文章编号:1004-0609(2012)05-1383-07

Ti-Si-N纳米复合薄膜的制备及其力学性能

杨莹泽,张玉娟,翟玉浩,张平余

(河南大学 特种功能材料重点实验室,开封 475004)

摘 要:采用离子束溅射与磁过滤阴极弧共沉积技术在单晶硅片(400)表面制备Si含量(摩尔分数)为3.2%~15.5%范围内的TiSiN薄膜。采用X射线光电子能谱(XPS)、电子散射谱(EDS)、X射线衍射仪(XRD)研究TiSiN薄膜的显微结构和力学性能。结果表明:低Si含量的薄膜以面心立方晶型的Ti(Si)N固溶体形式存在,择优晶面为(200)面;当Si含量饱和后,出现Ti(Si)N和Si3N4非晶相,形成Ti(Si)N/Si3N4纳米复合结构。薄膜硬度范围在22~26 GPa,采用Si3N4小球为对偶时薄膜的摩擦因数均维持在0.13~0.17之间。Si含量为10.9%时,硬度达最大值,结合较低的粗糙度,使其摩擦因数和磨损率达到最低值。

关键词:Ti-Si-N;纳米复合薄膜;纳米硬度;摩擦

中图分类号:TG174.44 文献标志码:A

Preparation and mechanical properties of Ti-Si-N nanocomposite films

YANG Ying-ze, ZHANG Yu-juan, ZHAI Yu-hao, ZHANG Ping-yu

(Laboratory of Special Functional Materials, Henan University, Kaifeng 475004, China)

Abstract: Ti-Si-N films containing 3.2%-15.5% Si (molar fraction) were deposited on Si(400) substrates by ion beam sputtering combined with filted cathodic arc system. X-ray photoelectron spectroscopy (XPS), energy dispersive spectroscopy (EDS) and X-ray diffractometry (XRD) were used to study the microstructure and mechanical properties of TiSiN films. The results suggest that a Ti(Si)N solid solution with face-centered cubic structure and (200) preferred crystalline orientation exist in the films with lower Si content. After saturation of Si, the films form a two-phase structure, consisting of Ti(Si)N and amorphous Si3N4. The hardness of films is in the range from 22 GPa to 26 GPa. The friction coefficients maintain at 0.13-0.17 using Si3N4 spheres as couples. The hardness of film with 10.9% Si reaches the maximum value, combined with lower roughness, which results that the friction coefficient and wear rate reaches the minimum value.

Key words: Ti-Si-N; nancomposite film; nanohardness; tribology

钛基涂层如TiN、TiAlN、TiC作为硬质耐磨涂层在切削工具领域得到广泛应用,但是随着加工条件的提高,该类薄膜在抗高温氧化、硬度、化学稳定性方面表现出了不足。近年来,有研究者在该类薄膜基础上掺入Si,制成TiSiN纳米复合薄膜,其硬度超过 40 GPa,抗氧化温度达900~1 000 ℃[1-4],因此,有关TiSiN纳米复合薄膜的研究备受关注。

用于制备TiSiN纳米复合薄膜的方法已有很多,如化学气相沉积、磁控溅射、离子束溅射、阴极弧离子镀[5-8]等,而物理气相沉积温度较低(300~400 ℃),且避免了危险气体的使用,更便于工业化应用。其中阴极弧离子镀产生的等离子体具有离化率、离子能量高的特点,更有利于提高涂层的致密性和结合力。针对硅靶导电性、热胀性差,不易作为阴极弧靶,BENDAVID等小组做了多种尝试,首先是采用Ti/Si合金靶[9],但是其固定比例降低了薄膜成分可控性;随后将阴极弧与CVD相结合,通入硅烷气体提供硅源[10],Ti阴极弧提供Ti离子。同时,BENDAVID 等[11]和KIM等[12]都采用了磁控溅射硅靶与Ti阴极弧相结合的方法。这两种方法都制备出了成分可控的超硬纳米复合膜,并且研究了参数对薄膜成分、微观结构以及硬度的影响。最近有一种新技术是将离子束溅射与带有90°磁过滤弯管的阴极弧相结合来制备TiSiN薄膜。由磁过滤Ti阴极弧提供Ti离子,离子束溅射α-Si3N4靶,提供Si源。其中阴极弧的90°磁过滤弯管可以过滤掉阴极弧产生的微米级大颗粒,使薄膜更平滑致密。Si以Si3N4的形式掺入,避免了Si的氮化不充分性。

