains but also at the grain boundaries. The Ag particles impede grain boundary sliding and dislocation movement so that the creep rupture life of the composite solder joints is improved. At the same time, Ag-Sn IMC layer formed between the matrix and Ag particles is found from Fig.5(c), which coats Ag particles and binds tightly the matrix and enhancement particles together. Therefore, the creep rupture life of the composite solder joint is superior to that of the SnCu eutectic solder joint.

Fig.4 Effect of stress on creep rupture life of solder joints: (a) 50 ℃; (b) 75 ℃; (c) 100 ℃; (d) 125 ℃

Fig.5 Microstructure of solder alloy: (a) Eutectic 99.3Sn0.7Cu solder; (b) Microstructure of composite solder; (c) SEM Micrograph of composite solder

However, at 125 ℃ with a dead load stress of 18.13 MPa, the rupture life of the composite solder joint (7 min) is inferior to that of the SnCu eutectic solder joint (11 min). This is because that a fine grained microstructure is acquired for Ag particle enhanced composite solder. The grain sizes of the composite solder and 99.3Sn0.7Cu eutectic solder are 36.1 μm and 16.4 μm, respectively, indicating that the grain size of the composite solders is bigger than that of non-composite solder. The fine grained microstructure possesses a large grain boundary area resulting in a high interface energy, which is disadvantageous to improving the creep resistance of solder alloys. ROSS[16] showed that materials with bigger grain size always have a higher creep resistance than the fine grain ones.

It can also be seen from Fig.4 that the rupture lives of solder joints decline with increasing stress at the same experimental temperature. And the rupture lives of the composite solder joints decline faster than those of the conventional SnCu eutectic solder joints. Form Fig.4(b), it can be calculated that the descendent rates of the composite solder joint and the conventional SnCu eutectic solder joint are respectively 2391 min/MPa and 277 min/MPa when stress is increased from 11.27 MPa to 18.13 MPa at 75 ℃. That is to say, the descendent rates of the composite solder joints is 8.6 times more than that of the matrix solder joints under the above test condition.

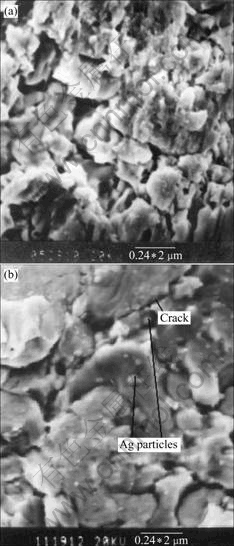

Representative fracture surfaces of the creep rupture solder joints are shown in Fig.6. Fig.6(a) shows the typical creep rupture surface of the SnCu eutectic solder joint in the creep rupture life test. Most of the fracture surface exhibits characteristics of intergranular fracture. Fig.6(b) shows the typical creep fracture surface of the Ag particle enhanced composite solder joints. Ag reinforcement particles are found at the grain boundaries and secondary cracks are developed along the grain boundaries, which shows that the enhancing particles become the origin of creep fracture. It is considered that at the higher temperature, the presence of Ag particles is disadvantageous for creep property of solder joints. Maybe this is because the rupture lives of the composite solder joints decline faster than those of the conventional SnCu eutectic solder joints.

Fig.6 SEM images of creep rupture surfaces of solder joints: (a) Intergranular fracture of SnCu solder; (b) Shearing surface of composite solder

At the same time, generally the equation of steady-state creep rate of a heat activated process is

expressed as the Dorn formula:

where  is the steady-state creep rate, A is a constant, τ is the stress, n is the stress exponent, Q is the apparent activation energy, R is the gas constant, and T is the absolute temperature.

is the steady-state creep rate, A is a constant, τ is the stress, n is the stress exponent, Q is the apparent activation energy, R is the gas constant, and T is the absolute temperature.

A, G, and R are constants for the same solder alloy. Under the same temperature and stress, the apparent

activation energy Q and the stress exponent n of the Ag particle enhanced composite solder joint are bigger than those of SnCu eutectic solder joint[17]. It is seen easily that the steady-state creep rate  of the composite solder joint decreases faster with increasing stress than that of SnCu solder joints at the same temperature.

of the composite solder joint decreases faster with increasing stress than that of SnCu solder joints at the same temperature.

4 Conclusions

1) The creep rupture lives of Ag particle enhanced SnCu based composite solder joints are longer than those of SnCu eutectic solder joints under the same condition. The creep property of the composite solder joints is superior to that of the SnCu eutectic solder joints.

