钎焊工艺对InAg低温焊料结构及剪切性能的影响

刘文胜,黄国基,马运柱,彭芬,崔鹏

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘要:针对不同回流工艺曲线对In3Ag焊膏焊点表面形貌、界面IMC(Intermetallic compound)层和剪切强度的影响进行研究。采用扫描电镜(SEM)和能量色散谱仪(EDS)分别对IMC层的微观结构和焊点的组织成分进行观察和分析,采用力学试验机测试焊点的剪切强度,并通过SEM观察其断口形貌。研究结果表明:IMC层厚度随钎焊曲线峰值温度升高而增加,焊点剪切强度随峰值温度升高而降低,断裂模式为韧性断裂。其合适的钎焊工艺为峰值温度160 ℃,并在150 ℃保温1 min,可得到表面光亮、润湿性能好、助焊剂残留少的焊点,其基体为富In相,在基体上弥散分布着AgIn2颗粒,IMC层是均匀、致密的扇贝状结构,厚度约为3 μm,成分约为(Ag0.8Cu0.2)In2;在此条件下,焊点剪切强度最高,为7.24 MPa。

关键词:InAg;焊料;钎焊;金属间化合物;剪切性能

中图分类号:TG425.1 文献标志码:A 文章编号:1672-7207(2011)12-3674-06

Influences of soldering process on structure and shear strength of InAg solder

LIU Wen-sheng, HUANG Guo-ji, MA Yun-zhu, PENG Fen, CUI Peng

(State Key Laboratory for Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The influences of different reflowing curves on In3Ag solder joint surface morphology, interfacial IMC(Intermetallic compound) layer and shear strength were studied. Scanning electricity microscope (SEM) and energy dispersive spectrometer (EDS) were used to observe and analyze the IMC layer microstructure and the composition of solder joint. Mechanical testing machine was used to test the shear strength of solder joint, and the shear fractography was measured by SEM. The results indicate that the IMC layer thickness increases and the solder joint shear strength decreases, with the increase of reflowing curve peak temperature; and the fracture mode is ductile fracture. The reflowing curve at 160 ℃ peak temperature and holding at 150 ℃ for 1 min is the appropriate soldering process. In this condition, the solder joint with shiny surface, good wettability, less solder flux residue is obtained, and the microstructure of solder joint consists of In-rich phase with a fine dispersion of AgIn2 particles. The IMC layer with a thickness of 3 μm and component of (Ag0.8Cu0.2)In2 is uniform and dense scallop-like structure. In this condition, the highest shear strength is 7.24 MPa.

Key words: InAg; solder; reflowing; intermetallic compound; shear property

根据无铅焊料的应用要求及其特征,可按照其熔点高低分为3个体系:高温(230~350 ℃)焊料、中温(180~230 ℃)焊料和低温(<180 ℃)焊料[1]。其中,低温焊料由于具有钎焊温度低、对元器件破坏小等优点,在温度敏感元器件焊接和分步焊接中被广泛应用。In基低温焊料与Sn基焊料相比,具有润湿性好,熔点低和疲劳寿命长等优点[2-3],如InAg焊料在LED或热感应传感器中具有非常重要的应用价值。Chen等[4]采用DSC研究了InAg焊料的熔化和固化特性。Reynolds等[5]对InAg共晶焊料焊点的蠕变性能进行了研究。Vianco等[6]针对97In-3Ag低温焊料的压缩应力应变和蠕变性能进行研究。而在回流钎焊过程中,焊料与铜板之间会发生界面反应生成IMC,根据已有研究结果表明[7-9],IMC层对焊点可靠性和焊点缺陷萌生具有重要的影响。所以,IMC层的厚度和形貌可作为衡量焊点性能及其可靠性的一个标准。而合适的钎焊工艺曲线是IMC厚度生成和形貌调控的关键。但文献中对InAg焊料钎焊曲线的研究鲜有报道。本文作者研究回流钎焊工艺曲线对In-Ag焊料IMC层组织结构及其剪切性能的影响。

