文章编号:1004-0609(2011)06-1214-06

挤压态AZ81镁合金的热压缩变形行为

曹凤红1, 2,龙思远1,G. S. COLE3

(1. 重庆大学 材料科学与工程学院,重庆 400030;

2. 成都理工大学 工程技术学院,乐山 614007;

3. 美国汽车通用公司, 美国,48090)

摘 要:在温度为320~440 ℃、应变率为0.001~1 s-1的变形条件下,采用Gleeble-1500热模拟机对挤压态AZ81镁合金的热压缩变形行为进行研究。结果表明:挤压态AZ81镁合金的流变应力随变形温度的升高而降低,随应变率的升高而升高,且随应变的增加,流动应力很快达到峰值,然后逐渐降低并趋于稳定。为评价挤压态AZ81镁合金在热模压成形过程中流动应力,结合Arrhenius方程并引入Zener-Hollomon参数,对流动应力做出相应的修正,根据修正后的流动应力构建挤压态AZ81镁合金流变应力高温变形本构模型。模拟结果表明:该模型的应力预测值与试验值吻合较好,计算精度较高,为后续的模压近/净终成形工艺参数的制定提供一定的理论参考。

关键词:挤压态AZ81镁合金;热压缩模拟;流变应力;本构模型

中图分类号:TG146.2; TG316.1 文献标志码:A

Hot compression deformation behaviors of

as-extruded AZ81 magnesium alloy at elevated temperature

CAO Feng-hong1, 2, LONG Si-yuan1, G. S. COLE3

(1. College of Material Science and Engineering, Chongqing University, Chongqing 400030, China;

2. College of Engineering and Technical, Chengdu University of Technology, Leshan 614007, China;

3. General Motors Corporation, USA, 48090)

Abstract: The hot compression tests of AZ81 magnesium alloy were performed on Gleeble-1500 at deformation temperature of 320-440 ℃ and strain rate of 0.01-10 s-1. The results show that the relationship between stress and strain is affected obviously by the strain rate and deformation temperature. The flow stress becomes higher with increasing strain rate at constant temperature and lower with increasing deformation temperature at constant strain rate. In order to evaluate the hot-pressing process, a flow stress model was constituted based on Arrhenius equation and temperature-compensated strain rate factor, the Zener-Hollomon parameter, and modified further by considering the effect of strain on stress. The results show that the modified model agrees well with the experimental stress value under the experimental condition what offer a experimental theoretical basis for close-pressing net-shape.

Key words: as-extruded AZ81 alloy; hot compression simulation; flow stress; constitutive model

镁的密度小,是最轻的金属结构材料,与铸造镁合金相比,变形镁合金在汽车、航空航天以及电子通讯等许多领域有更广阔的应用更前景[1]。目前,工业发达国家已大力着手高性能变形镁合金加工型材的研究与开发[2]。但镁合金具有密排六方结构,滑移系较少,低温塑性较差,加工难度大,且随着温度的升高,滑移系增多,塑性大大提高[4-5],龙思远和曹韩学[6]指出铸锻复合成形方法获得产品其力学性能得到了一定程度的改善,但因变形程度有限,不能满足高强韧镁合金承力结构件对用大变形加工提升材料机械性能的要求。为提高镁合金的塑性变形性能,提出了铸-挤-锻复合成形方法[7],通过挤压预成形塑性变形机制,使镁合金具有更大的塑性变形能力,通过模压一次成形工艺,使镁合金的综合力学性能得到明显改善。研究认为[8],挤压预成形坯Mg-Al-Zn系合金及其模压坯料Al含量为8.0%时可获得令人满意的强度和塑性指标,因此挤压态AZ81镁合金具有制备高性能结构件的潜力。目前,对板材AZ81镁合金的变形性能,尤其高温变形性能的研究未见报道。在模压成形工艺的研究中,流变应力常作为已知的基本参数,是合理进行数值模拟、制定成形工艺及选择变形设备的理论依据。

鉴于此,本文作者在温度320~440 ℃及应变速率为0.001~1 s-1的变形条件下,采用Gleeble-1500D热模拟试验机对AZ81镁合金进行单向压缩试验。利用Arrheniius方程并引入Zener-Hollomon参数建立AZ81镁合金的流动应力模型,同时进行修正,为模压成形工艺的制定提供一定的理论实验参考。

