DOI:10.19476/j.ysxb.1004.0609.2019.03.11

多孔铜的电沉积制备及力学性能

李星吾,阮 莹,魏炳波

(西北工业大学 应用物理系,西安 710072)

摘 要:以聚氨酯泡沫为基体,采用电沉积法制备三维网状多孔铜,研究不同工艺参数对多孔铜材料形貌、结构和力学性能的影响。结果表明:多孔铜的表观密度介于0.119~0.218 g/cm3之间,平均孔径为2.6 mm,孔隙率为 89.8%~92.6%;电沉积过程中降低主盐CuSO4 浓度和溶液温度,可获得较强的阴极极化作用;阴极电流密度和沉积时间对多孔铜的孔隙率和表观密度具有调控作用;多孔铜的准静态圧缩过程可依次分为线性弹性阶段、脆性破坏阶段和致密化阶段;压缩强度与表观密度的关系符合幂函数增长规律。在36 A/m2 电流密度下将沉积时间从 3 h延长至5 h,材料的压缩强度可提升53%。

关键词:多孔铜;电沉积;孔隙率;表观密度;力学性能

文章编号:1004-0609(2019)-03-0517-08 中图分类号:TG146 文献标志码:A

多孔金属具有高孔隙率、高比表面积、优良的耐冲击性等优点,在航空航天、交通、生物、能源等领域被广泛应用[1-18]。常用的制备方法有金属电沉积法[19-23]、粉末烧结法[24]、浇铸法[25]、发泡法[26]和定向凝固法[27-28]等。金属电沉积法通常以非导电海绵为基体,经过预处理、电沉积和热处理等工艺,可制备孔隙率高、孔径大、孔分布均匀的三维开孔多孔金属。并且可以通过改变基体形状、电沉积工艺参数等来调控材料的体积、孔隙率和孔径大小等结构参数。材料通常具有优良的导电、导热、吸声性能以及良好的通透性,可应用于电化学催化载体、多孔电极材料、吸声材料和过滤装置等[11, 14, 19]。

HOU等[22]通过在聚氨酯海绵上涂覆导电胶、电沉积Fe和热处理工艺制备获得多孔铁,其中热处理分为两步:首先于空气中在500 ℃下烧结 20 min,除去聚氨酯基体;再于H2氛围中在800 ℃下烧结1 h,将样品表面的氧化铁还原。张秋利等[23]采用粗化、敏化、活化、解胶和化学镀的方法对聚氨酯基体进行导电化处理,其中活化利用 (PdCl4)2-与Sn2+反应生成的Pd核作为催化金属层,热处理仍采用空气中焚烧和氢气中还原两步,并且发现在 750 ℃下还原处理后的多孔铜具有较好的抗拉强度和韧性。在电沉积过程中,阴极的析氢反应通常难以避免,SHIN等[29]则在较大的阴极极化条件下,以阴极析出的氢气泡作为金属沉积“模板”,成功制备出三维多孔铜薄膜和锡薄膜,孔径在50~100 μm之间,可用于催化电极材料的制作[30]。

多孔金属的力学性能主要由结构参数和基体材料决定。三维网状多孔金属的强度主要受密度和孔因子数的影响[31-33],而圆柱形孔多孔金属的某些力学性能则是各向异性的,如弯曲载荷取决于样品孔隙度和孔隙轴向[27, 34]。此外,也可以通过在表面覆盖其他金属层[22, 35]或者在电沉积过程中加入添加剂[36]来提高多孔金属的力学性能。

目前,对于电沉积法制备大体积多孔金属的过程存在基体预处理过程复杂、热处理环节耗能高以及污染环境等问题。对于性能的研究也主要集中在电化学和传热等方面。本研究以聚氨酯泡沫为基体,采用浸涂导电胶的方法制备导电基体,经过电沉积和单步热处理工艺成功制备三维多孔铜。通过分析电沉积过程中的阴极极化曲线,对主盐浓度和镀液温度参数进行了优化。针对不同电流密度和沉积时间,分析了材料的结构参数和力学性能的变化。