1 实验

1.1 原料

以铟锭(99.995%)和银锭(99.95%)熔炼成In3Ag母合金,并通过气雾化法制备In3Ag合金粉末;助焊剂为湖南金箭焊料有限公司生产。

1.2 实验方法

用SiC砂纸打磨25 mm×25 mm×0.5 mm(长×宽×厚)紫铜板,再用无水乙醇清洗,以去除其表面氧化膜。将In3Ag合金粉末与助焊剂按质量比8.5:1.5配制成焊膏。以手工印刷方式将焊膏通过直径为6 mm模板印刷到紫铜板上,采用不同钎焊曲线,使用北京七星天禹TYR108N-C台式回流焊机进行钎焊。

1.3 检测

使用数码相机对焊点拍照,观察其表面形貌。将铜板沿焊点中心纵向剪开,将其冷镶成金相试样,经过打磨、抛光、清洗、吹干后,使用HCl+FeCl3饱和溶液与无水乙醇按体积比1:4配制成腐蚀液腐蚀铜板,用35%HF+10%HNO3+55%H2O(体积分数)腐蚀液腐蚀焊点截面。将腐蚀后试样,采用日本电子株式会社JSM-6360LV型扫描电镜观察其截面IMC层形貌。

剪切试验参照JIS Z 3198-5无铅钎料试验方法[10], 剪切试样示意图如图1所示,材料为紫铜板,采用搭接方式钎焊,使用美国Instron3369力学试验机测试焊料剪切性能。

剪切强度由公式 计算得出,其中,PS为最大剪切载荷;A为接合部实际测量面积。

计算得出,其中,PS为最大剪切载荷;A为接合部实际测量面积。

图1 剪切试样示意图

Fig.1 Schematic diagram shear specimens

2 结果与分析

2.1 钎焊曲线的设计

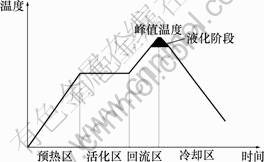

理想回流钎焊曲线[11](如图2所示)大致可分为5个阶段:预热区、活化区、回流区、液化区和冷却区。在预热区,溶剂随温度的升高逐渐挥发;在活化区,助焊剂充分清洗基板及焊粉表面的氧化膜;在回流区,焊膏和基板温度提升到合金熔点,部分焊粉熔化,发生铺展;液化区峰值温度直接影响到焊点的表面及其微观组织结构;冷却区通常选用较快的冷却速度防止晶粒长大,但冷却太快会引起内部热应力产生。

图2 理想回流曲线示意图

Fig.2 Ideal temperature curve of reflow soldering

根据InAg合金和助焊剂的特点,本实验设计回流钎焊曲线如下:预热区曲线升温速度为2 ℃/s,持续时间为2 min;活化区保温温度为150 ℃,保温时间为1 min;回流区升温速度为1 ℃/s;液化区峰值温度分别为160,170,180和190 ℃;冷却区降温速度为2 ℃/s。

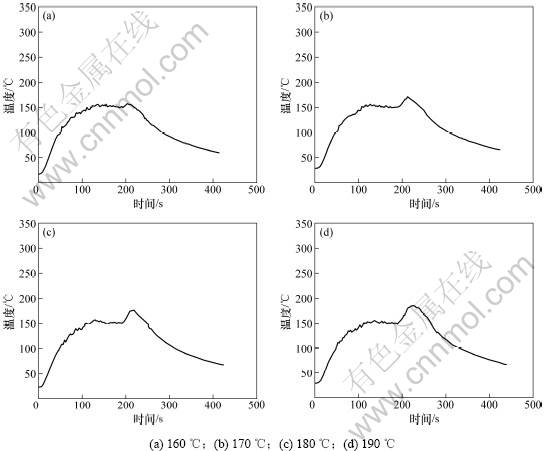

图3所示为在钎焊过程中焊接机绘制的实际工艺曲线。从图3可以看出:在150 ℃保温段有轻微波动,这是由于焊机控温存在误差引起的,但基本符合预设曲线。In3Ag合金熔点为141 ℃,回流焊钎焊温度通常高于熔点20~50 ℃,通过实验,在峰值为150 ℃时,无法完成钎焊,所以实验设计最低峰值温度为160 ℃。

