文章编号:1004-0609(2013)S1-s0148-05

Si对Ti-600合金热稳定性能的影响

曾立英,洪 权,赵永庆,戚运莲

(西北有色金属研究院,西安 710016)

摘 要:研究Ti-600合金d 140 mm镦制饼材固溶时效(STA)处理以及600 ℃热暴露100 h后毛坯热暴露与试样热暴露试样的室温拉伸性能,结合显微组织等的分析,探讨析出的硅化物对合金热稳定性能的影响。结果表明:经600 ℃热暴露100 h后,毛坯热暴露试样的强度较STA的稍有提高,伸长率减少20.4%。试样热暴露试样的抗拉强度降低1%左右,伸长率降低49%左右。在600 ℃热暴露100 h的过程中,合金内析出杆状不均匀分布的S2型硅化物,可使合金高温长时暴露后的塑性明显下降。

关键词:Ti-600合金;热暴露;热稳定;硅化物;塑性

中图分类号:TG146.2 文献标志码:A

Influence of element Si on thermal stability of Ti-600 alloy

ZENG Li-ying, HONG Quan, ZHAO Yong-qing, QI Yun-lian

(Northwest Institute for Nonferrous Metal Research, Xi’an 710016, China)

Abstract: Ti-600 alloy pancake with the diameter of 140 mm was upset and was solutioned at 1 020 ℃ for 1 h, aged at 650 ℃ for 8 h, air cooling. The tensile properties of specimen were tested at ambient temperature for the alloy prior to and after being exposed at 600 ℃ for 100 h. Microstructures for the alloy were observed. And the influence of silicides on thermal stability was also analyzed. The results indicate that for the alloy exposed at 600 ℃ for 100 h, the strength of the sample without oxidizing layers increases a little bit, the elongation decreases by 20.4%. While for the sample with oxidizing layers, the strength decreases by 1% or so, the elongation decreases by about 49%. The abrupt decrease of the plasticity is caused by the precipitation of rod-like S2 typed silicides in the alloy during the process of thermal exposure.

Key words: Ti-600 alloy; thermal exposure; thermal stability; silicides; plasticity

为了满足先进航空发动机的设计需求,世界各国都在竞相发展600 ℃及以上温度长期使用的高温钛合金[1-3]。高温钛合金热强性的提高往往导致热稳定性的下降,600 ℃高温钛合金的热稳定性问题较难解决。Ti-600合金是西北有色金属研究院研发的一种可在600 ℃使用的近α型高温钛合金,可用作航空航天发动机的高温结构材料。多名研究人员已对Ti-600合金的显微组织和力学性能做了大量研究[4-8],对高温长 时热暴露后合金的热稳定性能也有少量研究[9],但合金元素对热稳定性能的影响报导较少。因此,有必要对近α型Ti-600合金的热稳定性能进行研究,了解合金元素对其热稳定性能的影响。合金的热稳定性是通过热暴露前后的塑性损失率来衡量的,它表征了长时高温作用下合金保持塑性和韧性的能力,是高温钛合金重要力学性能指标之一[2, 10]。

Si是提高高温钛合金热强性和耐热性的重要元素之一。研究表明,加入适量(<0.5%)的Si对钛合金室温强度和高温性能是有利的[11]。不连续析出于β相或α/β相界上的硅化物,对位错运动产生阻碍作用,使合金的蠕变抗力大大提高[10]。但是硅化物的析出会损害合金的组织热稳定性能,表现为合金塑性降低,这是因为热暴露过程中形成的硅化物会阻碍晶粒之间塑性变形的协调,使合金热稳定性能降低,Si元素的加入对热稳定性能是不利的。但析出的硅化物对高温钛合金热稳定性能的影响有待于深入研究。本文作者研究了Ti-600合金镦制饼材固溶时效(STA)处理后以及高温长时热暴露后(600 ℃,100 h)的室温拉伸性能,并结合显微组织、位错结构等分析,揭示合金高温长时暴露前后析出的硅化物对合金热稳定性能的影响。

