Trans. Nonferrous Met. Soc. China 23(2013) 2951-2956

Phase evolution of plasma sprayed Al2O3-13%TiO2 coatings derived from nanocrystalline powders

Xue-cheng LU1,2, Dian-ran YAN1, Yong YANG1, Yan-chun DONG1, Ji-ning HE1, Jian-xin ZHANG1

1. College of Materials Science and Engineering, Hebei University of Technology, Tianjin 300130, China;

2. Military Logistics Department, Military Transportation University, Tianjin 300161, China

Received 24 November 2012; accepted 10 June 2013

Abstract: Commercial nanosized alumina and titania particles were selected as raw materials to prepare the blended slurry with composition of Al2O3-13%TiO2 (mass fraction), which were reconstituted into micrometer-sized granules by spray drying, subsequently sintering at different temperatures to form nanostructured feedstock for thermal spraying, and then Al2O3-13%TiO2 nanocoatings were deposited by plasma spraying. The evolution of morphology, microstructure, and phase transformation of the agglomerated powder and as-sprayed coatings were characterized by X-ray diffraction (XRD) and scanning electron microscopy (SEM). The results show that Al2O3 retains the same α phase as the raw material during sintering, while TiO2 changes from anatase to rutile. During plasma spraying, some α-Al2O3 phases solidify to form metastable γ-Al2O3, and the volume fraction of α-Al2O3 decreases as CPSP increases. However, peaks of the TiO2 phase are not observed from the as-sprayed coatings except for the coatings sprayed at the lower CPSP. As the CPSP increases, nanostructured TiO2 is dissolved easily in γ-Al2O3 or χ-Al2O3·TiO2 phase. After heat treatment, γ-Al2O3 in the coatings transforms to α-Al2O3, and rutile is precipitated.

Key words: Al2O3-13%TiO2; nanocrystalline powder; nanocoatings; phase evolution

1 Introduction

In the field of thermal spray, the atmospheric plasma spraying (APS), as a well-established technology, has been widely used to produce various coatings, such as wear, corrosion resistant, hydroxyapatite, and thermal barrier coatings [1]. Plasma spraying ceramic coating technique on metal surface is a promising means to combine advantages of the metal substrate and the ceramic coating, which can simultaneously meet the mechanical properties and environmental service demands, and it has been rapidly developed [2]. However, the application of conventional plasma sprayed ceramic coatings is limited due to their brittleness and poor machining property. The unique properties of nanostructured materials have been reported for both bulk materials and coatings [3]. Plasma sprayed nanostructured ceramic coatings, by taking advantage of properties associated with nanostructures, can improve the performance and durability of conventional plasma sprayed coatings that already have a wide variety of applications in the aerospace, biomedical, automobile and chemical industries [4-7]. For example, nanostructured Al2O3-TiO2 ceramic coatings show much higher wear resistance than the conventional Al2O3-TiO2 coatings [6-8].

The plasma prayed Al2O3-TiO2 nano coatings have been studied on processing, microstructure, interfacial mechanical properties and wear behavior [2-4,6-12]. However, there are few systematic works on the phase evolution of agglomerated Al2O3-13%TiO2 nano- crystalline powder and as-sprayed coatings. In the present study, nanostructured Al2O3-13%TiO2 coatings were prepared by atmosphere plasma spraying nanocrystalline powders, and the evolution of the morphology, microstructure, and phase transformation of the agglomerated powder and as-sprayed coatings were characterized by X-ray diffraction (XRD) and scanning electron microscopy (SEM).

2 Experimental

Commercial nanosized particles of α-Al2O3 with the mean diameter of 50 nm and anatase TiO2 with the mean diameter of 10 nm were used as the starting powders, and the performance parameters of them are shown in Table 1. It is well known that individual nanoparticles cannot be plasma sprayed because of their low mass and inability to be carried in a moving gas stream and deposition on a substrate [13]. So the most important thing using nanoparticles as raw material to generate the nanostructured coatings is to reconstitute individual nanoparticles into sprayable agglomerates, which are large enough for plasma spray deposition. The process of reconstitution consisted of spray drying the slurry that contains nanoparticles in the mass ratio of Al2O3- 13%TiO2, and sintering at high temperature (700-1200 °C).

