钨异形件等离子喷涂近净成形技术研究

王跃明1,熊翔2,解路2,徐玄2,闵小兵3

(1. 中南大学 冶金科学与工程学院,湖南 长沙,410083;

2. 中南大学 粉末冶金国家重点实验室, 湖南 长沙,410083;

3. 湖南省冶金材料研究所, 湖南 长沙,410014)

摘要:采用等离子喷涂近净成形技术制备钨喷管﹑钨药型罩等薄壁或复杂形状零部件,研究热等静压温度﹑压力及处理时间对其致密度﹑组织结构、显微硬度及拉伸强度等性能的影响。研究结果表明:喷涂成形件为典型的柱状晶层片结构,粒子层结合部位存在较多孔隙及微观缝隙,成形件致密度为85.6%,其显微硬度和拉伸强度等力学性能偏低。经低压热等静压( 1600 ℃,10 MPa,60 min)﹑高压热等静压(1 600 ℃,150 MPa,120 min)及二步热等静压(1 600 ℃,10 MPa,60 min和1 600 ℃,150 MPa,120 min)处理后,随着热等静压压力的升高以及处理时间的延长,钨构件的相对密度、显微硬度及拉伸强度逐渐增大,多面体再结晶晶粒逐渐长大,沉积层仍保持原始的层片结构。然而,当热等静压温度显著升高及时间延长(2 000 ℃,10 MPa,360 min),样品由层片结构转变为颗粒结构,再结晶晶粒显著长大,断口呈典型的穿晶断裂形貌。

关键词:钨构件;等离子喷涂成形;近净成形;热等静压;致密化

中图分类号:TG146.4+11 文献标志码:A 文章编号:1672-7207(2012)04-1267-09

Near-net-shape tungsten parts produced by plasma spray forming

WANG Yue-Ming1, XIONG Xiang2, XIE Lu2, XU Xuan2, MIN Xiao-Bing3

(1. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China;

2. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

3. Hunan Research Institute of Metallurgy and Materials, Changsha 410014, China)

Abstract: Complex and thin-walled parts including tungsten nozzle and tungsten shaped charge liner were produced by plasma spray forming (PSF) and hot isostatic pressing (HIPing). A lamellar structure consisting of vertical columnar grains, micron-sized pores and rough interlamellar contacts with gaps of sub-micron sizes between lamellae of tungsten were found in PSF deposits with relative density of 85.6%. The relative density, micro-hardness and ultimate tensile strength (UTS) of samples after low pressure HIPing (1 600 ℃, 10 MPa, 60 min), high pressure HIPing (1 600 ℃, 150 MPa, 120 min) and two-steps HIPing (1 600 ℃, 10 MPa, 60 min, and 1 600 ℃, 150 MPa, 120 min) increased with pressure and time. Lamellar structure was retained in these hot isolstatic processed (HIPed) samples with distinct boundaries between lamellae. In addition, grain growth with shape changing from columnar into polyhedral could be found within individual lamella. Dissimilarly, microstructure of sample after being HIPed under condition of 2 000 ℃, 10 MPa, 360 min transformed from lamellar into granular with large grain growth occuring during densification. The fracture surface was also dominated by transgranular rupture.

Key words: tungsten parts; plasma spray forming; near-net-shape; hot isostatic pressing; densification