1 实验

本试验中所用的材料为西北有色金属研究院研制的Ti-600合金棒材。合金β转变温度约为1 010 ℃。实验采用3次重熔的d 420 mm铸锭。铸锭经β相区开坯锻造后,在α+β两相区轧制获得d100 mm的棒材。在1 025 ℃下将棒材镦制成d140 mm的饼材,变形量为49.0%。

在镦制饼材上切取室温拉伸与热稳定试样,所有试样经固溶时效处理(1 020 ℃, 1 h, AC) + (650 ℃, 8 h, AC),随后将部分试样在600 ℃下热暴露100 h,空冷,获得毛坯热暴露与试样热暴露试样,再进行室温拉伸。所有STA与热暴露试样的室温拉伸均采用标距长25 mm,直径5 mm的棒状样品。在Instron-1185型电子拉伸机上进行拉伸试验,在奥林巴斯PMG-3型显微镜上观察合金金相组织,在JEM200CX型透射电镜(TEM)上观察合金的微观组织。采用双喷电解装置进行电解抛光获得透射电镜样品,电解液高氯酸、甲醇、正丁醇的体积比为1:10:6,温度≤-30 ℃,电压50 V。

2 结果与讨论

2.1 热暴露前后Ti-600合金的拉伸性能

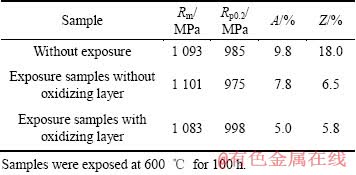

表1所列为Ti-600合金STA试样、试样热暴露与毛坯热暴露试样的室温拉伸性能。从表1中可以看出,在STA状态下,Ti-600合金具有适中的强度和较高的塑性(伸长率为9.8%,断面收缩率为18.0%)。在600 ℃下热暴露100 h后,毛坯热暴露试样室温抗拉强度(Rm)稍有升高(升幅为0.7%);屈服强度(Rp0.2)降低1%左右;伸长率(A)和断面收缩率(Z)均下降,室温拉伸伸长率从STA状态的9.8%降低至7.8%,保持率为79.6%;断面收缩率从STA状态的18.0%降至6.5%,保持率为36.1%。但试样热暴露试样的室温抗拉强度略有降低(降幅约1%),屈服强度升高1.3%,塑性明显降低;伸长率降低至5%,保持率为51.0%;断面收缩率降低至5.8%,保持率为32.2%。这是因为毛坯热暴露试样表面不含富氧层,但在600 ℃热暴露100 h后,组织内部析出硅化物等析出相[6],合金强度提高,塑性降低。而试样热暴露试样内除存在硅化物等析出相外,试样表面会有脆性富氧层,它易诱发细微裂纹,使试样过早断裂,宏观上表现为合金强度有所降低,塑性也明显下降。

表1 Ti-600合金热暴露前后室温拉伸性能

Table 1 Tensile properties of Ti-600 alloy at ambient temperature before and after thermal exposure