本文作者采用这种离子束溅射与磁过滤阴极弧共沉积法制备TiSiN纳米复合薄膜,并研究沉积参数对薄膜成分、结构,以及硬度、模量、摩擦磨损等力学性能的影响。

1 实验

1.1 薄膜制备

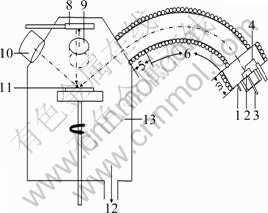

以(400)面单晶硅片(厚度550 μm)作为基底材料,依次用无水乙醇、丙酮、去离子水超声清洗20 min,经高纯氮气吹干后放入真空室内。实验采用自行设计的FDJ600高真空多功能薄膜沉积设备(如图1所示),本底真空为5.0×10-4 Pa。首先,用ICP(射频耦合离子源)产生的氩离子(离子能量为400 eV)轰击清洗基底表面20 min,然后,用氩离子束溅射Ti靶,沉积10 nm左右的Ti过渡层,之后,氩离子束溅射沉积Si3N4与磁过滤阴极弧沉积TiN同时进行,制备TiSiN纳米复合薄膜。其中四工位离子束溅射靶配有α-Si3N4和Ti靶(纯度99.99%),溅射离子枪束流分别控制在50、70和135 mA;磁过滤阴极靶材为Ti靶(纯度99.96%),反应气体采用氮、氩混合气(纯度均为99.999%),磁过滤线圈电流分别控制在5.0、4.0、3.5、3.0和2.6 A。通过改变离子束溅射的束流和磁过滤线圈电流制备出一系列不同Si含量的纳米复合薄膜。工作气压为 1.0×10-1 Pa,温度小于150 ℃,所有薄膜厚度均控制在200 nm左右。纯TiN薄膜单独由磁过滤阴极弧在同样条件下制备。

图1 离子束溅射与磁过滤阴极弧共沉积系统示意图

Fig. 1 Schematic diagrams of ion beam sputtering and filtered cathodic arc co-deposition system: 1—Gas inlet; 2—Ti target; 3—Cathodic binding post; 4—Trigger; 5—Outlet magnetic coil; 6—Filtered magnetic coil; 7—Arc source magnetic coil; 8—Sputtering target; 9—Ion gun; 10—ICP ion source; 11—Sample platform; 12—Pump; 13—Vacuum chamber

1.2 结构表征

采用Kratos Analytical公司Xis Ultra型X射线光电子能谱(XPS) 对薄膜中元素价态进行分析,薄膜的组织结构利用荷兰 Philips公司的X' Pert Pro MPD型Cu Kα激发的X射线衍射仪(XRD),以θ~2θ模式对薄膜的晶体结构进行表征。采用日本精工(SII)生产的SPA400原子力显微镜观察薄膜的微观形貌。利用日本电子株式会社(JEOL Ltd)的 JSM5600LV型扫描电子显微镜附带的电子散射谱(EDS)对薄膜的成分进行分析。

1.3 力学性能表征

用哈尔滨刀具厂2206-B型表面轮廓仪测量薄膜的厚度。利用美国CETR的UMT-2多功能摩擦仪考察薄膜在空气环境下的摩擦学性能。摩擦方式为球-盘往复摩擦,摩擦对偶为直径4 mm的Si3N4球,硬度18 GPa,单次行程为4 mm,湿度50%;摩擦因数测试条件:载荷0.1 N,转速30 r/min;磨损率测试条件:载荷0.1 N,转速60 r/min,时间10 min。薄膜的硬度和弹性模量测试采用安捷伦公司带有CSM(连续刚度,Countinuous stiffness measurement)功能的Nano Indenter G200型纳米压痕仪,通过测量薄膜硬度和模量对压入深度的变化,检测薄膜的硬度和模量结果。

2 结果与讨论

2.1 X射线衍射(XRD)分析

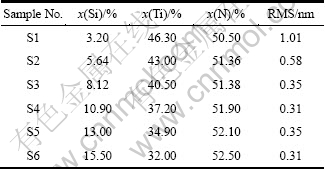

表1所列为6个样品(S1~S6)的EDS分析结果。由表1可知,薄膜中N含量(摩尔分数)保持基本不变,随着Si含量的增大,Ti含量逐渐下降。通过改变离子束溅射的束流和磁过滤线圈电流使薄膜中Si含量具有较强的可控性,所制备的TiSiN薄膜中Si含量在3.2%~15.5%的范围。