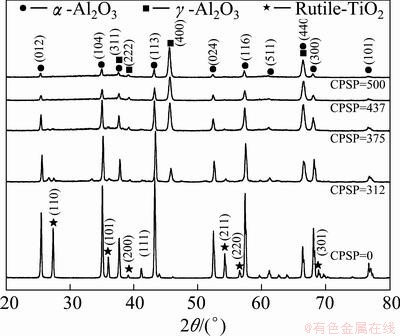

Table 1 Performance parameters of nanopowders

Plasma spraying was performed on a LP-50B plasma-spraying machine made in China. The critical plasma spray parameter (CPSP) is determined by the plasma output power in the numerator and argon gas flow rate in the denominator. Other processing variables, such as carrier gas flow rate, spray distance, flow rate ratio of argon to H2, powder feed rate, gun speed, were held constant in this study. Under these controlled processing conditions, CPSP can be directly related to the temperature of plasma and/or particles.

Mild steel substrate samples (Fe-0.45C-0.3Si- 0.75Mn-0.03P-0.035S, mass fraction, %) with dimensions of 9 mm × 8 mm × 10 mm were grit-blasted and then coated by plasma spraying Ni/Al powders to form a bonding layer about 100 μm in thickness. The nanostructured Al2O3-13%TiO2 coating was deposited by plasma spray using the agglomerated powders and the coating thickness was about 300 μm.

The phase compositions of the agglomerated powder and as-sprayed coatings were examined using PHILIPS X-PertMPD X-ray diffraction (XRD) with Cu Kα radiation. The microstructures were observed on a Philips XL30 scanning electron microscope (SEM).

3 Results and discussion

3.1 Microstructure of nanostructural agglomerated powders

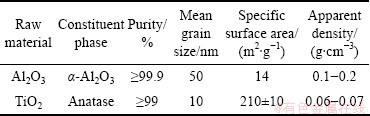

The morphology and line scanning results of the agglomerated Al2O3-13%TiO2 nanocrystalline powders before sintering are shown in Fig. 1. It can be seen from Fig. 1(a) that the agglomerated powders are well spherical and their size ranges from 20 mm to 70 mm, which improves powders feeding behavior during plasma spraying process. Figure 1(b) shows the surface morphology of an agglomerated powder that consists of many small nano-particles combined by the organic binder of PVA. Figure 1(c) shows that the nanosized TiO2 particles are distributed homogeneously within Al2O3 particles.

Fig. 1 SEM image (a), high magnification image of surface morphology (b) and line scanning result (c) of agglomerated Al2O3-13%TiO2 powders

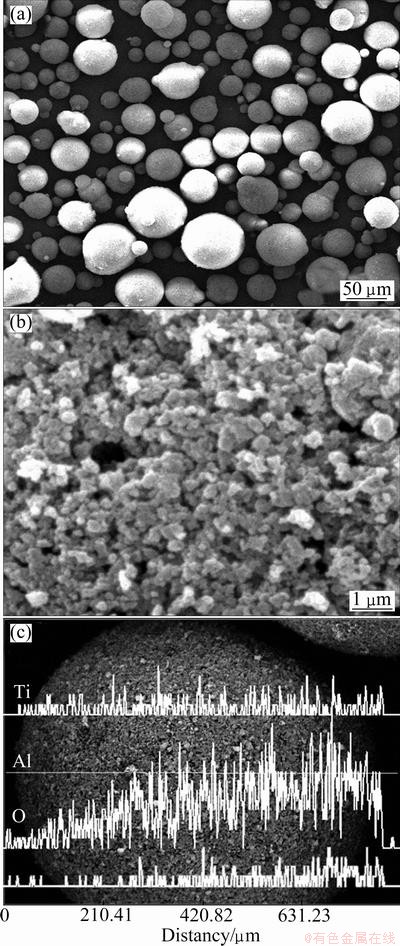

SEM images of agglomerated Al2O3-13%TiO2 powder sintered at different temperature are shown in Fig. 2. It demonstrates that the nano-particles grow into 100-300 nm in size, and the nano-particles connect together, indicating that sintering of the nano-particles occurs after the organic binder of PVA is burnt. As the sintering temperature increases, the nano-particles grow from nano-size to sub-micron or micron size, and more obvious necking exists between nano-particles due to sintering effect, which improves the strength of connection between nanoparticles, necessary for plasma spraying.

