焊丝对工业纯铜和304不锈钢钨极氩弧焊接的影响

来源期刊:中国有色金属学报(英文版)2012年第12期

论文作者:Sajjad Gholami SHIRI Mohsen NAZARZADEH Mahmood SHARIFITABAR Mehdi Shafiee AFARANI

文章页码:2937 - 2942

关键词:钨极氩弧焊;工业纯铜;304不锈钢;异种材料连接;显微组织;力学性能

Key words:gas tungsten arc welding; CP-copper; 304 stainless steel; dissimilar joint; microstructure; mechanical properties

摘 要:采用不同焊丝对工业纯铜和304不锈钢进行钨极氩弧焊接。结果表明,采用铜做焊丝时,焊缝无任何缺陷生成,而采用304不锈钢和Ni-Cu-Fe合金为焊丝材料时,焊缝中有凝固裂纹和未熔化区存在。在最优条件下,焊缝的抗拉强度能达到铜材的96%。焊缝在弯曲到180°下也没有分离、撕裂和断裂等现象发生。这表明铜是一种较好的工业纯铜与304不锈钢GTA焊的焊丝材料。

Abstract: The dissimilar joining of CP-copper to 304 stainless steel was performed by gas tungsten arc welding process using different filler materials. The results indicated the formation of defect free joint by using copper filler material. But, the presence of some defects like solidification crack and lack of fusion caused decreasing tensile strength of other joints. In the optimum conditions, the tensile strength of the joint was 96% of the weaker material. Also, this joint was bent till to 180º without any macroscopic defects like separation, tearing or fracture. It was concluded that copper is a new and good candidate for gas tungsten arc welding of copper to 304 stainless steel.

Trans. Nonferrous Met. Soc. China 22(2012) 2937-2942

Sajjad Gholami SHIRI1, Mohsen NAZARZADEH1, Mahmood SHARIFITABAR2, Mehdi Shafiee AFARANI1

1. Materials Science and Engineering Division, School of Engineering, University of Sistan and Baluchestan, Zahedan, Iran;

2. Department of Materials Science and Engineering, Ferdowsi University of Mashhad, Mashhad, Iran

Received 16 January 2012; accepted 25 May 2012

Abstract: The dissimilar joining of CP-copper to 304 stainless steel was performed by gas tungsten arc welding process using different filler materials. The results indicated the formation of defect free joint by using copper filler material. But, the presence of some defects like solidification crack and lack of fusion caused decreasing tensile strength of other joints. In the optimum conditions, the tensile strength of the joint was 96% of the weaker material. Also, this joint was bent till to 180° without any macroscopic defects like separation, tearing or fracture. It was concluded that copper is a new and good candidate for gas tungsten arc welding of copper to 304 stainless steel.

Key words: gas tungsten arc welding; CP-copper; 304 stainless steel; dissimilar joint; microstructure; mechanical properties

1 Introduction

Joints of dissimilar metals are commonly used in different industries such as power generation, chemical, electronics and nuclear industries, to combine different properties of these materials in a single component. MAI and SPOWAGE [1] stated that there are different parameters that control the weldability of these dissimilar materials such as their atomic diameter, crystal structure and compositional solubility in the liquid and solid states. Diffusion of alloying elements in the weld pool often leads to the formation of intermetallic phases. Many of these phases are hard and brittle and have detrimental effects on the mechanical strength and ductility of the joint.

According to the statements of SHARIFITABAR et al [2], stainless steels play an important role in the modern world. Austenitic stainless steels represent more than 2/3 of the total stainless steel production. These stainless steels are preferred more than other stainless steel types due to their good weldability. But there are some negative metallurgical changes during welding and application of these steels which should be considered. They are: 1) the formation of delta ferrite phase, 2) the formation of sigma phase, 3) stress corrosion cracking, 4) the precipitation of chromium carbide in grain boundaries and 5) the formation of hot cracks.

Copper and copper alloys are one of the most versatile engineering materials. The combination of copper properties such as strength, conductivity, corrosion resistance, machinability and ductility make copper suitable for a wide range of applications.

