DOI:10.19476/j.ysxb.1004.0609.2017.12.04

连续柱状晶组织纯铜室温超延展变形机理

吴 恒,张 鸿,吕佳峰,林 超,刘建纲,陈彦旭

(北京科技大学 材料科学与工程学院,北京 100083)

摘 要:通过下引式连续定向凝固设备,调控合理的工艺参数制备出表面光洁、单一<100>取向的柱状晶铜杆。然后经室温拉拔(不经过中间热处理),表现出超延展变形。通过组织观察和性能分析,发现其塑性变形可以分为3个阶段:一般硬化阶段(ε≤4.13),低硬化速率阶段(4.13≤ε≤10.16),部分亚微米等轴晶粒形成阶段(ε≥10.16)。每个阶段的塑性变形行为各有不同,各有其特点。研究结果全面地概括连续柱状晶组织铜杆在室温拉拔过程中的变形机理,同时也为超细铜丝的制备提供必要的理论依据。

关键词:铜杆;连续柱状晶组织;超延展变形;低硬化速率;亚微米等轴晶

文章编号:1004-0609(2017)-12-2426-08 中图分类号:TG249.7 文献标志码:A

连续定向凝固(Continuous unidirectional solidification,CUS)方法是通过加热液-固界面前沿的熔融液相、同时强制冷却已凝固固相,建立单向传热环境,使晶体逆着热流方向强制性生长,通过合理的控制铸型温度、拉铸速度和冷却水量,可获得单晶组织或连续柱状多晶(Continuous columnar grained,CCG)组织的铸锭,该铸锭组织致密,无气孔、缩孔、缩松等铸造缺陷,有利于后续的冷加工,可以减少甚至消除冷加工过程中的中间退火,节约了能源,提高了生产效率[1-3]。与普通多晶组织纯铜相比,连续定向组织纯铜表现出诸多的优点,例如在相同的变形量下,连续柱状晶组织具有更加优良的导电性能,同时伸长率和抗拉强度变化小,具有良好的塑性加工性能[4]。张鸿[5]利用连续定向凝固的方法制备出柱状晶铜杆,结合室温拉拔加工,不经过中间退火处理,最终制备出d 19.7 μm的铜丝,其累计真应变高达13.5,表现出超延展的特性,同时提出强<100>取向是柱状晶组织纯铜室温下优异的塑形延伸变形能力的主要原因,而加工硬化、<111>取向则有利于其强度的提高;GAO等[6]指出具有单一<100>取向的柱状晶铜杆,是其室温拉拔超延展性的必要条件。<100>为软取向织构,其形变储能和加工硬化率低,在变形过程中表现为较低的抗拉强度和流变应力;<111>为硬取向织构,其形变储能和加工硬化率高,在同一变形程度下<111>取向晶粒内的位错密度最高,而<100>取向晶粒内的位错密度最低,所以具有<100>取向的柱状晶组织,有利于获得高的塑性和室温超延展性,而<111>取向组织塑性差,不利于延展变形[2]。CHEN等[7]指出具有<100>取向的单晶铜杆,在大变形过程中,<100>取向会逐渐发生转变,生成<111>取向、<100>取向和其他取向。BAECK等[8]和CHO等[9]在键合铜丝的织构演变研究中指出,铜线材在拉拔至超细丝后,最终会演变成<100>和<111>双纤维织构。

本文作者采用连续定向凝固方法制备出表面光亮,单一<100>取向的柱状晶铜杆,然后进行室温拉拔,中间不经过热处理,直至无法继续拉拔为止,系统地研究了其在塑性变形过程中的变形机制,完善了柱状晶铜杆在室温拉拔变形过程中的塑性变形机理,为高强高导超细铜丝的制备提供参考。

1 实验

采用下引式定向凝固设备制备d 15.8 mm的连续定向凝固铜杆,原料为1号电解铜(纯度为99.97%以上),该设备主要由中频感应加热系统,真空及氩气保护系统、冷却系统、牵引机构等组成。然后对铸态铜杆进行室温拉拔,先采用链式拉拔机和卧式卷筒拉丝机进行粗拉,接着采用立式卷筒拉丝机、Xy-2000C 多模连续小拉机和Xy-2000多模连续细拉丝机进行细拉,最后采用Xy-2001多模连续微拉丝机进行精拉,得到d 30 μm的微丝。

