文章编号:1004-0609(2011)08-1997-06

Al基体表面熔盐化学法镀Pb工艺

蒋良兴,郝科涛,吕晓军,赖延清,洪 波,李 渊,李 劼,刘业翔

(中南大学 冶金科学与工程学院,长沙 410083)

摘 要:采用熔盐化学法在Al基体表面直接镀制Pb及其合金,并对其工艺条件进行优化。结果表明:熔体过热度对镀层与基体结合力的影响程度较基体浸入时间的大。随着过热度的升高,结合强度先迅速增大,在60 ℃之后变化不明显。在熔盐过热度为60 ℃,基体浸入时间2.5 min时,镀层与基体具有较好的结合强度(0.76 MPa)。往熔盐中加入适量的辅盐SnCl2可以促进Pb-Al-Sn三元合金的形成,并将镀层与基体的结合强度提高到2.1 MPa以上。在化学镀之后增加金属浴工序,可修补镀层在化学镀工序中形成的孔洞,在Al表面获得致密无孔、成分可调的Pb基合金镀层。

关键词:熔盐;化学镀;Al基体;Pb镀层;结合强度;金属浴

中图分类号:TF80 文献标志码:A

Electroless Pb plating on Al substrate in molten salt

JIANG Liang-xing, HAO Ke-tao, L? Xiao-jun, LAI Yan-qing, HONG Bo, LI Yuan, LI Jie, LIU Ye-xiang

(School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Pb and its alloy film were prepared on the Al substrate in molten salt by electroless plating directly, and the procedure was improved. The results show that the superheat of molten salt has greater effect on the combination strength between the film and substrate than dipping time of substrate. With the increase of the superheat, the combination strength increases fast firstly. While the superheat is higher than 60 ℃, the superheat has little effect on it. The film and substrate combined well when the superheat of molten salt and the dipping time of substrate are 60 ℃ and 2.5 min, respectively. The addition of auxiliary salt SnCl2 in molten salt can promote the interdiffusion of Al, Pb and Sn on the interface, and the combination strength can exceed 2.1 MPa. The metal bath procedure after electroless plating can mend the holes of the film, and a compact and composition adjustable Pb alloy film can be obtained on Al substrate.

Key words: molten salt; electroless plating; Al substrate; Pb film; combination strength; metal bath

金属Pb及其合金由于其在硫酸体系中优良的耐蚀性能而广泛的应用于有色金属电解提取和铅酸电池工业。但Pb及其合金也存在密度大、强度低、导电性差等缺点,这给其在实际应用中带来很多的不 便[1-4]。如在有色金属电解提取工业中,其较低的强度和易蠕变性能,使电极发生变形、挠曲而引起阴阳极短接。在铅酸电池中,Pb板栅的质量占到电池总质量的20%~30%,是电池能量密度较低(30~40 W?h/kg)的主要原因之一[5]。

为了能够在发挥Pb及其合金良好耐腐蚀性能的同时,提高电极的机械强度和导电率,并减轻电极质量,人们力图开发出轻质基体表层复合Pb或Pb合金的新型电极材料。金属Al的密度仅为Pb的1/4,导电率是Pb的8倍(仅次于Ag和Cu),抗拉强度是Pb的5倍以上,且非极化条件下,金属Al在硫酸溶液中可形成致密的保护膜。基于此,在金属Al表面复合Pb及其合金,可望制备出Al基轻质复合电极。但是,金属Al-Pb体系是典型的难混溶体系[6],且金属Al具有很强的亲氧性,其表面能在较短的时间内形成一层1 ~100 nm厚的氧化膜[7],严重阻碍Pb镀层与Al基体的有效结合。为此,必须选择一种合适的方法在Al基体表面预先镀制一层致密、无孔、结合力良好的Pb及其合金镀层。目前,Al(或Al合金)表面电镀Pb(或Pb合金)一般需要采用特殊的前处理方法[8-13],包括二次浸锌、预镀镍、预镀铜、包覆导电层等,虽然可以提高镀层结合力,但前处理过程步骤繁琐,产品质量不易控制,生产成本较高,且预镀层易溶于硫酸对电化学系统造成不利影响。张红安和陈刚报道[14]利用 固-液复合法铸造双金属复合材料,可以获得质量良好的复合界面。YOLSHINA等[15-16]和TIMMONS等[17]将Al基体浸入含Pb的氯化物熔盐中进行化学镀Pb,获得结合力良好的Pb镀层。该方法工序简单,不需对Al基体表面进行任何预处理。但是,所用熔盐中含有LiCl和KCl,而LiCl价格较贵,KCl吸水严重,这增加制备成本和难度。再加上该熔盐体系只能镀制纯Pb镀层,且镀层中存在孔洞,这严重影响复合电极材料的应用。