Stainless steels have low thermal conductivity in comparison to copper and its alloys. When these alloys are used at high temperatures, heat dissipation to the environment is low because of their low thermal conductivity. Joining of copper to stainless steels can increase the heat dissipation from these alloys during high temperature applications and decrease the formation probability of deterious phases such as sigma phase after prolong heating, but high thermal conductivity of copper is one of the main limitations regarding to its welding. In other words, high thermal conductivity of copper tends to rapidly dissipate heat away from the weld zone, leading to difficulties in reaching the melting temperature as stated by MAGNABASCO et al [3].

Till now, some researchers have investigated the welding of copper to steel by different welding processes such as electron beam welding by MAGNABOSCO et al [3], laser welding by MAI and SPOWAGE [1] and YAO et al [4], explosive welding by DURGUTLU et al [5] and friction stir welding by IMANI et al [6]. MAGNABOSCO et al [3] investigated the electron beam welding of copper to three different stainless steels. They indicated that different microstructural features were formed in the fusion zone of these materials. Also some voids and microfissures were formed due to process and geometry parameters. It should be considered that vacuum conditions can influence the quality of the joint in this process as stated by YAO et al [4]. Laser welding is a process that does not have this limitation. MAI and SPOWAGE [1] indicated that sound welds can be produced by laser welding with a pulsed Nd:YAG laser between tool steel and copper. YAO et al [4] fabricated good welds between carbon steel and copper using a new joint design to control dilution between copper and steel. They showed that the tensile strength of the joint was higher than that of base plates in the best condition and fracture occurred in the copper base plate. Unfortunately, aluminum and copper are difficult to melt with lasers due to their high reflectivity. Therefore, during laser welding of these materials precise control of the laser focus position with respect to the joint interface is essential to achieve a sound weld as shown by MAI and SPOWAGE [1]. Also, laser and electron beam welding are more expensive than conventional welding processes such as gas metal arc welding (GMAW), gas tungsten arc welding (GTAW) and submerged arc welding (SAW). DURGUTLU et al [5] examined explosive welding of copper to stainless steel. They concluded that this couple can be joined with this process by selecting suitable parameters without any problem, but according to the researches of some researchers like DURGUTLU et al [5], AKBARI MOUSAVI et al [7] and AKBARI MOUSAVI and FARHADI SARTANGI [8], explosive welding often is used for joining of plates in the Lap configuration.

Up to now, no work has been reported on GTA welding of copper to austenitic stainless steels. In the present study, copper was welded to 304 stainless steel by GTA welding process using Ni-Cu-Fe, 304 stainless steel and Cu filler materials. Microstructures of the joints were examined by scanning electron microscope (SEM). Also, the mechanical properties of welded samples were investigated using different mechanical tests.

2 Experimental

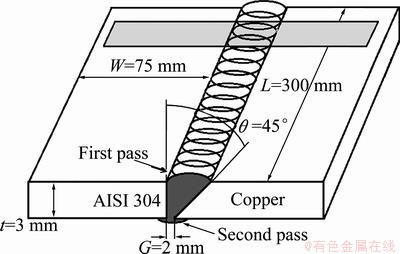

In order to join CP-copper to 304 austenitic stainless steel by GTA welding process, plates with dimensions shown in Fig. 1 were cut from rolled plates. Single bevel joint design was selected in order to concentrate heat flow on the copper plate to compensate heat loss due to its high thermal conductivity. Figure 1 also shows the dimensions of the joint used in this research. Before welding, copper plates were preheated to 500 °C for 10 min. Then GTA welding was performed using three different filler materials. Table 1 lists the chemical compositions of the base plates and filler materials. Also, the welding conditions and parameters are listed in Table 2.

Fig. 1 Schematic illustration of joint design (Unit: mm)

During welding, the first pass was performed into the bevel and the second one on the back of the joint in order to fill the lack of penetration of the first pass. In order to characterize the joints, metallographic samples of the cross section of the joint were cut and examined by VEGA/TESCAN scanning electron microscope in Razi Metallurgical Research Center (RMRC) after preparation by routine metallographic processes. The chemical composition of the joints was determined by energy dispersive spectroscopy (EDS) linked to the SEM. The mechanical properties of the welded samples were examined by three different tests including tensile, hardness and face bending tests. The tensile test specimens were cut perpendicular to the joint line with the dimensions of 140 mm×10 mm×3 mm while the beads were removed. This test was carried out by INSTRON 4208 tensile testing machine at a displacement rate of 1 mm/min. The Vickers micro hardness (HV) test was done with an applied load of 200 g for 30 s. Also, to examine the formability of the weld zone, samples with dimensions similar to the tensile test samples were prepared from the joints. Then, the face bending test was performed via bending samples around a bar with outer diameter of 6 cm.

