文章编号:1004-0609(2009)06-1044-05

不同制动速度下C/C-SiC-Fe材料的摩擦磨损行为及机理

肖 鹏,李 专,熊 翔,付美荣

(中南大学 粉末冶金国家重点实验,长沙 410083)

摘 要:以针刺炭纤维整体毡为预制体,采用化学气相沉积法制备C/C多孔体,然后熔融浸渗Si和Fe制得C/C-SiC-Fe材料,研究制动速度对C/C-SiC-Fe材料摩擦磨损性能的影响。采用SEM观察了C/C-SiC-Fe的磨损表面及磨屑形貌,结果表明:C/C-SiC-Fe材料的高速制动平稳,随制动速度的提高其摩擦因数先升高后降低,制动速度为12 m/s时,摩擦因数达到最大值0.59;随着制动速度的提高,磨损率先增加后降低;当制动速度为24 m/s时,磨损率又急剧上升至3.3×10?8cm3/(N?m);摩擦磨损机制在低速制动条件下主要表现为磨粒磨损;中速时以粘着磨损为主;高速时以疲劳磨损和氧化磨损为主。

关键词:C/C-SiC-Fe材料;熔融浸渗;制动速度;磨损性能

中图分类号:TB 331; TH 117.3 文献标识码: A

Tribological behaviour and mechanism of C/C-SiC-Fe composites at different braking speeds

XIAO Peng, LI Zhuan, XIONG Xiang, FU Mei-rong

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: C/C performs were prepared by densification of needled carbon fiber felts with CVD. The C/C-SiC-Fe braking composites were manufactured by infiltration of moltening Si and Fe into the obtained C/C performs. The tribological characteristics of C/C-SiC-Fe composites at different braking speeds were investigated. The worn surfaces of C/C-SiC-Fe and the wear debris were examined by SEM. The results show the brake of C/C-SiC-Fe composites at high speed is stable. The coefficient of friction rises to the maximum of 0.53 at braking speed of 12 m/s firstly and then falls with increasing braking speed. The wear rates have similar change at the beginning but increase rapidly to the maximum of 3.3×10?8cm3/(N?m) at braking speed of 24 m/s. The wear mechanism changes from abrasion, adhesion to fatigue and oxidation with increasing braking speed.

Key words: C/C-SiC-Fe material; reactive melt infiltration; braking speed; wear properties

随着科学技术的发展,人们对交通运输工具和动力机械的速度、负荷、安全性和舒适性的要求越来越高,传统的摩擦材料已不能完全适应高速高能载制动的需求[1?2]。C/C-SiC材料于20世纪90年代中期开始应用于制动领域,以其密度低、耐磨性好、摩擦因数高、抗腐蚀、耐高温和环境适应性强(如湿态下摩擦因数不衰退)等优异的摩擦磨损性能,迅速引起了我国和德、美、日等国研究者的重视[3?6]。

研究表明,C/C-SiC材料在高速制动过程中产生高频震动,制动不够平稳[7]。为此,本文作者根据摩擦理论中的分子作用理论[8],采用熔融浸渗法[9?12]制备了含Fe为10 %(质量分数)的C/C-SiC-Fe材料,研究制动速度对C/C-SiC-Fe材料摩擦磨损性能的影响,以期为C/C-SiC材料在制动领域的广泛应用奠定基础。

1 实验

1.1 C/C-SiC-Fe材料的制备

以针刺炭纤维整体毡为预制体(原始密度为0.6 g/cm3),采用化学气相沉积法(CVD)法增密至密度为1.13 g/cm3的C/C多孔体,然后在2 300 ℃时对C/C多孔体进行石墨化处理。最后将硅粉和铁粉熔融浸渗C/C多孔体制得C/C-SiC-Fe制动材料。在CVD增密工艺中,以C3H6为反应气,H2为稀释气,在1 000 ℃沉积。熔融浸渗工艺中,以纯度99.3%、粒径40 μm的硅粉为硅源,纯度99.0%、粒径80 μm的还原铁粉为铁源,于1 650 ℃进行浸渗实验。