Fig. 2 SEM images of agglomerated Al2O3-13%TiO2 nanocrystalline powder sintered at temperature of 700 °C (a), 900 °C (b) and 1100 °C (c)

3.2 Phase evolution of nanostructural agglomerated powders during sintering

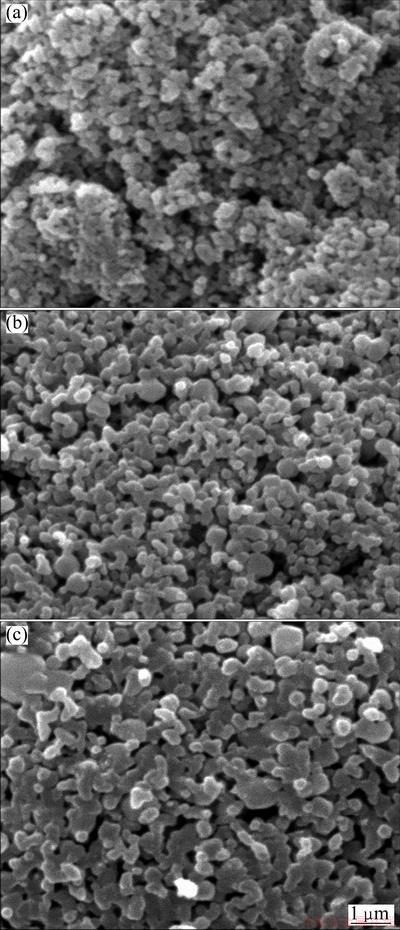

Figure 3 presents the XRD patterns of agglomerated Al2O3-13%TiO2 nanocrystalline powders before and after sintering. It can be seen that Al2O3 retains the same α phase as the raw material after sintering, while TiO2 changes from anatase to rutile due to an irreversible phase transition occurring at 610 °C [6]. And the reaction does not occur between alumina and titania to generate a new phase.

Fig. 3 XRD patterns for agglomerated Al2O3-13%TiO2 nanocrystalline powders before and after sintering

3.3 Phase evolution during plasma spraying

To further investigate the phase evolution of agglomerated Al2O3-13%TiO2 nanocrystalline powders during plasma spraying, various spraying parameters (CPSP) were taken. Figure 4 shows the XRD patterns of the nanostructured Al2O3-13%TiO2 coatings sprayed at different CPSP. It can be seen that during plasma processing, the stable α-Al2O3 phase rapidly solidifies to form metastable γ-Al2O3, since γ-Al2O3 forms more easily from the melt than α-Al2O3 at a high cooling rate because of the low interfacial energy between crystal and liquid [14]. Moreover, peaks of α-Al2O3 and γ-Al2O3 are found in XRD patterns from all the as-sprayed coatings. Melting and rapid solidification is the only processing route available for the formation of γ-Al2O3 [10], so the peak of α-Al2O3 is certainly due to the presence of unmelted or partially melted alumina. However, peaks of the TiO2 phase are not observed from the as-sprayed coatings except for the coatings sprayed at lower CPSP (i.e. 312) and only slight TiO2 peaks exist in the crystal planes (110), (101), (211). As mentioned in Ref. [7], the solubility of TiO2 in theα-Al2O3 is negligible, Ti ions are likely to be in the γ-Al2O3 lattice as either an interstitial or substitutional defect. The missing of Ti-containing phase peaks can be attributed to the fact that as the CPSP increases (along with particle/torch temperature), nanostructured TiO2 is easier to dissolve in γ-Al2O3 or χ-Al2O3·TiO2 phase presented in the nanocoatings, which is different from the investigation result of the conventional coatings reported [4,9].

Fig. 4 XRD patterns of nanostructured Al2O3-13%TiO2 coatings sprayed with different CPSP

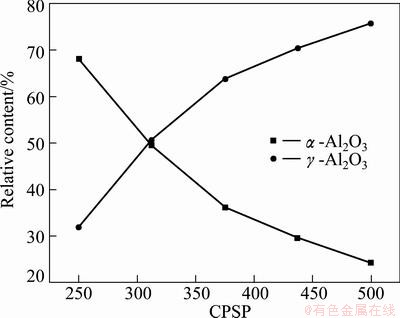

It is also seen from Fig. 4 that the phase component of the coatings is sensitive to the CPSP of the plasma spray gun during production. As the CPSP increases, the intensity of α-Al2O3 (113) peak, which is the main peak of α-Al2O3, decreases, while the intensity of γ-Al2O3 (400) peak increases. According to the results of XRD diffraction, the relative contents of α-Al2O3 and γ-Al2O3 in nanostructured Al2O3-13%TiO2 coating can be quantitatively calculated by direct K value method [7], as shown in Fig. 5. It is clear that as CPSP increases, the volume fraction of α-Al2O3 decreases, conversely, the volume fraction of γ-Al2O3 increases. Based on the above analysis, the phase transformation of the coatings can be controlled by adjusting critical plasma spray parameter (CPSP), meanwhile the microstructure can be changed, ultimately the purpose to improve the properties of the coatings will be attained.