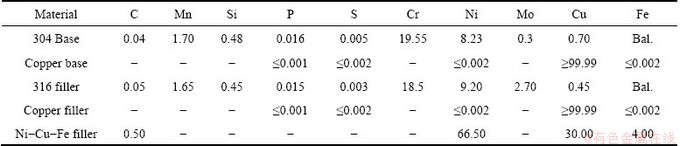

Table 1 Chemical composition of base plates and filler materials (mass fraction, %)

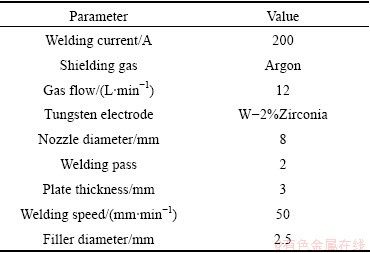

Table 2 Welding process conditions and parameters

3 Results and discussion

3.1 Macro and microstructures

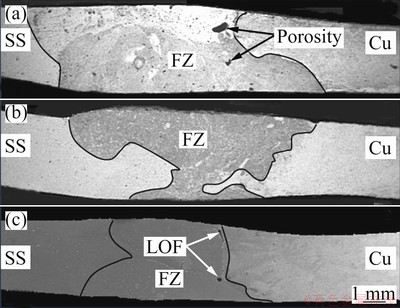

Figure 2 shows the SEM macrographs of the joints area fabricated by three different filler materials. Also, boundaries between the fusion zones (FZ) and the base materials are shown by black lines. Welding with Ni-Cu-Fe filler material produced uniform weld zone, but some voids were formed near the copper base materials as shown in Fig. 2(a). The formation of these defects may be due to the high cooling rate of the fusion zone because of the presence of base material with high thermal conductivity (copper plate) and entrapment of welding gases such as argon into the weld metal. Welding with Cu filler material led to the formation of a completely sound weld zone without any macroscopic defect (Fig. 2(b)). In the case of stainless steel filler material, a large lack of fusion (LOF) defect was formed on the copper plate side, but the rest of the fusion zone was free of macroscopic defect (Fig. 2(c)). This defect may also be formed as a result of high thermal conductivity of the copper plate. Comparing these macrographs, it can be seen that the fusion zones produced by three different filler materials in the stainless steel side were free of macroscopic defects. Therefore, these fillers can be used as candidates for welding of austenitic stainless steels. Nickel base alloys and austenitic stainless steel filler materials are usually used for this purpose as used by LIANG et al [9] for welding of 304 stainless, but copper cannot be used as filler for welding of stainless steels due to its lower strength compared to the base materials. As a general role, in the selection of filler material for welding of dissimilar materials, the mechanical and corrosion properties of the joint should be at least comparable to the metal that have lower properties.

Fig. 2 SEM images of joints area fabricated by Ni-Cu-Fe (a), Cu (b) and stainless steel (c) filler materials

The presence of large LOF defect in the fusion zone of the joint produced by stainless steel filler material affects the joint strength remarkably, and different microstructural features do not have any considerable effect on tensile properties of this joint. So, only the microstructures of different zones of the joints produced by Ni-Cu-Fe and Cu filler materials were investigated here.