1.2 性能测试

采用排水法测试C/C-SiC-Fe材料的体积密度和开孔率。用JR?3型激光导热仪测量垂直于摩擦面方向的热扩散率。采用摆锤式冲击试验机测试材料垂直纤维方向的冲击强度。

根据汽车用制动器衬片国家标准GB5763—86,在QDM150型可调速调压干摩擦试验机上进行摩擦磨损性能测试,采用盘?块接触形式。试样尺寸为25 mm×25×7 mm,以25 mm×25 mm面作为摩擦面。对偶件采用d 300 mm的灰铸铁圆盘。实验条件为干摩擦,制动压力1.50 MPa,测试温度100 ℃恒温,滑行速度分别为 8、12、16、20和24 m/s,滑行距离各为1 800 m。采用螺旋测微仪测量试样制动前后5点处厚度尺寸变化,取其平均值作为线磨损量,以此评价其磨损率。

采用JSM?6360LV型扫描电子显微镜(SEM)观察材料组织结构、摩擦表面形貌和磨屑形状。用Rigaku?3014 型X射线衍射仪(XRD)对试样进行物相分析。用X射线能谱仪(EDAX)分析微区成分。

2 结果与分析

2.1 材料组成及组织结构

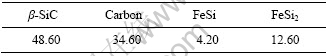

C/C-SiC-Fe材料的XRD物相分析结果和基本性能如表1和2所列。从表1和2可知,浸渗过程中硅与热解炭及铁分别反应生成了β-SiC、FeSi和FeSi2。C/C-SiC-Fe材料的开孔率(ε)为7.8%,孔隙可以减少制动过程中的噪音,并具有较高的热扩散率(α)和冲击韧性(αk),为高速高能载制动提供了保障。

表1 C/C-SiC-Fe材料的XRD物相分析

Table 1 XRD analysis results of C/C-SiC-Fe composites (mass fraction, %)

表2 C/C-SiC-Fe材料的基本性能

Table 2 Essential properties of C/C-SiC-Fe composites

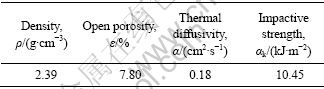

C/C-SiC-Fe材料的显微形貌分别如图1所示。由图1(a)可以看出,无纬布和网胎相互交替排布,能谱分析表明浅色部分为碳纤维及热解炭,深色部分为β-SiC及硅铁化合物(即FeSi和FeSi2的混和物)。材料中两种典型的孔隙、C/C多孔体中碳纤维束间的宏观孔隙(见图1(a))和碳纤维束内单丝纤维间(见图1(b))的微观孔隙)都填充了基体炭和SiC、FeSi及FeSi2。

图1 C/C-SiC-Fe材料的显微形貌及能谱分析

Fig.1 SEM images and energy dispersive analysis of C/C-SiC-Fe composites: (a) Macrograph; (b) Micrograph

