铝合金/碳钢药芯焊丝熔-钎焊时的界面层脱落

来源期刊:中国有色金属学报(英文版)2013年第6期

论文作者:董红刚 胡文金 张旭超

文章页码:1583 - 1588

关键词:铝合金;钢;异种金属连接;界面层;脱落

Key words:aluminum alloy; steel; dissimilar metal joining; interface; detachment

摘 要:采用锌基药芯焊丝对铝合金和无镀层低碳钢进行钨极氩弧熔-钎焊搭接。在焊缝中发现从界面层脱落的富铁层,Al-Zn相流入界面层和脱落层之间的夹层区域,并加速富铁层的进一步脱落。在焊缝凝固过程中,富铁脱落层逐渐向焊缝深处扩散、迁移。界面层的厚度为15 μm,焊态下铝/钢异种金属接头的抗拉强度达111 MPa。经焊后热处理,接头的抗拉强度提高到150 MPa。

Abstract: Aluminum alloy was directly lap joined to uncoated carbon steel by gas tungsten arc welding process with Zn-based flux-cored filler wire. The Fe-rich layer detaches from the interface during welding, and then Al-Zn phases flow into the zone between the detached layer and the interfacial layer, accelerating further detachment of the Fe-rich layer. The detached layer diffuses and migrates gradually into the weld upon solidification. The intermetallic layer is about 15 μm thick, and the tensile strength of the as-welded joint reaches 111 MPa. After heat treatment, the tensile strength is improved to 150 MPa.

Trans. Nonferrous Met. Soc. China 23(2013) 1583-1588

Hong-gang DONG, Wen-jin HU, Xu-chao ZHANG

School of Materials Science and Engineering, Dalian University of Technology, Dalian 116085, China

Received 27 August 2012; accepted 6 November 2012

Abstract: Aluminum alloy was directly lap joined to uncoated carbon steel by gas tungsten arc welding process with Zn-based flux-cored filler wire. The Fe-rich layer detaches from the interface during welding, and then Al-Zn phases flow into the zone between the detached layer and the interfacial layer, accelerating further detachment of the Fe-rich layer. The detached layer diffuses and migrates gradually into the weld upon solidification. The intermetallic layer is about 15 μm thick, and the tensile strength of the as-welded joint reaches 111 MPa. After heat treatment, the tensile strength is improved to 150 MPa.

Key words: aluminum alloy; steel; dissimilar metal joining; interface; detachment

1 Introduction

The requirements for weight reduction of vehicles lead to an increasing demand of dissimilar metal structures between aluminum alloy and steels. But the large differences in thermal-physical properties between aluminum alloy and steel result in great difficulties, such as incompatibility and generation of brittle intermetallic compounds during welding of these two materials. Many welding processes were investigated in order to overcome these difficulties. Brazing and pressure welding processes were conducted to solidly join aluminum alloy to steel. WU et al [1] researched the microstructure of joints between 6063 aluminum alloy and 1Cr18Ni9Ti stainless steel by contact reactive brazing with Cu as interlayer. Miyagawa et al [2] reported that friction stirring welding can join aluminum alloy to several kinds of steels. Paventhan et al [3] investigated the parameters optimization for dissimilar metal joint between 6082-T6 aluminum and AISI 304 austenitic stainless steel made by friction welding. Recently, arc-brazing has been taken particular attention due to its low cost and simple requirements of the joint design. Arc-brazing is a method that part of aluminum base material melts with the molten filler metal under an electrical arc to form weld, while the steel base material is brazed. Sierra et al [4] conducted laser welding and gas tungsten arc welding (GTAW) for joining aluminum alloy to galvanized steel. However, brittle Fe-Al intermetallic compounds easily formed under the arc and consequently deteriorated the mechanical properties of the resultant joint. The microstructure and growth mechanism of intermetallic compounds between molten aluminum and solid iron were investigated by Bouche et al [5] and Shahverdi et al [6]. To suppress the formation and growth of brittle intermetallic compounds, bimetal was introduced by SUN et al [7] to change the welding route from aluminum/steel to aluminum/ aluminum and steel/steel. Alternatively, inserting a third-part metal between two base materials, or coating zinc or aluminum or both on steel surfaces, as reported by ZHANG et al [8], could block the direct contact between aluminum and steel during welding. It was found that the compositions of filler metal determined the microstructure and mechanical properties of the aluminum/steel dissimilar metal joint. JACOME et al [9] and GUNGOR and GERRITSEN [10] revealed the influence of filler compositions on the properties of aluminum/steel joints made by arc welding. DONG et al [11] lap-joined aluminum alloy to galvanized steel sheets using several filler wires by tungsten inert gas arc-brazing process. SONG et al [12] investigated the effect of Si on the intermetallic layer during gas tungsten arc welding of aluminum to steel. However, Murakami et al [13] and DONG et al [14-16] suggested that flux-cored filler metals displayed apparent advantages in improving welding efficiency and mechanical properties of aluminum/steel joint since the flux could enhance the wetting of molten filler wire and aluminum base material onto the steel surface. Recently, a new phenomenon is detected that the interfacial layer detached from the steel surface and diffused into the weld during arc-brazing of aluminum to uncoated carbon steel with Zn-based flux-cored filler wire.