1 实验

试验用合金成分为,其合金成分为Mg-Al(8.15%)- Zn(0.82%)-Mn(0.27%)(质量分数),其中w(Fe)≤0.005,w(Si)≤0.019,w(Ni)≤0.000 7,w(Cu)≤0.001 6,所用原料均采用I级单质态,在坩埚电阻炉中熔炼合金,同时采用气体及少量熔剂进行保护,连铸成d 112(±0.2) mm×250 mm半连续铸锭,连铸过程中采用SO2(1%,体积分数)和CO2(99%,体积分数)混合气体进行保护,浇注后空冷至室温,然后在XJ-800卧室挤压机上进行挤压,挤压比16,挤压温度为400 ℃,挤压速度为13 mm/s,得到所需挤压型材,沿垂直型材挤压方向切割制备成12 mm×6 mm×8 mm压缩试样,如图1所示。

图1 压缩试样取样示意图

Fig.1 Sampling diagram of compression specimen

高温压缩试验在Gleeble-1500材料热模拟试验机上进行恒应变速率等温热压缩实验,压缩时在试样两端与压头接触的ICI垫上钮片,保证试样在加热和压缩过程中温度均匀减少摩擦。试验温度为320、360、400和440 ℃,热压缩实验开始前,试样以10 ℃/s的加热速度升温至预定温度,并保温3 min;应变速率为0.001、0.01、0.1和1 s-1;变形程度均为60%,压缩变形后的试样立即进行水淬处理,以保留形变后的组织;由Geeble-1500计算机系统自动采集应力、应变、压力、温度、位移及时间等数据,绘制真应力—真应变曲线。

2 结果与分析

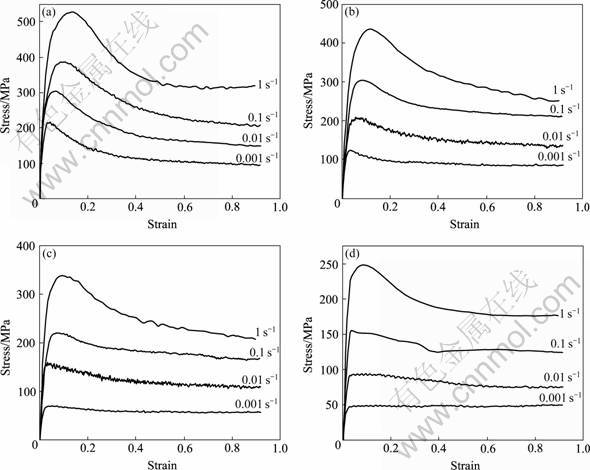

挤压态AZ81镁合金热压缩变形的真应力—真应变实验曲线如图2所示,其曲线属于典型的单峰动态再结晶,同时也说明AZ81镁合金在热变形过程中易于发生动态再结晶。

热压缩变形过程是加工硬化与动态再结晶软化相互竞争的一个动态平衡过程。挤压态AZ81镁合金在热压缩时流变应力的变化规律是(见图2):微应变阶段曲线斜率较大,应力上升快,主要是由于加工硬化占主导作用,合金中发生了部分动态回复或动态再结晶,流变应力随真应变的增加迅速上升;且随着变形量的增加,由于位错密度不断提高,使得动态回复和动态再结晶加快,软化作用增强,加工硬化逐渐被抵消,表现为曲线斜率逐渐减小,应力上升减缓,当流变应力达到峰值时,加工硬化和动态再结晶软化达到平衡;出现峰值后,随着变形的继续进行,动态再结晶继续发展,软化作用继续增强,使得流变应力逐渐下降,当达到一定的真应变量后,其流变应力基本不变。同时还可以看出,峰值应力与所对应的稳态流动应力之间的差值随温度的升高而减小,在440 ℃时,峰值流变应力与稳态流动应力基本变化不明显;当应变率一定时,其峰值流变应力随变形温度的升高而逐渐下降,此时非基面滑移的临界切应力下降,导致合金变形抗力降低,动态回复和动态再结晶更易发生,因此,峰值应力和峰值应变均减小[9-12]。

当变形温度一定时,峰值应力随应变率的增加,加工硬化作用也增大,其硬化速率超过了动态再结晶的软化速率,再结晶软化与加工硬化两者作用效果相互平衡时的峰值应力和峰值应变均增大;随应变速率的增大和温度的降低,进入稳态变形时对应的真应变值增大。

图2 不同变形条件下挤压态AZ81镁合金的流动应力—应变曲线

Fig.2 Flow stress—strain curves of AZ81 alloy under different deformation conditions: (a) 320 ℃; (b) 360 ℃; (c) 400 ℃; (d) 440 ℃

