SiO2/(γ-Fe2O3-SiO2)磁性催化剂载体的制备

王松威, 徐盛明, 陈崧哲, 徐景明

(清华大学 核能与新能源技术研究院, 北京 100084)

摘 要: 采用溶胶-凝胶法制备了具有高热稳定性的γ-Fe2O3-SiO2复合材料, 并在其表面进行SiO2包覆, 获得了纳米尺寸磁核的单分散球形SiO2/(γ-Fe2O3-SiO2)颗粒。 X射线衍射分析、 热重差热分析、 扫描电镜、 透射电镜以及振动样品磁强计等实验结果说明: Fe2O3-SiO2复合物经过700℃以上温度煅烧30min后才出现γ-Fe2O3晶相, 更高温度或者更长的煅烧时间将导致γ-Fe2O3向α-Fe2O3的转变; 经SiO2包覆后得到的SiO2/(γ-Fe2O3-SiO2)为粒径均匀的单分散球形颗粒, 颗粒尺寸在150~200nm左右, 内部核心为γ-Fe2O3颗粒, 外层则被严密的SiO2包裹。 通过将纯Fe3O4粉外层直接包覆SiO2做对比实验表明, SiO2/(γ-Fe2O3-SiO2)具有更加优异的磁性能, 是一种优良的催化剂磁性载体。

关键词: γ-Fe2O3; 磁性催化剂载体; 热稳定性; 包覆 中图分类号: TQ13

文献标识码: A

Preparation of SiO2/(γ-Fe2O3-SiO2) magnetic catalyst carrier

WANG Song-wei, XU Sheng-ming, CHEN Song-zhe, XU Jing-ming

(Institute of Nuclear and New Energy Technology,Tsinghua University, Beijing 100084, China)

Abstract: Fe2O3-SiO2 composite was prepared with sol-gel method. SiO2/(γ-Fe2O3-SiO2) magnetic catalyst carriers were obtained by coating composite with silica. These obtained samples were characterized by XRD, TG-DTA, TEM, SEM and VSM. The effects of processing temperature, time and initial dosage of iron nitrate on the properties of Fe2O3-SiO2 were studied. The results show that, after calcined at 700℃ for 30min, the composite oxide containing γ-Fe2O3 phase is secured. While further increase of the processing temperature (>800℃) or time results in the formation of α-Fe2O3 phase. SEM and TEM analyses show that the SiO2/(γ-Fe2O3-SiO2) sample is of nano-sized, monodisperse spherical particles with size of 150-200nm, which are well coated by amorphous SiO2 layer. The VSM data exhibit that SiO2/(γ-Fe2O3-SiO2) has much better magnetic properties than SiO2/Fe3O4. Such nano-composites are very promising in application as magnetic catalyst carriers and sorbent carriers.

Key words: γ-Fe2O3; magnetic catalyst carrier; heat-resistance; coating

超细以及纳米尺寸的催化剂由于具备比表面积大、 活性位丰富等特点, 其活性显著优于传统的大尺寸材料, 表现出巨大的应用价值。 可是这类材料在应用中存在着难分离的问题, 不仅容易造成浪费和提高使用成本, 同时还可能因为排放而引起环境污染。 如果使这类粉体材料具备磁性, 则可以在使用后通过外加磁场实现简单有效的分离。 目前人们已经开始了以多种磁性物质为核心, 外层包覆催化活性物质的“磁性催化剂”的研究[1, 2], 它作为一类具有磁响应特性的催化剂, 结合了磁性材料和催化材料特性, 在固体酸催化、 固体碱催化、 相转移催化、 光催化、 臭氧催化、 生物催化等领域内均有良好的应用前景[3, 4]。 其中铁的氧化物如四氧化三铁(Fe3O4)、 γ-三氧化二铁(γ-Fe2O3)等因成本低廉, 磁性能较好, 常被选作磁性催化剂的内核, 该方面尽管已有较多的研究进展[5-8], 但目前来说, 人们还都是以纯的四氧化三铁(Fe3O4)或γ-三氧化二铁(γ-Fe2O3)粒子为核心, 这在制备超细或纳米级催化剂时往往会遇到一些问题, 典型的是: 1)超细粒径的Fe3O4或者γ-Fe2O3均具有很强的团聚能力, 很难控制对其直接包覆得到最终产物的颗粒形状、 粒径大小及分布[9-11]; 2)在后继的外层活性物质包覆过程中, 往往需要高温煅烧(如以溶胶-凝胶法包覆锐钛矿型TiO2时, 需要400℃以上的煅烧温度), 此时上述磁核的热稳定性明显不足, 即: Fe3O4或者γ-Fe2O3在氧化甚至惰性条件下, 在400℃或更低温度下即会转变为弱磁性的α-Fe2O3[12], 导致磁性大大降低, 使材料失去可磁性回收的特性。