In this work, the detachment of interfacial layers and the microstructure and mechanical properties of the resultant joints were investigated.

2 Experimental

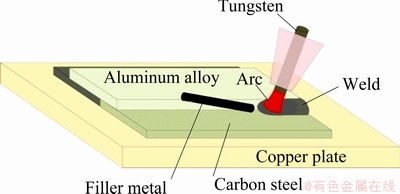

Zn-15%Al flux-cored filler wire was used during lap joining of 5A02-H34 aluminum alloy to Q235B carbon steel sheets with gas tungsten arc welding process. The nominal compositions of the base materials are listed in Table 1. The overlap was 18 mm wide with aluminum alloy on the top and carbon steel at the bottom, as shown in Fig. 1. The outside diameter of the filler wire, flux-cored with CsAlF4, was 1.8 mm. The dimensions of carbon steel sheet were 200 mm×80 mm×1.5 mm and those of the aluminum alloy sheet were 200 mm×80 mm×2 mm. During welding, the traveling speed was 60 mm/min, the wire filling speed was 300 mm/min, and the welding current was 40 A. Argon was used as shielding gas at a flow rate of 10 L/min, and the arc length was kept constant at 5 mm for the convenience of wire feeding. Before welding, the faying surfaces of the workpieces were brushed with a stainless steel brush to remove the oxide layer and cleaned with acetone to remove the grease or oil. The resultant joint was post-weld heat treated at 280 °C for 30 min in air in a furnace for comparison with that in as-welded state. Three 25 mm-wide samples were cut from each joint for tensile test. The cross section of the sample was prepared for microstructure examination, and the distribution of major alloying elements was identified with electron probe microanalysis (EPMA). The Vickers microhard- ness was tested under a loading force of 0.098 N and the loading duration was 10 s.

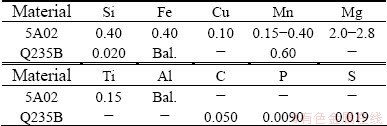

Table 1 Nominal compositions of base materials (mass fraction, %)

Fig. 1 Schematic diagram of lap welding of aluminum alloy to carbon steel sheets with GTAW process

