文章编号: 1004-0609(2006)02-0315-07

无铅波峰焊Sn-Bi-Ag-Cu钎料焊点剥离机制

何 鹏1, 赵智力2, 钱乙余1, 李忠锁3

(1. 哈尔滨工业大学 现代焊接生产技术国家重点实验室, 哈尔滨 150001;

2. 哈尔滨理工大学 材料科学与工程学院, 哈尔滨 150080;

3. 日东电子发展有限公司 无铅焊接研发中心, 深圳 518103)

摘 要: 对波峰焊常用的Sn-Bi-Ag-Cu无铅钎料进行了通孔波峰焊焊点剥离现象的模拟实验。 分析表明, 凝固延迟及铋元素偏析导致焊盘拐角附近钎料区在结晶后期残存液相最终成为缩孔的聚集区, 结晶后期该区的低塑性使收缩应变容易超过材料的塑性而发生开裂, 且发生机制与结晶裂纹发生的机制相同, 强偏析元素铋的存在导致剥离概率极高。 通孔拐角附近是应力应变的集中区, 沿界面至焊盘外缘, 应力应变逐渐降低。 Sn-Bi-Ag-Cu系钎料焊点剥离的发生机制是由于Bi元素在焊盘/钎料界面富集使拐角附近钎料的液相线温度降低, 结晶后期该区因固液共存而成为相对低塑性区, 在应力作用下开裂并向焊盘外缘扩展。

关键词: Sn-Bi-Ag-Cu钎料; 无铅波峰焊; 焊点剥离; 偏析; 结晶裂纹

中图分类号: TG406 文献标识码: A

Fillet-lifting mechanism for Sn-Bi-Ag-Cu solder joint in

lead-free wave soldering

HE Peng1, ZHAO Zhi-li2, QIAN Yi-yu1, LI Zhong-suo3

(1. State Key Laboratory of Advanced Welding Production Technology,

Harbin Institute of Technology, Harbin 150001, China;

2. School of Materials Science and Engineering,

Harbin University of Science and Technology, Harbin 150080, China;

3. Sun East Electronic Development Co. Ltd., Shenzhen 518103, China)

Abstract: The mechanism of fillet-lifting for the Sn-Bi-Ag-Cu solder was studied, which is one of the mainly used lead-free solder in wave-soldering. The analysis results show that the segregation of Bi becomes more remarkable at the corner of the solder body/PCB pad. The local irregularity of Bi delays the solidification of the solder at the above area, and thus the residual liquid solder at that place becomes the aggregation area of shrinkage void during the following crystallization. The shrinkage strain exceeds the low plasticity of the Bi segregation solder in the later crystallization, then the crack is similar to that of the crystal crack. The presence of strong segregation element Bi exacerbates the probability of lift-off, which could be reduced by the rapidly cooling only in a limited extent. The stress-strain concentration is detected at the corner of Cu pad, the lower stress for the outer of Cu pad. Based on the above two leading reasons for fillet-lifting, the stress-strain concentration at the corner of Cu pad and the solidification delay, the mechanisms of fillet-lifting for Sn-Bi-Ag-Cu through-hole lead-free solder joint were given. Near the interface region of solder and Cu-pad, the liquidus of solder is lowered by the enriched Bi element, and the low plasticized zone produces at this region due to the existence of residual liquid phase. With the stress-strain concentration, the cracks produces near the corner of Cu pad and then propagated to its outer.