2.2 摩擦磨损性能分析

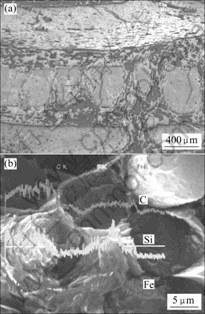

C/C-SiC-Fe材料的摩擦磨损性能随制动速度变化的关系如图2所示。由图2可知,制动速度较低(8 m/s)时,摩擦因数为0.47,没有出现像C/C复合材料在相似制动条件下因摩擦表面存在水膜而导致的低摩擦因数现象[13],线磨损量仅为1.2×10?8cm3/(N·m);当制动速度升至12 m/s时,摩擦因数达到最大值0.59,线磨损量也随之剧增至3.1×10?8cm3/(N·m);制动速度为16和20 m/s时,摩擦因数和线磨损量均没有继续上升,而是持续降低。同时虽然制动速度20 m/s时的摩擦因数(0.46)和8 m/s时接近,但其磨损量(2.4×10?8cm3/(N·m))却是8 m/s时的两倍;当制动速度达到24 m/s时,摩擦因数进一步降低至0.41,但线磨损量却上升到最大3.3×10?8cm3/(N·m)。从图2中还可看出,与C/C-SiC制动材料相比[7],C/C-SiC-Fe材料在不同制动速度下的摩擦因数均提高0.1左右,而磨损量却相差不大。摩擦磨损性能随制动速度变化的原因将在下面通过摩擦表面及磨屑形貌来解释。

图2 C/C-SiC-Fe摩擦磨损性能随制动速度变化的关系

Fig.2 Relationship between friction properties and braking speeds of C/C-SiC-Fe

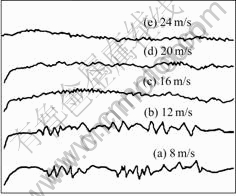

2.3 制动力矩曲线分析

不同制动速度下C/C-SiC-Fe材料的制动曲线如图3所示。由图3可知,低速制动时,曲线波动较大;随着制动速度的提高,曲线越来越平稳。与C/C-SiC制动材料的制动曲线相比[7],C/C-SiC-Fe材料在不同制动速度下的平稳性均有所提高,尤其是高速制动时不会产生类似C/C-SiC制动材料的高频震动现象。

图3 不同制动速度下C/C-SiC-Fe的制动曲线

Fig.3 Braking curves of C/C-SiC-Fe at different braking speeds

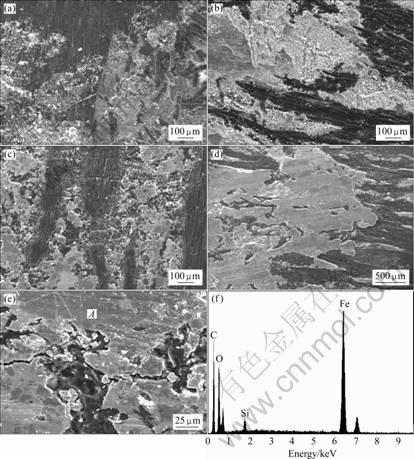

2.4 摩擦表面及磨屑形貌分析

图4所示为不同制动速度下C/C-SiC-Fe材料摩擦表面显微形貌。由图4(a)可知,在制动速度为8 m/s

时,摩擦表面聚集有断裂的大块磨屑。由于摩擦表面的剪切力较小,C/C-SiC-Fe材料的摩擦表面只有少量的微突体(由基体炭、SiC和硅铁化合物脆性相组成)。在制动过程中由于剪切力的作用断裂脱落而成为磨屑,且断裂的微突体在低能下难以进一步磨细。

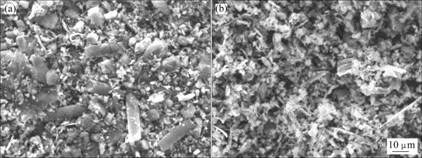

制动速度为12 m/s时摩擦因数达到最大值,磨损量也急剧增加(见图2)。图4(b)显示摩擦表面形成了大量的磨屑。其磨屑显微形貌如图5(a)所示,图中显示有大块磨屑和断裂的炭纤维。由于当制动速度升至12 m/s时,摩擦表面剪切力增大,断裂的微突体相应增加。观察对偶件摩擦表面可见犁沟划痕,说明在此速度下表现为磨粒磨损机制。

当制动速度为16 m/s时,能量增加导致试样表面的微突体进一步断裂并被不断碾细。同时摩擦表面温度升高,磨屑在摩擦过程中易变形并填满周围的凹坑,在局部开始形成连续的摩擦膜(见4(c)),摩擦膜有润滑作用,使得摩擦因数和磨损量均降低。