3 Results and discussion

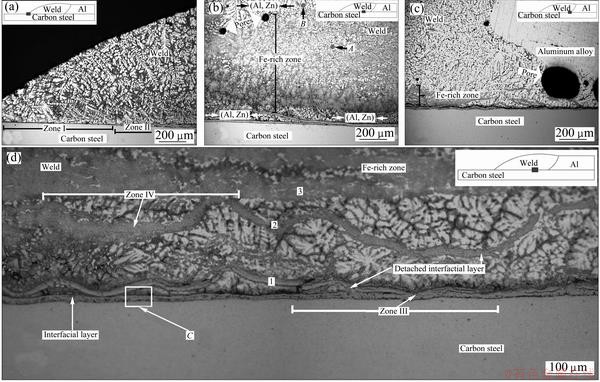

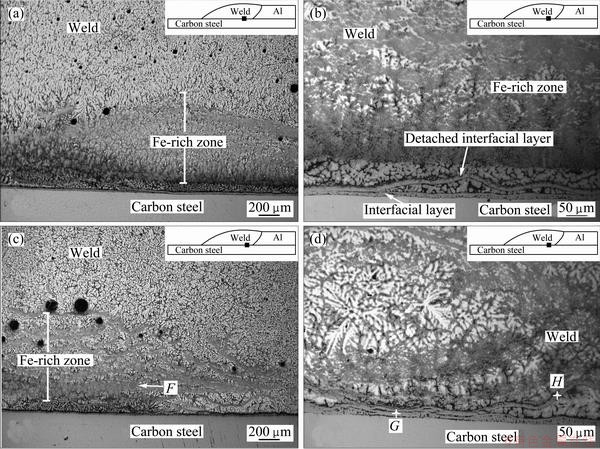

Since the aluminum alloy was melted but the steel was brazed during welding, the weld consisted of the mixture of molten filler wire and aluminum alloy base material. The OM images of the outside, middle and inner parts of the interface in the as-welded joint are shown in Fig. 2. It can be seen that the interfacial layer becomes thicker inward the interface, by comparing Zone I with Zone II, as shown in Fig. 2(a). Small pores due to the evaporation of Zn can be seen in the weld in Fig. 2(b), which is common during the arc-brazing of aluminum to steel with Zn-based filler metal, as reported by Mathieua et al [17]. An Fe-rich zone is detected mainly in the middle and inner parts of the interface, as shown in Figs. 2(b) and (c). Spot A, close to the interfacial layer, contains 5%Fe (molar fraction), while spot B, away from the interfacial layer, is measured to contain only 0.1%Fe, as seen in Fig. 2(b). Big pores appear in the inner part of the interface, as shown in Fig. 2(c) which could degrade the mechanical properties of the joint. Figure 2(d) reveals the microstructure of the joint in a wider zone. It can be found that when the interfacial layer grows thicker, it breaks off into two layers. One layer (about 15 μm thick) is detached into the weld, while the other continues growing on the steel surface, as shown in the marked Zone III in Fig. 2(d). However, the detached layer migrates into the weld during solidification, as seen in the marked Zone IV in Fig. 2(d).

The middle part of the interface has experienced larger heat input during welding, compared with the other parts, because it is right under the welding arc. Consequently, more detached interfacial layers and thicker Fe-rich zone occur in the middle part. An Al-Zn solid solutions zone appears between the detached interfacial layer and the one still sitting on the steel surface, as shown by the marked (Al, Zn) phases in Fig. 2(b). Especially, the detached interfacial layer possesses considerable continuity, as seen in Figs. 2(b) and (d). The interfacial layer mainly consists of Fe-Al intermetallic compounds, and its linear expansion coefficient is much different from that of the carbon steel. When the interfacial layer grows thicker, it becomes weaker and easier to break, and then the liquid Al-Zn metal flows under the broken interfacial layer to accelerate its detachment. It can be seen that the detached interfacial layer grows wider into the weld due to the diffusion of Fe from the layer into the Al-Zn alloy weld, by comparing the width of layers 1, 2 and 3 shown in Fig. 2(d).