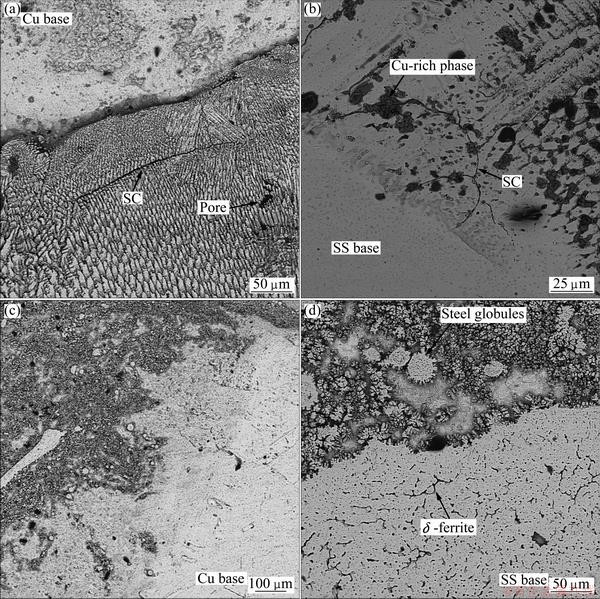

Figure 3(a) and (b) indicate the microstructures of the fusion zone produced by Ni-Cu-Fe filler materials in the copper and stainless steel sides, respectively. Solidification mode of the fusion zone was dendritic with lower dendrite arm spacing close to the copper plate. Some solidification cracks (SC) and pores were formed along the fusion zone-base plate interface and inter-dendrites, respectively (Fig. 3(a)). Also, there existed solidification cracks at the grain boundaries of the fusion zone at the stainless steel side (Fig. 3(b)). Lower dendrite arm spacing near the copper plate is due to the high cooling rate of the fusion zone as stated by CHALMERS [10]. Also, high thermal expansion and high thermal conductivity of the copper caused the formation of considerable thermal stresses in this region and cracking. On the other hand, high thermal expansion of the austenitic stainless steel and the presence of low melting temperature phase between the grain boundaries led to the formation of solidification cracks in the stainless steel side. EDX chemical analysis showed that this phase was rich in copper.

The microstructures of fusion zone produced by Cu filler material at the copper and stainless steel sides are shown in Figs. 3(c) and (d), respectively. These zones were free of microscopic defects like cracks, pores, etc. There were some steel globules in the fusion zone and delta ferrite phase in the austenite grain boundaries at the stainless steel side (Fig. 3(d)). The presence of these globules led to the formation of a steel-copper composite in this region. According to Fe-Cu binary phase diagram [4], there is a low solubility of Cu in Fe and vice versa. MAGNABOSCO et al [3] showed the formation of steel globules in copper matrix and copper globules in steel matrix in the fusion zone during electron beam welding of copper to 304L and 304 stainless steels. They stated that although the presence of Cr and Ni in the stainless steel may extend the solubility of Cu in Fe, but high cooling rate of the joint restricted the re-distribution of these alloying elements. Therefore, two different phases, one with high copper content and the other with high Fe, Cr and Ni contents, are formed in the fusion zone. During solidification, Fe rich phase with high melting point acts as nucleation sites at the fusion zone. Because of the high cooling rate of the joint due to the presence of filler material with very high thermal conductivity, the number of these nucleation sites is high and the globules are fine. Also, because of steep concentration gradients, globules could not grow long enough to form dendrites.

Fig. 3 Microstructures of interfaces at copper and stainless sides produced by Ni-Cu-Fe filler material (a, b) and Cu filler material (c, d)

MAGNABOSCO et al [3] indicated some copper penetration into the stainless steel heat affected zone grain boundaries. They also observed the formation of crack at the interface of copper and stainless steel. But, there was no evidence of copper penetration into the stainless steel grain boundaries and the formation of crack at the interface of copper and stainless steel in this investigation. HEIPLE et al [11] stated that several mechanisms have been proposed for liquid metal embrittlement. The most widely accepted one is the reduction of the strength of the surface atomic bonds of the solid by liquid metal. Failure occurs by progressive rupture of the atomic bonds at a crack tip. In this "adsorption" model a crack propagates as rapidly as liquid metal is supplied to the crack tip. It is generally believed that some plastic deformation, associated with crack initiation and possibly crack propagation, is required for embrittlement to occur. In the present study, the formation of no crack and copper penetration at the interface of copper and stainless steel may be due to the lower cooling rate of TIG welding compared to electron beam welding, which reduced the thermal stresses at the Cu-steel interface. In other words, lower thermal stresses decrease the stress concentration and plastic deformation in the heat affected zone of the stainless steel and consequently copper penetration and cracking.