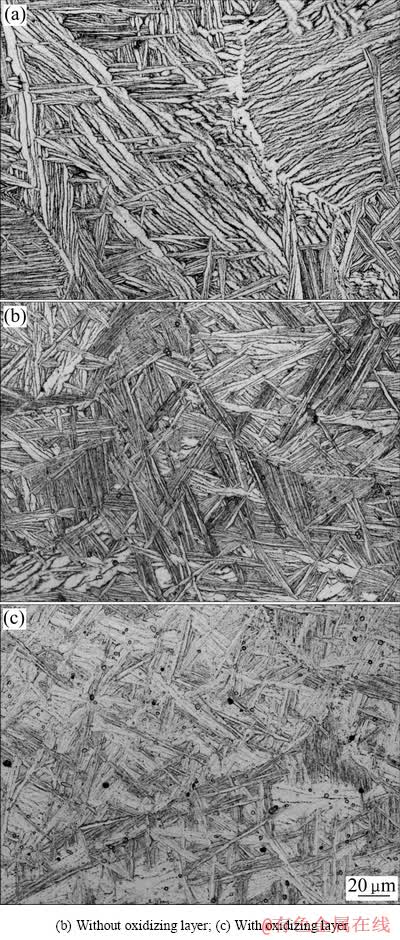

2.2 热暴露前后的金相组织

图1所示为Ti-600合金镦制饼材热暴露前后的金相(OM)组织。热暴露前,合金饼材在1 020 ℃固溶1 h,随后在650 ℃下时效8 h,空冷。因为试样的固溶温度高于βt,合金组织特征为片层状组织,由交替编织排列的片层状α和残余β相构成,晶粒尺寸超过100 mm,如图1(a)所示。由图1(b)和(c)可以看出,在600 ℃下热暴露100 h后,不论是毛坯热暴露还是试样热暴露试样,其OM组织与STA的差别不大,没有本质区别,只是热暴露后试样的原始β晶粒稍有长大。STA状态下晶界与板条相对平直一些;热暴露后少数板条发生弯曲现象,板条较短较细小。这也表明Ti-600合金具有组织稳定性,热暴露后表面氧化对合金拉伸性能的影响可能会大一些。从图1中还可看出,试样热暴露后,合金内α与β板条比毛坯热暴露的粗大。金相组织照片中不能明显地分辨出合金内析出的硅化物。

2.3 Si元素对Ti-600合金热稳定性能的影响

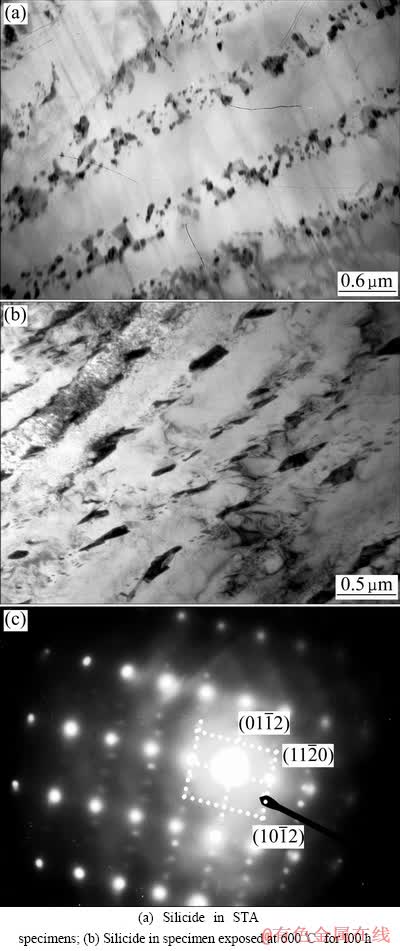

Si是β稳定元素,β相中的Si含量大于α相内的,

因此,时效后,硅化物主要在β相中析出。图2所示为热暴露试验前后Ti-600合金中析出的硅化物形貌。在STA状态下,硅化物析出于原始β相中及α/β相界面附近,析出的硅化物呈点状、球状、橄榄状或椭球状,极少数呈短杆状,尺寸在0.02~0.3 μm之间,如图2(a)所示。在600 ℃下热暴露l00 h后,硅化物优先在β相中、α/β相界面处析出,α相中的析出量相对较少,其形状大多为短杆状,尺寸为0.05~0.4 μm,如图2(b)所示。从图2中可以看出,热暴露后,尺寸较大的硅化物会有所长大。

图1 热暴露前后Ti-600合金试样的金相组织

Fig. 1 Optical microstructures of Ti-600 alloy before (a) and after being exposed at 600 ℃ for 100 h ((b), (c))