Fig. 2 OM images showing outside (a), middle (b), inner parts (c) and detached interfacial layer (d) of as-welded joint between 5A02 aluminum alloy and uncoated Q235 carbon steel made with Zn-15%Al flux-cored filler wire

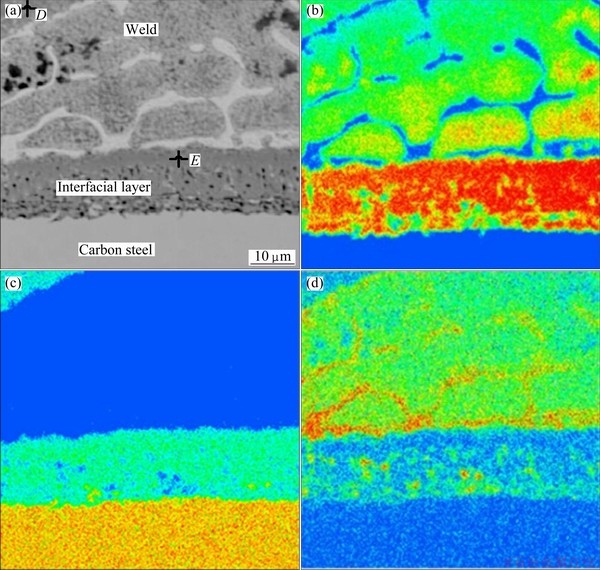

Figure 3 shows the backscattered electron image and distribution of major alloying elements in area C as marked in Fig. 2(d). The thickness of the interfacial layer is about 15 μm. The composition of detached interfacial layer measured at point D is 64%Al-21%Fe-10%Zn as shown in Fig. 3(a). Point E in Fig. 3(a) is measured to contain 62%Al, 28%Fe and 7%Zn, similar to point A. The upper part of the interfacial layer seems denser and contains more Al, while bulk Zn-rich phases are detected in the lower part, as seen in Figs. 3(b) and (d). The microstructure in the zone between the detached interfacial layer and the one sitting on the steel surface consists of white Zn-rich phases and grey Al-Zn solid solutions, as shown in Fig. 3(a), and no Fe is distributed in this zone, as seen in Fig. 3(c).

Figure 4 reveals the microstructure of the as-welded and post-weld heat treated joints. Figures 4(a) and (c) show the typical Fe-rich zone in both joints, respectively. The composition of spot F in Fig. 4(c) contains 7%Fe, which is similar to that at spot A in Fig. 2(b). The thickness of the interfacial layer of both joints is about 15 μm. The compositions at point G (67%Al, 25%Fe and 7%Zn) and point H (67%Al, 22%Fe and 9%Zn) in Fig. 4(d) are also similar to those at points E and D in Fig. 3(a), respectively.

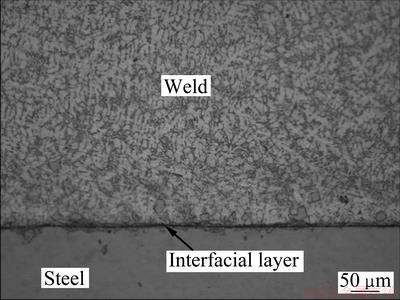

However, the dissimilar metal joint between 5A02 aluminum alloy and uncoated Q235 carbon steel is made with Al-12%Si flux-cored filler wire with the same welding parameters as those with Zn-15%Al flux-cored filler wire, but the detachment of interfacial layer is not detected, as shown in Fig. 5. In addition, the detached interfacial layer does not occur during the arc brazing of 5A02 aluminum alloy to 304 stainless steel with Zn-15%Al flux-cored filler wire by DONG et al [14-16]. So the detachment of the interfacial layer into the weld is related to the properties of steel base material and filler wire, which reveals the comparability of dissimilar metal structure between aluminum alloy and steels.

The tensile strength of the as-welded joint between 5A02 aluminum alloy and uncoated Q235 carbon steel made with Zn-15%Al flux-cored filler wire is 111 MPa and the specimen fractures along the interfacial layer during tensile test. After PWHT, the tensile strength reaches 150 MPa and the specimen fractures in the weld. The diffusion of Fe is slow under 280 °C, so neither the width of Fe-rich zone nor the thickness of the interfacial layer changes apparently after post-weld heat treatment (PWHT), as seen in Fig. 4. Therefore, PWHT improves the joint strength mostly by relieving the thermal and residual stress in the joint.