钨具有熔点高﹑密度高和高温导电性能好等优异性能,在国防工业及国民经济中发挥着重要作用,尤其在航天航空和核工业等尖端领域有着不可或缺的重要地位。随着国防工业及国民经济的迅速发展,钨及钨合金薄壁或复杂形状零部件在各部门的应用日益广泛,典型例子如固体火箭发动机喷管喉衬[1-2]、姿轨控卫星发动机用喷管[3]、破甲弹药型罩[4]、稀土、有色金属冶炼及石英玻璃熔炼用坩埚[5]及感应炉用发热体[6]等。就目前的技术水平而言,薄壁或复杂形状钨构件的制备技术是国际上公认的难题,传统的方法包括化学气相沉积(CVD)[7-8]、物理气相沉积(PVD)[9]、自蔓延高温合成(SHS)[10]、粉末冶金(PM)[11-12]等。PM法冷压生坯相对密度仅为60%~65%[13-14],后续高温烧结过程中体积收缩高达30%~40%,导致薄壁或复杂形状零部件产生严重变形、开裂或崩塌等问题。而CVD、PVD、SHS等方法则生产周期长、成形效率低,加工成本十分昂贵。材料科学的发展迫切需要新的成形与加工手段的跟进,等离子喷涂成形技术因其喷射温度高达10 000 ℃以上,喷射速度达300~400 m/s[15],非常适合钨基难熔金属粉末熔化粘结成形。等离子喷涂将粉末直接喷射到预先制备的成形用芯模上[16],粉末沉积效率可达8 kg/h,涂层厚度可以精确控制(误差在±0.025 mm内);等离子喷涂施工灵活,不受成形件尺寸及形状限制。因此,选用等离子喷涂技术制备各类薄壁或复杂形状钨构件,易于实现其短流程精密近净成形。目前,国内外均开展了等离子喷涂成形钨异形件的探索性研究。Rea等[17]采用真空等离子喷涂成形W-HfC纳米复合材料管件。吴子健等[18]采用等离子喷涂成形制备了大尺寸钨管发热体,应用于高温 (≥2300℃)中频感应烧结炉上。闵小兵等[19]采用等离子喷涂成形技术制备了钨坩埚及发热体等难熔金属异形件,并对其应用领域进行了初步探讨。等离子喷涂沉积层致密度一般不到90%,需对其进行高温烧结或热等静压等后续致密化处理[20-21]。然而,目前尚未见有关高温烧结及热等静压技术对喷涂成形钨构件显微结构及力学性能影响的研究报道。为此,本文作者采用等离子喷涂成形技术制备钨喷管及药型罩等薄壁或复杂形状构件,采用热等静压进一步提高其致密度,系统研究热等静压前后成形件致密度﹑组织结构﹑显微硬度及拉伸强度等性能,分析成形件的热等静压致密化机理。

1 实验

1.1 等离子喷涂成形

实验原料为株洲硬质合金集团有限公司提供的商业化普通钨粉,等离子体球化设备为DH-1080等离子喷涂设备(最大功率80 kW)。球化实验过程中,球化功率设定为40 kW,采用氩气为主工作气体,氢气为辅助工作气体,氮气为送粉气体。实验将钨粉垂直射入蒸馏水中进行冷却,水中收集的粉末先用无水乙醇洗涤,再用电热恒温鼓风干燥箱于60 ℃烘干10 h,然后,在氢气氛烧结炉中于600 ℃脱氧还原4 h。

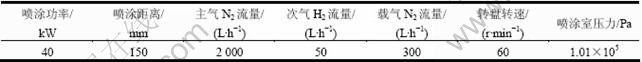

实验采用DH-1080等离子喷涂设备进行等离子喷涂成形。为防止等离子喷涂过程中粉末材料严重氧化,等离子喷涂成形实验在1个直径×长度为1 300× 1 700 mm的密闭喷涂室内进行,将预先制备的石墨芯模固定在密闭室内的转盘上,密闭室先抽真空,然后充入压力为1.01×105 Pa的高纯氩气进行保护。喷涂过程中室内通以循环冷却气体进行冷却。当喷涂沉积层厚度达零部件设计要求(本研究钨喷管壁厚约6 mm﹑药型罩壁厚约2 mm)后停止喷涂,充分冷却后取出喷涂成形件。等离子喷涂成形工艺参数见表1。

1.2 热等静压

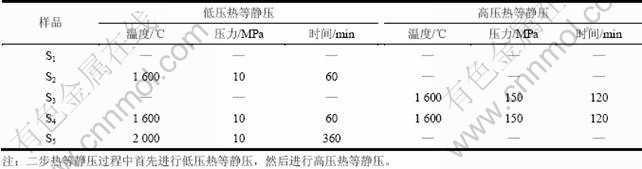

等离子喷涂成形完毕后,采用机械加工去除石墨芯模,然后将成形件进行热等静压致密化处理。实验用FPW180/250-100-SP型低压热等静压设备为日本真空株式会社所生产,额定温度2 200 ℃,额定压力20 MPa。实验用QIH-6型高压热等静压设备为美国ABB公司生产,额定压力200 MPa,额定温度为2 000 ℃,工作室尺寸(直径×长度)为110 mm×220 mm。热等静压过程中升温速度均为5 ℃/min,压力介质为高纯氩气,工艺参数见表2,处理完毕后样品随炉冷却。

