Trans. Nonferrous Met. Soc. China 22(2012) s79-s83

Effects of rolling deformation on microstructure and mechanical properties of network structured TiBw/Ti composites

HUANG Lu-jun, CUI Xi-ping, GENG Lin, FU Yu

National Key Laboratory of Science and Technology on Precision Heat Processing of Metals, Harbin Institute of Technology, Harbin 150001, China

Received 9 July 2012; accepted 30 August 2012

Abstract: TiB whiskers reinforced pure Ti (TiBw/Ti) composites with a novel network microstructure were successfully fabricated by reaction hot pressing (RHP). TiB whiskers are in situ synthesized around the large pure Ti matrix particles, and subsequently formed into TiBw network structure. The novel TiBw/Ti composites with a network microstructure exhibit a superior combination of mechanical properties. In order to further improve the mechanical properties and guide the subsequent plastic forming, the rolling deformation behavior of the novel composites was investigated. The results show that the strength of the novel TiBw/Ti composites can be effectively enhanced by rolling deformation due to the matrix deformation strengthening effect, and increased with increasing the rolling reduction. The strength of 8.5%TiBw/Ti (volume fraction) composite is significantly increased from 842 MPa to 1030 MPa by rolling deformation. It is certain that the TiB whiskers are gradually broken with increasing the rolling reduction, which is harmful to the mechanical properties of the composites.

Key words: titanium matrix composites (TMCs); rolling deformation; reaction hot pressing (RHP); network microstructure; tensile properties

1 Introduction

As a typical member of metal matrix composites (MMCs) family, titanium matrix composites (TMCs) offer a combination of good mechanical properties and high temperature durability that render them attractive materials for automotive, aerospace and military applications [1-6]. In particular, discontinuously reinforced titanium matrix composites (DRTMCs) fabricated by in situ methods such as reaction hot pressing (RHP) and melting technique are sought-after due to their superior and isotropic properties and low cost [5-8].

However, irrespective of which processing method used, the aim is always to achieve a homogeneous microstructure where the reinforcements are uniformly distributed [5-8]. The reality is that many TMCs with a homogeneous microstructure exhibit a limited improvement or inferior mechanical properties particularly for DRTMCs fabricated by the conventional RHP technique, exhibiting extreme brittleness [6-10].

It is encouraging that the ductility of the TiBw/Ti composites is significantly improved by tailoring the TiBw distribution to a novel network microstructure. The network boundary region can exploit a superior strengthening effect of TiBw reinforcement, while the relatively large matrix (TiBw-lean) region contributes positively to the ductility of the composites [11,12]. This work echoes a recent proposal by LU [13] that the overall properties of composites can be further enhanced by assembling metals with other components in a controlled way to form novel multiscale hierarchical structures, compared with a conventional or homogeneous composite structure. It is certain that the subsequent hot deformation can further improve mechanical properties of the composites fabricated by RHP [14]. Therefore, it is significant to investigate the rolling deformation behavior of the novel network structured TiBw/Ti composites in order to further improve their mechanical properties and guide the subsequent plastic forming.