为此,本文作者对Al基体表面直接熔盐化学镀Pb工艺进行研究,并对熔盐成分和化学镀Pb工艺进行了改进,使之能够镀制致密无孔、成分可调的Pb合金镀层。

1 实验

1.1 试样制备

实验选用的试剂均为分析纯,包括氯化钠(NaCl)、氯化钙(CaCl2)、氯化铅(PbCl2)和氯化亚锡(SnCl2),所用Al片为原铝,纯度大于99.7%。

Al基体表面熔盐化学镀Pb的过程包括以下步骤:1) 熔盐准备:按要求称量一定量的干燥的氯化物,搅拌均匀,并在马弗炉中加热至设定的温度后,保温3 h;2) Al片预处理:Al片经过200#和400#砂纸打磨后,水洗、烘干待用;3) 化学镀Pb:将处理好的Al片预热至一定温度,浸入熔盐中一定时间后取出,冷却后用自来水将熔盐冲洗干净,获得Pb镀层。

1.2 测试方法

利用扫描电子显微镜(PHILIPS XL30 ESEM)观察铅镀层的表面形貌和结合界面,并利用能谱分析仪(EDX)测定镀层成分。

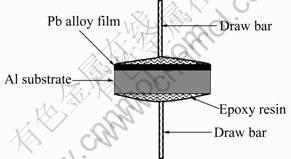

镀层与基体的结合强度通过万能材料试验机(CSS-44100)测试镀层的剥离力来评价。试样的制备过程为:将表面镀有Pb或其合金的Al片切割成 10 mm×10 mm大小,用环氧树脂将样品与拉杆粘接,制成如图1所示拉伸试样。结合强度与剥离力之间的关系如式(1)所示,

(1)

(1)

式中:σ为界面结合强度,Pa;S为样品面积,m2;F为拉伸过程中镀层从基体分离时的最大力,即剥离力,N。

图1 结合强度测试试样

Fig.1 Sample for combination strength tests

2 结果与讨论

2.1 熔盐成份的选择

已报道的熔盐化学镀铅工艺所用熔盐为PbCl2、LiCl和KCl的混合物。本研究对化学镀的熔盐成分进行改进,改用价格低廉、易得的NaCl和CaCl2与PbCl2混合,进行Al基体表面化学镀Pb。前期的探索实验发现,该熔盐成分加热后可得澄清的熔融盐,并可在Al基体表面制得平整的Pb镀层。

在PbCl2-CaCl2-NaCl三元体系中,各二元体系除NaCl-CaCl2外,均为简单共晶体系。其中,PbCl2-NaCl二元体系的共晶点在PbCl2的摩尔分数为70%附近,共晶温度约为410 ℃,PbCl2-CaCl2二元体系的共晶点在PbCl2的摩尔分数为82%附近,共晶温度约为480 ℃。而NaCl-CaCl2二元体系在NaCl摩尔分数为47.9%和79.7%时,分别存在一个共晶点和一个包晶点,其中共晶温度为504 ℃。因此,可以推断PbCl2-CaCl2-NaCl三元体系应为含一个包晶点的共晶体系,且共晶温度低于410 ℃。熔盐化学镀的本质就是利用金属Al比Pb活泼,Pb2+在金属Al表面发生置换反应生成金属Pb,并附着在新鲜的Al表面。因此,为保证反应过程的稳定,就要求熔盐中的Pb2+含量比较高,或能够得到不断补充。故三元熔盐中PbCl2的含量占绝大部分,NaCl和CaCl2的加入起到改善熔盐质量和降低初晶点的作用。

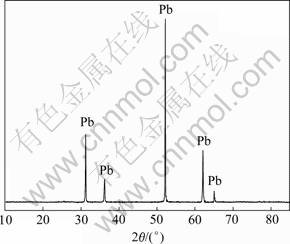

对不同组分的PbCl2-CaCl2-NaCl三元体系的初晶点进行测试,获得了各组分点的初晶温度,从降低能耗并兼顾镀层形貌考虑,选择PbCl2 83.2 g+NaCl 10.2 g+CaCl2 6.6 g体系作为Al基体表面直接化学镀Pb的熔盐成分,测试得到其初晶温度约为400 ℃。对Al表面所得的镀层进行XRD分析,其结果如图2所示。从图2中可以看出,金属Pb的特征峰十分尖锐,且未发现其它杂质峰,这说明通过熔盐化学法可以在Al基体表面获得结晶性良好的纯Pb镀层。