采用型号为D/MAX-RB的X射线衍射仪对铸态铜杆进行取向测试,采用金相显微镜、LEO-1450扫描电镜和JEM-2010透射电镜观察不同拉拔态铜丝的组织、形貌和微观结构。拉伸性能测试参照《金属材料室温拉伸试验方法》(GB/T228)和《有色金属细丝拉伸试验方法》(GBT 10573—1989),将试样加工为标准样,采用WDW-200D微机电子万能材料试验机和YG001A电子单纤维强力机测试各试样的抗拉强度、断后伸长率。导电性能测试选用TH251.23型号数字灵敏微欧表,将直径大于2 mm试样加工成规格为2 mm×2 mm×20 mm的电阻条,直径较小的则采用原样品。金相试样的腐蚀试剂采用为FeCl3酒精溶液,配比为三氯化铁和酒精的液固比为1 g:20 mL,侵蚀时间为50~60 s。

2 结果与分析

2.1 铸态铜杆的取向

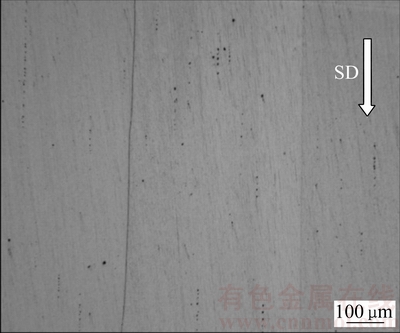

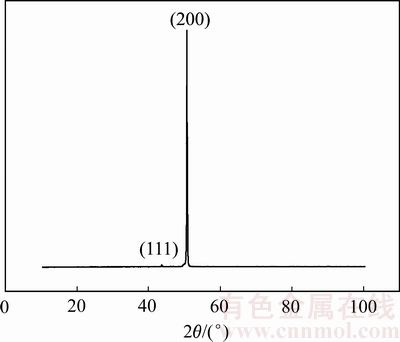

图1和2所示分别为铜杆的金相照片和XRD取向图。

从图1金相照片可以看出,铜杆由连续柱状晶组成,且晶界较为平直,为观察其取向性,借助XRD进一步测定,结果如下所示。

图1 铜杆的金相照片(SD为凝固方向)

Fig. 1 Metallographic figure of copper rod (SD is solidification direction)

从图2可以看出,铜杆主要为<100>取向晶粒,同时含有很少的<111>取向,这是由于不同的取向生长速度不同,针对面心立方金属<100>取向晶粒生长速度最快、<110>的次之、<111>的最慢[10]。因此,在晶粒竞争生长过程中,<100>取向晶粒会逐步占据优势,最终会生成只含有<100>取向的晶粒。综合金相观察和XRD检测的结果可以得出,定向凝固的d 15.8 mm铜杆取向单一,为强的<100>取向。