3.4 Microstructure transformation of as-sprayed coatings

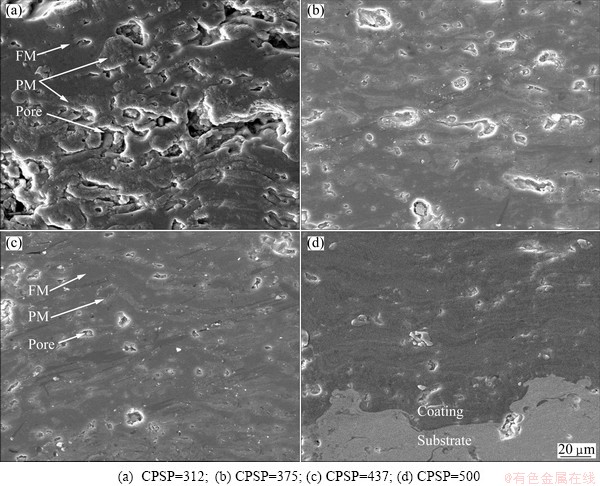

Because the heat input applied to nanopowders increases with increasing CPSP, which is accompanied with higher probability for spray nanopowders to be melted inside the plasma flame, the morphology and microstructure transformation of the coatings can reveal the melting state during plasma spraying at different CPSP, which accords with the phase evolution rule.

Fig. 5 Relative contents of α-Al2O3 and γ-Al2O3 in nanostructured Al2O3-13%TiO2 coating as function of CPSP

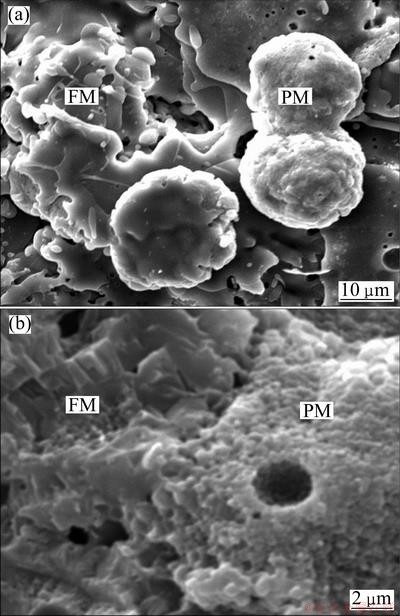

Figure 6 presents SEM images of the cross-section of the nanostructured Al2O3-13%TiO2 coatings sprayed at different CPSP. In all the coatings, some pores are observed because of the technology characteristics of plasma spraying. And the nanostructured coatings all exhibit a particular bimodal microstructure feature, consisting of unmelted or partially melted regions (bright-gray colored, marked with PM in Fig. 6) and fully melted regions (dark-gray colored, marked with FM in Fig. 6). During the process of plasma spraying, a large amount of nanoparticles are fully melted because of high temperature of flames (more than 104 K). These melting droplets struck the surface of the substrates or the as-sprayed coatings to form micron-sized lamellar structure under the action of high speed flames. Simultaneously, high speed flames are too fast to melt a part of nanoparticles completely, hence forming the partially melted regions consisting of nanoparticles. Therefore, the as-sprayed nanostructured ceramic composite coatings are composed of lamellar structure and partially unmelted nanoparticles, which can be clearly and detailedly seen from Fig. 7. It is believed that the unique bimodal microstructure contributes to the significantly enhanced mechanical properties of the nanostructured coatings.

Fig. 6 Cross sectional SEM images of nanostructured Al2O3-13%TiO2 coatings sprayed at different CPSP

Fig. 7 High magnification SEM images of top surface (a) and fracture surface (b) of nanostructured Al2O3-13%TiO2 coating sprayed at CPSP=437

It is obvious that increasing the CPSP makes more powders fully molten; hence reducing the proportion of the unmelted or partially melted regions in the nanostructured coatings, reducing the proportion and size of the pore, and the coating becomes denser and more uniform at the same time. It can be concluded that the plasma spray parameter (CPSP) plays an essential role in adjusting and controlling the microstructure of the coatings.