表1 TiSiN系薄膜的EDS分析结果

Table 1 EDS analysis results of TiSiN films

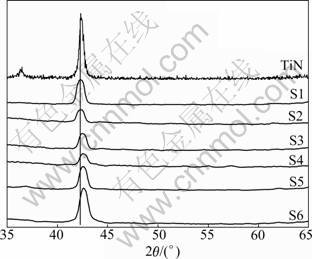

图2所示为不同薄膜的XRD谱。从图2可以看出,纯TiN薄膜为面心立方(FCC)结构,具有(200)面择优取向。TiSiN薄膜中晶相同样具有(200)面择优取向的FCC结构,且(200)峰明显宽化。根据TiN薄膜的研究结果,当薄膜中不存在或存在较小的残余应力时,以表面能最小的(200)面择优取向[13-14]。由此可见,样品S1~S6中的残余应力均较小。图2中未出现晶相Si3N4和钛硅化物的衍射峰,Si除了可能以非晶态Si3N4形式存在之外,由于物理气相沉积的过程往往被认为是极不平衡的过程,所以还有可能以Ti(Si)N固溶体的形式存在,当固溶体中的Si达到饱和之后才能形成非晶态Si3N4[15-16]。当TiN中部分Ti元素被Si元素取代后,由于Si的半径小于Ti,必然会导致其晶格常数的降低。图2中样品S1~S3随着Si含量的增 加,(200)晶面逐渐向高角移动,之后稳定在42.6°。由此可见,样品S1~S3薄膜中晶相是以Ti(Si)N固溶体的形式存在,当固溶体中Si饱和后,又有非晶态Si3N4相出现。根据(200)晶面衍射峰的半高宽,利用谢乐公式计算了薄膜中的晶粒尺寸,如图3所示。TiSiN薄膜中的晶粒尺寸在20~30 nm之间。随着Si的掺入,晶粒尺寸变化不大,只在Si含量大于10.9%之后明显下降。此现象与其他研究结构相似[10,17],非晶相Si3N4的出现,限制了晶粒的进一步生长,导致了晶粒粒径的下降。

2.2 X射线光电子能谱(XPS)分析

从XRD结果分析得到的信息在XPS结果中得到进一步的证明。图4所示为薄膜样品S4中的Si 2p XPS谱。经过拟合分峰,从图4可以看出,样品S4(Si含量10.9%)中的Si 2p峰由两个峰合成,1号峰位于101.7 eV附近,与Si3N4中的Si 2p峰位一致,2号峰位于102.6 eV附近,应该对应于Ti(Si)N固溶体中Si 2p的结合能,由于它既不对应于更高键能的SiO2(103.1 eV)中的Si,也不对应于较低键能的TiSi(98.8 eV)中的Si,且与所报道的非平衡状态Ti(Si)N固溶体中Si 2p峰的峰位相吻合[15-16]。结合XRD结果可知,薄膜中晶相是以Ti(Si)N固溶体的形式存在,当固溶体中Si饱和后,又有非晶态Si3N4相出现。由此可见,即使利用了磁过滤阴极弧这种离化率和离子能量较高的方法,在不对基底加热、加负偏压的情况下,仍然不利于TiN和Si3N4的两相分离。

图2 不同薄膜的XRD谱

Fig. 2 XRD patterns of different films

图3 晶粒尺寸与Si含量的关系

Fig. 3 Crystallite size of films as function of Si content

图4 样品S4的Si 2p XPS谱

Fig. 4 XPS spectra of Si 2p peak in sample S4

2.2 形貌分析

图5所示为不同Si含量TiSiN薄膜的三维原子力显微镜图。随着Si含量的增加,薄膜的表面形貌和粗糙度(见表1)发生了明显的改变。根据XRD和XPS结果的分析,结合所得的薄膜微观结构可知,开始少量的Si溶入TiN晶格形成固溶体,薄膜表面仍是柱状晶生长形成的晶粒凸起(见图5(a)~(c)),随着Si含量的进一步增大,形成的Si3N4非晶相的增加,附着在晶粒表面,阻碍了晶粒的进一步增大,同时填补了表面晶粒凸起间的凹坑,使得薄膜表面变得更加平滑(见图5(d)~(f))。这与已有的研究结果一致[10,18]。