2) The rupture lives of solder joints decline with increasing stress at the same temperature. And the rupture life of the composite solder joint declines faster than that of the conventional SnCu eutectic solder joint under the same experimental condition.

References

[1] BRUSH L N, GRUGE R N. The effect of an electric current on rod-eutectic solidification in Sn-0.9wt.%Cu alloys [J]. Materials Science and Engineering, 1997, A238(1): 176-171.

[2] LEE Y G, DUH J G. Phase analysis in the solder joints of SnCu solder/IMC/Cu substrate [J]. Materials Characterization, 1999, 42(2): 143-160.

[3] DHABAL S, GHOSH T B. On the interfacial composition of vapor deposited Bi-layer thin film of SnCu on the glass substrate [J]. Applied Surface Science, 2003, 211(1): 13-23.

[4] HAMPSHIRE W B. The search for lead-free solders [A]. Surface Mount International Conference [C]. San Jose, CA, 1992: 729-737.

[5] MCDOUGALL J, CHOI S, BIELER T R, LUCAS J P. Quantitication of creep strain distribution in small crept lead-free in-situ composite and non-composite solder joints [J]. Materials Science and Engineering, 2000, A285: 25-29.

[6] GUO F, LEE J, CHOI S, LUCAS J P, BIELER T R, SUBRANMANIAN K N. Processing and aging characteristics of eutectic Sn-3.5Ag solder reinforced with mechanically incorporated Ni particles [J]. J Electronic Materials, 2001, 31: 1415-1427.

[7] CHOI S, LUCAS J P, SUBRANMANIAN K N, BIELER T R. Formation and growth of interfacial intermetallic layers in eutectic Sn-Ag solder and its composite solder joints [J]. Journal of Materials Science:Materials in Electronics, 2000, 11: 497-501.

[8] SIGELKO J, CHOI S, SUBRANMANIAN K N, LUCAS J P. The effect of small additions of copper on the aging kinetics of the intermetallic layer and intermetallic particles of eutectic tin-silver solder joints [J]. J Electronic Materials, 2000, 29: 1307-1311.

[9] SIGELKO J, CHOI S, LUCAS J P, SUBRANMANIAN K N, BIELER T R. Effect of cooling rate on microstructure and mechanical properties of eutectic Sn-Ag solder joints with and without intentionally incorporated Cu6Sn5 reinforcement [J]. J Electronic Materials, 1999, 28: 1184-1188.

[10] MARSHALL J L, CALDERON J, SEES J, LUCEY G, HWANG J S. Composite solders [J]. IEEE Transactions on Components, Hybrids, and Manufacturing Technology, 1991, 14(4): 698-704.

[11] CLOUGH R B, PETEL R, HWANG J S, LUCEY G. Preparation and properties of reflowed paste and bulk composite solder [A]. Proceedings of Nepcon West Conference [C]. Anaheim, CA. 1992: 1256-1258.

[12] MAVOORI H, JIN S. New, creep-resistant, low melting point solders with ultrafine oxide dispersions [J]. Journal of Electronic Materials, 1998, 27(11): 1216-1222.

[13] SHI Yao-wu, YAN Yan-fu, LIU Jian-ping, XIA Zhi-dong, CHEN Zhi-gang, LEI Yong-ping, LI Xiao-yan. Metal Particles Enhanced SnCu Based Composite Solder and Manufacture [P]. 2002, 2003101168092.

[14] YAN Yan-fu, SHI Yao-wu, LIU Jian-ping, FU Guo, XIA Zhi-dong. Study of Metal Particles Enhanced Particles of SnCu Based Composite Solder[C]. Doctoral Forum of China, HIT, 2004: 336-343.

[15] MCDOUGALL J, CHOI S, BIELER T R, SUBRAMANIAN K N, LUCAS J P. Isothermal creep of eutectic SnBi and SnAg solder and solder joints [J]. Materials Science and Engineering, 2000, A285(25): 471-477.

[16] ROSS R T. crack propagation in solder joints during thermal- mechanical cycling [J]. Journal of Electronic Packaging, 1994, 116(2): 68-75.

[17] YAN Y F. Study of Particle Enhancement Tin Based Composite Solder [D]. Beijing University of Technology, 2004.

Foundation item: Project(2004-294) supported by the Innovative Ability Foundation of Henan Province, China

Corresponding author: YAN Yan-fu; Tel: +86-13241790440; E-mail: yanyanfu@mail.haust.edu.cn

(Edited by YANG Bing)