2 Experimental

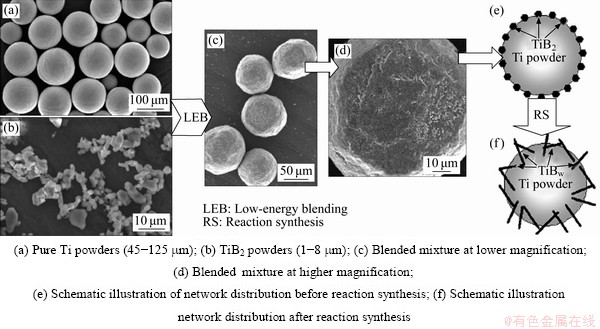

The TiBw/Ti composites with a novel network microstructure were fabricated by RHP based on the system of large spherical Ti powders and fine prismatic TiB2 powders. Firstly, the spherical Ti powders with a large particle size of 45-125 μm (Fig. 1(a)) and the prismatic TiB2 powders with a fine size of 1-8 μm (Fig. 1(b)) are selected. Secondly, the selected two raw material powders are blended at the speed of 150 r/min for 5 h using a planetary blender. The size of large Ti powders is retained by using the low-energy blending. Finally, the blended powder mixtures (Figs. 1(c) and (d)) are reaction hot pressed at 1 200 °C under a pressure of 20 MPa for 1 h. As shown in Figs. 1(e) and (f), TiBw can be in situ synthesized around the large Ti matrix particles according to the following reaction equation (1) [7]:

Ti(s)+TiB2=2TiB(s) (1)

In general, the TiB phase is thermodynamically more stable than TiB2 phase with excess Ti [15]. According to the above reaction equation, 8.5% and 12% TiBw/Ti volume fraction composites are prepared. For comparison, the pure Ti sample is also fabricated using the same processing parameters.

Tensile tests are carried out using an Instron-5569 universal testing machine at a constant crosshead speed of 0.5 mm/min. The tensile specimens have gauge dimensions of 20 mm×5 mm×2 mm and a total of five specimens are tested for each material. Microstructural examination is performed by scanning electron microscopy (SEM, Hitachi S-4700).

3 Results and discussion

3.1 Microstructure of as-sintered composites

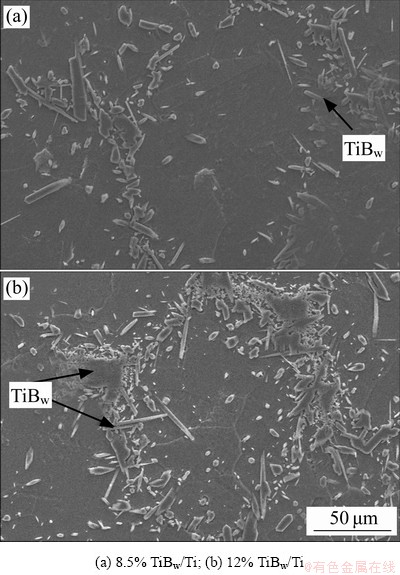

Figure 2 shows the micrographs of the 8.5% and 12%TiBw/Ti composites with a network microstructure. It can be seen from Fig. 2 that the TiBw whiskers are in situ synthesized by network distribution around Ti particles and form a novel network microstructure. Additionally, many TiB whiskers grow into the inside of Ti particles like dowel connectors linking the neighboring Ti particles, which can effectively improve the strength and fracture toughness of TMCs as shown in Fig. 2. Moreover, the local volume fraction of TiBw reinforcement in the network boundary increases with increasing the overall volume fraction. This is positive to improve the strength of the network structured composites. By comparison, many agglomerations are formed in the 12%TiBw/Ti composite, which is possibly positive to strength but certainly negative to the ductility of the composite. The agglomerations are similar to the TiB whisker cluster formed due to the large B4C raw material reported by NI et al [16]. Therefore, the formation of the TiB whisker agglomerations can be attributed to the much high local volume fraction of reinforcement in the network boundary.

3.2 Tensile properties of as-sintered composites

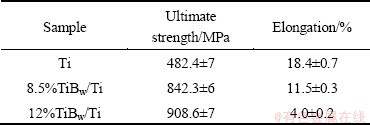

Table 1 shows the tensile properties of the as-sintered pure Ti and TiBw/Ti composites with a network microstructure. The strength of the network structured TiBw/Ti composites is remarkably increased compared with that of pure Ti fabricated using the same parameters, and the strength increases with increasing the volume fraction of TiBw reinforcement. In particular, the ultimate strength (σb) of 12% TiBw/Ti composite is increased by 88%, from about 482 MPa to 908 MPa. The σb of 8.5% TiBw/Ti composite is increased to about 842 MPa or by 75%. The remarkable improvement of strength appears to reveal the most effective strengthening effect for the DRTMCs to date. For the present composites, the remarkable improvement of the strength can be attributed to the tailored network microstructure and the dowel like structures of TiB whiskers. Therefore, the strengthening effect of TiBw reinforcement can be significantly improved by tailoring the network distribution.