本文作者采用溶胶-凝胶法制备了γ-Fe2O3-SiO2复合物, SiO2的复合提高了γ-Fe2O3的热稳定性, 有效抑制了其向α-Fe2O3的转变[13-15], 然后以此复合物为磁性内核, 在其上包覆SiO2层, 并利用多次包覆的方法控制所得物的粒径分布, 最终获得了粒径均匀且具有较高热稳定性的球状磁性催化剂载体SiO2/(γ-Fe2O3-SiO2)。

1 实验

1.1 γ-Fe2O3-SiO2复合物的制备

将正硅酸乙酯(分析纯)、 无水乙醇(分析纯)、 去离子水按摩尔比为1∶3.85∶10.2配制成溶液, 按照Fe2O3与(Fe2O3+SiO2)的摩尔比范围0.071~0.350, 将一定量的Fe(NO3)3·9H2O溶于溶液中, 搅拌1h, 并控制溶液pH值在0.7左右以得到较稳定的溶胶, 在空气中自然凝胶化, 所得凝胶置于烘箱中缓慢升温至110℃得到干凝胶。 研磨后分别在不同温度条件下(300~900℃)煅烧得到Fe2O3-SiO2复合物。

1.2 SiO2/(γ-Fe2O3-SiO2)的制备

将1.0g 上述复合物颗粒加入至40mL无水乙醇中并超声处理30min, 加入20mL正硅酸乙酯溶液(4mL正硅酸乙酯+16mL无水乙醇), 并逐滴加入一定量氨水溶液, 搅拌条件下反应6h以保证正硅酸乙酯水解完全, 离心过滤后将反应物颗粒于110℃条件下烘干, 得到SiO2/(γ-Fe2O3-SiO2)磁性催化剂载体。 重复此步骤即可进行二次包覆, 以调节SiO2包覆层的厚度以及颗粒的大小。

为了做对比实验, 以商用Fe3O4(ALDRICH化学药品公司产, 粒度小于5μm, 纯度98%)作为磁性内核, 采用相同的实验操作步骤及药品用量进行SiO2包覆, 最终得到SiO2/Fe3O4。

1.3 样品的表征

样品的X射线衍射分析在日本理学 D/max-RB型X射线衍射仪上进行, 检测条件为: Cu Kα, 管压40kV, 管流100mA; 用NETZSCH STA 409C型差热热重联合分析仪(升温速率20℃/min)对Fe2O3-SiO2复合物的煅烧过程进行热重-差热分析实验(TG-DTA); Fe2O3-SiO2复合物和SiO2/(γ-Fe2O3-SiO2)磁性催化剂载体的形貌用美国Amary 1910FE型扫描电镜(SEM)进行检测, 内部结构采用JEM-2010型高分辨透射电子显微镜(HRTEM, 加速电压200.0kV)及JEM-1200EX型透射电子显微镜(TEM, 加速电压120.0kV)进行检测。 采用美国LakeShore 7307型振动样品磁强计(VSM)对样品进行磁性测量。

2 结果和讨论

2.1 γ-Fe2O3-SiO2复合物的性质表征

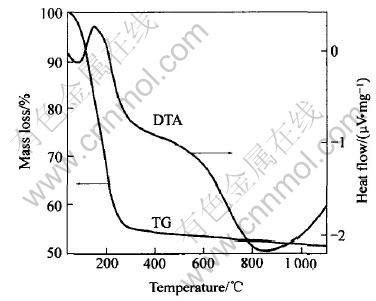

γ-Fe2O3-SiO2复合物煅烧制备过程的热重-差热分析结果如图1所示。 TG曲线表明复合物干凝胶加热至330℃时质量损失已经基本完全; DTA曲线则显示, 样品从650℃左右开始, 出现了缓慢的吸热过程, 结合γ-Fe2O3-SiO2复合物的X射线衍射谱(图2)可知, 该吸热过程对应于复合氧化物中无定型Fe2O3逐渐形成γ-Fe2O3晶体, 进而向α-Fe2O3晶体转变的过程。