1 实验

1.1 三维网状多孔铜的制备

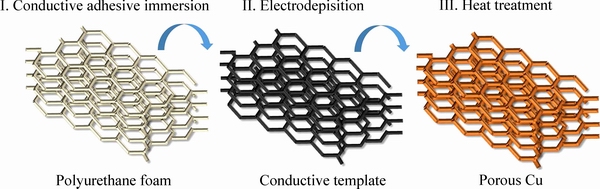

多孔铜的制备流程如图 1 所示。选取孔隙率高 (≥90%)、孔径大(1~4 mm)的聚氨酯泡沫,将其依次浸入稀 NaOH 溶液和稀 HCI 溶液中搅拌清洗,除去泡沫表面的油污等杂质,再放入 3 g/L CrO3和4 ml/L H2SO4的混合液中粗化,打开泡沫内部可能存在的盲孔,增大聚氨酯泡沫表面的粗糙度。将石墨导电胶涂覆于泡沫表面并固化处理。以铜片(99.9%)为阳极,导电泡沫为阴极,在 CuSO4+NH3·H2O+H2C2O4体系中以18~55 A/m2电流密度沉积铜1~5 h,再置于 300 ℃流通惰性氛围下保温3 h,除去内部的聚氨酯泡沫基体 后即得到三维多孔铜材料。

为探究电沉积工艺中最佳的主盐浓度和镀液温度,采用 CHI660E 电化学工作站中的线性伏安扫描法(LSV),测量了不同条件下镀液的阴极极化曲线。工作电极为表观面积 5 cm2 的聚氨酯泡沫基体(已经过导电化处理),对电极为较大面积的环形铜片,参比电极为饱和硫酸亚汞电极(SMSE)。电位扫描区间:开路电位约为-1.3 V,扫描速率为2 mV/s。实验溶液所需试剂均为分析纯,蒸馏水配制。

1.2 形貌结构表征和力学性能测试

1) 沉积层厚度

通过显微分析法测量沉积层厚度。在金相显微镜下统计样品截面中一定数量的沉积层厚度,取平均值作为沉积层厚度 δ。

2) 孔隙率和表观密度

采用排液法测量多孔铜的孔隙率。由于样品均为规则长方体,因而总体积 V 可通过测量三边长度计算获得。将样品分别用乙醇和蒸馏水超声清洗并干燥后,悬挂于细线上并浸入放置于天平上的蒸馏水中,保证样品完全淹没但不接触容器壁,待天平示数稳定后记录此时读数 m*,则样品的孔隙率P为

P=1-m*/(ρwV) (1)

式中:ρw为蒸馏水的密度;V为样品总体积。

通过电子天平测量样品的质量 m,表观密度ρ为

ρ=m/V (2)

3) 力学性能

通过测量多孔铜压缩时的应力-应变曲线研究其力学性能。采用 Instron5969 万能试验机对样品进行单向准静态压缩试验,压缩速率 2 mm/min,试样平均尺寸15 mm×15 mm×40 mm。

2 结果与讨论

2.1 主盐浓度和溶液温度与阴极极化的相关规律

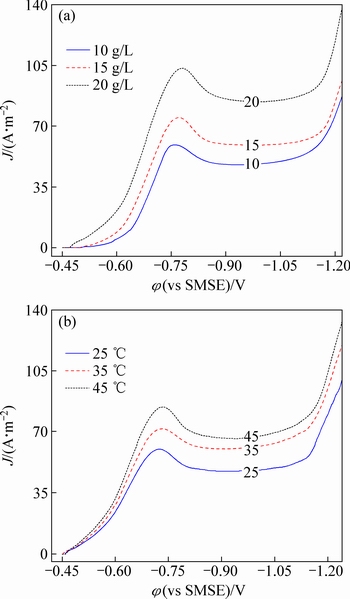

在一定电流密度下溶液的阴极极化作用越大,沉积层的结晶细致程度和均匀程度更好[37-38]。为确定溶液配比和温度的最佳参数,实验测量了室温下主盐 CuSO4 浓度分别为 10,15 和 20 g/L 时的阴极极化曲线(见图2(a))。结果表明,随着溶液中 CuSO4 含量的减少,溶液的极化作用增强。这是由于主盐的减少会导致NH3·H2O和H2C2O4的含量相对提高,溶液中络合Cu2+相较于自由Cu2+的比例上升,阴极表面上Cu2+还原所受到的阻碍作用增强,因而溶液的阴极极化作用增强,极化曲线负移。但CuSO4浓度的降低会使阴极附近溶液的浓度梯度减小,在由扩散主导的浓差极化阶段内,Cu2+扩散速率的变慢会导致极限电流密度降低。取CuSO4为10 g/L,对比25、35和45 ℃溶液温度下的阴极极化曲线(见图2(b))发现,温度升高会使溶液中离子的运动速率和电极上的反应速率加快,电流密度增大,但溶液中金属络离子的稳定性会降低,同时NH3·H2O的分解速率加快,导致溶液阴极极化作用减弱。此外,温度升高会使晶体的生长速率加快,晶粒尺寸变大,不利于形成致密的沉积层。