Fig. 1 Flow chart showing processing route together with morphologies of raw materials and schematic illustrations of network distribution

Fig. 2 SEM micrographs of TiBw/Ti composites with network microstructure

Table 1 Tensile properties of as-sintered pure Ti and TiBw/Ti composites with novel network microstructure

Additionally, Table 1 also reveals the tensile ductility of the novel composites. For the 8.5% TiBw/Ti composite with a network microstructure, the superior elongation of about 11.5% appears to be the most effective improvement to date, giving the remarkable σb increment of 75%. The superior ductility of the present composites can also be attributed to the tailored network reinforcement microstructure and the dowel-like TiBw structure. On one hand, the large matrix region can effectively restrict the crack propagation, and effectively reduce the crack propagation speed; On the other hand, the large matrix region can effectively bear tensile strain during tensile deformation.

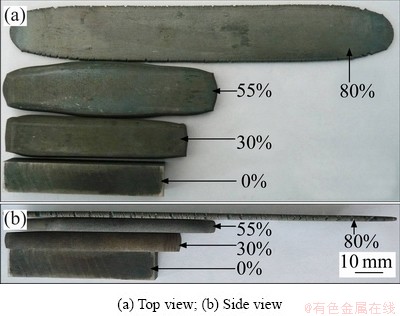

Figure 3 shows the macro images of the composites after rolling deformation. It can be seen that no crack forms before 55% rolling reduction, and just small cracks occur around the edge till 80% rolling reduction. This phenomenon indicates that the prepared composite possesses a good plastic forming ability.

Fig. 3 Macro images of network structured TiBw/Ti composites with different rolling reductions

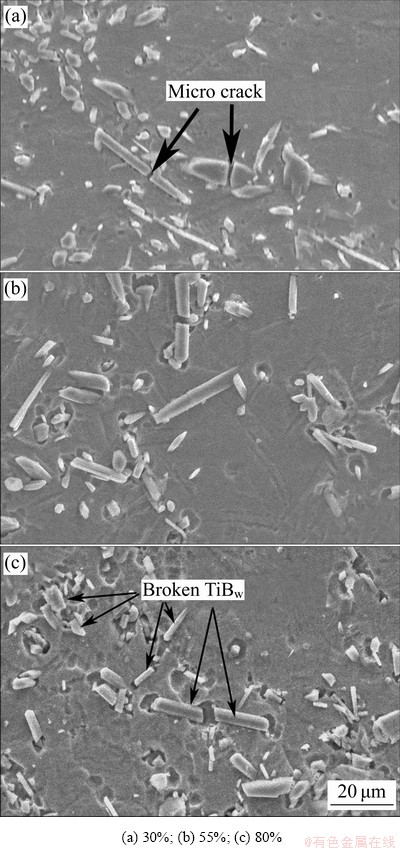

3.3 Microstructure of as-rolled composites

Figure 4 shows the SEM micrographs of the as-rolled 8.5% TiBw/Ti composite with different rolling reductions. The partial TiBw particles undergoing a little deformation are broken, leading to some micro cracks which will serve as the origin of crack during subsequent tensile deformation. However, the distance of the broken segments of TiBw increases with increasing the rolling reduction, which will make the previous micro crack open and be filled by deformed matrix. This can be demonstrated by the remote two broken segments of TiBw and the increasing etched holes caused by residual stress etching around the broken TiBw, as shown in Fig. 4. Therefore, the aspect ratio of TiBw decreases with increasing the rolling reduction, which is beneficial to the toughness or ductility of the composites. The deformation strengthening effect of Ti matrix increases with increasing the rolling reduction, which positively improves the strength of the composites.