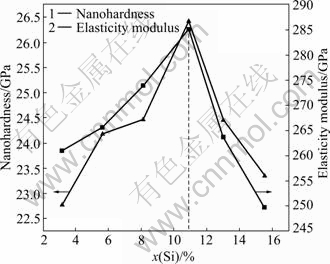

2.4 薄膜纳米硬度和弹性模量测试

采用CSM模式测量薄膜硬度与压入深度之间的关系。曲线的平台区硬度值即为薄膜的硬度值,每个样品取5个不同点,测试后取平均值。图6所示为不同Si含量样品的纳米硬度和弹性模量。从图6可以看出,薄膜的硬度值均在22~26 GPa之间,随着Si含量的增加,薄膜硬度随之增大;Si含量为10.9%时,硬度达到最大值,之后硬度减小。弹性模量也表现出与硬度相似的变化趋势,在Si含量为10.9%时,弹性模量达到了最大值。关于薄膜材料的增硬理论有很多:压应力增强[19],固溶体增强[20],晶粒细化增强,混凝土微观结构增强[1]等。根据XRD结果可知,薄膜中的应力较小,晶粒粒径变化不大,且样品S4的晶粒还比其他样品稍大,因此排除了应力增强和晶粒细化增强的原因。据报道,基于固溶体增强的机理,TiSiN薄膜中存在最佳的Si含量导致薄膜出现增强效应。在本实验中薄膜材料同样存在Ti(Si)N固溶体微观结构,基于固溶体增强机理,最佳Si含量为10.9%。虽然在高Si含量的样品中出现了Si3N4非晶相,但是在本实验范围内,薄膜中晶相的晶粒粒径较大,非晶相的相对较少,未出现混凝土结构增强效应。

图5 不同Si含量样品的原子力形貌图

Fig. 5 AFM images of films with various Si contents: (a) Sample S1; (b) Sample S2; (c) Sample S3; (d) Sample S4; (e) Sample S5; (f) Sample S6

图6 薄膜硬度和弹性模量与Si 含量之间的关系

Fig. 6 Nanohardness and elasticity modulus of films as function of Si content

2.5 摩擦学性能测试

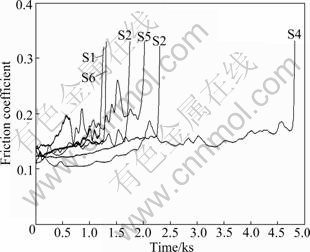

作为硬质涂层使用的TiSiN薄膜,其摩擦学性能对其应用是至关重要的。根据以往报到,此类硬质薄膜在与金属对偶对磨的时候,由于硬质薄膜对软金属的黏着、切削导致摩擦因数较高,在0.6~0.9之间[21-22]。在本研究考察了不同Si含量的TiSiN薄膜在低载荷下与硬度较高的陶瓷对偶的摩擦学性能。采用了硬度为18 GPa的Si3N4球,载荷为0.1 N,湿度为50%。摩擦因数与时间、摩擦因数和磨损率与Si含量之间的关系如图7和8所示。由图7可见,所有样品的摩擦因数均维持在0.13~0.17之间,未出现磨合阶段,整个过程波动较小,稳定性较好。同时,从图8还可以看到,随着薄膜中Si含量逐渐增加,薄膜的摩擦因数和磨损率逐渐减小,Si含量为10.9%时,两者达到最佳值;当Si 含量大于10.9%后,摩擦因数和磨损率均有所增大。此现象与所报道的Si3N4对偶与Si3N4薄膜以及TiSiN薄膜在潮湿环境中对磨的摩擦行为一致[18,23]。由于在潮湿环境中,Si3N4在摩擦过程中与水反应生成了具有减摩作用的硅的氧化物、氢氧化物,大大降低了摩擦因数。更由于本研究所制备的薄膜表面光滑致密,且载荷较小,致使所有样品的摩擦因数均维持在0.13~0.17之间,未出现磨合阶段。从样品S1到样品S4,随着粗糙度的降低和硬度的增大,导致其摩擦因数和磨损率随之下降,而样品S5和S6的硬度下降,促使其磨损率增大,同时磨损产生的磨屑会使摩擦因数升高。从图7可以看到,样品S1、S2、S5和S6薄膜的摩擦曲线有轻微的震荡,说明磨损产生的磨屑导致其摩擦因数和磨损率升高。