3.2 Mechanical properties

3.2.1 Tensile properties

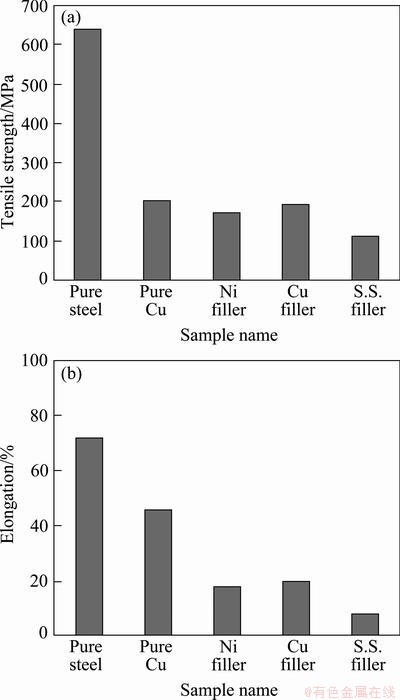

Figure 4 represents the transverse tensile strength and elongation of the base plates and the joints, respectively. In all welded samples fracture occurred in the fusion zone. The tensile strength and elongation of the joint produced by stainless steel filler material were low due to the presence of LOF defect. But, two other joints showed considerable strength and elongation compared to the base material which is copper in this joints. For Ni-Cu-Fe filler material, the tensile strength and elongation are 89% and 39% of the copper base plate. But, in the best condition, the maximum tensile strength and elongation obtained are 96% and 44% of the copper base plate respectively for the copper filler material. Lower strength and elongation for Ni-Cu-Fe filler material is because of the presence of cracks and voids in the fusion zone as indicated in Figs. 3(a) and (b).

3.2.2 Bending properties

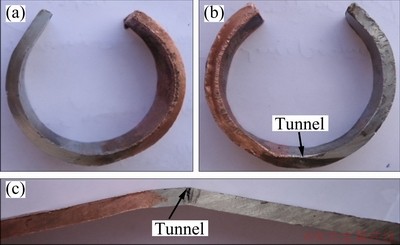

In order to investigate the formability of the joint, face bending test was carried out via bending samples around a cylindrical bar with outer diameter of 6 cm. Figure 5 represents the macrographs of the bended specimens. The sample welded with Cu filler material was bent till to 180° around the bar without any macroscopic defects like separation, tearing or fracture as shown in Fig. 5(a). This shows that copper–stainless steel welding was safely carried out in the present study. No intermetallic phases and defects formation in the fusion zone of Cu filler materials was the main reason for the high formability of the joints. A tunnel and a large tear were formed in the joint area of samples welded with Ni-Cu-Fe and stainless steel filler materials after about 180° and 25° bending around the bar, respectively. These are due to the presence of solidification cracks and voids formed in the fusion zone of the Ni-Cu-Fe filler material and LOF defect at the interface of stainless steel filler material and copper base plate.

Fig. 4 Tensile properties of base materials and welded samples

Fig. 5 Macrographs of bended specimens produced by Cu (a), Ni-Cu-Fe (b) and stainless steel (c) filler materials

3.2.3 Microhardness

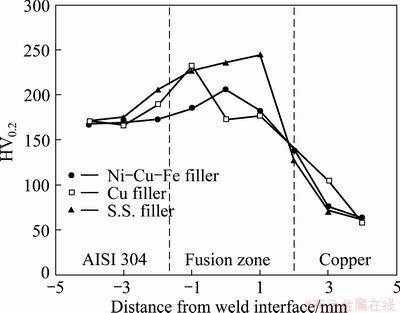

The results of Vickers microhardness test across the mid-plane of the different joints are shown in Fig. 6. In all samples the harnesses of the weld zones are higher than those of base materials. Also, there was a gradual increase in the hardness from copper plate to weld zone. It reached to the maximum at the middle of the joint and then decreased in the stainless steel side. The maximum hardness for the joint produced by Cu filler material was at the interface of filler and stainless steel, but in the case of stainless steel filler material the maximum hardness was at the interface of stainless steel filler material and copper base plate. The hardness of the Ni-Cu-Fe filler was higher than that of the other two base materials. This caused higher hardness of the fusion zone than that of the base materials. In the case of Cu and stainless steel filler materials, high cooling rate of the fusion zones led to the formation of solidification microstructure with low grains size and higher overall hardness of these zones in comparison to the base materials. As stated in the section of 3.1, the formation of steel-Cu composite at the interface of copper and stainless steel caused the maximum hardness at the joint interfaces for these samples.

Fig. 6 Hardness profiles across joints produced by different filler materials

4 Conclusions

1) Ni-Cu-Fe and Cu filler materials can be used for welding of copper to 304 stainless steel. In the case of Cu filler material, no macro and micro crack formed in the fusion zone. But the formation of solidification cracks caused the reduction of tensile strength and elongation of the joint produced by Ni-Cu-Fe filler materials.