1.3 性能检测

采用标准漏斗法、激光粒度分析仪及化学分析法分别测定粉末经球化前后的流动性、平均粒度及氧含量等性能;采用阿基米德排水法测定喷涂成形件经热等静压前后的密度;采用Buehler 5410 维氏硬度计测定其显微硬度,加载25 g,加载时间15 s,测6个点后取平均值;采用线切割沿钨喷管的轴线方向切取工字形拉伸样,厚2.5 mm,总长25 mm,宽5 mm,工字中部长11 mm,宽2.5 mm;采用Instron3369万能实验机测定成形件经热等静压前后的拉伸强度,拉伸位移速度为1.0 mm/min;将氨水与双氧水按体积比1:2比例混合配制腐蚀剂,腐蚀时间为30~60 s,腐蚀完毕后采用德国MeF3A型金相显微镜观察样品的微观晶粒组织;采用JEOL JSM-6360LV型扫描电子显微镜观察喷涂成形件经热等静压前后的显微结构及断口形貌。

表1 等离子喷涂成形工艺参数

Table 1 Main deposition parameters

表2 等离子喷涂成形钨构件热等静压工艺参数表

Table 2 Parameters for HIPing of PSF W parts

2 结果与讨论

2.1 等离子体球化对钨粉形貌及性能的影响

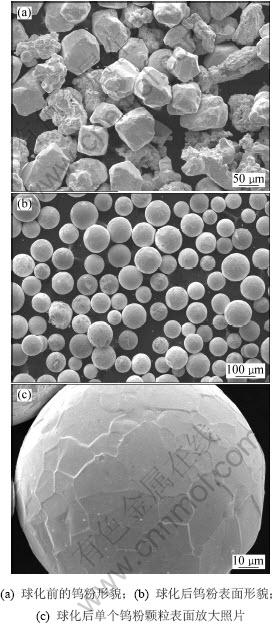

图1所示为喷涂钨粉SEM形貌照片。由图1(a)可见,球化前单颗粒粉末为多边形结构,且存在一定的团聚现象,因而流动性较差,约为(16.35±0.2) s/(50 g),氧的质量分数约为0.03%。已有研究认为,通过振动送粉器也能实现商品钨粉的正常送出[22],然而,将其直接用于等离子喷涂时粉末沉积效率偏低,且所得涂层质量较差。由图1(b)可见:等离子体球化法制备的喷涂钨粉为规则的球形颗粒,而且没有团聚现象,粒度较为均匀,平均粒度为(65.09±1) μm,泊松比为(6.45±0.1) g/cm3,流动性提高至(9.08±0.2) s/(50 g)。此外,经等离子体球化及氢气氛还原后的钨粉氧的质量分数约为0.08%,相对于原料钨粉而言并无明显提高。单个粉末表面放大照片中可观察到大量纹理,如图1(c)所示。分析结果表明:等离子体焰流温度高达10 000 ℃以上,形状不规则的钨颗粒由气体携带通过送粉管进入等离子体焰流后,被迅速加热至熔融状态,熔融的颗粒在表面张力作用下形成球形度很高的液滴,进入蒸馏水后瞬间冷却凝固成规则的球形颗粒。

图1 喷涂钨粉SEM形貌照片

Fig.1 SEM microstructures of tungsten feedstock

2.2 喷涂成形件显微结构分析

等离子喷涂成形完毕后,采用机械加工去除石墨芯模并精加工至规定尺寸,制备的钨喷管及药型罩如图2所示。由于等离子喷涂层厚度可以精确控制(误差在±0.025 mm内),本研究钨喷管及药型罩外表面抛光加工量仅约0.2 mm,从而可显著提高材料利用率并降低成本。因此,等离子喷涂成形技术可实现钨异形件的近净成形。

图2 等离子喷涂成形薄壁或复杂形状钨构件

Fig.2 Thin-walled or complex tungsten parts fabricated by PSF

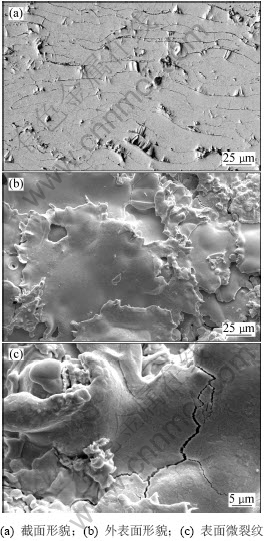

图3所示为等离子喷涂W构件(S1)SEM显微形貌照片。由图3(a)可见:等离子喷涂沉积层为典型的层片组织结构,层片间结合部位可观察到较多孔隙及亚微米级尺寸的缝隙。由图3(b)可见:沉积层表面较为光滑,W颗粒熔化铺展程度较好,在层片粒子边缘即层片与层片搭界部位可观察到细微孔隙。此外,沉积层表面还可观察到微裂纹,如图3(c)所示。分析表明:等离子喷涂过程中,高速熔融粒子撞击到已凝固的沉积层表面时,由于对粗糙表面的不完全填充及与粒子之间的不完全结合,不可避免地在粒子层结合部位产生孔隙和微观缝隙。此外,喷涂成形过程中,成形件的增厚是靠高温粒子高速撞击到冷基表面而形变成片状叠加起来的,因此,每一片层粒子均受激冷而产生张应力,这种张应力随叠加过程的进行而不断增大,增大到一定程度后只有通过沉积层开裂释放,导致沉积层产生裂纹。