3 本构模型的建立

由于材料在塑性加工过程中的动态响应是材料内部组织演化过程引起的硬化和软化过程中综合作用的结果,故本构关系是高度非线性的,不存在普遍使用的构造方法。

热加工变形是一个热激活过程,对外加应力、应变速率和温度极其敏感,是受热激活的控制。通过对不同热加工数据的研究得出在任何应变或稳态下的高温流变应力σ强烈地取决于变形温度T和应变速率 ,SELLARS和MCTEGRAT[13]和WHITTENBERGER[14]提出一种包含变形激活能Q和温度T的双曲线正弦形式修正Arrhenius关系来描述这种热激活行为,通常可用下列3种形式进行描述[15]:1) 在低应力水平下,流变应力峰值σp和Z之间的关系可用指数关系描述,见式(1);2) 而在高应力水平下可用幂指数关系描述,见式(2);3) 在整个应力水平下可用双曲函数关系描述,见式(3)。

,SELLARS和MCTEGRAT[13]和WHITTENBERGER[14]提出一种包含变形激活能Q和温度T的双曲线正弦形式修正Arrhenius关系来描述这种热激活行为,通常可用下列3种形式进行描述[15]:1) 在低应力水平下,流变应力峰值σp和Z之间的关系可用指数关系描述,见式(1);2) 而在高应力水平下可用幂指数关系描述,见式(2);3) 在整个应力水平下可用双曲函数关系描述,见式(3)。

(1)

(1)

(2)

(2)

(3)

(3)

式中:A1、A2、A、n1、 和β均为常数,

和β均为常数, ;Q为变形激活能,J/mol,又称动态软化激活能,反映材料变形材料的难易程度,也是材料在热变形过程中重要的力学性能参数;R为摩尔气体常数,8.314 J/(mol·K);T为绝对温度。

;Q为变形激活能,J/mol,又称动态软化激活能,反映材料变形材料的难易程度,也是材料在热变形过程中重要的力学性能参数;R为摩尔气体常数,8.314 J/(mol·K);T为绝对温度。

目前所报道的关于镁合金应力方程的描述有多种。TAKUDA等[16]采用指数关系对AZ31和AZ91镁合金热变形镁合金流变应力进行描述,GALIYE 等[17-18]采用幂指数关系对ZK60镁合金热变形镁合金流变应力进行描述,BARNETT[19]采用双曲函数关系对AZ31镁合金热变形镁合金流变应力进行描述,结合本实验情况将式(1)~(3)分别两边取自然对数,

(4)

(4)

(5)

(5)

(6)

(6)

对式(4)~(6)两边分别求偏导,得

(7)

(7)

(8)

(8)

(9)

(9)

其中:

(10)

(10)

(11)

(11)

(12)

(12)

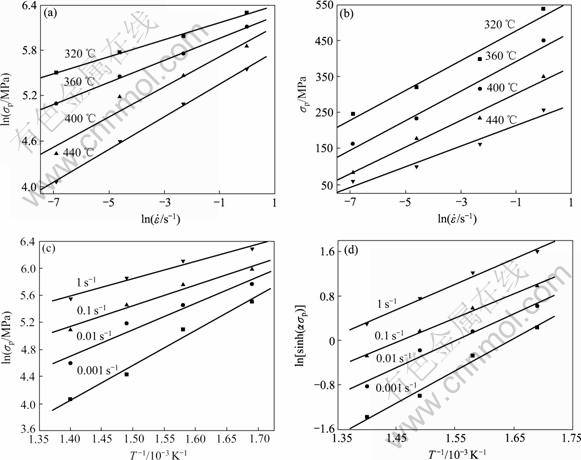

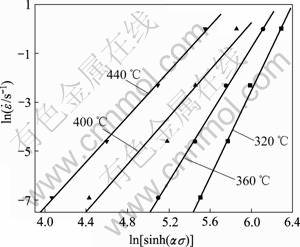

图3所示为挤压态AZ81镁合金不同变形条件下的峰值应力、应变率和温度的关系。由曲线 —

— 和

和 —

— 看出,峰值应力与应变率基本呈线性关系,并由分析可知,n1=6.303 1,β=0.027 1,经优化处理α值为0.004 3。

看出,峰值应力与应变率基本呈线性关系,并由分析可知,n1=6.303 1,β=0.027 1,经优化处理α值为0.004 3。

通过对 —

— 和

和 —

— 及图4

及图4  与

与 的曲线分析可知,n=4.486 5,b=4.883 8。且从图4可以看出,不同变形条件下的峰值应力与应变率及温度均为较为近似的平行直线,相关系数均在0.984 3以上,说明挤压态AZ81镁合金在热压缩实验条件下的变形激活能几乎保持不变,其变形激活能为Q=182.17 kJ/mol,A=8.905 7×1012。