图2 铜杆的XRD取向图

Fig. 2 XRD orientation map of copper rod

2.2 粗拉和细拉过程中的显微组织和微观结构的演变

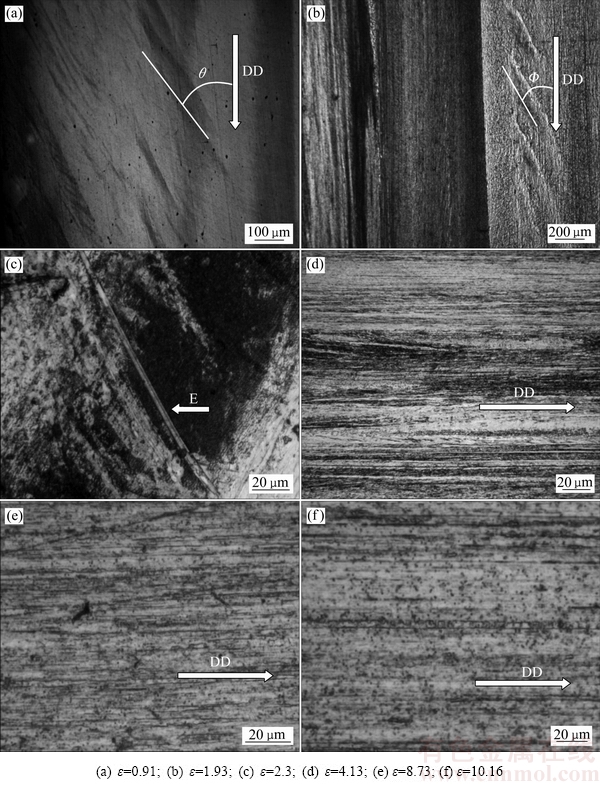

当真应变由ε=0增大至ε=10.16时(ε均为累积真应变)试样的显微组织演变如图3所示,宏观上,柱状晶金属经塑性变形后与多晶体金属相似,晶粒发生宏观分裂现象,不同滑移系开动后,组织中可观察到形变带的出现,形成不同取向的基体带,基体带间为过渡带,过渡带内有较多且连续的晶体转动,以保持晶体取向的连续性和变形的持续性[11]。

整个变形过程中,宏观形貌主要是粗大柱状晶向纤维晶发展,以及纤维晶逐渐细化的过程。当ε=0.91时,晶粒分裂破碎不明显,线材表层开始出现形变带,图3(a)所示,形变带与拉拔方向之间的夹角θ大致呈45°。随着变形加深,当ε=1.93时,中心晶粒也开始分裂,出现形变带,原晶界逐渐模糊,图3(b)所示形变带与拉拔方向之间的夹角Φ大致呈30°,越靠近表层,形变带越模糊,且呈现出纤维晶的特征,形变带与拉拔方向之间的夹角逐渐减小[12-13]。当ε=2.3时,变形组织中发现了孪晶,图3(c)中白色箭头E所指。陈建等[14]在单晶铜杆室温拉拔的研究中发现,当ε为0.94、1.39、1.96时,组织中观察到少量的形变孪晶;GAO等[6]在柱状晶铜杆室温拉拔的研究中表明,当ε=1.16时,组织中观察到形变孪晶。对于滑移系众多的中高层错能面心立方金属铜而言,孪生所需的临界切应力要比滑移的大的多,形变孪晶的出现与变形过渡阶段的局部剪切变形以及切变带的形成有关。当ε=4.13时,晶粒已破碎并形成纤维晶结构,其方向与拉拔方向大致平行,图3(d)所示。随着变形量的进一步增大,纤维晶的宽度逐渐减小,组织不断地细化,具体如图3(e)和(f)所示。

图3 拉拔态铜线材的显微组织(DD为拉拔方向)

Fig. 3 Microstructures of drawing-state copper wires (DD is drawing direction)

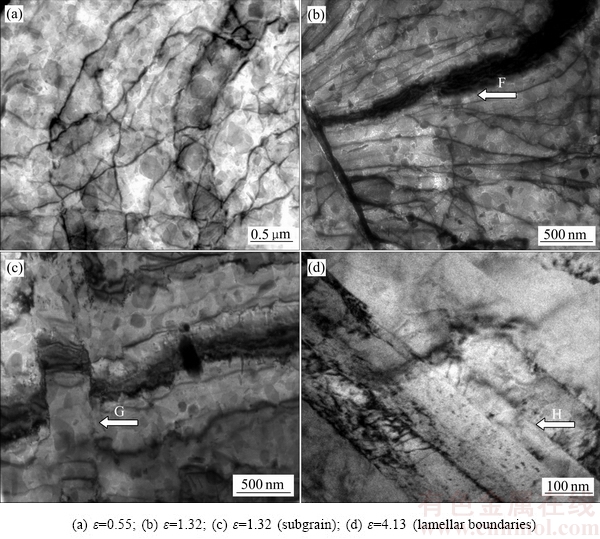

当真应变由ε=0增大至ε=4.13时,位错组态发生了很大的变化,图4(a)滑移位错缠结成稠密位错墙,产生大量次生界面,引起加工硬化。当变形进一步增加时(ε=1.32),发现晶粒内的位错网络增加,且逐渐向晶界处靠拢,如图4(b)所示,这些位错网都终止于晶界处,白色箭头F所指。随着累积真应变的增加,位错不断在晶界处聚集,当位错在晶界处聚集到一定程度时,会造成很大的应力集中,在随后的变形中,分裂优先在应力集中严重的晶界处产生,从而形成亚晶,如图4(c)白色箭头G所指。随着变形的进一步增加(ε=4.13),如图4(d)所示,形成了层状界面的位错组态,白色箭头H所指,层状界面间的位错密度较低,且具有较大的界面间距,其可以承载大量的滑移位错,随着变形量的进一步增加,其层状界面的厚度变薄,同时界面间距减小、界面取向差增大、界面取向差分布变广[2, 15-16]。