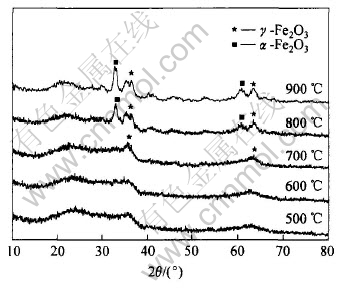

γ-Fe2O3-SiO2复合物在Fe2O3的摩尔分数为0.188, 煅烧时间为0.5h的条件下, 经过不同的煅烧温度(500~ 900℃)煅烧后所得Fe2O3-SiO2的X射线衍射谱如图2所示。 由图可知, 在500和600℃下煅烧时, 复合物没能形成Fe2O3晶体, 直至700℃时才出现γ-Fe2O3晶体的衍射峰, 800℃以上同时出现γ-Fe2O3和α-Fe2O3晶体的衍射信号, 且在500 ~ 900℃的煅烧条件下均无其它物质生成(如硅酸铁等)。 由此可知, SiO2的复合能够显著提高复合氧化物中Fe2O3的相变温度, 这很可能是复

图1 γ-Fe2O3-SiO2复合物的热重-差热曲线

Fig.1 TG-DTA curves of precursor of γ-Fe2O3-SiO2 sample

图2 经不同温度煅烧后γ-Fe2O3-SiO2复合物的X射线衍射谱

Fig.2 XRD patterns of γ-Fe2O3-SiO2 samples heat treated at different temperatures

合物中网状结构的SiO2延缓了Fe2O3的晶化以及进一步的晶型转变, 其微观机理还需进一步探讨。

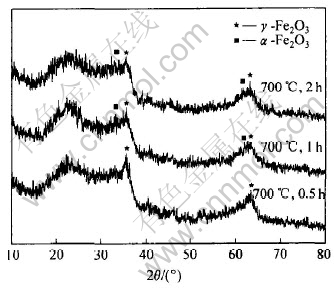

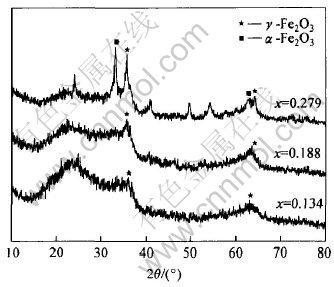

为考察煅烧时间的影响, 在x=0.188, 煅烧温度700℃的条件下, 对干凝胶分别进行了0.5, 1.0和2.0h的煅烧, 其X射线衍射结果如图3所示。 经过0.5h的煅烧复合物中只出现了γ-Fe2O3晶体, 而随着煅烧时间的延长, 将出现α-Fe2O3晶体并逐渐增多。 图4所示为t=0.5h, θ=700℃时, 在不同的x值(即不同Fe2O3含量)条件下所得样品的X射线衍射谱。 可看出复合物中Fe2O3含量较少时能够仅出现γ-Fe2O3晶体, 但Fe2O3含量增加到一定程度时(x=0.279), 所制样品中会同时出现γ和α-Fe2O3, 也就是说, 随着复合物中Fe2O3含量的增多, γ-Fe2O3向α-Fe2O3相的转变温度将会降低。

图3 不同煅烧条件下Fe2O3-SiO2样品的X射线衍射谱

Fig.3 XRD patterns of Fe2O3-SiO2 samples heat treated under different conditions

图4 不同Fe2O3含量时Fe2O3-SiO2样品经煅烧后的X射线衍射谱

Fig.4 XRD patterns of Fe2O3-SiO2 samples with different contents of Fe2O3 after heat-treatment