2) In the samples welded by Cu filler material, the tensile strength of the joint was 96% of the weaker material. These joints also were bent till 180° without macroscopic defects like separation, tearing or fracture and showed good formability.

3) Fusion zones had higher hardness than base materials in all samples. Also, the formation of Fe-Cu composite at the interface of stainless steel-Cu filler material caused the highest hardness in the fusion zone.

4) Copper is a good candidate for gas tungsten arc welding of copper to 304 stainless steel.

Acknowledgments

The authors would like to thank Prof. A. H. KOKABI for scientific aids.

References

[1] MAI T A, SPOWAGE A C. Characterisation of dissimilar joints in laser welding of steel–Kovar, copper–steel and copper–aluminium [J]. Materials Science and Engineering A, 2004, 374: 224-233.

[2] SHARIFITABAR M, HALVAEE A, KHORSHAHIAN S. Microstructure and mechanical properties of resistance upset butt welded 304 austenitic stainless steel joints [J]. Materials and Design, 2011, 32: 3854-3864.

[3] MAGNABOSCO I, FERRO P, BONOLLO F, ARNBERG L. An investigation of fusion zone microstructures in electron beam welding of copper–stainless steel [J]. Materials Science and Engineering A, 2006, 424: 163-173.

[4] YAO C, XU B, ZHANG X, HUANG J, FU J, WU Y. Interface microstructure and mechanical properties of laser welding copper–steel dissimilar joint [J]. Optics and Lasers in Engineering, 2009, 47: 807-814.

[5] DURGUTLU A, GULENCE B, FINDIK F. Examination of copper/stainless steel joints formed by explosive welding [J]. Materials and Design, 2005, 26: 497-507.

[6] IMANI Y, BESHARATI GIVI M K, GUILLOT M. Improving friction stir welding between copper and 304L stainless steel [J]. Advance Materials Research, 2011, 409: 263-268.

[7] AKBARI MOUSAVI S A A, BARRETT L M, Al-HASSANI T S. Explosive welding of metal plates [J]. Materials Processing Technology, 2008, 202: 224-239.

[8] AKBARI MOUSAVI S A A, FARHADI SARTANGI P. Explosive welding of cp-titanium/AISI 304 stainless steel [J]. Materials and Design, 2009, 30: 459-468.

[9] LIANG D, SOWARD J W, FRANKEL G S, ALEXANDROV B T, LIPPOLD J C. Corrosion resistance of welds in type 304L stainless steel made with a nickel–copper–ruthenium welding consumable [J]. Corrosion Science, 2010, 52: 2439-2451.

[10] CHALMERS B. Principals of solidification [M]. New York: John Wiley & Sons, 1964: 170.

[11] HEIPLE C, BENNETT W, RISING T. Embrittlement of several stainless steels by liquid copper and liquid braze alloys [J]. Materials Science and Engineering, 1982, 52: 277-289.

Sajjad Gholami SHIRI1, Mohsen NAZARZADEH1, Mahmood SHARIFITABAR2, Mehdi Shafiee AFARANI1

1. Materials Science and Engineering Division, School of Engineering, University of Sistan and Baluchestan, Zahedan, Iran;

2. Department of Materials Science and Engineering, Ferdowsi university of Mashhad, Mashhad, Iran

摘 要:采用不同焊丝对工业纯铜和304不锈钢进行钨极氩弧焊接。结果表明,采用铜做焊丝时,焊缝无任何缺陷生成,而采用304不锈钢和Ni-Cu-Fe合金为焊丝材料时,焊缝中有凝固裂纹和未熔化区存在。在最优条件下,焊缝的抗拉强度能达到铜材的96%。焊缝在弯曲到180°下也没有分离、撕裂和断裂等现象发生。这表明铜是一种较好的工业纯铜与304不锈钢GTA焊的焊丝材料。

关键词:钨极氩弧焊;工业纯铜;304不锈钢;异种材料连接;显微组织;力学性能

(Edited by YUAN Sai-qian)

Corresponding author: Mahmood SHARIFITABAR; Tel: +98-5516613963; E-mai: msharifitabar@eng.usb.ac.ir

DOI: 10.1016/S1003-6326(11)61553-7