Key words: Sn-Bi-Ag-Cu solder; lead free wave soldering; fillet lifting; segregation; crystalline crack

焊点剥离现象是指钎焊后立即出现的钎焊圆角从焊盘上升起的现象, 是无铅波峰焊需克服的主要缺陷之一, 频繁发生于含Bi 钎料焊点中[1], 如Sn-Ag-Bi-Cu系钎料由于合适的熔点、 良好润湿性和力学性能在波峰焊中得到了广泛应用, 但Bi添加量在2%时就有剥离现象发生, 添加量达到5%时剥离概率达到100%[2-5]。 1997年, National Center for Manufacturing Sciences首先报导了无铅钎料、 特别是含Bi和Pb污染的高锡合金钎料焊点的剥离现象, 认为钎料/焊盘间的热膨胀系数失配是焊点剥离发生的直接驱动力[6]。 1998年, 日本大阪大学学者Suganuma[7]对Sn-Bi系二元合金组织和Sn-22Bi-2Ag焊点剥离界面的微观组织进行了研究, 认为Sn-Bi系及Sn-Bi-Ag系钎料在进行通孔波峰焊时产生的焊点剥离现象与Bi元素在钎料/焊盘界面的聚集有关。 2000年, Suganuma等[8]对通孔波峰焊点凝固过程进行了热模拟, 认为剥离与钎料的凝固收缩与基板和钎料的热收缩有关。 继含Bi元素钎料焊点剥离现象之后, 文献[9, 10]也报道了Sn-Ag和Sn-Cu系钎料焊点中的剥离现象。 Suganuma[11]研究了Sn-0.7Cu钎料焊点的剥离现象, 并观察到富Pb相存在于钎料/引线界面、 钎料/铜焊盘界面。 在Sn-Cu钎料波由印制电路板底面通过通孔向上喷流到顶端过程中, 由于钎料的冲刷作用, 引线镀层中的铅溶解于钎料中并运送到PCB(printed circuit boad)上面的焊盘上, 在焊盘上形成富Pb的低熔点相, 元器件及基板镀层含Pb是导致这些钎料焊点剥离的原因[12]。 ESPEC环境测试中心对Sn-Pb、 Sn-Ag-Cu和剥离的Sn-2.0Ag-0.5Cu-2.0Bi钎料焊点进行了热循环测试[13, 14]。 结果表明, 与Sn-Pb焊点不同, 无铅焊点热循环后都没有粗化的再结晶组织, 且裂纹首先发生在焊盘/钎料界面, 而不是在钎焊圆角的表面开裂。 由于剥离使焊点的应力得到释放, 在1000个循环内焊点无明显变化, 可靠性仍能够达到基本要求。 综上所述, 无铅钎料剥离现象的产生机理, 特别是Bi、 Pb元素影响剥离发生的实质原因还存在争论, 因此急需建立较完善的剥离发生机制, 并据此研究缺陷的抑制措施。

本文作者以波峰焊中广泛应用Sn-Bi-Ag-Cu钎料为对象, 模拟剥离现象并探讨其发生机制和抑制措施。

1 实验与结果

将Sn-2.5Ag-1.0Bi锡棒在坩锅中加热熔化, 加入适量的纯度为99.99%的锡粒、 铋粒和铜丝使钎料中制成铋含量分别达到1.0%、 2.0%、 3.0%、 5.0%和7.5%Bi(质量分数)的钎料备用(7.5%Bi即H合金, 熔化温度为189~213℃[15] , 也有为206~212℃)。

采用双面FR-4基板, 厚度为1.6mm; 铜焊盘直径为1.57mm, 通孔直径为0.812mm, 元器件引脚直径为0.5mm。

焊点温度曲线采用RC-50 Flow Profiler专用测试仪记录。 助焊剂为铺展率为92%±3%的免清洗焊剂。 模拟实验在具有恒温控制的小型波峰焊炉中进行, 焊接温度控制在(260±5)℃, 接触时间为5~7s, 取出立即采用不同介质冷却, 考察冷却对剥离现象的抑制作用。

切割相应数量的焊点, 进行金相试样的镶嵌、 研磨和抛光, 采用金相显微镜统计剥离缺陷。 采用S-570扫描电镜分别观察剥离纵切面的外观、 显微组织和剥离断面的形貌。 采用GEOLsuperobe733电子探针仪进行通孔焊点剥离缺陷的成分分析。