图4 拉拔态铜线材位错组态特征

Fig. 4 Dislocation configuration feature of drawing-state copper wires

综合考虑拉拔过程中显微组织和微观结构的演变,0≤ε≤10.16的塑性变形机制可以分为一般变形阶段(0≤ε≤4.13)和大变形阶段(4.13≤ε≤10.16)两种情况,一般变形阶段表现为随着应变量的增加,位错不断增值,其密度不断增加,开始形成稠密位错墙和大量次生界面,进而诱发亚晶和孪晶的生成;大变形阶段表现为随着应变量的增加,动态回复明显,大量滑移位错不断形成新的层状界面,以及随后在层状界面上异号位错相遇而发生抵消等过程,从而使位错密度不断地减小,位错的增值速率和消亡速率趋于平衡[17],该阶段主要是层状界面的演化与发展[18-20]。

2.3 超细丝拉拔阶段的显微组织

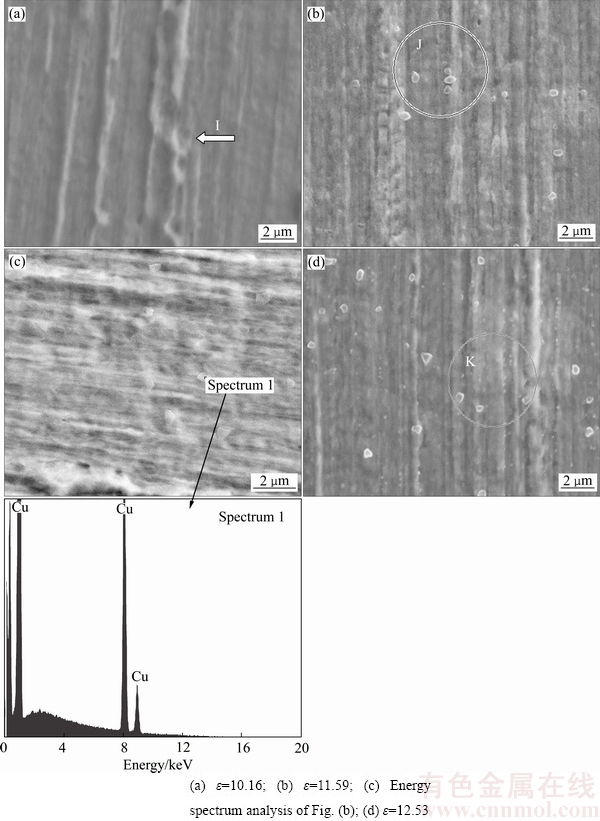

极大变形阶段(ε≥10.16)的纵截面组织和能谱分析如下图5所示,图5(a)中可以看到细长的纤维晶组织,同时部分纤维晶周围出现连续的小突起,白色箭头I所指;图5(b)中发现有一些细小的等轴晶粒,白色圆圈J所示,通过能谱分析发现其成分为铜,排除杂质的可能,初步推断其是在拉拔变形中形成的;图5(d)中发现这种小等轴晶逐渐增多,同时尺寸也进一步变小,在几百纳米之间,白色圆圈K所示,所以可以断定这些小等轴晶是铜杆在极大拉拔变形过程中发生动态再结晶形成的,即连续柱状晶铜杆在室温下经过极大的拉拔变形发生了部分动态再结晶[21-24]。由图5的形貌可知,铜线材的纤维晶仍在不断地细化。