图1 多孔铜的制备流程

Fig. 1 Preparation process of porous Cu

图2 不同CuSO4浓度和溶液温度下的阴极极化曲线

Fig. 2 Cathode polarization curves of different concentrations of CuSO4 (a) and solution temperatures (b)

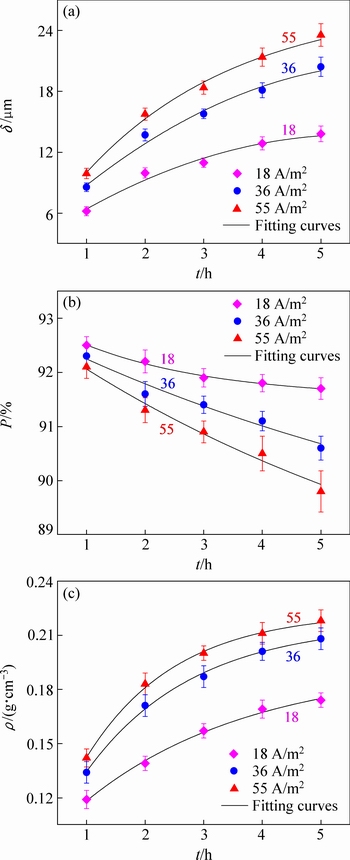

2.2 电流密度和沉积时间对多孔铜结构的调控作用

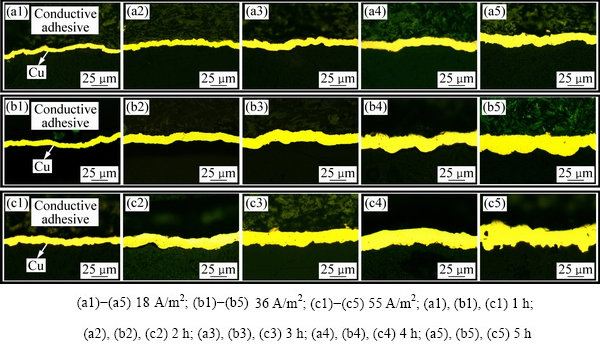

阴极电流密度和沉积时间决定了沉积层的形貌和结构。一般情况下,电沉积的工作电流密度应小于极限电流密度。由图2(b)可知,在优选参数 10 g/L CuSO4 和25 ℃条件下,溶液的阴极极限电流密度为 60 A/m2。分别在18、36和55 A/m2电流密度下沉积Cu 1、2、3、4和5 h,观察沉积层形貌(见图3和图4)并统计其厚度δ(见图5(a))。结果表明,在 1~3 h 沉积时间内,沉积层厚度增加显著,而继续延长沉积时间,沉积层的增厚速率会相对减慢,这可能是由阳极钝化导致,因为实验中发现,长时间沉积后的阳极表面有淡蓝色结晶物附着,阳极的溶解过程受阻,导致沉积速率减小。当电流密度从18 A/m2升高至36 A/m2时,沉积速率大幅提高,沉积层增厚明显。当电流密度增大至55 A/m2接近极限电流密度时,电极上的析氢和析氧等副反应加剧,同时阳极钝化增强,导致沉积速率难以大幅提高,沉积层的增厚趋势减小。在36 A/m2电流密度下沉积5 h后,表面出现起伏状结构(见图3(b5)和图4),说明溶液的均镀能力下降,这可能与NH3·H2O的分解以及阳极面积由于钝化而减小等因素有关。而在55 A/m2下沉积5 h后,沉积层表面出现局部的毛刺状结构,内部也出现孔洞(见图3(c5)),这是由于电流密度过大,阴极表面上的析氢反应加剧,Cu的沉积过程受到干扰,大量的氢气泡附着在沉积层表面甚至进入其内部[39],造成表面的粗糙结构以及内部的孔洞。

图3 不同电流密度和沉积时间下的沉积层截面形貌

Fig. 3 Microscope images of cross-section deposited at different current densities for different time