图3 等离子喷涂成形W构件(1号样品, S1)SEM形貌像

Fig.3 SEM images of PSF W parts (Sample S1)

2.3 热等静压对成形件显微结构影响分析

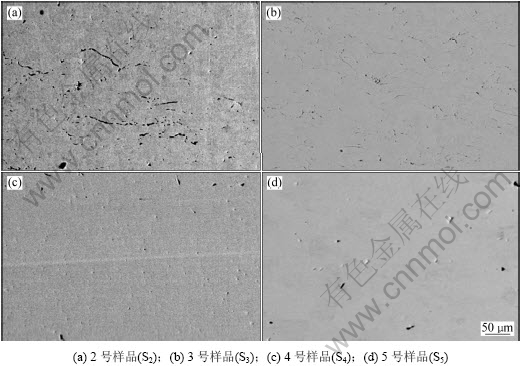

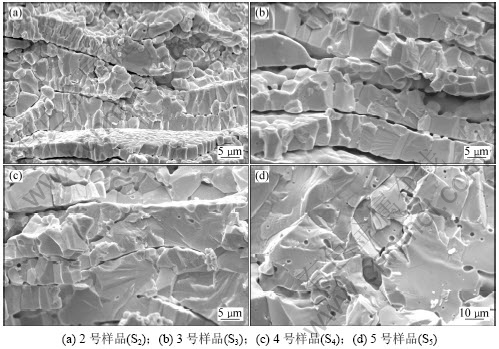

由于等离子喷涂成形钨构件(S1)中存在较多的孔隙和微裂纹,因而对其进行热等静压致密化处理。经1 600 ℃低压热等静压处理后,样品(S2)中仍存在较多孔隙,且局部可观察到明显的微观缝隙,如图4(a)所示。经高压热等静压处理后,样品(S3)中大部分微观缝隙和孔隙均愈合,仅局部可观察到微观缝隙及细微孔隙的存在(见图4(b))。经二步热等静压处理后,粒子层间微观缝隙彻底消失,样品(S4)中仍存在较多细微孔隙(见图4(c))。当热等静压温度升高至2 000 ℃﹑时间延长至360 min后,样品(S5)中仅存在极少量微细孔隙,见图4(d)。

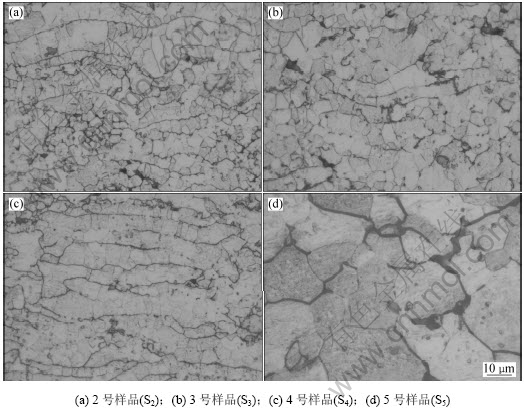

图5所示为热等静压样品腐蚀形貌照片。由图5(a)~(c)可见,经1 600 ℃低压热等静压﹑高压热等静压及二步热等静压处理后,样品S2,S3及S4均保持原始的层片结构特征,沉积层中仍可观察到明显的层片结合界面。此外,片层内还可观察到再结晶晶粒组织,且随着热等静压压力的升高及处理时间的延长,再结晶晶粒有长大趋势。然而,当热等静压温度升高至2 000 ℃、时间延长至360 min后,沉积层由原始的层片结构转化为颗粒结构,且钨晶粒显著长大(见图5(d))。分析表明,热等静压温度升高时元素扩散加剧,随着烧结时间的延长,喷涂沉积层的层片结构逐渐减弱直至最后消失[23]。