Fig. 4 SEM micrographs of as-rolled 8.5%TiBw/Ti composites with different reductions

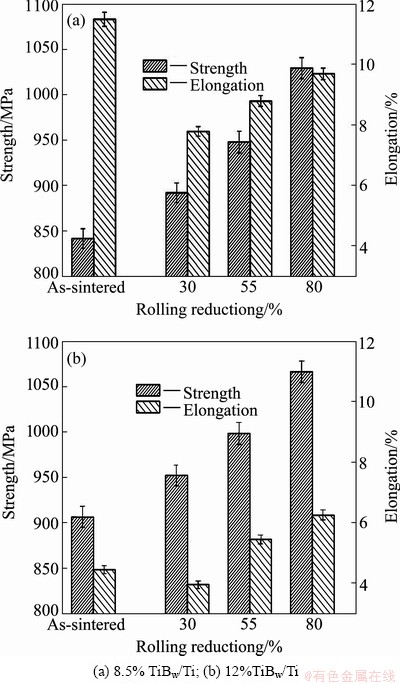

3.4 Tensile properties of as-rolled composites

Figure 5 shows the variations of tensile properties of 8.5% TiBw/Ti and 12%TiBw/Ti composites with increasing the rolling reductions from 0% to 80%. As predicted above, the low rolling reduction weakens the ductility of TMCs due to the formation of TiBw micro crack and deformation strengthening effect of the Ti matrix. Further increasing the rolling reduction improves the ductility of TMCs due to the further dispersing TiBw and reducing aspect ratio of TiBw. The strength of 8.5% TiBw/Ti composite is increased from about 842 MPa to about 1030 MPa after 80% rolling reduction. However, the ductility of 8.5%TiBw/Ti composite reduces after rolled deformation (Fig. 5(a)), which is mainly due to the deformation strengthening effect of Ti matrix. The strength of 12%TiBw/Ti composite is increased from about 908 MPa to about 1068 MPa. Moreover, the ductility of 12%TiBw/Ti composite is effectively improved from 4% to 6.3% mainly due to the significant dispersing role of TiBw reinforcement for higher volume fraction. The strength of the composites always increases with increasing the rolling reduction mainly due to the deformation strengthening effect of Ti matrix. In addition, it is reasonable that the strength of the as-rolled 12%TiBw/Ti composite is always higher and the ductility is lower than those of the as-rolled 8.5%TiBw/Ti composite with the same rolling reduction due to the higher volume fraction of TiBw reinforcement.

Fig. 5 Comparison of tensile properties of composites rolled by different reductions

4 Conclusions

1) The novel TiBw/Ti composites with a network microstructure can be successfully fabricated by selecting large Ti powders and low-energy milling process. The novel composites exhibit a superior combination of mechanical properties and a superior forming ability.

2) The strength of the novel TiBw/Ti composites can be effectively enhanced by rolling deformation due to the matrix deformation strengthening effect, and increase with increasing the rolling reduction. The strength of 8.5% TiBw/Ti composite is increased from about 842 MPa to about 1030 MPa by rolling deformation.

3) The TiB whiskers are gradually broken with increasing the rolling reduction, which is harmful to the mechanical properties of the composites.

References

[1] HUANG L J, GENG L, LI A B, YANG F Y, PENG H X. In situ TiBw/Ti-6Al-4V composites with novel reinforcement architecture fabricated by reaction hot pressing [J]. Scripta Materialia, 2009, 60(11): 996-999.

[2] TJONG S C, MAI Y W. Processing-structure-property aspects of particulate- and whisker- reinforced titanium matrix composites [J]. Composite Science and Technology, 2008, 68(3-4): 583-601.

[3] WANG Xiang, GAI Peng-tao. Effect of carbon content on microstructure and property of TiC/Ti-6Al-4V composites [J]. Transactions of Nonferrous Metals Society of China, 2007, 17 (S1): s546-s550.