图4 在0.36 A/dm2下沉积5 h后沉积层断面SEM像

Fig. 4 SEM image of cross-section deposited at 36 A/m2 for 5 h

多孔铜的孔隙率 P 和表观密度 ρ 的统计结果如图5(b)和5(c)所示。在所选的电流密度和沉积时间内,制备的多孔铜孔隙率在 89.8%~92.6%,表观密度介于0.119~0.218 g/cm3。随着电沉积时间的延长,孔隙率由于沉积层厚度的增加而降低,材料内部大量孔隙的存在导致质量的增加相比总体积的增加更加显著,因而表观密度增大。随着沉积的进行,沉积速率会逐渐减小,但对比36 A/m2和55 A/m2电流密度下制备的多孔铜的沉积层厚度、孔隙率和表观密度可发现,表观密度的变化幅度随沉积时间增大的“衰减”更为明显,这是由于氢气析出而在沉积层表面造成的粗糙结构以及沉积层内部的微小孔洞,对沉积层厚度和孔隙率有额外的“补偿”作用。但是,三者随沉积时间以及电流密度的变化规律总体上依然具有良好的统一性和自洽性。

选取孔隙率为95%的聚氨酯泡沫,经导电化处理后在10 g/L CuSO4和25 ℃的溶液中,以36 A/m2电流密度沉积铜3 h,再于300 ℃流通氩气氛围中保温3 h,去除材料内部的聚氨酯基体后获得三维网状多孔铜材料(见图6(a))。制备的多孔铜表面平整、光亮,孔隙连通且分布均匀,平均孔径 2.6 mm,基体分解率达 85%。图6(b)所示为多孔铜的横截面形貌。由图6可知,网丝横截面形状为三角形,与基体材料结构特征吻合。最外层为铜沉积层,紧接内层为石墨导电胶,中心区域为聚氨酯基体分解后的残留中空区。图中可见,导电胶在棱面出的附着量大于棱角和棱边处,但铜沉积层分布均匀,说明导电化处理后的聚氨酯泡沫基体具备良好并且完整的导电能力。

图5 不同电流密度和沉积时间下多孔铜的沉积层厚度、孔隙率和表观密度

Fig. 5 Deposit thickness (a), porosity (b) and apparent density (c) of porous Cu prepared at different current densities and deposition time

2.3 多孔铜的力学性能

图6 在36 A/m2沉积3 h后多孔铜的表观形貌和横截面形貌

Fig. 6 Morphology and characteristics of porous Cu deposited at 36 A/m2 for 3 h

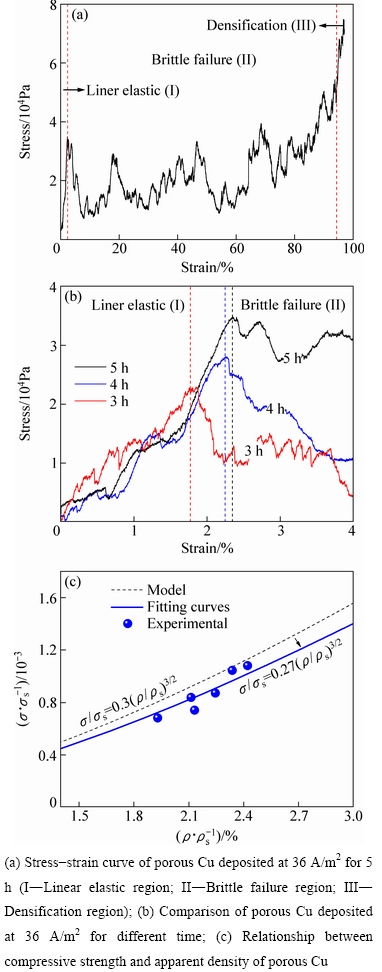

单向准静态压缩试验结果表明,多孔铜的应力应变曲线(见图7(a))为锯齿状,呈现出脆性多孔材料特 征[40]。圧缩过程可分为3个阶段。试样首先发生弹性形变(区域 I),这一阶段的主要变形机制是孔壁的弹性弯曲,试样未发生整体性、明显的断裂。当应变达到 1.9%~2.4% 范围内(见图7(b))时,应力值到达多孔铜的压缩强度值。继续压缩时试样发生脆性破坏形变(区域 II),骨架中较脆弱的区域开始断裂,部分应力被释放,曲线下降。随着应变的增加,断裂的部分被压实后,试样中又有其他区域发生断裂并且重复上述过程,因此曲线中可见明显的应力波动现象。应变超过 94% 以后,所有断裂的部分被压实并且互相接触(区域 III),应力值随应变增大而急剧升高。多孔铜的脆性一方面是由金属沉积层较薄所致,其次是由于在电沉积过程中,阴极析氢反应产生的氢气分子渗入基体材料,导致样品韧性降低。