2.2 SiO2/(γ-Fe2O3-SiO2)的形貌表征

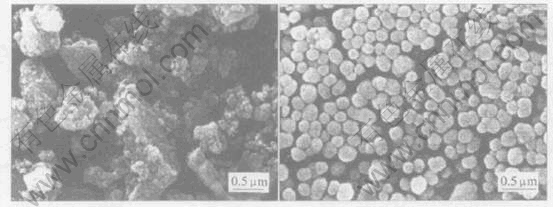

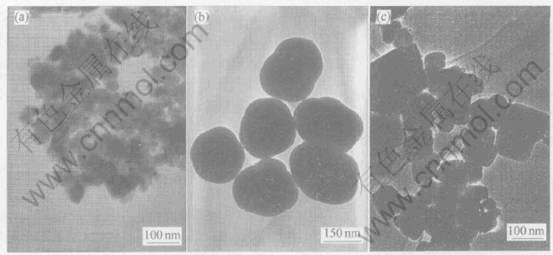

图5所示为x=0.188, 700℃煅烧0.5h的条件下所得的γ-Fe2O3-SiO2复合物包覆SiO2前后的扫描电镜照片。 可以看到, 包覆前复合物形状很不规则, 粒径分布也很不均匀, 而经过两次SiO2包覆后, 所得到的SiO2/(γ-Fe2O3-SiO2)颗粒已变成形状较为规则的单分散球形颗粒, 颗粒尺寸在150~200nm左右。 γ-Fe2O3-SiO2及SiO2/(γ-Fe2O3-SiO2)颗粒的内部结构透射电镜照片如图6所示。 图6(a)所示为x=0.188, 700℃煅烧0.5 h时所得的γ-Fe2O3-SiO2复合物的透射电镜照片, 其中γ-Fe2O3(图中衬度较深颗粒)与SiO2杂乱地烧结在一起, 部分γ-Fe2O3颗粒裸露在外部; 而经过两次SiO2包覆后得到的SiO2/(γ-Fe2O3-SiO2)颗粒, 如图6(b)所示, 其外层完全被严密的SiO2层所覆盖, 内部包裹着一个较大的γ-Fe2O3-SiO2颗粒或数个较小的γ-Fe2O3-SiO2颗粒。 图6(c)所示为对比实验中纯Fe3O4经过两次SiO2包覆后所得到的SiO2/ Fe3O4颗粒, 可以看到由于Fe3O4内核颗粒大小不一, 导致SiO2/ Fe3O4产物形状较不规则, 粒径分布不均匀, 同时SiO2包覆层厚度不均匀, 且存在局部没有包覆完全的现象。 上述SEM和TEM结果表明, 本实验的制备工艺流程能够较好地完成SiO2对γ-Fe2O3-SiO2复合物的包覆, 获得所需要的规则的单分散球形颗粒; 而另一方面, SiO2/(γ-Fe2O3-SiO2)颗粒中, 各粒子γ-Fe2O3含量尚不均匀, 还需展开进一步的实验工作对其进行完善。

2.3 磁性能表征

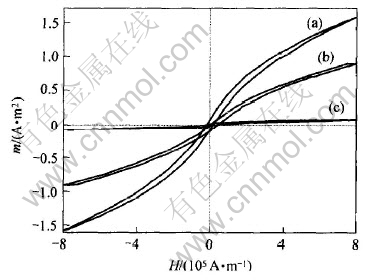

对γ-Fe2O3-SiO2(x=0.188, 700℃煅烧0.5h)及包覆SiO2后所得的SiO2/(γ-Fe2O3-SiO2) 进行振动样品磁强测试(VSM), 结果如图7所示。 图中还给出了对照样品SiO2/ Fe3O4(700℃煅烧0.5h)的VSM测试结果。 可以看出, 在最大磁化场强下, SiO2/ Fe3O4已达到饱和, 而γ-Fe2O3-SiO2和SiO2/(γ-Fe2O3-SiO2)均未达到饱和, 并且在8.0×105A/m的磁化场强下, γ-Fe2O3-SiO2的磁矩(1.58A·m2)和SiO2/(γ-Fe2O3-SiO2)的磁矩(0.89A·m2)均比SiO2/ Fe3O4的磁矩(0.08A·m2)要大得多, 这是因为经700℃煅烧后, SiO2/(γ-Fe2O3-SiO2)中的γ-Fe2O3晶型未发生改变, 而SiO2/ Fe3O4中Fe3O4转化为α-Fe2O3晶体从而导

图5 γ-Fe2O3-SiO2包覆SiO2前(a)和包覆后(b)的扫描电镜照片

Fig.5 SEM images of γ-Fe2O3-SiO2 before(a) and after(b) coating

图6 γ-Fe2O3-SiO2包覆SiO2前(a)、 包覆后(b)和Fe3O4包覆SiO2后(c)的透射电镜照片

Fig.6 TEM images of γ-Fe2O3-SiO2 before coating (a),γ-Fe2O3-SiO2 after coating (b) and Fe3O4 after coating (c)

致磁性大大降低[12]。 这表明在本实验条件下, 经过包覆后所得的SiO2/(γ-Fe2O3-SiO2)载体的磁性要优于直接将SiO2包覆于纯Fe3O4上所得产物的磁性。

图7 γ-Fe2O3-SiO2包覆SiO2前(a)、 包覆后(b)和Fe3O4包覆SiO2后(c)的振动样品磁滞回线

Fig.7 VSM data of γ-Fe2O3-SiO2 before coating (a), γ-Fe2O3-SiO2 after coating (b) and Fe3O4 after coating (c)