图2 Al基体表面Pb镀层的XRD谱

Fig.2 XRD pattern of Pb film on surface of Al substrate

2.2 工艺条件优化

2.2.1 过热度

熔盐初晶点与实际使用温度之间的差值,称为过热度。一般说来,熔盐的实际使用温度都要超过其初晶温度,一方面可以保证熔盐始终处于熔融状态,并具有良好的流动性;另一方面温度对化学反应和原子扩散速度影响较大。在Al基体表面进行化学镀Pb,就是利用新生态的Pb原子能够在新鲜的铝表面扩散、附着,以期增加两者的结合强度。

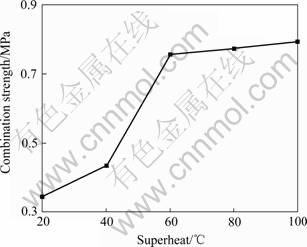

固定Al片浸入熔盐时间为3 min,在不同的过热度下进行Al基体表面熔盐化学镀Pb,并对样品的结合强度进行测试,其结果如图3所示。从图3中可以看出,随着过热度的增加,Pb镀层与Al基体的结合强度增加,且当过热度低于60 ℃时,结合强度增加速度较快;当过热度高于60 ℃时,结合强度增加幅度很小。在过热度为60 ℃时,结合强度为0.68 MPa。

图3 过热度对结合强度的影响

Fig.3 Effects of superheat on combination strength

在化学镀之前,需要对Al片进行预热,但为了防止Al片表面生成过厚的氧化膜,预热温度一般小于100 ℃。因此,在Al片浸入熔盐初期热交换不充分时,Al基体表面会生成一层坚硬的结壳,阻止置换反应的进行。只有在Al基体的温度达到熔盐的初晶温度时,结壳才会开始融化、脱落。过热度越低,结壳时间就越长,当浸入时间一定时,真正的反应时间就越短。一方面从熔盐中还原出来的Pb量越少;另一方面,金属Pb向Al基体扩散、镶嵌的时间越短,从而影响镀层与基体的结合强度。当过热度低于60 ℃时,结壳时间相对较长、对化学镀过程的影响较大,使得镀层与基体的结合强度随过热度的增加而迅速增加。当温度继续升高时,Al结壳时间对化学反应的影响基本可以忽略,且当Pb原子将Al基体表面覆盖完全后,置换反应难度增大,反应温度的升高对整个反应的影响变小,镀层与基体的结合强度主要受Pb向Al基体的扩散情况的影响。虽然温度升高有利于扩散,但金属Al和Pb为典型的不互溶体系,两者基本不能形成二元合金,从而导致Pb向Al基体的扩散有限,结合强度不能得到有效的提高。故从节能降耗的角度考虑,选择过热度为60 ℃。

2.2.2 浸入时间

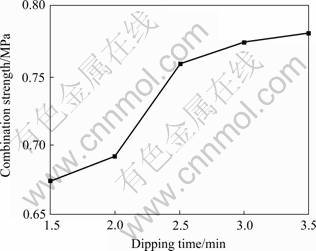

固定熔盐的过热度为60 ℃,将Al片浸入溶盐中不同时间制备Pb镀层,并对样品的结合强度进行测试,其结果如图4所示。

从图4中可以看出,浸入时间对基体与镀层之间结合强度的影响较过热度要小的多,在测试的时间范围内,结合强度在0.7~0.8 MPa的范围内变化。当浸入时间小于2.5 min时,结合强度较小;当浸入时间大于2.5 min后,随着时间的继续延长,镀层与基体的结合强度略有升高。当浸入时间为2.5 min时,结合强度为0.76 MPa。由于过热度保持不变,Al片在浸入熔盐中的结壳时间恒定。随着浸入时间的延长,置换反应时间变长。但同样,Pb原子向Al基体的扩散量有限,当化学镀时间大于2.5 min时,扩散已基本饱和,时间的延长对扩散影响不大,故结合强度也就基本保持不变。因此,选择Al片浸入时间为2.5 min,此时镀层与基体的结合强度为0.76 MPa。