所以,在极大变形阶段,其组织演变相对于大变形阶段发生了变化,有亚微米等轴晶粒的生成。

2.4 力学性能

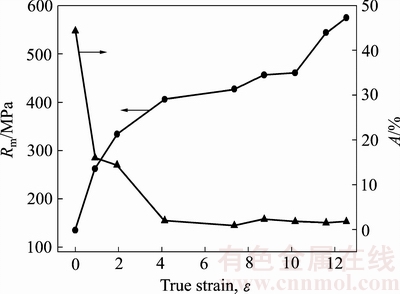

不同变形程度下线材的力学性能如图6所示。在一般变形阶段,抗拉强度随变形的增大迅速增加,同时伸长率显著下降。在大变形阶段,抗拉强度随变形程度的增大缓慢增加,以低加工硬化速率持续硬化。在极大变形阶段,抗拉强度随变形的增大,又明显增加,表明微丝的组织发生了变化,有亚微米等轴晶粒生成,其晶界对位错运动有较强的阻碍作用。当真应变ε=12.53时,微丝的抗拉强度高达565.36 MPa,是铸态铜杆抗拉强度(135.00 MPa)的4.26倍。同时,柱状晶铜杆在大变形和极大变形阶段,其伸长率总体较低且几乎保持不变。

图5 拉拔态铜线材纵截面组织以及能谱分析图

Fig. 5 Microstructure and energy spectrum analysis figure of longitudinal section of drawing-state copper wires

图6 不同真应变下铜线材的力学性能

Fig. 6 Mechanics properties of copper wires at different true strains

2.5 导电性能

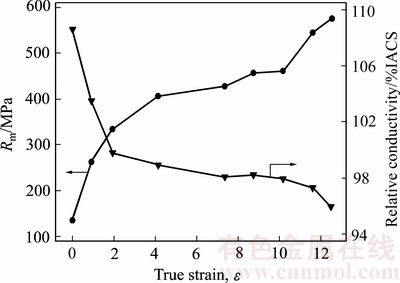

不同变形程度下线材在20 ℃下的导电率如图7所示。在一般变形阶段,导电率随变形的增大而显著降低。在大变形阶段,导电率为97.94%IACS~ 98.92%IACS,随变形的增大其导电率几乎保持不变。在极大变形阶段,导电率又开始下降,这也表明微丝的组织发生了变化,有亚微米等轴晶粒生成,其晶界对电子的散射作用增强。

综上所述可知,连续柱状晶组织纯铜杆在室温拉拔变形过程中,其力学性能和导电性能呈现出一定的规律。一般变形阶段,抗拉强度显著增加,伸长率和导电率显著减小,显微组织表现为柱状晶在变形过程中先后发生晶粒拉长、晶粒分裂与纤维化;大变形阶段,抗拉强度缓慢增加,伸长率和导电率几乎保持不变,显微组织表现为纤维晶不断地细化、层状界面逐渐变薄和界面取向差增大;极大变形阶段,抗拉强度又明显增加,导电率又开始下降,伸长率仍保持不变,显微组织表现为纤维晶进一步细化,同时伴随着亚微米等轴晶粒的生成。

图7 不同真应变下铜线材的强度和电导率

Fig. 7 Strength and conductivity of copper wires at different true strains

3 讨论

通过对连续柱状晶纯铜杆室温拉拔过程中的组织、力学性能和导电性能的研究,发现其在变形过程中存在临界变形量K1(ε1=4.13)和K2(ε2=10.16),当累积真应变小于K1时,连续柱状晶纯铜杆以位错滑移和孪生进行塑性变形;当累积真应变超过K1后,连续柱状晶纯铜杆能够承载超延展变形所产生的大量滑移位错,当位错塞积到一定程度后,便开始形成层状界面,界面运动、滑移和流变可以吸收高密度的位错,但同时界面上也存在异号位错的抵消过程,二者趋于平衡,导致抗拉强度略有增加,以低加工硬化速率持续硬化,同时伸长率和导电率基本保持不变。但当累积真应变超过K2后,层状界面也无法承载大量高密度的位错,薄片状界面达到饱和,为了使材料进一步发生塑性变形,故而需要降低位错密度,开始发生部分动态再结晶,伴随亚微米等轴晶粒生成。MA等[19]、WANG等[25]和陈亮维等[26]也指出在大的拉拔塑性变形过程中,存在临界变形量K,当变形量超过K时,织构<111>/<100>的比值基本保持不变,即取向保持不变。