在制动速度为20 m/s时,在惯量一定的条件下,制动能量与速度的平方成正比,因此摩擦表面单位面积的能载(刹车片所转化的能量称为能载)随制动速度的提高快速上升。大量制动能量转化为摩擦热后摩擦表面温度急剧升高,摩擦表面形成相对连续的摩擦膜(见图4(d))。另一方面,试样中不易氧化的FeSi和FeSi2磨屑在界面聚集或填充空洞,起到缓冲作用,可有效地阻止振动。因而高速制动时曲线平稳,摩擦因数和线磨损量继续降低。

当制动速度达到24 m/s时,摩擦过程中材料表面受到的压力和摩擦热的作用足以使表面形成不稳定的温度场和压力场[14](见图4(e))。因为C/C-SiC-Fe材料中各组元的热膨胀系数不同,从而导致受热表面层和次表层的热膨胀率不同,以及表面层中不同区域热膨胀率的差异。因此,摩擦表面层会产生疲劳磨损形成的疲劳磨损裂纹,材料表面的这些微裂纹在压力的作用下经过与相对较硬的对偶件反复摩擦,便造成了磨屑被碾磨得更加细小。图5(b)所示为制动速度24 m/s时的磨屑显微形貌,图中大部分磨屑成片状或丝状。另一方面,摩擦表面温度继续上升,“闪点”温度可达1 000 ℃以上。C在350 ℃以上即开始氧化生成CO2,SiC在800~1 140 ℃之间抗氧化性能较差,易氧化生成疏松的SiO2层[15]。由图4(f)可看出,能谱分析有氧存在,说明摩擦表面发生了氧化反应。因此,刹车速度为24 m/s时,摩擦因数降低,而磨损急剧上升,主要以疲劳磨损和氧化磨损为主。

图4 不同制动速度时C/C-SiC-Fe材料摩擦表面的SEM像及A点的EDAX谱

Fig.4 SEM images of C/C-SiC-Fe worn surfaces at different braking speeds and EDAX pattern of point A: (a) 8 m/s; (b) 12 m/s; (c) 16 m/s; (d) 20 m/s; (e) 24 m/s; (f) EDAX pattern of point A

图5 不同制动速度时C/C-SiC-Fe材料磨屑的SEM像

Fig 5 SEM images of C/C-SiC-Fe wear debris at different braking speeds: (a) 12 m/s; (b) 24 m/s

3 结论

1) 熔融浸渗法制备的C/C-SiC-Fe材料在摩擦因数较高,磨损量较低,尤其是高速制动平稳,具有优良的摩擦磨损性能。

2) C/C-SiC-Fe材料的摩擦因数随制动速度的提高先升高而后降低,当制动速度为12 m/s时,达到最大值0.59;随着制动速度的提高,线性磨损量先升高而后降低;但当制动速度为24 m/s时,线性磨损量急剧升至3.3×10?8cm3/(N·m)。

3) C/C-SiC-Fe材料在低速制动条件下摩擦磨损机制主要表现为磨粒磨损;中速制动条件下以粘着磨损为主;高速制动时主要表现为疲劳磨损和氧化磨损。

REFERENCES

[1] HEIDENREICH B, RENZ R, KRENKEL W. Short fiber reinforced CMC materials for high performance brakes[C]// KRENKEL W, NASLAIN R, SCHNEIDER H. 4th International Conference on High Temperature Ceramic Matrix Composites (HT-CMC4). Munich, Germany: WILEY-VCH Verlag Gmbh, 2001: 68?74.

[2] GADOW R, KIENZLE A. Processing and manufacturing of C-fiber reinforced SiC-composites for disk brakes[C]// NIIHARA K. Proceeding of 5th International Symposium on Ceramic Materials and Components for Engineering. Arita, Japan: Elsevier, 1997: 412?418.

[3] 肖 鹏, 熊 翔, 张红波, 黄伯云. C/C-SiC陶瓷制动材料的研究现状与应用[J]. 中国有色金属学报, 2005, 15(5): 667?674.