图4 浸入时间对结合强度的影响

Fig.4 Effects of dipping time on combination strength

2.2.3 辅盐SnCl2

从图3和4可以看出,受制于Al与Pb为不互溶体系,在Al基体上直接镀制的纯Pb镀层与基体的结合强度较低。对镀层与基体界面进行Pb和Al元素EDX线扫描后发现(见图5(a)),在结合界面处,金属Pb和Al的过渡层不明显,这进一步证明Pb向Al基体的扩散非常有限,两者无法形成有效的冶金结合。因此,需要向熔盐中加入一定量的辅盐,在Al基体上镀制Pb合金以提高结合强度。所加入的辅盐需满足以下条件:1) 对熔盐体系影响较小;2) 能与金属Pb在Al表面共沉积;3) 能与金属Pb和Al形成三元合金。

据文献[18]可知,Sn加入Pb-Al合金中可缩小熔体的混溶间隙,且Pb-Al-Sn三元系存在三相共晶,其共晶点成分为38.1%Pb、61.7%Sn、0.08%Al,熔点为183 ℃。因此,在纯Pb镀层中加入元素Sn有利于镀层与Al基体形成冶金结合,增加结合强度。再加上金属Sn的化学性质与Pb相似,氧化/还原电位相近[19],实现两者在Al上的共沉积在理论上具有可行性。

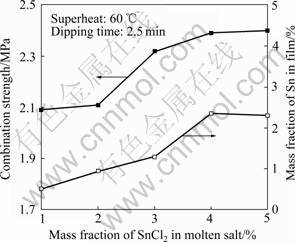

在过热度为60 ℃,浸入时间2.5 min时,往熔盐中添加一定量的SnCl2,并对所得镀层的Sn含量及与基体的结合强度进行测试,其结果如图6所示。从图6中可以看出,随着熔盐中SnCl2的质量分数从1%增加到4%,镀层中Sn含量呈线性增加,这表明当SnCl2的加入量少于4%时,熔盐中的SnCl2可以按比例置换并与Pb形成合金。当继续增加SnCl2的加入量时,熔盐在加热过程中会产生大量烟雾,且熔融盐表面会悬浮一层未溶物,这说明SnCl2在熔盐中的溶解已经饱和或需要更高的溶解温度,从而导致镀层中Sn含量不再增加。

从图6中还可以看出,熔盐中加入SnCl2能够显著提高镀层与基体的结合强度,强度值由不加SnCl2时的低于0.8 MPa增加到了2.1 MPa以上。随着熔盐中SnCl2添加量的增加,结合强度也不断提高。结合强度的变化与镀层中Sn含量呈现出较好的对应关系,即在熔盐中SnCl2添加量少于4%时,结合强度迅速提高,SnCl2添加量大于4%之后,结合强度变化不明显。这说明往熔盐中加入少量SnCl2,可以获得Pb-Sn合金镀层,并且有利于提高镀层与基体的结合强度。

对所得合金镀层与基体的结合界面进行SEM观察并对Al、Pb和Sn元素进行EDX线扫描,其结果如图5所示。从图5中可以看出,镀层与基体结合紧密,结合界面未发现任何开裂、起皮现象,且都在一定程度上发生了元素的相互扩散。当熔盐中加入SnCl2后,界面出现的Pb、Al这2种合金元素的浓度梯度较未加SnCl2时的更宽,说明元素Sn促进了金属元素在界面的相互扩散,有利于形成冶金结合,这正是结合强度大幅度提高的原因。对镀层的成分进行EDX分析发现,当熔盐中SnCl2添加量为3%(质量分数)时,镀层中除含Sn外,还含有1.52%(质量分数)的Al,这进一步验证上面的推论。同时,镀层中金属Al的存在,有利于在镀层完全覆盖基体时置换反应的继续发生,以增加镀层的厚度。

图5 镀层与基体结合界面的EDX线扫描

Fig.5 EDX linear scanning of interface between substrate and film: (a) Without SnCl2; (b) With SnCl2