图2 Ti-600合金中硅化物的形貌及其衍射花样

Fig. 2 Morphologies ((a), (b)) and diffraction pattern (c) of silicides precipitated in Ti-600 alloy

高温钛合金中主要有S1型的Ti5Si3和S2型的Ti6Si3 两种硅化物,二者均为六方结构[11]。加入其他合金元素时(如Sn和Zr),它们将置换S1和S2中部分Ti或Si元素,形成晶体结构相同、晶格常数略有差异的新S1或S2型[10]。S2型硅化物与α基体之间没有固定的晶体学位向关系,两者之间为非共格界面[6]。电子衍射花样分析表明,Ti-600合金中存在六角结构的(Ti,Zr)6(Si,Sn)3化合物(S2型硅化物),如图2(c)所示。

研究表明,钛合金中若形成均匀分布、尺寸为微米级或更小的硅化物,对提高力学性能是有益的,若形成的硅化物为大颗粒或呈聚集分布的小颗粒则使力学性能下降[11]。在Ti-600合金中,S2型硅化物是不均匀形核的,优先在α/β界面上形核,少数在α相中的位错上形核。Ti-600合金饼材毛坯热暴露和试样热暴露试样中硅化物主要在β相中和α/β相界面处析出(图2)。

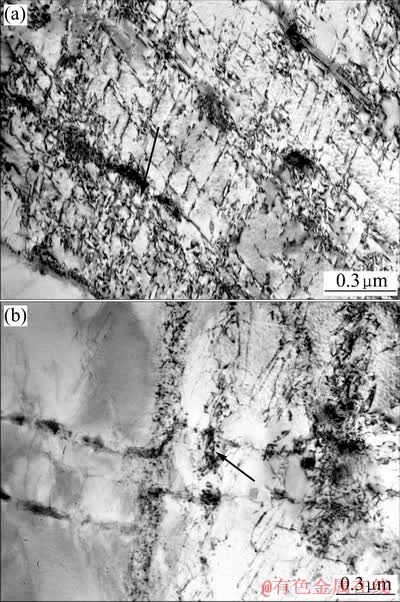

当运动的位错与硅化物颗粒相遇时,不能切割硅化物颗粒,位错与颗粒相互作用形成位错缠结与堆积,阻碍位错的进一步滑移变形,如图3所示。硅化物可将α片层内不同方向的位错列阻挡在α片层界面、α/β相界面处,因而这些部位容易产生应力集中,诱使形成空洞和裂纹,富氧层中的细微裂纹优先选择这些路径扩展,宏观表现为合金的拉伸强度升高、塑性下降,这和表1所列的数据相吻合。因此可以认为,硅化物的析出是引起高温长时暴露过程钛合金塑性下降的主要原因。

图3 Ti-600试样热暴露后原始β板条上析出的硅化物与位错形貌

Fig. 3 Morphologies of silicides and dislocations in primary β layer for exposed Ti-600 samples without (a) and with (b) oxidizing layer

3 结论

1) 在600 ℃下热暴露100 h后,镦制饼材毛坯热暴露试样的强度较STA的稍有提高,伸长率从STA状态的9.8%降低至7.8%,保持率为79.6%。试样热暴露试样的抗拉强度降低1%左右,塑性大大降低,伸长率降低至5%,保持率为51.0%。

2) 在600 ℃下热暴露100 h的过程中,合金内析出杆状不均匀分布的S2型硅化物。

3) 在高温长时暴露过程中Ti-600合金塑性明显下降是由硅化物的析出引起的。

REFERENCES

[1] 黄 旭, 李臻熙, 黄 浩. 高推重比航空发动机用新型高温钛合金研究进展[J]. 中国材料进展, 2011, 30(6): 21-27.

HUANG Xu, LI Zhen-xi, HUANG Hao. Recent development of new high-temperature titanium alloys for high thrust-weight ratio aero-engines [J]. Materials China, 2011, 30(6): 21-27.