2.2 钎焊曲线对焊点表面和界面组织的影响

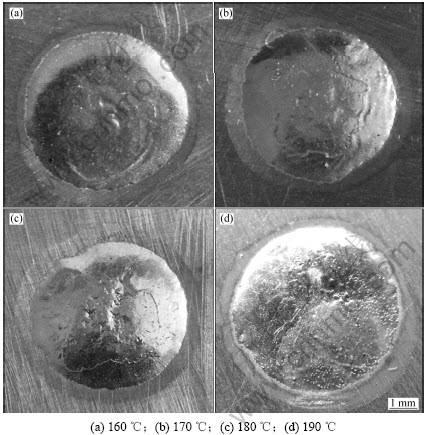

图4所示为经不同钎焊曲线所得焊点表面形貌照片。从图4可以看出:不同温度曲线所得试样形貌相似。铜板基本没有被腐蚀,助焊剂残留较少,说明助焊剂与焊粉质量配比合适,能很好地完成钎焊。4条曲线所得焊点充分铺展于铜板上,成型为规则的圆形,焊点较为饱满,表面光亮,周围无小锡珠出现。从图4(d)可以看出:此时所得的焊点表面有小坑洞出现且焊点颜色轻微发黄,主要原因是此回流曲线峰值温度过高,导致焊点表面发生了部分氧化。

图3 不同峰值温度实际钎焊曲线

Fig.3 Actual curves of reflow soldering at different temperatures

图4 焊点表面形貌照片

Fig.4 Solder joint surface morphology photos

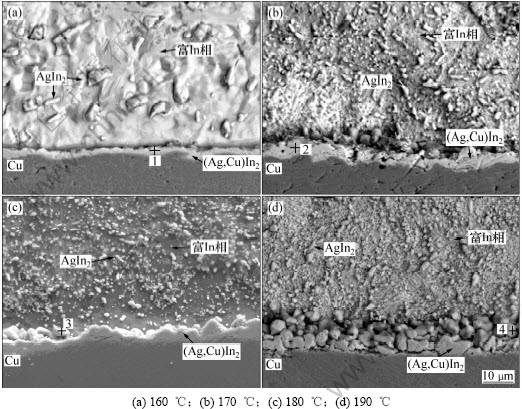

图5所示为不同钎焊曲线所得焊点微观组织的SEM照片。从图5可以看出:在焊料基体上分布着颗粒状的二次相颗粒,基体为富In相,二次相颗粒为AgIn2。这种基体焊料中弥散分布的细小IMC会提高焊料的蠕变性能和力学性能,也起到了增强基体强度和硬度的效果。

从图5还可以看出:随着回流曲线峰值温度逐渐升高,IMC层厚度不断增加。峰值温度为160,170和180 ℃的试样,IMC层为致密的扇贝状结构,厚度均匀,为3~8 μm;而峰值温度为190 ℃试样IMC层较厚,约为12 μm,晶粒也较粗大,IMC层发生断裂,呈团簇状。由此可得,随着峰值温度的增加,IMC层晶粒不断长大,从连续的细晶粒层逐渐长大成粗大晶粒层,在凝固过程中由于铜基板与IMC层热膨胀系数不同,而引起大晶粒层发生断裂。而由于温度升高,原子扩散速率增加,而且IMC生长具有各向异性,IMC晶粒在原来已形成的IMC层边缘继续生长,使得其呈团簇状分布。

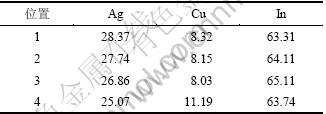

通过EDS分析,图5中4个试样IMC成分如表1所示。可见:4个试样的成分均为(Ag,Cu)In2。图5(a)中1点的Ag,Cu和In元素物质的量比为28.37:8.32:63.31,成分约为(Ag0.8Cu0.2)In2,其余3点IMC物质的量比也基本相近。有研究表明,IMC层的厚度生长动力学曲线呈抛物线状,其生长主要由扩散机制控制,且符合Arrhenius方程[12]:

(1)

(1)

其中:D为扩散系数;D0为扩散常数;Q为激活能;R为气体常数;T为热力学温度。

在钎焊过程中,Cu基板上的Cu原子会扩散到液态的In3Ag焊料中,而基体中的In原子也会反向扩散到Cu基板中,两者会发生反应形成IMC,而IMC厚度受原子扩散系数影响。D0,Q,R对于相同扩散体系均为常数,所以随着温度T升高,扩散系数D增大,即在相同时间下,温度越高,原子扩散的量越大,反应生成的IMC层厚度也越大。