图7 多孔铜的压缩性能

Fig. 7 Compression performance of porous Cu

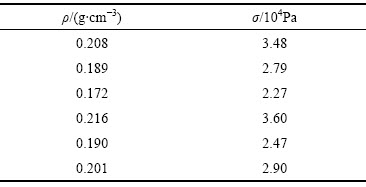

多孔铜的力学性能与表观密度等结构参数有关。从图7(b)中可以看出,在36 A/m2电流密度下将沉积时间从 3 h 增加至 5 h,多孔铜的压缩强度由2.27×104 Pa提升至3.48×104 Pa,这是由于沉积层的增厚以及材料表观密度的增大所致。根据 Ashby 的多孔固体形变模型[41],多孔铜的相对压缩强度和相对密度满足如下关系:

σ/σs=0.3(ρ/ρs)3/2 (3)

式中:σ和ρ分别为多孔铜的压缩强度和表观密度;σs和ρs分别为铜在室温下的压缩强度(33.3 MPa)和密度(8.93 g/cm3)[42]。将不同条件下制备的多孔铜的表观密度和压缩强度值(见表1)与理论模型对比(见图7(c))可知,多孔铜的压缩强度随表观密度的增大而提高,其变化关系基本符合模型中的幂函数规律,但测量值均不同程度地向下偏离理论预测值,经拟合发现,本实验中制备的多孔铜材料满足如下关系:

σ/σs=0.27(ρ/ρs)3/2 (4)

导致这一偏差的主要原因可能是材料内部残留的石墨导电胶和聚氨酯基体,其对于表观密度有所贡献,但抗压强度却小于铜的,因而造成实际拟合结果常数项的减小。

表1 多孔铜的表观密度和压缩强度

Table 1 Apparent density and compressive strength of porous Cu

3 结论

1) 以聚氨酯泡沫为基体,采用电沉积法成功制备三维网状多孔铜材料。在电沉积过程中,选取较低的主盐CuSO4 浓度与溶液温度时,溶液具有较高的阴极极化作用。在 36 A/m2(极限电流密度的60%)下电沉积铜3 h,再于300 ℃下保温3 h后可获得表面平整光亮、结构完整的多孔铜。

2) 电流密度和沉积时间对多孔铜的孔隙率和表观密度具有调控作用。在18~55 A/m2电流密度范围内沉积1~5 h制备的多孔铜,孔隙率在89.8%~92.6%,平均孔径2.6 mm,表观密度介于0.119~0.218 g/cm3。

3) 多孔铜的准静态压缩过程可分为前期的线性弹性区、中期的脆性破坏区和后期的致密化区。其压缩强度随表观密度增大而指数性提高,变化规律符合Ashby的多孔固体形变模型。在36 A/m2电流密度下将电沉积时间从3 h延长至5 h,压缩强度由2.27×104 Pa提升至3.48×104 Pa。

REFERENCES

[1] GIBSON L J, ASHBY M F. Cellular Solids: Structure and properties[M]. Cambridge: Cambridge University Press, 1999.

[2] NAKAJIMA H. Fabrication, properties and application of porous metals with directional pores[J]. Proceedings of the Japan Academy, 2010, 86(9): 884-899.

[3] 刘培生, 陈 祥, 李言祥. 泡沫金属[M]. 长沙: 中南大学出版社, 2012.

LIU Pei-sheng, CHEN Xiang, LI Yan-xiang. Metal foams[M]. Changsha: Central South University Press, 2012.

[4] 张勇明, 何思渊, 何德坪, 卢天健, 王 辉, 黄 可. 超轻多孔金属的耐腐蚀性能[J]. 中国有色金属学报, 2007, 17(11): 1808-1813.

ZHANG Yong-ming, HE Si-yuan, HE De-ping, LU Tian-jian, WANG Hui, HUANG Ke. Corrosion resistance of ultra-light porous metals[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(11): 1808-1813.

[5] LIU Yuan, ZHANG Hua-wei, LI Yan-xiang. Effect of melt superheat on structural uniformity of lotus-type porous metals prepared by unidirectional solidification[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(3): 1004-1010.