Fig. 3 Backscattered electron image (a) and distribution of major alloying elements Al (b), Fe (c) and Zn (d) around interfacial layer in as-welded joint shown in Fig. 2(d)

Fig. 4 SEM images of as-welded joints (a, b) and post-weld heat treated joints between 5A02 aluminum alloy and uncoated Q235 carbon steel made with Zn-15%Al flux-cored filler wire (c, d)

Fig. 5 SEM image of as-welded joint between 5A02 aluminum alloy and uncoated Q235 carbon steel made with Al-12%Si flux-cored filler wire

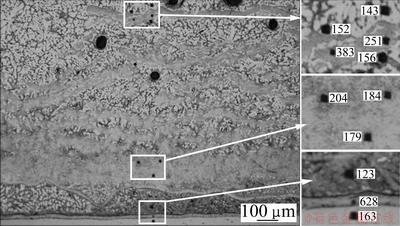

Figure 6 displays the distribution of Vickers microhardness in the dissimilar metal joint between 5A02 aluminum alloy and uncoated Q235 carbon steel made with Zn-15%Al flux-cored filler wire. It can be seen that the microhardness value is only HV 143 in the zone that Al-Zn solid solutions domains, but it changes from HV 184 to HV 383 in the weld where Fe distributes. However, the highest microhardness, up to HV 628, appears in the interfacial layer tightly sitting on the steel surface. The detachment of interfacial layers into the weld increases the amount of brittle intermetallic compounds in the zone close to the interface between the weld and steel, consequently increases the microhardness and degrades the mechanical properties of the resultant joint. This phenomenon reveals that the distribution of Fe which diffuses or detaches from the steel base material into the interface and weld controls the local microhardness of the joint.

Fig. 6 OM image showing Vickers microhardness distribution in dissimilar metal joint between 5A02 aluminum alloy and uncoated Q235 carbon steel made with Zn-15%Al flux cored filler wire

4 Conclusions

1) The lap joining of 5A02-H34 aluminum alloy to uncoated Q235B carbon steel by gas tungsten arc welding process with Zn-15%Al flux-cored filler wire is conducted. The Fe-rich layer detaches from the interfacial layer, and then diffuses in the weld.

2) During welding, the Al-Zn phases flow into the zone between the detached interfacial layer and the one still sitting on the steel surface and accelerate the further detachment of the interfacial layer into the weld. The microhardness of the resulted joint depends on the distribution of Fe which diffuses from the steel base material. The tensile strength of the as-welded joint reaches 111 MPa, and PWHT improves the joint strength to 150 MPa by relieving thermal and residual stress in the joint.

3) The detachment of interfacial layers is not detected in the dissimilar metal joint between 5A02 aluminum alloy and uncoated Q235B carbon steel made with Al-12%Si flux-cored filler wire or between 5A02 aluminum alloy and 304 stainless steel with Zn-15%Al flux-cored filler wire.

References

[1] WU Ming-fang, SI Nai-chao, CHEN Jian. Contact reactive brazing of Al alloy/Cu/stainless joints and dissolution behaviors of interlayer [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(5): 1035-1039.

[2] Miyagawa K, Yasui T, Tsubaki M, Fukumoto M. Spot welding between aluminum alloy and several kinds of steels by friction stirring [J]. Quarterly Journal of the Japan Welding Society, 2009, 27(2): 89-93.

[3] Paventhan R, LAKSHMINARAYANAN P R, BALASUBRAMANIAN V. Prediction and optimization of friction welding parameters for joining aluminium alloy and stainless steel [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(7): 1480-1485.

[4] Sierra G, Peyre P, Deschaux B F, Stuart D, Fras G. Galvanised steel to aluminium joining by laser and GTAW processes [J]. Materials Characterization, 2008, 59(12): 1705-1715.

[5] Bouche K, Barbier F, Coulet A. Intermetallic compound layer growth between solid iron and molten aluminum [J]. Materials Science and Engineering A, 1998, 249(1-2): 167-175.