所以室温下连续柱状晶组织纯铜杆拉拔超延展变形可以分为3个阶段:1) 一般硬化阶段( ≤4.13),柱状晶破碎,晶粒转动、拉长,晶界模糊,逐渐形成纤维晶和层状界面结构,这一阶段的变形机制为位错滑移和孪生;2) 低硬化速率阶段(4.13≤

≤4.13),柱状晶破碎,晶粒转动、拉长,晶界模糊,逐渐形成纤维晶和层状界面结构,这一阶段的变形机制为位错滑移和孪生;2) 低硬化速率阶段(4.13≤ ≤10.16),纤维晶宽度逐渐减小,组织不断地细化,层状界面厚度变薄,界面取向差增大,这一阶段的变形机制为层状界面演化和发展;3) 亚微米等轴晶粒形成阶段(

≤10.16),纤维晶宽度逐渐减小,组织不断地细化,层状界面厚度变薄,界面取向差增大,这一阶段的变形机制为层状界面演化和发展;3) 亚微米等轴晶粒形成阶段( ≥10.16),纤维晶进一步细化,层状界面越来越薄,层状界面取向差不断增大,亚微米等轴晶粒出现,这一阶段的变形机制为部分动态再结晶。

≥10.16),纤维晶进一步细化,层状界面越来越薄,层状界面取向差不断增大,亚微米等轴晶粒出现,这一阶段的变形机制为部分动态再结晶。

4 结论

1) 连续柱状晶组织纯铜杆在室温下的良好塑性与超延展变形,与柱状晶在变形过程中先后发生晶粒拉长、晶粒分裂与纤维化,进一步强化其组织异向性密切相关;与初生柱状晶组织相比,形变过程中所形成的大量次生亚结构才是决定变形态柱状晶组织材料力学性能、导电性能以及加工性能的主要原因。

2) 连续柱状晶组织纯铜杆在室温拉拔变形过程中,其力学性能和导电性能呈现出一定的规律:一般变形阶段(ε≤4.13),抗拉强度显著增加,伸长率和导电率显著减小;大变形阶段(4.13≤ε≤10.16),抗拉强度缓慢增加,伸长率和导电率几乎保持不变;极大变形阶段(ε≥10.16),抗拉强度又明显增加,导电率又开始下降,伸长率仍保持不变。

3) 连续柱状晶组织纯铜杆在室温拉拔过程中,其塑性变形经历了3个阶段:一般硬化阶段(ε≤4.13)、低硬化速率阶段(4.13≤ε≤10.16)、部分亚微米等轴晶粒形成阶段(ε≥10.16)。

REFERENCES

[1] 袁 静. 金属连续定向凝固技术[J]. 上海有色金属, 2011, 32(1): 42-44.

YUAN Jing. Continuous unidirectional solidification of metal[J]. Shanghai Nonferrous Metals, 2011, 32(1): 42-44.

[2] 谢建新, 王 宇, 黄海友. 连续柱状晶组织铜及铜合金的超延展变形行为与塑性提高机制[J]. 中国有色金属学报, 2011, 21(10): 2324-2336.

XIE Jian-xin, WANG Yu, HUANG Hai-you. Extreme plastic extensibility and ductility improvement mechanisms of continuous columnar-grained copper and copper alloys[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2324-2336.

[3] 胡 炜, 王彦红, 赵小军, 肖来荣, 饶 博, 章 玮. 热型连铸铝线的制备及其显微组织和性能[J]. 中国有色金属学报, 2015, 25(7): 1882-1889.

HU Wei, WANG Yan-hong, ZHAO Xiao-jun, XIAO Lai-rong, RAO Bo, ZHANG Wei. Preparation of aluminum wire by Ohno continuous casting and its microstructure and properties[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(7): 1882-1889.

[4] 刘美艳, 谢建新, 刘雪峰, 高克玮. 连续柱状晶组织和普通多晶组织纯铜线材性能的对比研究[C]// 2004年材料科学与工程新进展. 北京: 中国材料研究学会, 2004: 1295-1299.