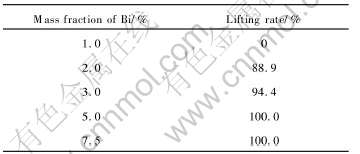

在不同Bi含量PCB板的相同位置上各取18个焊点进行缺陷统计, 其发生率如表1所列。 当Bi含量超过2%时, 缺陷率迅速上升并接近100%。 在金相显微镜下可观察钎料与IMC(intermetallic compound)间发生开裂, 由此可见剥离与润湿无关。

表1 不同Bi含量焊点剥离的发生率

Table 1 Lifting ratio of fillet with different Bi content

2 焊点剥离的机制分析

2.1 钎料界面区铋元素的分布

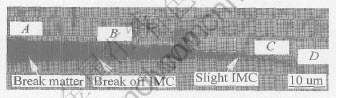

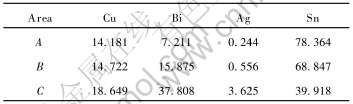

以Sn-2.0Ag-0.5Cu-7.5Bi钎料焊点为对象进行剥离机制研究。 图1所示为剥离焊点的界面形貌。 纵切面上A、 B、 C 3个区域的成分列于表2。 由图1和表2可知, 越接近焊盘中心, 界面区钎料中的铋含量越大, 焊盘拐角处的铋含量达到原成分的5~6倍。 根据凝固理论, 先结晶的固相溶质含量低, 后结晶的固相溶质含量高。 焊点上部区域和A、 B、 C区铋含量的巨大差异证明, 焊点凝固是从一端向另一端沿一定方向顺序进行的, 除枝晶偏析外, 焊点内部还发生了区域偏析。

图1 250℃时Sn-2.0Ag-0.5Cu-7.5Bi钎料剥离界面的形貌

Fig.1 Morphology of fillet-lifting interface of Sn-2.0Ag-0.5Cu-7.5Bi at 250℃

表2 250℃时Sn-2.0Ag-0.5Cu-7.5Bi钎料剥离界面成分分析

Table 2 Elemental analyses results of lift-off interface of Sn-2.0Ag-0.5Cu-7.5Bi at 250℃(mass fraction, %)

2.2 剥离的断面特征

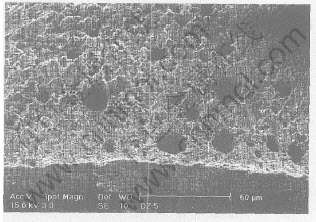

图2所示为剥离焊点横断面的形貌。 由图2可看出, 在焊盘拐角附近环形区域存在大量凹入的缩孔, 缩孔周边和相界有液相痕迹, 缩孔和液相的存在会严重削弱界面的连接强度。

图2 焊盘拐角附近钎料剥离面上缩孔的形貌

Fig.2 Morphology of shrinkhole at fillet-lifting surface fractures near corner

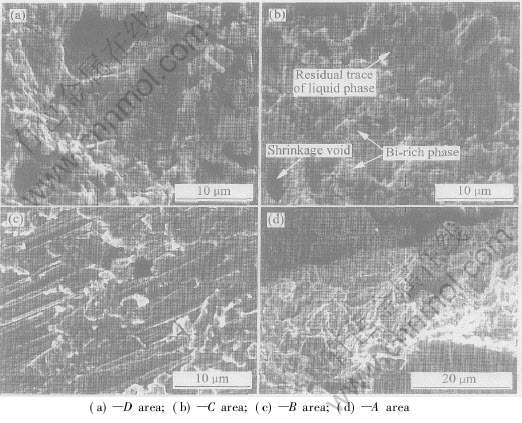

[TS)] 图3所示为不同位置的剥离钎料断面的形貌。 由图3可看出, 与中心通孔的距离不同, 钎料的断面特征存在较大差别。 D区呈脆性断裂特征, 断面含大量折断的IMC, 这与通孔拐角处IMC承受较大的剪切应力有关(见图3(a)); C区断面存在明显的液相痕迹(见图3(b)); A区和B区断面相同, 呈现指向孔中心的平行划痕(见图3(c))。