3 结论

通过将Fe2O3预先与SiO2制备成复合氧化物, 能够有效地抑制Fe2O3的相变, 获得高热稳定性的γ-Fe2O3-SiO2, 在此基础上进行SiO2包覆, 成功地获得了单分散球形SiO2/(γ-Fe2O3-SiO2)颗粒。 由于该颗粒能够在较高温度下保持其中Fe2O3组分为γ相, 维持其磁性, 因此适于采用煅烧法在其上进行进一步的活性组分负载, 从而得到磁性催化剂, 因此本实验所制出的SiO2/(γ-Fe2O3-SiO2)颗粒是一种优良的催化剂磁性载体。

REFERENCES

[1]Watson S, Beydoun D, Amal R. Synthesis of a novel magnetic photocatalyst by direct deposition of nanosized TiO2 crystals onto a magnetic core[J]. Journal of Photochemistry and Photobiology A: Chemistry, 2002, 148: 303-313.

[2]Beydoun D, Amal R, Low G, et al. Occurrence and prevention of photodissolution at the phase junction of magnetite and titanium dioxide[J]. J Mole Catal A: Chem, 2002, 180: 193-200.

[3]Nixon L, Koval C A, Noble R D, et al. Preparation and characterization of novel magnetite-coated ion-exchange particles[J]. Chem Mater, 1992, 4: 117-121.

[4]Pierre A, Vladimir S, Richard J, et al. Preparation and properties of magnetite and polymer magnetite nanoparticles[J]. Langmuir, 1999, 15: 1945-1951.

[5]Redl F X, Cho K S, Murray C B, et al. Three-dimensional binary superlattices of magnetic nanocrystals and semiconductor quantum dots[J]. Letters to Nature, 2003, 423: 968-971.

[6]Larken E, Stephaine G, OBrien S, et al. Cooperative assembly of magnetic nanoparticles and block copolypeptides in aqueous media[J]. Nano Letters, 2003, 3: 1489-1493.

[7]David I, Frank C. Spontaneous phase transfer of nanoparticulate metals from organic to aqueous media[J]. Angew Chem Int Ed, 2001, 40(16): 3001-3004.

[8]Patricia B, Nicholas B, Katie J, et al. Preparation and properties of an aqueous ferrofluid[J]. Journal of Chemical Education,1999, 76(7): 943-948.

[9]Liu Q X, Xu Zh H, Finch J A, et al. A novel two-step silica-coating process for engineering magnetic nanocomposites[J].Chem Mater, 1998, 10: 3936-3940.

[10]Albert P, Michel P B, Chellapah P. Magnetic silica dispersions: preparation and stability of surface-modified silica particles with a magnetic core[J]. Langmuir, 1994, 10: 92-99.

[11]Taeghwan H, Su S L, Jongnam P, et al. Synthesis of highly crystalline and monodisperse maghemite nanocrystallites without a size-selection process[J]. J Am Chem Soc, 2001, 123: 12798-12801.

[12]刘祥萱, 王煊军, 刘振玉, 等. 制备方法对纳米氧化铁晶型的影响[J]. 火炸药学报, 2002, 4: 85-86.

LIU Xiang-xuan, WANG Xuan-jun, LIU Zhen-yu, et al. Effect of synthesis method on crystal phase of iron oxide nanocrystalline powders[J]. Chinese Journal of Explosives & Propellants, 2002, 4: 85-86.

[13]Ennas G, Musinu A, Piccaluga G, et al. Characterization of iron oxide nanoparticles in an Fe2O3-SiO2 composite prepared by a sol-gel method[J]. Chem Mater, 1998, 10: 495-502.

[14]Cannas C, Concas G, Falqui A, et al. Investigation of the precursors of γ-Fe2O3 in Fe2O3/SiO2 nanocomposites obtained through sol-gel[J]. Journal of Non-Crystalline Solids, 2001, 286: 64-73.

[15]Cannas C, Musinu G, Piccaluga G. Structural investigation of Fe2O3-SiO2 nanocomposites through radial distribution functions analysis[J]. Phys Chem Chem Phys, 2004, 6: 3530-3534.

(编辑龙怀中)

基金项目: 国家自然科学基金资助项目(50274045)

收稿日期: 2005-07-15; 修订日期: 2005-08-20

作者简介: 王松威(1980-), 男, 博士研究生

通讯作者: 徐盛明, 副教授; 电话: 010-89796082; 传真: 010-62773585; E-mail: smxu@ tsinghua.edu.cn