LIU Mei-yan, XIE Jian-xin, LIU Xue-feng, GAO Ke-wei. Research on properties’ difference between pure copper wires with continuous columnar crystal and those with common polycrystalline structures[C]// Materials Science and Engineering Progress in 2004. Beijing: The Chinese Materials Research Society, 2004: 1295-1299.

[5] 张 鸿. 连续纤维晶组织纯铜线材制备的基础研究[D]. 北京: 北京科技大学, 2003: 70-93.

ZHANG Hong. Fundamental research on fabrication for pure copper wires containing fibrous crystals[D]. Beijing: University of Science and Technology Beijing, 2003: 70-93.

[6] GAO K, LIU M, ZOU F L, PANG X L, XIE J X. Characterization of microstructure evolution after severe plastic deformation of pure copper with continuous columnar crystals[J]. Materials Science and Engineering A, 2010, 527(18): 4750-4757.

[7] CHEN J, YAN W, DING R G, FAN X H. Dislocation boundaries in drawn single crystal copper wires produced by Ohno continuous casting[J]. Journal of Materials Science, 2009, 44(8): 1909-1917.

[8] BAECK S M, PARK K K, HA H, OH Y J, PARK Y J, MOON J T, LEE J, OH K H. Texture analysis of copper bonding wire[J]. Materials Science Forum, 2002, 408: 803-808.

[9] CHO J H, ROLLETT A D, CHO J S, PARK Y J, MOON J T,OH K H. Investigation of recrystallization and grain growth of copper and gold bonding wires[J]. Metallurgical and Materials Transactions A, 2006, 37(10): 3085-3097.

[10] 张 鸿, 谢建新, 王自东, 王 浩. 连续定向凝固铜棒及其冷加工后的组织和力学性能[J]. 机械工程材料, 2004, 28(2): 31-33.

ZHANG Hong, XIE Jian-xin, WANG Zi-dong, WANG Hao. Microstructure and mechanical properties of continuous unidirectional solidification copper bar and cold processed wires[J]. Materials for Mechanical Engineering, 2004, 28(2): 31-33.

[11] 刘 润, 王军丽, 周 蕾, 史庆南. 异步叠轧法制备超细晶铜的组织及性能[J]. 材料热处理学报, 2013, 34(3): 78-83.

LIU Run, WANG Jun-li, ZHOU Lei, SHI Qing-nan. Microstructure and properties of ultra-fine-grained copper prepared by asymmetrical accumulative rolling bonding[J]. Transactions of Materials and Heat Treatment, 2013, 34(3): 78-83.

[12] WULFF F, BREACH C D, DITTMER K. Crystallographic texture of drawn gold bonding wires using electron backscattered diffraction (EBSD)[J]. Journal of Materials Science Letters, 2003, 22(19): 1373-1376.

[13] PAUL H, DRIVER J H, MAURICE C,JASIENSKI Z. Shear band microtexture formation in twinned face centred cubic single crystals[J]. Materials Science and Engineering A, 2003, 359(1): 178-191.

[14] 陈 建, 严 文, 苗 健, 彭渝莉, 范新会.OCC技术制备的单晶铜线材冷拔组织TEM分析[J]. 稀有金属材料与工程, 2011, 40(10): 1727-1731.

CHEN Jan, YAN Wen, MIAO Jian, PENG Yu-li, FAN Xin-hui. TEM analysis of drawn single crystal copper wires produced by OCC method[J]. Rare Metal Materials and Engineering, 2011, 40(10): 1727-1731.

[15] HUANG C X, WANG K, WU S D, ZHANG Z F, LI G Y, LI S X. Deformation twinning in polycrystalline copper at room temperature and low strain rate[J]. Acta Materialia, 2006, 54(3): 655-665.

[16] SURESH K S, SINHA S, CHAUDHARY A, SUWAS S. Development of microstructure and texture in copper during warm accumulative roll bonding[J]. Materials Characterization, 2012, 70: 74-82.

[17] HUGHES D A, HANSEN N. Microstructure and strength of nickel at large strains[J]. Acta Materialia, 2000, 48(11): 2985-3004.

[18] TSUJI N, HANAZAKI K. Nanostructure formation during deep wire-drawing of copper[J]. Materials Science Forum, 2010, 654: 1201-1204.