图4 热等静压样品SEM显微形貌像

Fig.4 SEM images of cross section of HIPed samples

图5 热等静压样品腐蚀形貌照片

Fig.5 Etched metallographic pictures of HIPed samples

2.4 成形件力学性能及断口形貌分析

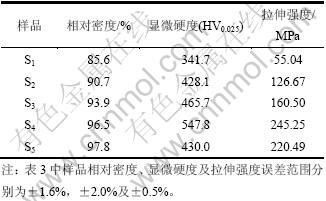

等离子喷涂成形钨构件经热等静压处理前后的相对密度、显微硬度及拉伸强度如表3所示。

表3 热等静压工艺参数对钨构件相对密度﹑显微硬度及拉伸强度的影响

Table 3 Influences of HIPing conditions on relative density, micro-hardness, UTS of PSF parts

由表3可知:等离子喷涂成形钨构件(S1)中层片结合部位可观察到较多孔隙及亚微米级尺寸的缝隙,相对密度偏低,导致其显微硬度及拉伸强度偏低;在1 600 ℃热等静压处理过程中,随着压力的升高及处理时间的延长,原来互相连通的孔隙逐渐收缩成闭孔,且沉积层中大部分微观缝隙逐渐愈合,样品相对密度递增,其显微硬度及拉伸强度随之增大;当温度升高至2 000 ℃、时间延长至360 min后,元素扩散加剧导致沉积层相对密度进一步提高。然而,由于此时钨晶粒显著长大,样品显微硬度及拉伸强度反而有所 降低。

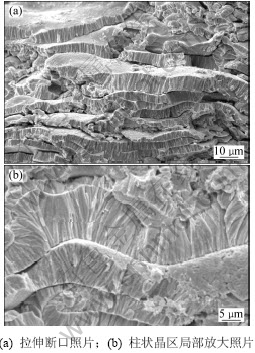

等离子喷涂成形钨构件(S1)拉伸断口中可观察到垂直生长的定向凝固柱状晶组织,断口呈现出典型的沿晶脆性断裂形貌,还可以观察到片状粒子层间剥离现象,且粒子层结合界面存在较多孔隙和微观缝隙(见图6(a))。由于上述典型等离子喷涂层形貌特征,使得成形件拉伸强度偏低,仅为55.04 MPa。图6(b)所示为沉积层断口定向凝固柱状晶区域局部放大照片。有研究表明[24],熔融粒子在与沉积表面接触撞击直至凝固过程中的冷却速度较高, 陶瓷粒子为1×(104~106) ℃/s,金属粒子为1×(106~108) ℃/s,甚至更高。而前一熔滴撞击到沉积表面形成涂层与后一熔滴撞击它的表面区域相隔大约0.1 s。由此可见:在熔融颗粒高速撞击喷涂表面的瞬间,前一熔滴有足够的时间变形凝固并得到充分冷却。因此,等离子喷涂过程中每个粉末颗粒的行为都是独立的[25]。高速撞击后,熔融颗粒在已凝固并充分冷却的沉积层表面铺展变形、形核、凝固并冷却。在熔滴粒子的凝固过程中,晶粒的生长方向是各向异性的,最大的生长速度方向为平行于散热的相反方向,喷涂粒子凝固过程中散热方向为垂直指向基体方向,即此时晶粒生长速度最大的方向为垂直背离基体方向,该方向晶粒挤压相邻的晶粒而迅速生长,结果形成了定向凝固柱状晶。

图6 等离子喷涂成形钨构件(S1)SEM断口形貌像

Fig.6 SEM images of fracture surfaces of PSF parts

图7所示为热等静压样品断口形貌照片。由图7(a)可见:经1 600 ℃低压热等静压处理后,样品(S2)由定向凝固柱状晶组织转变成细小再结晶组织,且粒子层间颗粒接触部位形成烧结颈,导致相对密度及拉伸强度均有所提高。由于热等静压压力偏低,处理时间偏短,成形件保持原始的层片结构,断口仍呈沿晶脆性断裂形貌。此外,由于低压热等静压未能有效消除层片结合部位的微观缝隙及孔隙等薄弱部位,在拉伸实验中,裂纹遭遇上述薄弱部位时将迅速扩展至整个层片结合面,导致断口中还可观察到粒子层间剥离现象。

高压热等静压处理后,由样品(S3)断口形貌图7(b) 可见,沉积层仍呈现以钨晶粒界面断裂为主导的沿晶脆性断裂,沉积层仍保持层片结构,再结晶晶粒进一步长大。分析表明:在高压热等静压过程中,在高温高压的联合作用下,烧结颈长大及原子扩散加剧导致再结晶晶粒长大的同时,粒子层片间微观缝隙及孔隙大量消失,大部分粒子层界面粘合在一起。因此,经高压热等静压处理后,沉积层自身性能得以改善,断裂从粒子层间发生的可能性降低,成形件拉伸强度进一步提高。