的曲线分析可知,n=4.486 5,b=4.883 8。且从图4可以看出,不同变形条件下的峰值应力与应变率及温度均为较为近似的平行直线,相关系数均在0.984 3以上,说明挤压态AZ81镁合金在热压缩实验条件下的变形激活能几乎保持不变,其变形激活能为Q=182.17 kJ/mol,A=8.905 7×1012。

将上述分析得到的参数带入式(3),则挤压态AZ81合金高温压缩下的流变应力行为的本构方程为

(13)

(13)

图3 不同条件下AZ81镁合金峰值应力与应变速率和温度的关系:

Fig.3 Relationship between peak stress, strain-rate and temperature under different conditions: (a)  —

— ; (b)

; (b)  —

— ; (c)

; (c)  —

— ; (d)

; (d)  —

—

图4  与

与 关系

关系

Fig.4 Relationship between  and

and

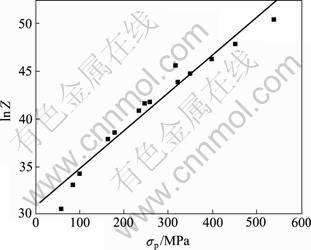

在式(2)中通过引入参数Z,并采用最小系数二乘法进行线性拟合得到挤压态AZ81镁合金流动应力模型,

σ=36.90lnZ-919.14 (14)

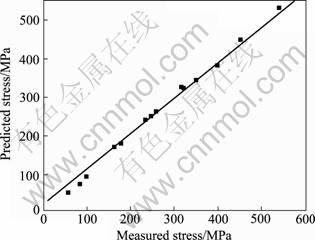

图5所示为挤压态AZ81镁合金压缩变形参数Z与峰值应力σp的关系。由图5的拟合结果分析看出,参数lnZ与峰值应力σp之间线性关系很明显,其线性相关系数为0.976 8,实测值与预测值之间的数据吻合的较好(见图6),其线性相关系数均大于0.987 6,因此本回归模型的相关性高度显著。

图5 挤压态AZ81镁合金压缩变形Z参数与峰值应力σp的关系

Fig.5 Relationship between compression deformation parameter Z and flow stress σp of as-extruded AZ81 alloy

图6 计算值与实测值之间的比较

Fig.6 Comparison between predicted value and measured value

4 结论

1) 挤压态AZ81镁合金高温压缩变形时流变应力取决于变形温度与变形速率,当应变率一定时,流变应力随变形温度的升高而降低,当变形温度一定时,随应变率的升高而升高。且在变形初期,由于加工硬化占主导,流变应力迅速达到峰值;此外在高温和低应变率下,流变应力相对比较稳定,没有明显的峰值;低温和高温应变速率下,流变应力持续增加到峰值后呈现流变软化趋势。

2) 挤压态AZ81镁合金高温塑性变形存在热激活过程。在实验条件下,AZ81镁合金热压缩变形时的应力指数为4.486 5,其变形激活能为182.17 kJ/mol,其高温压缩流变应力模型为

。

。

3) 在应变速率为0.001~1 s-1和变形温度为320~440 ℃条件下,挤压态AZ81镁合金热压缩变形的流变应力模型,可以用Zener-Hollomon参数的双曲函数形式进行描述,该模型为镁合金进一步的模压塑性成形工艺参数的制定提供较为科学的实验理论依据。

REFERENCES

[1] 耿义海, 李保成, 张晓芳, 张治民. AZ80变形镁合金高温变形流变应力分析[J]. 热加工工艺, 2008, 37(2): 46-49.

GENG Yi-hai, LI Bao-cheng, ZHANG Xiao-fang, ZHANG Zhi-min. Analysis on flow stress of AZ80 magnesium alloy during high temperature deformation[J]. Hot Working Technology, 2008, 37(2): 46-49.

[2] 栾 娜, 李落星, 李光耀, 钟志华. AZ80镁合金的高温热压缩变形行为[J]. 中国有色金属学报, 2007, 17(10): 1678-1684.

LUAN Na, LI Luo-xing, LI Guang-yao, ZHONG Zhi-hua. Hot compression deformation behaviors of AZ80 magnesium alloy at elevated temperature[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(10): 1678-1684.

[3] 吴立鸿, 关绍康, 王利国, 刘 俊. 锻造镁合金及影响锻造成形的几个关键因素[J]. 锻压技术, 2006, 31(4): 7-11.