图6 熔盐中SnCl2添加量对镀层的影响

Fig.6 Effects of addition of SnCl2 in molten salt on film

2.2.4 金属浴处理

对在上述条件下进行化学镀所得Pb-Sn镀层的表面形貌进行SEM观察,其结果如图7(a)所示。从图7(a)中可以看出,所得镀层并不完全致密,存在直径约50 μm的孔洞,这与YOLSHINA等[9]的报道一致。孔洞的出现,一方面作为置换反应的通道,使Pb2+能够与Al基体接触,保证反应的持续进行;另一方面使该材料在使用过程中容易被腐蚀性介质渗入而引起基体的腐蚀。将样品置于5 mol/L H2SO4溶液中发现,经过约10 h的浸泡,部分镀层与基体脱离。同时,由化学镀的原理可知,通过化学镀在Al基体表面获得的Pb基合金种类有限,且组分含量分布不易控制,不利于镀层性能的调控。

针对这一现象,本文作者将化学镀之后的样品在与熔盐等温的Pb基合金熔体中进行金属浴处理。对所得样品表面进行SEM观察(见图7(b))发现,即使放大到5 000倍,镀层表面仍然非常致密,没有发现任何孔洞。同时,镀层的厚度有所增加,由金属浴之前的50 μm左右增加到100 μm左右,这有利于提高镀层的寿命。对镀层成分进行EDX元素分析可知,镀层成分与金属熔体的成分完全一致。将在Pb-1.0%Sn (质量分数)熔体中金属浴处理之后的样品在5 mol/L H2SO4溶液中浸泡3个月,未发现任何起皮、脱落现象。这说明在化学镀之后进行金属熔体浸镀,可以对化学镀之后Pb镀层的孔洞进行有效修补,获得成分可控、致密无孔的Pb基合金镀层。

图7 金属Al表面Pb镀层形貌

Fig.7 Morphologies of Pb film on Al substrate: (a) Before dip plating; (b) After dip plating

3 结论

1) 在PbCl2-NaCl-CaCl2熔盐体系中进行化学镀,可在Al基体表面形成Pb镀层。当熔盐的过热度为 60 ℃、Al片的浸入时间为2.5 min时,所得试样的Pb镀层与Al基体间结合强度最高。

2) 辅盐SnCl2的加入,可促进元素Pb、Al在结合界面的相互扩散,从而在Al基体表面获得与基体冶金结合的Pb-Al-Sn三元合金镀层,镀层结合强度由未加SnCl2时的0.8 MPa以下提高到2.1 MPa以上。

3) 在化学镀之后增加金属浴工序可有效消除镀层表面的孔洞,并增加镀层厚度,获得致密、无孔的Pb基合金镀层,从而大大提高复合电极的耐硫酸腐蚀性能。同时,可对Al基体表面的Pb基合金镀层成分进行调控,扩大该类材料的应用范围。

REFERENCES

[1] YAN Mi-lin, ZHAO Wen-zhen. Influence of temperature on corrosion behavior of PbCaSnCe alloy in 4.5 M H2SO4 solution[J]. Journal of Power Sources, 2010, 195: 631-637.

[2] PEIXOTO L C, OS?RIO W R, GARCIA A. Microstructure and electrochemical corrosion behavior of a Pb-1wt%Sn alloy for lead-acid battery components[J]. Journal of Power Sources, 2009, 192: 724-729.

[3] LAI Yan-qing, JIANG Liang-xing, LI Jie, ZHONG Shui-ping, L? Xiao-jun, PENG Hong-jian, LIU Ye-xiang, ZHONG Shui-ping, L? Xiao-jun. A novel porous Pb-Ag anode for energy-saving in zinc electro-winning (Part Ⅰ): Laboratory preparation and properties[J]. Hydrometallurgy, 2010, 102: 73-80.

[4] LAI Yan-qing, JIANG Liang-xing, LI Jie, ZHONG Shui-ping, L? Xiao-jun, PENG Hong-jian, LIU Ye-xiang. A novel porous Pb-Ag anode for energy-saving in zinc electro-winning (Part Ⅱ): Preparation and pilot plant test of large size anode[J]. Hydrometallurgy, 2010, 102: 81-86.

[5] 刘广林. 铅酸蓄电池工艺学概论[M]. 北京: 机械工业出版社, 2009.

LIU Guang-ling. An introduction to technology of lead-acid battery[M]. Beijing: China Machine Press, 2009.

[6] 贾 均, 赵九洲. 难混溶合金及其制备技术[M]. 哈尔滨: 哈尔滨工业大学出版社, 2002.

JIA Jun, ZHAO Jiu-zhou. Immiscible alloy and its preparation techniques[M]. Harbin: Harbin Institute of Technology Press, 2002.