图7 热等静压样品的断口形貌照片

Fig.7 SEM images of fracture surfaces of HIPed samples

经二步热等静压处理后,样品(S4)断口中可观察到层片组织结构及穿晶断裂形貌,粒子层结合部位基本愈合,仅局部存在少量细微孔隙和微观缝隙,见图7(c)。分析表明:二步热等静压处理过程中,首先进行的低压热等静压可大幅降低沉积层开孔率,起到了与包套处理类似的作用。随后进行的高压热等静压使得沉积层微观缝隙及孔隙基本愈合,仅局部存在极少量细微孔隙及微观缝隙,相对密度显著提高,从而拉伸强度大幅提高。

由图7(d)可见:当烧结温度升高至2 000 ℃、烧结时间延长至360 min时,样品(S5)断口中可观察到明显的穿晶断裂现象,解理面内分布着少量细微孔隙。然而,由于钨晶粒明显长大,导致沉积层拉伸强度反而有所降低,如表3所示。

2.5 成形件热等静压致密化机制

不同于粉末冶金冷压生坯的颗粒结构,等离子喷涂成形件为特殊的层片结构,因而,有必要对其热等静压致密化机制进行探讨。

2.5.1 加热阶段

热等静压升温过程中,沉积层仍保持其原始的定向凝固柱状晶层片组织,细微孔隙及微观缝隙分布于层片结合部位,成形件致密度无明显变化。

2.5.2 再结晶及晶粒长大阶段

据报道[26],等离子喷涂钨涂层的再结晶温度为 1 400 ℃左右,当热等静压温度升高至1 400 ℃时成形件片层内出现细小的再结晶组织。随着热等静压继续进行,成形件再结晶晶粒长大。粉末冶金冷压生坯热等静压过程中,再结晶晶粒的长大可在3维空间方向进行。然而,由于喷涂成形件为特殊的层片结构,热等静压过程中,再结晶晶粒的长大是由层片内晶粒互相吞噬造成的,即晶粒长大在2维平面方向进行,并不能突破粒子层片界限。与此同时,晶粒自扩散导致晶界迁移,钨晶粒由柱状晶形转变为多面体形,且缺陷、元素扩散及再结晶导致沉积层局部细微孔隙及微观缝隙消失,致密度提高。

2.5.3 层片微移动阶段

在热等静压高温和高应力场的联合作用下,粒子层间的原子扩散导致元素由层片向其结合部位的孔隙中迁移,从而导致临近层片互相靠近直至接触,孔隙数量减少,成形件致密度得以提高。

2.5.4 塑性屈服及蠕变阶段

在热等静压施加的高应力场作用下,当颗粒之间的接触应力超过其塑性屈服应力后,层片之间相互接触的晶粒将产生塑性屈服和蠕变,晶粒间孔隙变形缩小直至最后消失,沉积层由层片结构转变为颗粒结构,其致密度进一步提高。

由于粉末冶金冷压生坯为颗粒结构,且致密度仅60%~65%,后续高温烧结或热等静压过程中其体积收缩达30%~40%,导致薄壁或复杂形状零部件产生严重变形、开裂或崩塌等问题[13-14]。而喷涂成形件为典型的定向凝固柱状晶层片结构,致密度达85.6%,热等静压过程中仅发生约10%的体积收缩,远比粉末冶金冷压生坯的体积收缩小,因而能消除构件因体积收缩引起的变形及应力集中等问题。随着热等静压温度的升高及处理时间的延长,成形件将由层片结构转变为颗粒结构。显然,就致密化机制而言,喷涂成形件与粉末冶金生坯之间存在较大区别。由于等离子喷涂近净成形技术在喷管、药型罩等难熔金属薄壁或复杂形状构件的制备上极具优势,因而具有广阔的应用前景。

3 结论

(1) 采用等离子喷涂近净成形技术制备了喷管、药型罩等钨异形件,研究发现成形件为典型的定向凝固柱状晶层片组织, 其致密度仅为85.6%,显微硬度(HV)为341.7﹑拉伸强度为55.04 MPa。

(2) 经1 600 ℃热等静压处理后,样品仍保持原始的层片结构,且随着热等静压压力的升高及处理时间的延长,再结晶晶粒长大,沉积层致密度逐步提高,其显微硬度及拉伸强度随之增大。当热等静压温度升高至2 000 ℃、烧结时间延长至360 min时,样品由层片结构转变为颗粒结构,再结晶晶粒显著长大,沉积层致密度进一步提高,其显微硬度及拉伸强度反而降低。

(3) 对比分析了等离子喷涂成形件与粉末冶金冷压生坯在热等静压致密化机制上的差异,初步提出了一个由加热阶段、再结晶及晶粒长大阶段、层片微移动阶段、塑性屈服及蠕变阶段4个阶段组成的热等静压致密化机制。由于等离子喷涂近净成形技术在喷管、药型罩等难熔金属薄壁或复杂形状构件制备上的特殊优越性,因而具有广阔的应用前景。

参考文献:

[1] 吕文树. 小发动机钨渗铜喉衬的烧蚀冲刷探讨[J]. 推进技术, 1986, 7(3): 15-19.