图7 不同Si含量薄膜的摩擦因数

Fig. 7 Friction coefficient of films with different Si contents

图8 薄膜的摩擦因数、磨损率与Si含量之间的关系

Fig. 8 Friction coefficient and wear rate as function of Si contents

3 结论

1) 采用离子束溅射和磁过滤阴极弧等离子体共沉积技术在单晶硅基底上成功制备了TiSiN纳米复合薄膜。

2) XPS、EDS和XRD结果表明,薄膜由晶态的Ti(Si)N固溶体和非晶态的Si3N4组成,薄膜中的晶相以(200)面择优取向。磁过滤阴极弧这种离化率和离子能量较高的方法,在不对基底加热、加负偏压的情况下,仍然不利于TiN和Si3N4的两相分离。

3) 薄膜硬度在22~26 GPa之间,基于固溶体增强效应,Si含量(摩尔分数)为10.9%时,薄膜的硬度和弹性模量均达到最大值。

4) 以Si3N4为对偶,薄膜的摩擦因数均维持在0.13~0.17之间;在Si含量为10.9%时,薄膜的摩擦因数和磨损率达到最低值。

REFERENCES

[1] VEPREK S, REIPRICH S. A concept for the design of novel superhard coating [J]. Thin Solid Films, 1995, 268: 64-71.

[2] VEPREK S, VEPREK-HEIJMAN M G J, ZHANG R F. Chemistry, physics and fracture mechanics in search for superhard materials, and the origin of super-hardness in nc-TiN/a-Si3N4 and related nano-composites [J]. Journal of Physics and Chemistry of Solids, 2007, 68: 1161-1168.

[3] CARVALHO S, REBOUTA L, CAVALEIRO A, ROCHA L A, GOMES J, ALVES E. Microstructure and mechanical properties of nanocomposite (Ti,Si,Al)N coatings [J]. Thin Solid Films, 2001, 398/399: 391-396.

[4] MANNLING H D, PATIL D S, MOTO K, JILEK M, VEPREK S. Thermal stability of superhard nanocomposite coatings consisting of immiscible nitrides [J]. Surface and Coatings Technology, 2001, 146/147: 263-267.

[5] YANG Z T, YANG B, GUO L P. Effect of bias voltage on the structure and hardness of Ti-Si-N composite coatings synthesized by cathodic arc assisted middle-frequency magnetron sputtering [J]. Journal of Alloys and Compounds, 2009, 473: 437-441.

[6] 胡晓萍, 李戈扬, 戴嘉维, 丁正明, 顾明元. Si含量和基片温度对Ti-Si-N纳米复合薄膜的影响[J]. 上海交通大学学报, 2003, 37(2): 252-256.

HU Xiao-ping, LI Ge-yang, DAI Jia-wei, DING Zheng-ming, GU Ming-yuan. Influences of Si content and substrate temperature on Ti-Si-N nanocomposite films [J]. Journal of Shanghai Jiaotong University, 2003, 37(2): 252-256

[7] MARTIN P J, BENDAVID A, CAIRNEY J M. Nanocomposite Ti-Si-N, Zr-Si-N, Ti-Al-Si-N, Ti-Al-V-Si-N thin film coatings deposited by vacuum arc deposition [J]. Surface & Coatings Technology, 2005, 200: 2228-2235.

[8] MA D, MA S, XU K. The tribological and structural characterization of nano-structured Ti-Si-N films coated by pulsed-d.c. plasma enhanced CVD [J]. Vacuum, 2005, 79: 7-13.

[9] BENDAVID A, MARTIN P J, TAKIKAWA H. The properties of nanocomposite aluminium–silicon based thin films deposited by filtered arc deposition [J]. Thin Solid Films, 2002, 420/421: 83-88.

[10] BENDAVID A, MARTIN P J, PRESTON E W, CAIRNEY J, XIE Z H, HOFFMAN M. Deposition of nanocomposite thin films by a hybrid cathodic arc and chemical vapour technique [J]. Surface & Coatings Technology, 2006, 201: 4139-4144.

[11] MARTIN P J, BENDAVID A. Properties of Ti1-xSixNy films deposited by concurrent cathodic arc evap- oration and magnetron sputtering [J].Surface & Coatings Technology, 2003, 163: 245-250.