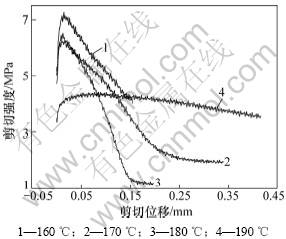

2.3 焊料合金剪切性能分析

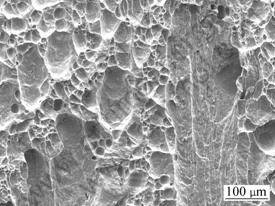

图6所示为不同钎焊曲线所得焊料合金剪切试验强度-位移曲线。从图6可以看出:InAg合金焊料剪切应力随钎焊峰值温度升高,总体呈下降趋势。峰值温度为160 ℃的钎焊曲线所得试样的剪切应力最大,约为7.24 MPa,峰值温度为170 ℃和180 ℃所得试样的剪切应力相当,分别为6.29和6.52 MPa,而190 ℃曲线所得试样的剪切应力急剧下降,只有4.32 MPa左右。图7所示为峰值温度为160 ℃时试样剪切断口形貌SEM照片,从图7可以看出:断口存在大量的韧窝,而且还有明显的剪切滑移带存在,表明In3Ag合金剪切断裂方式为韧性断裂,这与文献[13]中提到的InAg合金断裂方式一致。

图5 焊点界面形貌SEM照片

Fig.5 SEM images of solder joint interface

表1 焊点IMC层的成分(原子数分数)

Table 1 Composition of solder joint IMC layer %

图6 焊料剪切试验强度-位移曲线

Fig.6 Strength-displacement curves of solder shear test

图7 160 ℃所得试样剪切断口SEM照片

Fig.7 SEM image of solder shear fractography at 160 ℃

从图5可以看出:峰值温度分别为160,170和180 ℃ 3个试样IMC层都较致密,但170 ℃和180 ℃试样IMC厚度较大,使得两者剪切性能较160 ℃试样有所下降。而190 ℃试样由于峰值温度最高,其IMC层的厚度是4个试样中最大的,IMC层形貌由160,170和180 ℃试样致密的扇贝状细晶粒长大成粗大的团簇状晶粒结构,使得其剪切性能急剧下降。虽然IMC熔点高、强度高,有助于提高焊点强度,但是由于IMC晶体结构对称性低,脆性大,粗大的IMC结构会降低焊料界面结合强度,并会在IMC层与焊料基体接触界面上萌生损伤,并导致破坏[14]。如果IMC层过厚,在焊点受剪切应力过程中,粗大且断裂的IMC层会降低焊点剪切性能。因此,致密均匀且厚度小的IMC层,可提高焊料合金的剪切性能。

3 结论

(1) 峰值温度为160 ℃的钎焊曲线所得焊点表面较好,焊点表面光亮,助焊剂残留少;而峰值温度为190 ℃的曲线所得试样由于峰值温度过高,其焊点表面出现较严重的氧化现象。

(2) In3Ag焊料基体为富In相,在基体上弥散分布着颗粒状的AgIn2。IMC层成分为(Ag0.8Cu0.2)In2;IMC层的生长主要受扩散控制,其厚度随钎焊曲线峰值温度升高而增加。峰值温度为160,170和180 ℃的试样的IMC层为致密的扇贝状结构,厚度均匀,为3~8 μm;而190 ℃试样的IMC层为团簇状,且厚度为12 μm。

(3) 焊料合金剪切强度随钎焊曲线峰值温度增加而降低,断裂形式为韧性断裂。峰值温度160 ℃钎焊曲线所得试样的剪切强度最高,为7.24 MPa,峰值温度190 ℃钎焊曲线所得试样的剪切强度最低,为4.32 MPa。

参考文献:

[1] 徐骏, 胡强, 林刚, 等. Sn-Bi系列低温无铅焊料及其发展趋势[J]. 电子工艺技术, 2009, 30(1): 1-4.