剥离断面没有拉伸形成的韧窝, 不是韧性断口; 断口形貌也不同于一般固态下所示的脆性断口, 断面有液相痕迹, 特征与热裂纹中结晶裂纹的断口特征相似(图3(d))。

2.3 剥离的发生时期

铋元素富集会导致C区钎料液相线的温度降低, 缩孔的存在证明了C区钎料凝固延迟。 这与文献[9]中对Sn-5Bi波峰焊点凝固的温度场模拟结果不完全相同, 模拟并未考虑到液态钎料向上冲击与回落会使PCB板上下焊点热分布不同, 从而下方焊点更易剥离。

在结晶后期, 只有C区界面的钎料处于固液共存状态, 该温度范围内的塑性最低, 这一时期的焊点局部区域低塑性是发生剥离的冶金因素。 当金属全部凝固以后, 塑性会迅速提高。 因此, 剥离应发生于焊点结晶的固-液态温度期间, 而不应发生于固相线以下。

2.4 通孔焊点的应力应变分析

无铅钎料的抗蠕变性好于锡铅钎料, 经历热循环后, 无铅焊点在焊盘与钎料界面开裂倾向会相对增加。 但焊点凝固过程的应力应变分布与热循环过程不同, 蠕变对焊点凝固过程中的开裂不起主要作用, 因此, 焊点应力应变场分布的模拟极为必要。

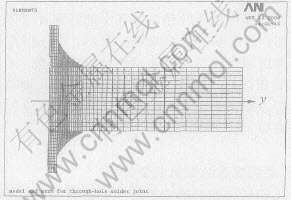

2.4.1 有限元几何模型

建立通孔焊点的二维有限元力学模型, 模型包括了钎料、 PCB、 元器件引脚及Cu焊盘部分, 由于通孔插装焊点的对称特征, 只需要建立模型的一半。 图4所示为通孔插装焊点的几何模型。 图中的尺寸与实际结构尺寸相同。 模型采用四节点单元, 并进行了映射网格划分, 该模型共有1204个节点, 1123个单元。 有限元分析使用商用非线性有限元程序ANSYS8.0, 分析过程为直接热-位移偶合分析。

图3 同位置剥离钎料断面的形貌

Fig.3 Morphologies of fracture surface at different areas

图4 通孔焊点的有限元模型

Fig.4 FEA model of through-hole solder point

2.4.2 温度场模拟的数学模型

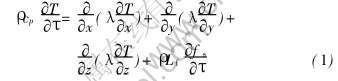

在本模型中采用以下几点假设: 1) 模型关于y轴对称分布; 2) 忽略熔融钎料金属流动的对流换热; 3) 考虑电路板与周围介质的对流换热; 4) 考虑钎料凝固过程中的相变潜热。 因此, 波峰焊后冷却过程中由热传导过程引起的内部能量平衡方程为

式中 ρ为材料密度; cp为热容; λ为导热系数; fs为凝固的固相分数。 当知道了钎料的相变潜热Hf, 则结晶过程释放的相变潜热可计算为

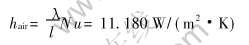

式中 C*=Hf/ΔT, ΔT为材料的熔化温度范围。 温度场计算参数如表3所列。

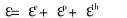

2.4.3 应力场模拟的数学模型

材料的总应变由三部分组成, 即

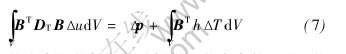

式中 εe为弹性应变; εp为塑性应变; εth温度产生的热应变。 弹性应变满足虎克定律, 因此写成增量形式为

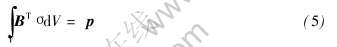

式中 DT为依赖于温度的弹塑性系数矩阵, 包含弹性和塑性的贡献; h为热应变对应力贡献大小的张量。 由单元应力σ与节点上的等效外力p之间的平衡关系:

式中 BT为建立节点位移u和单元总应变ε之间线性关系的转换矩阵, 即

综上整理可得

按小变形热弹塑性分析进行热应变的处理, 热应变的变化为

焊盘及引脚的材料模式选用各向同性的线弹性材料, PCB为各向异性的线弹性材料, 计算中采用的材料力学参数如表4所列。

2.4.4 载荷分布及边界条件的处理

1) 热分析过程 根据工艺实验条件设定初始温度, 模型边界与外界环境介质产生对流换热, 其对流换热边界条件为

式中 hc为对流换热系数, W/(m2·K); T0为环境介质温度。

本研究假设焊点结构各接触面为理想接触, 因此在界面处热流连续、 温度连续的界面条件表达式为

式中 λ1、 λ2和T1、 T2分别是界面处不同材料的导热系数和温度。 因此, 热分析的关键问题是对流换热系数的确定。

2) 应力分析过程 材料在温度作用下的体积变化会产生热应变, 当结构热应变受到约束不能自由发展时, 就会产生热应力。 PCB、 钎料及镀铜层材料热膨胀系数间的差异是焊点冷却过程中内部产生应力的原因, 而非均匀的温度分布即温度梯度也会产生热应力。 在应力分析过程中, 各节点的温度来自于热分析的计算结果。

2.4.5 对流换热系数的确定

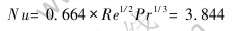

空气温度为30℃, 树脂板温度为250℃, 则

据此查得空气的物性值为ρair=0.854kg/m3, 运动粘度ηair=27.80×10-6 m2/s, 普朗特数Prair=0.684, λair=3.49 ×10-2 W/(m·℃)。 本模型中的板长为12mm, 在流速v=0.1m/s条件下, 雷诺数为

为层流, 其努塞尔数为

对流换热系数为

2.4.6 计算结果及焊点的起裂扩展

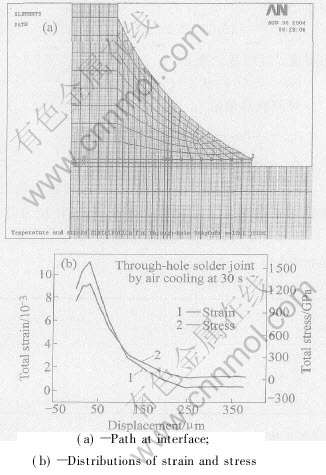

焊点凝固的温度场和应力场模拟结果表明, 焊盘拐角区钎料是应力应变集中区, 拐角区应力应变

表3 焊点材料的热物理参数

Table 3 Thermophysical parameters of fillet

表4 焊点材料的力学性能

Table 4 Mechanical parameters of fillet

图5 焊点空冷30秒后应变分布

Fig.5 Distribution of strain after air cooling 30s

图6 空冷30s后通孔焊点钎料/焊盘界面的应力应变分布

Fig.6 Distributions of strain and stress of through-hole solder joint after air cooling 30s

值远大于焊盘外缘(见图5和6)。 在结晶后期, 界面A区没有明显的薄弱组织, 应力应变较小, 而C区的液相层塑性很低, 又是应变集中区, 在应变作用下就容易被首先拉开, 因此, 剥离可能在焊盘拐角处起源, 之后向外缘扩展。

2.5 剥离开裂机制的探讨

剥离作为一种裂纹, 其发生也必然满足拉伸变形量(ε)超过材料本身的塑性(δ为材料本身塑性的极限)(ε>δmin)这一基本条件。 C区为焊点凝固延迟区, 铋元素在C区偏析富集使该区钎料的液相线大大降低, 同其他钎料焊点相比, 凝固过程中处于低塑性的固液共存时间更长。 另外, 缩孔削弱了界面连接强度, 促进开裂发生, 即金属学因素使开裂处材料塑性急剧降低。 根据焊点应力应变模拟结果, 由于应力集中最大和凝固延迟使拐角区钎料容易满足εintC>δminC的开裂条件; 而A区没有明显的薄弱相, εintA>δminA时A区才会发生开裂。