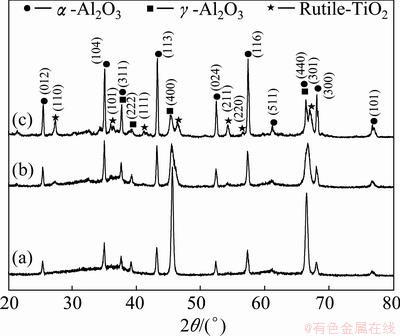

3.5 Phase evolution of as-sprayed coatings with post heat treatment

It was reported that γ-Al2O3 in as-sprayed Al2O3- 13%TiO2 coatings is a metastable phase, and it can easily transform to α-Al2O3 in a certain environment or heat treatment process [13]. It can be seen from Fig. 8 that, when the Al2O3-13%TiO2 nano coatings were heat treated at different temperatures, the diffraction peak of α-Al2O3 stable phase were significantly enhanced, while the diffraction peaks of γ-Al2O3 metastable phase were relatively weakened, and the diffraction peaks of rutile phase appeared, indicating that certain amount of γ-Al2O3 transformed to α-Al2O3 and TiO2 phase precipitated during heat treatment. Because of stresses associated with the volume change, the phase transformation will deteriorate thermal shock resistance of the coatings. The higher the heating temperature is, the larger the diffraction peak intensity ratio of α-Al2O3 (113) to γ-Al2O3 (400) ( ) is, and the more the γ-Al2O3 transforms to α-Al2O3. Then the greater stress will be induced, so that the coating will show a worse performance of thermal shock [15].

) is, and the more the γ-Al2O3 transforms to α-Al2O3. Then the greater stress will be induced, so that the coating will show a worse performance of thermal shock [15].

Fig. 8 XRD patterns of Al2O3-13%TiO2 coating (a) and heat treated coatings at temperatures of 900 °C (b) and 1000 °C (c)

4 Conclusions

1) Agglomerated Al2O3-13%TiO2 nanocrystalline powders were prepared by spray drying, and Al2O3 retained the same α phase as the raw material during sintering, while TiO2 changed from anatase to rutile during sintering. The reaction did not occur between alumina and titania to generate a new phase.

2) When the nanostructured Al2O3-13%TiO2 feedstocks were plasma sprayed on the steel, some α-Al2O3 solidified to form metastable γ-Al2O3, and the volume fraction of α-Al2O3 decreased as CPSP increased. However, the peaks of TiO2 phase were not observed from the as-sprayed coatings except for the coatings sprayed at the lower CPSP. As the CPSP increased, nanostructured TiO2 was be dissolved easily in γ-Al2O3 or χ-Al2O3·TiO2 phase presented in the nanocoatings. The microstructure can be changed because the phase transformation of the coating can be controlled by adjusting critical plasma spray parameter (CPSP).

3) After heat treatment, γ-Al2O3 in the coatings transformed to α-Al2O3, and rutile will be precipitated.

References

[1] SHAN Y G, WANG Y L, COYLE T. Analysis of deposits formation in plasma spraying with liquid precursors [J]. Applied Thermal Engineering, 2013, 51: 690-697.

[2] WANG Dong-sheng, TIAN Zong-jun, SHEN Li-da, LIU Zhi-dong, HUANG Yin-hui. Microstructural characteristics and formation mechanism of Al2O3-13%TiO2 coatings plasma-sprayed with nanostructured agglomerated powders [J]. Surface & Coatings Technology, 2009, 203: 1298-1303.

[3] SONG R G, WANG C, JIANG Y, LI H, LU G, WANG Z X. Microstructure and properties of Al2O3/TiO2 nanostructured ceramic composite coatings prepared by plasma spraying [J]. Journal of Alloys and Compounds, 2012, 544: 13-18.

[4] DEJANG N, WATCHARAPASORN A. Fabrication and properties of plasma-sprayed Al2O3/TiO2composite coatings: A role of nano-sized TiO2 addition [J]. Surface & Coatings Technology, 2010, 204: 1651-1657.

[5] MONTICELLI C, BALBO A, ZUCCHI F. Corrosion and tribocorrosion behaviour of thermally sprayed ceramic coatings on steel [J]. Surface & Coatings Technology, 2011, 205: 3683-3691.