L? Wen-shu. Ablation properties of copper infiltrated tungsten throat for small motor[J]. Journal of Propulsion Technology, 1986, 7(3): 15-19.

[2] 宋桂明, 周玉, 王玉金, 等. 固体火箭发动机喉衬材料[J]. 固体火箭技术, 1998, 21(2): 51-55.

SONG Gui-ming, ZHOU Yu, WANG Yu-jin, et al. Throat materials for solid rocket motors[J]. Journal of Solid Rocket Technology, 1998, 21(2): 51-55.

[3] 胡昌义, 邓德国, 高逸群, 等. CVD铱涂层/铼基复合喷管研究进展[J]. 宇航材料工艺, 1998, 28(3): 7-10.

HU Chang-yi, DENG De-guo, GAO Yi-qun, et al. The development of CVD iridium-coated rhenium thruster[J]. Aerospace Materials & Technology, 1998, 28(3): 7-10.

[4] 张全孝, 高云, 贾万明, 等. 机械合金化铜-钨药型罩材料的研究[J]. 兵器材料科学与工程, 2000, 23(3): 44-50.

ZHANG Quan-xiao, GAO Yun, JIA Wan-ming, et al. Study of mechanically alloyed Cu-W shaped charge liner materials[J]. Ordancema Terial Science and Engineering, 2000, 23(3): 44-50.

[5] 吴志盈, 窦永庆. 稀土用钨坩埚的研制[J]. 稀有金属快报, 2001(1): 21-22.

WU Zhi-ying, DU Yong-qing. Research on tungsten crucible for rare earth[J]. Rare Metal Letters, 2001(1): 21-22.

[6] 吴德荣. 发热体的动向[J]. 工业炉, 1995, 77(3): 57-58.

WU De-rong. Pulse of heating elements[J]. Industrial Furnace, 1995, 77(3): 57-58.

[7] 李汉广, 彭志辉. 氟化物CVD法直接制取特纯高致密异型钨制品[J]. 稀有金属材料与工程, 1994, 23(6): 74-77.

LI Han-guang, PENG Zhi-hui. High purity and density of abnormal parts fabricated by fluorides CVD methods[J]. Rare Metal Materials and Engineering, 1994, 23(6): 74-77.

[8] 马捷, 毕安国, 王从曾, 等. 化学气相沉积制备钼钨合金[J]. 真空科学与技术学报, 2005, 25(3): 229-232.

MA Jie, BI An-yuan, WANG Cong-zeng, et al. Preparation of Mo-W alloy by chemical vapor deposition[J]. Journal of Vacuum Science and Technology (China), 2005, 25(3): 229-232.

[9] 李汉广. 独联体国家的难熔金属氟化物化学气相沉积技术[J]. 稀有金属与硬质合金, 1994, 119(4): 59-62.

LI Han-guang. Fluorides CVD methods for refractory metal in CIS countries[J]. Rare Metals and Cemented Carbides, 1994, 119(4): 59-62.

[10] 曹雯, 陈祖熊. 热爆SHS法制备金属陶瓷块体工艺过程研究[J]. 华东理工大学学报, 1997, 23(1): 73-78.

CAO Wen, CHEN Zu-xiong. Study on the process of “thermal explosion” self-propagating high-temperature synthesis of bulk cermet[J]. Journal of East China University of Science and Technology, 1997, 23(1): 73-78.

[11] 李栋梁, 董剑敏. 用粉末冶金法制造钨钼及其合金坩埚[J]. 上海钢研, 1993, (3): 24-27.

LI Dong-liang, DONG Jian-min. Crucibles of tungsten, molybdenum and their alloys fabricated by powder metallurgy[J]. Journal of Shanghai Iron and Steel, 1993, (3): 24-27.

[12] 吕大铭. 粉末冶金钨钼材料发展的国内外近况[J]. 粉末冶金工业, 1997, 7(3): 40-43.

L? Da-ming. The present development of powder metallurgy tungsten and molybdenum materials in home and abroad[J]. Powder Metallurgy Industry, 1997, 7(3): 40-43.