XIAO Peng, XIONG Xiang, ZHANG Hong-bo, HUANG Bai-yun. Progress and application of C/C-SiC ceramic braking materials[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(5): 667?674.

[4] KRENKEL W, BERNDT F. C/C-SiC composites for space applications and advanced friction systems[J]. Mater Sci Eng A, 2005, 412(1/2): 177?181.

[5] EL-HIJA H A, KRENKEL W, HUGEL S. Development of C/C-SiC brake pads for high-performance elevators[J]. International Journal of Applied Ceramic Technology, 2005, 2(2): 105?113.

[6] KRENKEL W, HEIDENREICH B, RENZ R. C/C-SiC composites for advanced friction systems[J]. Advanced Engineering Materials, 2002, 4(8): 427?436.

[7] 肖 鹏, 熊 翔, 任芸芸. 制动速度对CC-SiC复合材料摩擦磨损性能的影响[J]. 摩擦学学报, 2006, 26(1): 12?18.

XIAO Peng, XIONG Xiang, REN Yun-yun. Effect of braking speed on friction properties of CC-SiC composites[J]. Tribology, 2006, 26(1): 12?18.

[8] 温诗铸. 摩擦学原理[M]. 北京: 清华大学出版社. 2002.

WEN Shi-zhu. Tribology principle[M]. Beijing: Tsinghua University Press, 2002.

[9] KRENKEL W. Cost effective processing of CMC composites by melt infiltration (LSI-process)[J]. Ceramic Engineering and Science Proceeding, 2001, 22(3): 443?454.

[10] GADOW R. Current status and future prospects of CMC brake composites and their manufacturing technologies[J]. Ceramic Engineering and Science Proceeding, 2000, 21(3): 15?29.

[11] YANG J, ILEGBUSI O J. Kinetics of silicon-metal infiltration into porous carbon[J]. Composites: Part A. 2000, 31(6): 617?625.

[12] LI J G, HANS H. Reactive wetting in the liquid-silicon/solid- carbon system[J]. J Am Ceram Soc, 1996, 79(4): 873?800.

[13] 熊 翔, 黄伯云, 徐惠娟, 吉冬英, 彭剑昕. 不同制动速度下炭布叠层炭炭复合材料的摩擦磨损行为及机理[J]. 中国有色金属学报, 2002, 12(2): 255?259.

XIONG Xiang, HUANG Bai-yun, XU Hui-juan, JI Dong-ying, PENG Jian-xin. Frictional and wear behaviors of C/C composites from carbon fiber cloth at different braking speeds [J]. The Chinese Journal of Nonferrous Metals, 2002, 12(2): 255?259.

[14] 杜心康, 石宗利, 叶明惠, 李重庵. 高速列车铁基烧结闸片材料的摩擦磨损性能研究[J]. 摩擦学学报, 2001, 21(4): 256?259.

DU Xin-kang, SHI Zong-li, YE Ming-hui, LI Chong-an. Friction and wear behavior of Fe-based sintered lining material for high way train[J]. Tribology, 2001, 21(4): 256?259.

[15] 周松青, 肖汉宁. 碳化硅陶瓷摩擦化学磨损机理及磨损图的研究[J]. 硅酸盐学报, 2002, 30(5): 641?644.

ZHOU Song-qing, XIAO Han-ning. Tribo-chemistry and wear map of silicon carbide ceramics[J]. Journal of the Chinese Ceramic Society, 2002, 30(5): 641?644.

基金项目:国家高技术研究发展计划资助项目(2006AA03Z560);湖南省杰出青年科学基金资助项目(06JJ1007)

收稿日期:2008-02-26;修订日期:2009-03-09

通讯作者:肖 鹏,教授,博士;电话/传真:0731-8830131;E-mail: xiaopeng@mail.csu.edu.cn

(编辑 李艳红)