综上所述, Sn-Bi-Ag-Cu钎料的剥离发生在结晶后期, 在钎料偏析产生的低熔点相的液相线以上稍高温度期间, 剥离可能起源于焊盘拐角附近的环形区域, 并沿焊盘/钎料界面向外缘扩展。 C区张开后, 连接面积减小, 而应力并没有完全释放, 当界面应变(εint)进一步累积超过材料的塑性δmin而完全裂开。 也正是由于偏析使固液共存的低塑性区间增大和该状态停留时间增加, 导致这类钎料焊点剥离发生的概率很大, 存在一定规律性和必然性。

3 结论

Sn-Bi-Ag-Cu钎料焊点剥离发生在结晶后期较高温度期间, 开裂可能起源于焊盘拐角附近的环形区域, 并沿焊盘/钎料的界面向外缘扩展。 区域偏析使凝固延迟区钎料的液相线显著降低, 使低塑性脆性温度区间增大, 局部液相存在时间更长, 应变量易超过液相层的最低塑性而开裂。

REFERENCES

[1]Nakatsuka T. Reliability of Pb-free solder joints of surface-mounted LSI packages after flow-solder[J]. IMAPS, 2000, 9: 330-335.

[2]Handwerker C. NIST Research in Lead Lead-Free Solders: Properties, Processing, Reliability[R]. National Institute of Standards and Technology (NIST), 2002.

[3]Suganuma K. Influence of various factors on lift-off phenomenon in wave soldering with Sn-Bi alloy[J]. Jpn Inst Electron Package, 1999, 2: 116-20.

[4]Suganuma K. Advances in lead-free electronics soldering[J]. Current Opinion in Solid State and Materials Science, 2001, 5: 55-64.

[5]Suganuma K. Mechanism and prevention of lift-off in lead-free soldering[A]. Proc 33rd International Symposium on Microelectronics[C]. Boston: Massa-chusetts, 2000. 303-307.

[6]Lead-Free Solder Project Final Report[R]. Germany: UNCMS, Report0401RE96. 1997.

[7]Suganuma K. Microstructural features of lift-off phenomenon in through-hole circuit soldered by Sn-Bi alloy[J]. Scripta Materialia, 1998, l38(9): 1333-1340.

[8]Suganuma K. Lift-off phenomenon in wave soldering[J]. Acta Materialia, 2000, 48: 4475-81.

[9]Ishizuka K, Kawano T. Tests of fillet lifting phenomena in lead-free solder[A]. 6th Microjoining and Assembly Technology in Electronics[C]. USA: 6th MATE Organise, 2000. 297-302.

[10]Mitlin D, Raeder C H, Messler R W. Solid solutioncreep behavior of Sn-xBi alloys[J]. Metallurgical and Materials Transactions A, 1999, A30: 115-21.

[11]Suganuma K. Mechanism and prevention of lift-off in lead-free soldering[J]. IMAPS, 2000, 9: 325-329.

[12]John H. Electronics manufacturing with lead-free[J]. Halogen-Free & Conductive-Adhesive Materials, 2003, 16: 20-27.

[13]Hirokazu T, Yuichi A, Hiroko K. Evaluation Results on Reliability of Lead-free Solder-Tabai Espec Efforts to Develop Viable Lead-free Solder[R]. ESPEC Technology Report, 2002, 11.

[14]Hua F, Mei Z, Lavagnino A. Eutectic Sn-Bi as an Alternative Pb-free Solder[A]. Proceedings of an International Summit on Lead-free Electronics Assemblies[C]. USA: ISLEA Organise, 1999. 56-61.

[15]Database for Solder Properties with Emphasis on New Lead-free Solders[R]. Germany: National Institute of Standards and Technology & Colorado School of Mines, 2002.

(编辑李艳红)

基金项目: 国家自然科学基金资助项目(50505008)

收稿日期: 2005-05-23; 修订日期: 2005-09-20

作者简介: 何 鹏(1972-), 男, 副教授, 博士

通讯作者: 何 鹏, 副教授; 电话/传真: 0451-86418146; E-mail: hepeng@hope.hit.edu.cn