WU Li-hong, GUAN Shao-kang, WANG Li-guo, LIU Jun. Wrought magnesium alloys and several key factors affecting the forging forming[J]. Forging & Stamping Technology, 2006, 31(4): 7-11.

[4] ZHANG P, LINDEMANN J. Influence of shot peening on high cycle fatigue properties of the high-strength wrought magnesium alloy AZ80[J]. Scripta Materialia, 2005, 52: 485-490.

[5] AGHION E, ELIEZER D. Magnesium and magnesium alloys[M]. Israel: Avi Moshe Bregman Ltd, 2004.

[6] 龙思远, 曹韩学. 镁合金复合成形方法. 中国, 200410040086.7[P]. 2005-03-16.

LONG Si-yuan, CAO Han-xue. Magnesium alloy composite forming method. CN 200410040086.7[P]. 2005-03-16.

[7] 龙思远, 曹凤红, 廖慧敏. 镁合金复合成形方法. 中国, 200810069225.7[P]. 2008-01-10.

LONG Si-yuan, CAO Feng-hong, LIAO Hui-min. Magnesium alloy composite forming method. CN 200810069225.7[P]. 2008-01-10.

[8] 杜 勇. 热挤压和Al含量对AZ系镁合金组织和性能影响研究[D]. 重庆: 重庆大学,2009: 38-43.

DU Yong. Influence of hot extrusion and Al on microstructure and properties of AZ based magnesium alloys[D]. Chongqing: Chongqing University, 2009: 38-43.

[9] 郭 强, 严红革, 陈振华, 张 辉. AZ31镁合金高温热压缩变形特性[J]. 中国有色金属学报, 2005, 15(6): 900-906.

GUO Qiang, YAN Hong-ge, CHEN Zhen-hua, ZHANG Hui. Hot compression deformation behavior of AZ31 magnesium alloy at elevated temperature[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(6): 900-906.

[10] 刘晓霏, 严 巍, 陈国学. AZ31B镁合金塑性变形动态再结晶的实验研究[J]. 塑性工程学报, 2005, 12(3): 10-13.

LIU Xiao-fei, YAN Wei, CHEN Guo-xue. The experimental study on recrystallization of magnesium alloy AZ31B during plastic defromation[J]. Journal of Plasticity Engineering, 2005, 12(3): 10-13.

[11] 杨亚琴, 李保成. 变形镁合金热压缩变形流变应力研究[J]. 中北大学学报, 2007, 28: 145-148.

YANG Ya-qin, LI Bao-cheng. Flow stress of wrought magnesium alloys during hot compression deformation[J]. Journal of North University of China, 2007, 28: 145-148.

[12] 黄光杰, 赵国丹. AZ31镁合金热变形规律的研究[J]. 重庆工学院学报, 2006, 20(2): 61-64.

HUANG Guang-jie, ZHAO Guo-dan. Deformation behavior for AZ31 magnesium alloy in thermomechanical processes[J]. Journal of Chongqing Institute of Technology, 2006, 20(2): 61-64.

[13] SELLARS C M, MCTEGART W J. On the mechanism of hot deformation[J]. Acta Metallurgica, 1966, 14(9): 1136-1138.

[14] WHITTENBERGER D J. The influence of grain size and composition on slow plastic flow in FeAl between 1100 and 1 400 K[J]. Mater Sci Eng A, 1986, 77: 103-113.

[15] MCQUEEN H J. Metal forming: Industrial, mechanical, computational and microstructure[J]. Journal of Materials Processing Technology, 1993, 37(1/4): 3-36.

[16] TAKUDA H, FUJIMOTO H, HATTA N. Modeling on flow stress of Mg-Al-Zn alloys at elevated temperatures[J]. Journal of Materials Processing Technology, 1998, 80/81(4): 513-516.

[17] GALIYEV A, KAIBYSHEV R, SAKAI T. Continuous dynamic recrystallization in magnesium alloy[J]. Materials Science Forum, 2003, 419/422(1): 509-514.

[18] GALIYEV A, KAIBYSHEV R, GOTTSTEIN G. Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60[J]. Acta Materialia, 2001, 49(7): 1199-1207.

[19] BARNETT M R. Influence of deformation conditions and texture on the high temperature flow stress of magnesium AZ31[J]. Journal of Light Metals, 2001, 1(3): 167-177.

(编辑 李艳红)

基金项目:重庆市科技攻关项目(CSTC2007AA4008)

收稿日期:2010-06-28;修订日期:2010-09-28

通信作者:曹凤红,讲师,博士;电话:15348137697;E-mail: caofh2004@yahoo.com.cn