[6] ZHANG J X, HE J N, DONG Y C, LI X Z, YAN D R. Microstructure and properties of Al2O3-13%TiO2 coatings sprayed using nanostructured powders [J]. Rare Metals, 2007, 26(4): 391-397.

[7] JORDAN E H, GELL M, SOHN Y H, GOBERMAN D, SHAW L, LIANG S, WANG M, XIAO T D, WANG Y, STRUTT P. Fabrication and evaluation of plasma sprayed nanostructured alumina–titania coatings with superior properties [J]. Materials Science and Engineering A, 2001, 301: 80-89.

[8] SONG E P, AHN J, LEE S. Effects of critical plasma spray parameter and spray distance on wear resistance of Al2O3-8%TiO2 coatings plasma-sprayed with nanopowders [J]. Surface & Coatings Technology, 2008, 202: 3625-3632.

[9] YILMAZ R, KURT A O, DEMIR A. Effects of TiO2 on the mechanical properties of the Al2O3-TiO2 plasma sprayed coating [J]. Journal of the European Ceramic Society, 2007, 27(2): 1319-1323.

[10] ZHANG J X, HE J N, DONG Y C, LI X Z, YAN D R. Microstructure characteristics of Al2O3-13%TiO2 coating plasma spray deposited with nanocrystalline powders [J]. Journal of Materials Processing Technology, 2008, 197(1-3): 31-35.

[11] WEI Z Y, YE H. Microstructure and property of nanostructured Al2O3-13%TiO2 coatings prepared by plasma spraying [J]. Transactions of Materials and Heat treatment, 2009, 30(2): 146-151.

[12] WANG Dong-sheng, TIAN Zong-jun, SHEN Li-da, LIU Zhi-dong, HUANG Yin-hui. Microstructure and formation mechanism of plasma-sprayed nanostructured composite ceramic coatings [J]. The Chinese Journal of Nonferrous Metals, 2009, 19(1): 77-83. (in Chinese)

[13] WANG Y, TIAN W, YANG Y. Thermal shock behavior of nanostructured and conventional Al2O3-13%TiO2 coatings fabricated by plasma spraying [J]. Surface & Coatings Technology, 2007, 201: 7746-7754.

[14] LIN X H, ZENG Y, ZHOU X M, DING C X. Microstructure of alumina-3% titania coatings by plasma spraying with nanostructured powders [J]. Materials Science and Engineering A, 2003, 357: 228-234.

[15] LU Xue-cheng, YAN Dian-ran, YANG Yong, HE Ji-ning, DONG Yan-chun. Thermal behavior of nanostructured Al2O3/TiO2 ceramic coatings deposited by plasma spraying [J]. Ordnance Material Science and Engineering, 2011, 33(5): 9-13. (in Chinese).

纳米Al2O3-13%TiO2粉末及其等离子喷涂涂层的相变

路学成1,2,阎殿然1,杨 勇1,董艳春1,何继宁1,张建新1

1. 河北工业大学 材料科学与工程学院,天津 300130;

2. 军事交通学院 军事物流系,天津 300161

摘 要:将商用纳米Al2O3与TiO2粉末混合制浆,通过喷雾造粒技术重构成大颗粒纳米Al2O3-13%TiO2团聚粉体,然后采用不同加热温度进行烧结,制备用于热喷涂的纳米喂料。采用等离子喷涂技术沉积形成纳米涂层。利用XRD和SEM对纳米粉末和涂层的形貌、显微结构和晶相进行表征。结果表明,在烧结过程中纳米氧化铝没有发生相变,而纳米氧化钛则由锐钛矿相转变为金红石相;在等离子喷涂过程中,部分α-Al2O3发生熔化转变为γ-Al2O3,且转变量与喷涂工艺参数有关;而TiO2相只在较低喷涂工艺参数下存在衍射峰,在较高喷涂工艺参数下则以χ-Al2O3·TiO2固溶体存在;涂层在热处理过程中会发生γ-Al2O3向α-Al2O3的转变,且有TiO2相析出。

关键词:Al2O3-13%TiO2;纳米粉末;纳米涂层;相变

(Edited by Hua YANG)

Foundation item: Projects (51072045, 51102074) supported by the National Natural Science Foundation of China

Corresponding author: Dian-ran YAN; Tel: +86-22-26564581; E-mail: yandianran@126.com

DOI: 10.1016/S1003-6326(13)62819-8