XU Jun, HU Qiang, LIN Gang, et al. Low temperature lead-free solder and its developing tendency[J]. Electronics Process Technology, 2009, 30(1): 1-4.

[2] Lau J H, Wong C P, Lee N C, et al. Electronics manufacturing with lead-free, halogen-free, and conductive-adhesive materials[M]. New York: Mc Graw Hill, 2003: 4-13.

[3] Glazer J. Metallurgy of low temperature Pb-free solders for electronic assembly[J]. International Materials Reviews, 1995, 40(2): 65-93.

[4] Chen S W, Lin C C, Chen C M. Determination of the melting and solidification characteristics of solders using differential scanning calorimetry[J]. Metallurgical and Materials Transactions A, 1998, 29(7): 1965-1972.

[5] Reynolds H L, Kang S H, Morris J W, et al. The creep behavior of In-Ag eutectic solder joints[J]. Journal of Electronic Materials, 1999, 28(1): 69-75.

[6] Vianco P T, Rejent J A, Fossum A F, et al. Compression stress-strain and creep properties of the 52In-48Sn and 97In-3Ag low-temperature Pb-free solders[J]. Journal of Materials Science: Materials in Electronics, 2007, 18(1/2/3): 93-119.

[7] 李晓延, 严永长, 史耀武. 金属间化合物对SnAgCu/Cu 界面破坏行为的影响[J]. 机械强度, 2005, 27(5): 666-671.

LI Xiao-yan, YAN Yong-chang, SHI Yao-wu. Influence of IMC on the interface failure of tin-silver-copper solder joints[J]. Journal of Mechanical Strength, 2005, 27(5): 666-671.

[8] Li G Y, Chen B L. Formation and growth kinetics of interfacial intermetallics in Pb-free solder joint[J]. IEEE Transactions on Components and Packaging Technologies, 2003, 26(3): 651-658.

[9] Yoon J W, Lee Y H, Kim D G. Intermetallic compound layer growth at the interface between Sn-Cu-Ni solder and Cu substrate[J]. Journal of Alloys and Compounds, 2004, 381: 151-157.

[10] 王春青, 李明雨, 田艳红, 等. JIS Z 3198 无铅钎料试验方法简介与评述[J]. 电子工艺技术, 2004, 25(2): 47-54.

WANG Chun-qing, LI Ming-yu, TIAN Yan-hong, et al. Review of JIS Z 3198: Test method for lead-free solders[J]. Electronics Process Technology, 2004, 25(2): 47-54.

[11] 刘宏斌. Sn-Ag-Cu系无铅焊锡膏组成优化及性能研究[D]. 西安: 西安理工大学材料科学与工程学院, 2008: 19-21.

LIU Hong-bing. The improvement and performance analysis of Sn-Ag-Cu lead-free solder paste[D]. Xi’an: Xi’an University of Technology. School of Materials Science and Technology, 2008: 19-21.

[12] Liu Y M, Chuang T H. Interfacial reactions between In10Ag solders and Ag substrates[J]. Journal of Electronic Materials, 2000, 29(11):1328-1332.

[13] Chuang T H, Jain C C, Wang S S. Intermetallic compounds formed in In-3Ag solder BGA packages with ENIG and ImAg surface finishes[J]. Journal of Materials Engineering and Performance, 2009, 18(8): 1133-1139.

[14] 刘琼, 卢斌, 栗慧, 等. 添加0.1% Ce 对Sn-3.0Ag-0.5Cu 焊料与铜基板间的金属间化合物的影响[J]. 中国稀土学报, 2007, 25(6): 707-712.

LIU Qiong, LU Bin, LI Hui, et al. Effect of Adding 0.1%Ce into Sn-3.0Ag-0.5Cu solder alloy on its microstructure and intermetallic compounds with Cu substrate[J]. Journal of the Chinese Rare Earth Society, 2007, 25(6): 707-712.

(编辑 赵俊)

收稿日期:2010-12-20;修回日期:2011-04-15

基金项目:国家军工配套项目资助(JPPT-115-2-1057)

通信作者:马运柱(1975-),男,河南驻马店人,副教授,从事电子材料、难熔金属材料的研究;电话:0731-88877825;E-mail:zhuzipm@csu.edu.cn