[6] JAYARAJ J, PARK B J, KIM D H, JAYARAJ J, PARK B J, KIM D H, KIM W T, FLEURY E. Nanometer-sized porous Ti-based metallic glass[J]. Scripta Materialia, 2006, 55(11): 1063-1066.

[7] 薛向欣, 刘 欣, 张 瑜. 泡沫铝基多孔金属复合材料吸波性能[J]. 中国有色金属学报, 2007, 17(11): 1755-1760.

XUE Xiang-xin, LIU Xin, ZHANG Yu. Electromagnetic wave absorption properties of aluminum foams-based porous metal composite[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(11): 1755-1760.

[8] 刘培生, 徐新邦, 孙进兴, 崔 光. 真空烧结泡沫304不锈钢吸声性能[J]. 中国有色金属学报, 2017, 27(12): 2560-2566.

LIU Pei-sheng, XU Xin-bang, SUN Jin-xing, CUI Guang. Sound absorption property of vacuum sintered 304 stainless steel foam[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(12): 2560-2566.

[9] SONG T, YAN, M, SHI, Z, ATRENS, A, QIAN M. Creation of bimodal porous copper materials by an annealing- electrochemical dealloying approach[J]. Electrochimica Acta, 2015, 164: 288-296.

[10] 刘培生, 周茂奇, 刘安东, 侯兴刚. 多孔金属负载多沟道结构TiO2光催化膜系统[J]. 稀有金属材料与工程, 2009, 38(s3): 250-253.

LIU Pei-sheng, ZHOU Mao-qi, LIU An-dong, HOU Xing-gang. Photocatalytic TiO2 film system with ditches supported by porous metallic carriers[J]. Rare Metal Materials and Engineering, 2009, 38(s3): 250-253.

[11] 胡思江, 李庆余, 黄世稳, 王红强, 王芳平, 钟新仙. 多孔泡沫铜支撑锡薄膜阳极材料的制备及性能[J]. 中国有色金属学报, 2009, 19(11): 2006-2010.

HU Si-jiang, LI Qing-yu, HUANG Shi-wen, WANG Hong-qiang, WANG Fang-ping, ZHONG Xin-xian. Synthesis and characteristics of porous Sn thin film on foam copper as anode material[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(11): 2006-2010.

[12] DU M, ZHANG H W, LI Y X, LIU Y, CHEN X, HE Y. Depositing and alloying on the inner surface of Gasar Cu pores by plating and annealing treatment[J]. Applied Surface Science, 2015, 342: 69-75.

[13] VESENJAK M, HOKAMOTO K, MATSUMOTO S, MARUMO Y, REN Z. Uni-directional porous metal fabricated by rolling of copper sheet and explosive compaction[J]. Materials Letters, 2016, 170: 39-43.

[14] PASERIN V, MARCUSON S, SHU J, WILKINSON D S. CVD Technique for inco nickel foam production[J]. Advanced Engineering Materials, 2004, 6(6): 454-459.

[15] OCHIAI S, NAKANO S, FUKAZAWA Y, ALY M S, OKUDA H, KATO K, ISOBE T, KITA K, HONMA K. Tensile deformation and failure behavior of open cell nickel and copper foams[J]. Materials Transactions, 2010, 51(4): 699-706.

[16] GULSOY H O, GERMAN R M. Production of micro-porous austenitic stainless steel by powder injection molding[J]. Scripta Materialia, 2008, 58(4): 295-298.

[17] 刘 源, 李言祥, 刘润发, 周 荣, 蒋业华, 黎振华. 连铸法Gasar工艺中抽拉速率对多孔金属结构影响的理论分析[J]. 金属学报, 2010, 46(2): 129-134.

LIU Yuan, LI Yan-xiang, LIU Run-fa, ZHOU Rong, JIANG Ye-hua, LI Zhen-hua. Theoretical analysis on effect of transference velocity on structure of porous metals fabricated by continuous casting Gasar process[J]. Acta Metallurgica Sinica, 2010, 46(2): 129-134.

[18] GADOT B, MARTINEZ O R, ROSCOAT S R D, BOUVARD D, RODNEY D, Orgéas L. Entangled single-wire NiTi material: A porous metal with tunable superelastic and shape memory properties[J]. Acta Materialia, 2015, 96: 311-323.