[7] 张 峰, 王旭辉, 肖耀坤. 铝和铝合金电镀前处理工艺及其对镀层结合力的影响[J]. 电镀与涂饰, 2005, 24(10): 20-21.

ZHANG Feng, WANG Xu-hui, XIAO Yao-kun. Pre-plating processes and their influences on deposit adhesion for aluminum and its alloy[J]. Electroplating & Finishing, 2005, 24(10): 20-21.

[8] 王媛媛, 徐 强, 唐致远, 苏 鹏, 刘 萍, 刘元刚. 铝基电镀Pb-Sn合金工艺及镀层性能研究[J]. 电镀与精饰, 2006, 28(4): 5-9.

WANG Yuan-yuan, XU Qiang, TANG Zhi-yuan, SU Peng, LIU Ping, LIU Yuan-gang. Study on the technology of Pb-Sn alloy electroplating on aluminium and the performance of the coating[J]. Plating & Finishing, 2006, 28(4): 5-9.

[9] 马洪芳, 刘志宝, 殷风铃. 铝合金电镀工艺研究[J]. 腐蚀与防护, 2003, 24(4): 162-163.

MA Hong-fang, LIU Zhi-bao, YIN Feng-ling. Electroplating of aluminum alloys[J]. Corrosion & Protection, 2003, 24(4): 162-163.

[10] 李 军. 铝及铝合金的电镀工艺综述[J]. 表面技术, 2000, 23(4): 3-5.

LI Jun. Review of the electroplating process of aluminum and its alloy[J]. Surface Technology, 2000, 23(4): 3-5.

[11] 杨志鸿, 黄 惠, 祝 星, 郭忠诚. 铝及铝合金表面直接电镀铅工艺[J]. 材料保护, 2009, 42(7): 36-38.

YANG Zhi-hong, HUANG Hui, ZHU Xing, GUO Zhong-cheng. Process for direct lead electroplating of aluminum and its alloy[J]. Materials Protection, 2009, 42(7): 36-38.

[12] 于紫阳, 徐 强, 唐致远. 铅酸蓄电池铝基板栅表面镀层的电化学性能研究[J]. 电源技术, 2008, 132(4): 233-235.

YU Zi-yang, XU Qiang, TANG Zhi-yuan. Study on electrochemical performances of deposit of aluminum light grid for lead-acid battery[J]. Chinese Journal of Power Sources, 2008, 132(4): 233-235.

[13] 柳 东, 王浩程, 孙荣禄. 铝及其合金表面改性技术的研究与发展[J]. 表面技术, 2007, 36(5): 75-83.

LIU Dong, WANG Hao-cheng, SUN Rong-lu. Study and development on surface modification technology of aluminum and its alloys[J]. Surface Technology, 2007, 36(5): 75-83.

[14] 张红安, 陈 刚. 铜/铝复合材料的固-液复合法制备及其界面结合机理[J]. 中国有色金属学报, 2008, 18(3): 414-420.

ZHANG Hong-an, CHEN Gang. Fabrication of Cu/Al compound materials by solid-liquid bonding method and interface bonding mechanism[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(3): 414-420.

[15] YOLSHINA L A, KUDYAKOV V Y, ZYRYANOV V G. A lead-film electrode on an aluminium substrate to serve as a lead-acid battery plate[J]. Journal of Power Sources, 1999, 78: 84-87.

[16] YOLSHINA L A, KUDYAKOV V Y, ZYRYANOV V G. Development of an electrode for lead-acid batteries possessing a high electrochemical utilization factor and invariable cycling characteristics[J]. Journal of Power Sources, 1997, 65: 71-76.

[17] TIMMONS J B, ORSINO J A, BHARDWAJ R. High energy, light weight, lead-acid storage battery: USA, 6447954[P]. 2002-09-10.

[18] 李松瑞. 铅及铅合金[M]. 长沙: 中南大学出版社, 1996.

LI Song-rui. Lead and lead alloys[M]. Changsha: Central South University Press, 1996.

[19] 文斯雄. 铅锡低熔二元合金电镀[J]. 腐蚀与防护, 2000, 21(2): 76-77.

WENG Si-xiong. Electroplating of lead-tin low melting binary alloy[J]. Corrosion & Protection, 2000, 21(2): 76-77.

(编辑 李艳红)

基金项目:湖南省院士基金资助项目(06FJ4059)

收稿日期:2010-12-20;修订日期:2011-03-27

通信作者:赖延清,教授,博士;电话:0731-88830649;E-mail: csulightmetals03@163.com