[6] Shahverdi H R, Ghomashchi M R, Shabestari S, Hejazi J. Microstructure analysis of interfacial reaction between molten aluminium and solid iron [J]. Journal of Materials Processing Technology, 2002, 124(3): 345-352.

[7] Sun X, Stephens E V, Khaleel M A, Shao H, Kimchi M. Resistance spot welding of aluminum alloy to steel with transition material-from process to performance-part I: experimental study [J]. Welding Journal, 2004, 83(6): 188-195.

[8] Zhang H T, Feng J C, He P, Zhang B B, Chen J M, Wang L. The arc characteristics and metal transfer behaviour of cold metal transfer and its use in joining aluminium to zinc-coated steel [J]. Materials Science and Engineering A, 2009, 499(1-2): 111-113.

[9] JAcome L A, Weber S, Leitner A. Influence of filler composition on the microstructure and mechanical properties of steel-aluminum joints produced by metal arc Joining [J]. Advanced Engineering Materials, 2009, 11(5): 350-358.

[10] GUngOr O E, Gerritsen C. Effect of filler wire composition and metallic coating on the joint performance of aluminum/steel braze-welds [J]. Welding and Cutting, 2008, 7(5): 303-312.

[11] Dong H, Hu W, Duan Y, Wang X, Dong C. Dissimilar metal joining of aluminum alloy to galvanized steel with Al-Si, Al-Cu, Al-Si-Cu and Zn-Al filler wires [J]. Journal of Materials Processing Technology, 2012, 212(2): 458-464.

[12] Song J, Lin S, Yang C, Fan C. Effects of Si additions on intermetallic compound layer of aluminum-steel TIG welding-brazing joint [J]. Journal of Alloys and Compounds, 2009, 488(1): 217-222.

[13] Murakami T, Nakata K, Tong H J, Ushio M. Dissimilar metal joining of aluminum to steel by MIG arc brazing using flux cored wire [J]. ISIJ International, 2003, 43(10): 1596-1602.

[14] Dong H, Yang L, Dong C, Kou S. Arc joining of aluminum alloy to stainless steel with flux-cored Zn-based filler metal [J]. Materials Science and Engineering A, 2010, 527(26): 7151-7154.

[15] DONG H, YANG L, DONG C, KOU S. Improving arc joining of Al to steel and Al to stainless steel [J]. Materials Science and Engineering A, 2012, 534: 424-435.

[16] DONG H, LIAO C, YANG L, DONG C. Effects of post-weld heat treatment on dissimilar metal joint between aluminum alloy and stainless steel [J]. Materials Science and Engineering A, 2012, 550: 423-428.

[17] Mathieua A, Shabadi R, Deschamps A, Suery M, Mattei S, Grevey D, Cicala E. Dissimilar material joining using laser (aluminum to steel using zinc-based filler wire) [J]. Optics & Laser Technology, 2007, 39(3): 652-661.

董红刚,胡文金,张旭超

大连理工大学 材料科学与工程学院,大连 116085

摘 要:采用锌基药芯焊丝对铝合金和无镀层低碳钢进行钨极氩弧熔-钎焊搭接。在焊缝中发现从界面层脱落的富铁层,Al-Zn相流入界面层和脱落层之间的夹层区域,并加速富铁层的进一步脱落。在焊缝凝固过程中,富铁脱落层逐渐向焊缝深处扩散、迁移。界面层的厚度为15 μm,焊态下铝/钢异种金属接头的抗拉强度达111 MPa。经焊后热处理,接头的抗拉强度提高到150 MPa。

关键词:铝合金;钢;异种金属连接;界面层;脱落

(Edited by Jing-hua FANG)

Foundation item: Project (50904012/E041607) supported by the National Natural Science Foundation of China; Project (20092152) supported by the Natural Science Foundation of Liaoning Province, China

Corresponding author: Hong-gang DONG; Tel: +86-411-84706283; Fax: +86-411-84709284; E-mail: donghg@dlut.edu.cn

DOI: 10.1016/S1003-6326(13)62634-5