[19] PANG Q, WU G H, XIU Z Y, CHEN G Q,SUN D L. Synthesis and mechanical properties of open-cell Ni-Fe-Cr foams[J]. Materials Science and Engineering A, 2012, 534: 699-706.

[20] BOONYONGMANEERAT Y, SCHUH C A, DUNAND D C. Mechanical properties of reticulated aluminum foams with electrodeposited Ni-W coatings[J]. Scripta Materialia, 2008, 59(3): 336-339.

[21] 李 宇, 沈 伟, 赵 鹏, 浦玉萍. 泡沫铜压缩屈服强度有限元计算方法[J]. 粉末冶金技术, 2017, 35(1): 3-9.

LI Yu, SHEN Wei, ZHAO Peng, PU Yu-ping. Finite element analysis for the yield strength of copper foam[J]. Powder Metallurgy Technology, 2017, 35(1): 3-9.

[22] HOU G Y, WU C S, TANG Y P, SUN L Y, CAO H Z, ZHENG G Q. Effects of surface aluminizing on structure and compressive strength of Fe foam prepared by electrodeposition[J]. Materials Science and Engineering A, 2014, 602(4): 33-40.

[23] 张秋利, 杨志懋, 丁秉钧. 电沉积法制备泡沫金属铜[J]. 有色金属工程, 2009, 61(1):30-32.

ZHANG Qiu-li, YANG Zhi-mao, DING Bing-jun. Copper foam preparation by electrodeposition[J]. Nonferrous Metals, 2009, 61(1): 30-32.

[24] GOLABGIR M H, EBRAHIMIKAHRIZSANGI R, TORABI O, TAJIZADEGAN H, JAMSHIDI A. Fabrication and evaluation of oxidation resistance performance of open-celled Fe(Al) foam by space-holder technique[J]. Advanced Powder Technology, 2014, 25(3): 960-967.

[25] DIOLOGENT F, COMBAZ E, LAPORTE V, GOODALL R, WEBER L, DUC F, MORTENSEN A. Processing of Ag-Cu alloy foam by the replication process[J]. Scripta Materialia, 2009, 61(4): 351-354.

[26] 黄 粒, 杨东辉, 王 辉, 叶 丰, 吕昭平. 钪锆元素增强泡沫铝合金的压缩和吸能性能[J]. 中国有色金属学报, 2014, 24(3): 718-724.

HUANG Li, YANG Dong-hui, WANG Hui, YE Feng, LU Zhao-ping. Improving compressive strength and energy absorption properties of cellular Al foams alloyed with Sc and Zr[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(3): 718-724.

[27] 刘新华, 姚 迪, 刘雪峰, 谢建新. 藕状多孔铜沿垂直于气孔方向的压缩变形行为与本构关系[J]. 中国有色金属学报, 2009, 19(7): 1237-1244.

LIU Xin-hua, YAO Di, LIU Xue-feng, XIE Jian-xin. Deformation behaviors and constructive relation of lotus-type porous copper under compressive direction perpendicular to pores[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(7): 1237-1244.

[28] PARK J S, HYUN S K, SUZUKI S, NAKAJIMA H. Effect of transference velocity and hydrogen pressure on porosity and pore morphology of lotus-type porous copper fabricated by a continuous casting technique[J]. Acta Materialia, 2007, 55(16): 5646-5654.

[29] SHIN H C, DONG J, LIU M. Nanoporous structures prepared by an electrochemical deposition process[J]. Advanced Materials, 2003, 15(19): 1610-1614.

[30] 周颖华, 岑树琼, 李则林, 牛振江. 电沉积三维多孔Pt/SnO2薄膜及其对甲醇的电催化氧化[J]. 化学学报, 2007, 65(23): 2669-2674.

ZHOU Yin-hua, CEN Shu-qiong, LI Ze-lin, NIU Zhen-jiang. Electrodeposition of Pt/SnO2 films with three-dimensional pores for electrocatalytic oxidation of methanol[J]. Acta Chimica Sinica, 2007, 65(23): 2669-2674.

[31] CHAWLA N, DENG X. Microstructure and mechanical behavior of porous sintered steels[J]. Materials Science and Engineering A, 2005, 390(1/2): 98-112.

[32] 刘培生. 泡沫金属双向承载的力学模型[J]. 中国有色金属学报, 2006, 16(4): 567-574.