[13] 刘祖岩, 于洋, 王尔德. 钨铜粉末材料烧结-挤压致密化研究[J]. 稀有金属, 2006, 30(S1): 72-75.

LIU Zu-yan, YU Yang, WANG Er-de. Research on densification of tungsten-copper powders by sintering and hot hydrostatic extrusion[J]. Chinese of Rare Metals, 2006, 30(S1): 72-75.

[14] Akhtar F. An investigation on the solid state sintering of mechanically alloyed nano-structured 90W-Ni-Fe tungsten heavy alloy[J]. International Journal of Refractory Metals and Hard Materials, 2008, 26(3): 145-151.

[15] Kang H K. Microstructure of high volume SiC reinforced tungsten composites produced by plasma spray[J]. Scripta Materialia, 2004, 51(11): 1051-1055.

[16] Maneshian M H, Simchi A. Solid state and liquid phase sintering of mechanically activated W-20%Cu powder mixture[J]. Journal of Alloys and Compounds, 2008, 463(1/2): 153-159.

[17] Rea K E, Viswanathan V, Kruize A, et al. Structure and property evaluation of a vacuum plasma sprayed nanostructured tungsten-hafnium carbide bulk composite[J]. Materials Science and Engineering A, 2008, 477(1/2): 350-357.

[18] 吴子健, 张虎寅, 堵新心, 等. 大直径钨管发热体等离子喷涂成形制造技术[J]. 粉末冶金工业, 2005, 15(5): 1-4.

WU Zi-jian, ZHANG Hu-ying, DU Xin-xin, et al. Plasma spraying manufacturing technique for heating objection of tungsten tubular[J]. Powder Metallurgy Industry, 2005, 15(5): 1-4.

[19] 闵小兵, 王跃明, 夏光明, 等. 一种新型难熔金属异型件的制备技术及其应用[J]. 粉末冶金技术, 2010, 28(4): 297-301.

MIN Xiao-bing, WANG Yue-ming, XIA Guang-ming, et al. Preparation and applications of a new heterotypical refractory metal part[J]. Powder Metallurgy Technology, 2010, 28(4): 297-301.

[20] WANG Yue-ming, XIONG Xiang, MIN Xiao-bing, et al. Near-net-shape 95W-3.5Ni-1.5Fe thin-walled products produced by plasma spray forming[J]. Materials Science and Engineering A, 2010, 527(21/22): 5782-5789.

[21] WANG Yue-ming, XIONG Xiang, MIN Xiao-bing, et al. Near-net-shape refractory metal products produced by plasma spray forming[C]//Powder Metallurgy 2010 World Congress. Florence, Italy: Institute of Powder Metallurgy Italy Ltd, 2010: 617-625.

[22] 郭双全, 葛昌纯, 冯云彪,等. 低成本等离子体球化技术制备热喷涂用球形钨粉的工艺研究[J]. 粉末冶金工业, 2010, 20(3): 1-4.

GUO Shuang-quan, GE Chang-chun, FENG Yun-biao, et al. Research on low-cost plasma spheroidization technology for spherical tungsten powder used thermal spraying[J]. Powder Metallurgy Industry, 2010, 20(3): 1-4.

[23] Khor K A, Murakoshi Y, Takahashi M, et al. Microstructure changes in plasma sprayed TiAl coatings after hot isostatic pressing[J]. Journal of Materials Science Lettters, 1996, 15(20): 1801-1804.

[24] Bemdt C C, Mcpherson R. Adhesion measurement of films and coatings[C]//Proceedings of the 9th International Thermal Spray Conference. Amsterdam: Institute of Materials Engineering Netherlands Ltd, 1980: 310-316.

[25] Mcpherson R, Shafer B V. Interlamellar contact within plasma-sprayed coatings[J]. Thin Solid Films, 1982, 97: 201-204.

[26] Liu X, Tamura S, Tokunaga K, et al. High heat flux properties of pure tungsten and plasma sprayed tungsten coatings[J]. Journal of Nuclear Materials, 2004, 329-333(1/2/3): 687-691.

(编辑 邓履翔)

收稿日期:2011-04-23;修回日期:2011-06-24

基金项目:国防基础科研项目(B3720061191);湖南省应用基础研究计划重点项目(2007FJ2004,2010FJ3010);湖南省自然科学基金面上项目(10JJ5056);中南大学博士后基金资助项目(2012)

通信作者:王跃明(1979-),男,湖南安化人,博士,从事粉末冶金新材料研究;电话:0731-84657536;E-mail:wym_@163.com