[2] 贾蔚菊, 曾卫东, 俞汉清, 周义刚. 热暴露对Ti60合金性能及断裂行为的影响[J]. 中国有色金属学报, 2009, 19(6): 1032-1037.

JIA Wei-ju, ZENG Wei-dong, YU Han-qing, ZHOU Yi-gang. Effect of thermal exposure on properties and fracture behavior of Ti60 alloy [J]. The Chinese Journal of Nonferrous Metals, 2009, 19(6): 1032-1037.

[3] 许国栋, 王凤娥. 高温钛合金的发展和应用[J]. 稀有金属, 2008, 32(6): 774-779.

XU Guo-dong, WANG Feng-e. Development and application on high-temperature Ti-based alloys [J]. Chinese Journal of Rare Metals, 2008, 32(6): 774-779.

[4] 洪 权, 张振祺, 杨冠军, 罗国珍. Ti600合金的热机械加工工艺与组织性能[J]. 金属学报, 2002, 38(Sl): 135-137.

HONG Quan, ZHANG Zhen-qi, YANG Guan-jun, LUO Guo-zhen. Influence of thermomechanical processing and treatment on microstructure and mechanical properties of Ti600 alloy [J]. Acta Metallurgical Sinica, 2002, 38(Sl): 135-137.

[5] ZENG Li-ying, ZHAO Yong-qing, HONG Quan, YANG Guan-jun. High cycle fatigue property of Ti-600 alloy at ambient temperature [J]. Journal of Alloys and Compounds, 2011, 509(5): 2081-2086.

[6] CUI W F, LIU C M, ZHOU L, LUO G Z. Characteristics of microstructures and second-phase particles in Y-bearing Ti-1100 alloy [J]. Material Science and Engineering A, 2002, A323(1/2): 192-197.

[7] 辛社伟, 洪 权, 卢亚锋, 奚正平, 郭 萍, 戚运莲, 曾立英. Ti600高温钛合金中析出物与蠕变性能的关系[J]. 中国有色金属学报, 2010, 20(11): 2142-2147.

XIN She-wei, HONG Quan, LU Ya-feng, XI Zheng-ping, GUO Ping, QI Yun-lian, ZENG Li-ying. Relationship between precipitate and creep property of Ti600 high-temperature alloy [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(11): 2142-2147.

[8] 郭 萍, 洪 权, 赵永庆, 戚运莲, 辛社伟, 刘 伟. Ti600高温钛合金的力学性能[J]. 中国有色金属学报, 2010, 20(S1): s36-s39.

GUO Ping, HONG Quan, ZHAO Yong-qing, QI Yun-lian, XIN She-wei, LIU Wei. Mechanical properties of Ti600 high temperature titanium alloy [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s36-s39.

[9] 曾立英, 洪 权, 赵永庆, 戚运莲. Ti-600合金的热稳定性研究[J]. 稀有金属材料与工程, 2013, 42(11): 2253-2256.

ZENG Li-ying, HONG Quan, ZHAO Yong-qing, QI Yun-lian. Thermal stabilities of Ti-600 alloy [J]. Rare Metal Materials and Engineering, 2013, 42(11): 2253-2256.

[10] SINGH A K, ROY T, RAMACHANDRA C. Microstructural stability on aging of an α+β titanium alloy: Ti-6A1-1.6Zr-3.3Mo- 0.30Si [J]. Metallurgical and Materials Transactions A, 1996; 27(5): 1167-1173.

[11] NEAL D F, FOX S P. The influence of silicon and silicides on the properties of near-alpha titanium alloy [C]// Titanium’92 Science and Technology. Warrendale: TMS, 1993: 287-294.

(编辑 李向群)

基金项目:陕西省重点科技创新团队计划“钛合金研发创新团队”项目(2012KCT-23)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:曾立英,教授级高级工程师,博士;电话:029-86250729;传真:029-86360416;E-mail: ZENG-ly@163.com