[12] KIM DO-GEUN, SVADKOVSKI I, LEE SEUNGHUN, CHOI JONG-WON, KIM JONG-KUK. Synthesis Ti-Si-N nanocomposite coating prepared by a hybrid system of double bending filtered vacuum arc source and magnetron sputtering [J]. Current Applied Physics, 2009, 9: S179-S181.

[13] PELLEG J, ZEVIN L Z, LUNG S, CROITORU N. Reactive- sputter-deposited TiN films on glass substrates [J].Thin Solid Films, 1991, 197(1/2):117-128.

[14] 张玉娟,吴志国,张伟伟, 李 鑫, 阎鹏勋, 刘维民, 薛群基. 磁过滤等离子体制备TiN 薄膜中沉积条件对薄膜织构的影响[J]. 中国有色金属学报, 2004, 14: 1264-1268.

ZHANG Yu-juan, WU Zhi-guo, ZHANG Wei-wei, LI Xin, YAN Peng-xun, LIU Wei-min, XUE Qun-ji. Effect of deposition parameters on texture of TiN films deposited by filtered cathodic arc plasma [J]. The Chinese Journal of Nonferrous Metals, 2004, 14: 1264-1268.

[15] KUZNETSOV M V, SHALAEVA E V, BORISOV S V, MITROFANOV B V, IVANOVSKY A L. Metastable TiSixNyOz films of B1-type structure prepared by the arc process [J]. Thin Solid Films, 1996, 279: 75-81.

[16] SHALAEVA E V, BORISOV S V, DENISOV O F, KUZNETSOV M V. Metastable phase diagram of Ti-Si-N(O) films (CSi<30 at.%) [J]. Thin Solid Films, 1999, 339: 129-136.

[17] CHAWLA V, JAYAGANTHAN R, CHANDRA R. A study of structural and mechanical properties of sputter deposited nanocomposite Ti-Si-N thin films [J]. Surface & Coatings Technology, 2010, 204: 1582-1589.

[18] LI Z G, MIYAKE S J, KUMAGAI M, SAITO H, MURAMATSU Y. Structure and properties of Ti-Si-N films deposited by dc magnetron cosputtering on positively biased substrates [J]. Japanese Journal of Applied Physics, 2003, 42: 7510-7515.

[19] VAZ F, REBOUTA L, GOUDEAU P, RIVIERE J P, SCHAFFER E, KLEER G, BODMANN M. Residual stress states in sputtered Ti1-xSixNy films [J]. Thin Solid Films, 2002, 402: 195-202.

[20] NOSE M, DEGUCHI Y, MAE T, HONBO E, NAGAE T, NOGI K. Influence of sputtering conditions on the structure and properties of Ti-Si-N thin films prepared by r.f.-reactive sputtering [J].Surface and Coatings Technology, 2003, 174/175: 261-265.

[21] 杨友志, 郑晓华. 磁控溅射TiN/Si3N4 纳米复合膜的制备及其环境摩擦学特性[J]. 材料科学与工程学报, 2008, 26: 380-384.

YANG You-zhi, ZHENG Xiao-hua. Preparation and tribological performance of the TiN/Si3N4 composite films deposited by magnetron sputtering at different environments [J]. Journal of Materials Science & Engineering, 2008, 26: 380-384.

[22] 刘传胜, 杨种田, 杨 兵, 田灿鑫, 付德君. 多弧-磁控溅射法制备Ti-Si-N 纳米复合涂层及涂层的结构和力学性能[J].粉末冶金材料科学与工程, 2010, 15: 543-548.

LIU Chuan-sheng, YANG Zhong-tian, YANG Bing, TIAN Can-xin, FU De-jun. Structure and mechanical properties of Ti-Si-N nanocomposite coatings prepared by cathodic arc assisted magnetron [J]. Materials Science and Engineering of Powder Metallurgy sputtering process, 2010, 15: 543-548.

[23] TAKADOUM J, HOUMID-BENNANI H, MAIREY D. The wear characteristics of silicon nitride [J]. Journal of the European Ceramic Society, 1998, 18: 553-556.

(编辑 何学锋)

基金项目:省部共建河南大学科研项目(SBGJ090502)

收稿日期:2011-02-21;修订日期:2011-07-04

通信作者:张玉娟,副教授,博士;电话:13693895146;Fax:0378-3881358; E-mail: cnzhangyujuan@yahoo.com.cn