LIU Pei-sheng. Mechanical model for metallic foams under biaxial loads[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(4): 567-574.

[33] QUEHEILLALT D T, KATSUMURA Y, WADLEY H N G. Synthesis of stochastic open cell Ni-based foams[J]. Scripta Materialia, 2004, 50(3): 313-317.

[34] HYUN S K, NAKAJIMA H, BOYKO L V, SHAPOVALOV V I. Bending properties of porous copper fabricated by unidirectional solidification[J]. Materials Letters, 2004, 58(6): 1082-1086.

[35] YANG L, WU X, WENG D. Study of oxidation-resistant NiCrAl-Al coatings co-deposited by electrophoresis on nickel foams[J]. Scripta Materialia, 2006, 55(1): 107-110.

[36] NAM D H, KIM R H, HAN D W, KIM J H, KWON H S. Effects of (NH4)2SO4 and BTA on the nanostructure of copper foam prepared by electrodeposition[J]. Electrochimica Acta, 2011, 56(25): 9397-9405.

[37] PORTELA A L, TEIJELO M L, LACCONI G I. Mechanism of copper electrodeposition in the presence of picolinic acid[J]. Electrochimica Acta, 2006, 51(16): 3261-3268.

[38] LU Y, GENG S, SHI Z. Effect of pH of the galvanic bath on electrodeposition of Cu-Mn3O4, composite coatings[J]. Materials Chemistry and Physics, 2017, 189: 176-182.

[39] 刘 萌, 郭向飞, 王景明, 江 雷. 不同浸润性多孔电极表面的气泡行为[J]. 物理化学学报, 2012, 28(12): 2931-2938.

LIU Meng, GUO Xiang-fei, WANG Jing-ming, JIANG Lei. Behavior of bubbles on electrodes with hierarchical microporous structures and different wettability[J]. Acta Physico-Chimica Sinica, 2012, 28(12): 2931-2938.

[40] MAITI S K, ASHBY M F, GIBSON L J. Fracture toughness of brittle cellular solids[J]. Scripta Metallurgica, 1984, 18(3): 213-217.

[41] ASHBY M F, MEDALIST R F M. The mechanical properties of cellular solids[J]. Metallurgical Transactions A, 1983, 14(9): 1755-1769.

[42] 黄德彬. 有色金属材料手册[M]. 北京: 化学工业出版社, 2005: 63.

HUANG De-bin. Handbook of ferrous metals materials[M]. Beijing: Chemical Industry Press, 2005: 63.

Electrodeposition processing and mechanical properties of porous Cu

LI Xing-wu, RUAN Ying, WEI Bing-bo

(Department of Applied Physics, School of Natural and Applied Sciences, Northwestern Polytechnical University, Xi’an 710072, China)

Abstract: Three dimensional open-cell porous Cu was prepared by electrodeposition. The effects of experimental parameters on its morphology, structure and mechanical properties were studied. The results show that the porous Cu with apparent density within the range of 0.119-0.218 g/cm3, average pore size of 2.6 mm and the porosity within the range of 89.8%-92.6% are achieved. During the electrodeposition, a stronger cathode polarization can be obtained by reducing the CuSO4 concentration and solution temperature. Meanwhile, the porosity and apparent density of porous Cu can be controlled by the current density and deposition time. The deformation process of porous Cu can be divided into the early linear elastic stage, the next brittle failure stage and the last densification stage. The relationship between apparent density and compressive strength satisfies the power function. Moreover, the compressive strength is improved by 53% once extending the deposition time from 3 h to 5 h at 36 A/m2.

Key words: porous Cu; electrodeposition; porosity; apparent density; mechanical property

Foundation item: Projects(U1806219, U1660108, 51327901) supported by the National Natural Science Foundation of China; Project(2016GY-247) supported by the Key Science and Technology Program of Shaanxi Province, China; Project(3102018jgc009) supported by the Fundamental Research Funds for the Central Universities, China

Received date: 2018-01-19; Accepted date: 2018-05-30

Corresponding author: RUAN Ying; Tel: +86-29-88431669; E-mail: ruany@nwpu.edu.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(U1806219,U1660108,51327901);陕西省科技攻关计划项目(2016GY-247);中央高校基本科研业务费专项资金资助项目(3102018jgc009)

收稿日期:2018-01-19;修订日期:2018-05-30

通信作者:阮 莹,教授,博士;电话:029-88431669;E-mail:ruany@nwpu.edu.cn