[19] MA X G, CHEN J, CHEN Z, WEN Y. Evolution of microstructure and texture of cold-drawn polycrystalline Ag with low stacking fault energy[J]. Science China Technological Sciences, 2015, 58(7): 1146-1153.

[20] HANAZAKI K, SHIGEIRI N, TSUJI N. Change in microstructures and mechanical properties during deep wire drawing of copper[J]. Materials Science and Engineering A, 2010, 527(21): 5699-5707.

[21] SAKAI T, BELYAKOV A, KAIBYSHEV R, MIURA H, JONAS J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions[J]. Progress in Materials Science, 2014, 60: 130-207.

[22] LI Y S, TAO N R, LU K. Microstructural evolution and nanostructure formation in copper during dynamic plastic deformation at cryogenic temperatures[J]. Acta Materialia, 2008, 56(2): 230-241.

[23] 李 祎, 张祥凯, 何克坚, 杨续跃. 层错能对铜合金室温变形及退火过程中晶粒细化的影响[J]. 中国有色金属学报, 2016, 26(1): 66-76.

LI Wei, ZHANG Xiang-kai, HE Ke-jian, YANG Xu-yue. Effect of stack fault energy on grain refinement of Cu alloy during room temperature deformation and subsequent annealing[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(1): 66-76.

[24] 康志新, 彭勇辉, 赖晓明, 李元元, 赵海东, 张卫文. 剧塑性变形制备超细晶/纳米晶结构金属材料的研究现状和应用展望[J]. 中国有色金属学报, 2010, 20(4): 587-598.

KANG Zhi-xin, PENG Yong-hui, LAI Xiao-ming, LI Yuan-yuan, ZHAO Hai-dong, ZHANG Wei-wen. Researches status and application prospect of ultrafine grained and/or nano-crystalline metallic materials processed by severe plastic deformation[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(4): 587-598.

[25] WANG Y, HUANG H Y, XIE J X. Texture evolution and flow stress of columnar-grained polycrystalline copper during intense plastic deformation process at room temperature[J]. Materials Science and Engineering A, 2011, 530: 418-425.

[26] 陈亮维, 史庆南, 陈登权, 王军丽, 谢 明. 叠轧法深度塑性变形铜组织的研究[J]. 昆明理工大学学报(理工版), 2008, 33(6): 11-16.

CHEN Liang-wei, SHI Qing-nan, CHEN Deng-quan, WANG Jun-li, XIE Ming. Research of Severe Plastic deformation microstructures of pure copper produced by accumulative rolling-bonding[J]. Journal of Kunming University of Science and Technology (Science and Technology), 2008, 33(6): 11-16.

Extreme plastic extensibility mechanism of continuous columnar-grained copper at ambient temperature

WU Heng, ZHANG Hong, Lü Jia-feng, LIN Chao, LIU Jian-gang, CHEN Yan-xu

(School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: The smooth surface and single <100> oriented columnar-grained copper rods were prepared by downward continuous unidirectional solidification equipments with reasonable process parameters, then, the copper rods were drawn at ambient temperature (without intermediate heat treatment), which exhibits the extreme plastic extensibility. The results show that the plastic deformation of the copper rod can be divided into three different stages by observation of its microstructure and properties, general hardening stage (ε≤4.13), low hardening rate stage (4.13≤ε≤10.16). Some submicron equiaxed grain forming stage (ε≥10.16). Each stage of the plastic deformation behavior is different and has its own characteristics. Not only the drawing mechanism of continuous columnar-grained copper rods at ambient temperature was comprehensively summarized, but also the necessary theoretical basis for the preparation of ultrafine copper wire was provided.

Key words: copper rod; continuous columnar grains; extreme plastic extensibility; low hardening rate; submicron equiaxed grain

Foundation item: Project(51274265) supported by the National Natural Science Foundation of China

Received date: 2016-05-03; Accepted date: 2017-11-03

Corresponding author: ZHANG Hong; Tel: +86-13691098964; E-mail: zhanghong@ustb.edu.cn

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51274265)

收稿日期:2016-05-03;修订日期:2017-11-03

通信作者:张 鸿,副教授,博士;电话:13691098964;E-mail: zhanghong@ustb.edu.cn