[4] LI Jian-kang, YANG Yan-qing, YUAN Mei-ni, LUO Xian, LI Li-li. Effect of properties of SiC fibers on longitudinal tensile behavior of SiC(f)/Ti-6Al-4V composites [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(3): 523-530.

[5] XIAO L, LU W J, YANG Z F, QIN J N, ZHANG D, WANG M M, ZHU F, JI B. Effect of reinforcements on high temperature mechanical properties of in situ synthesized titanium matrix composites [J]. Materials Science and Engineering A, 2008, 491(1-2): 192-198.

[6] MORSI K, PATEL V V. Processing and properties of titanium– titanium boride (TiBw) matrix composites—A review [J]. Journal of Materials Science, 2007, 42(6): 2037-2047.

[7] MA Z Y, TJONG S C, GEN L. In-situ Ti-TiB metal-matrix composite prepared by a reactive pressing process [J]. Scripta Materialia, 2000, 42(4): 367-373.

[8] LI J, YU Z S, WANG H P, LI M P. Microstructural characterization of titanium matrix composite coatings reinforced by in situ synthesized TiB plus TiC fabricated on Ti6Al4V by laser cladding [J]. Rare Metals, 2010, 29(5): 465-472.

[9] GORSSE S, MIRACLE D B. Mechanical properties of Ti-6Al-4V/TiB composites with randomly oriented and aligned TiB reinforcements [J]. Acta Materialia, 2003, 51(9): 2427-2442.

[10] XU G H, YANG Y Q, FENG G H, HUANG B, LUO X, CHEN Y. Effect of heat treatment on mechanical properties of SiC/Ti-6Al-4V composites [J]. Rare Metal Materials and Engineering, 2011, 40(8): 1367-1371. (in Chinese)

[11] HUANG L J, GENG L, PENG H X, ZHANG J. Room temperature tensile fracture characteristics of in situ TiBw/Ti6Al4V composites with a quasi-continuous network reinforcement architecture [J]. Scripta Materialia, 2011, 64(9): 844-847.

[12] YANG F Y, LI A B, HUANG L J, CHENG Y, GENG L. Study on the fabrication and heat treatment of the sheet material of in situ TiBw/Ti60 composites [J]. Rare Metals, 2011, 30(S1): 614-618.

[13] LU K. The future of metals [J]. Science, 2010, 328: 319-320.

[14] WANG Rui-ning, XI Zheng-ping, ZHAO Yong-qing, QI Yun-lian. Hot deformation and processing maps of titanium matrix composite [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(S1): s541-s545.

[15] ZHANG X N,  W J, ZHANG D, WU R J. In situ technique for synthesizing (TiB+TiC)/Ti composites [J]. Scripta Materialia, 1999, 41(1): 39-46.

W J, ZHANG D, WU R J. In situ technique for synthesizing (TiB+TiC)/Ti composites [J]. Scripta Materialia, 1999, 41(1): 39-46.

[16] NI D R, GENG L, ZHANG J, ZHENG Z Z. Effect of B4C particle size on microstructure of in situ titanium matrix composites prepared by reactive hot processing of Ti-B4C system [J]. Scripta Materialia, 2006, 55(5): 429-432.

轧制变形对网状结构TiBw/Ti复合材料组织与力学性能的影响

黄陆军,崔喜平,耿 林,付 玉

哈尔滨工业大学 金属精密热加工国家级重点实验室, 哈尔滨 150001

摘 要:通过反应热压技术成功制备出网状结构TiB晶须增强纯钛(TiBw/Ti)复合材料。原位合成的TiB晶须分布在大尺寸Ti基体颗粒周围形成网状结构。这种新型的网状结构TiBw/Ti复合材料表现出优异的综合力学性能。为了进一步改善力学性能及指导后续塑形变形加工,研究这种新型复合材料的轧制变形行为。结果表明:由于基体的形变强化,这种新型TiBw/Ti复合材料的强度可以通过轧制变形得到有效的提高,并且强度水平随着变形量的增加而增加。其中,通过轧制变形,可以使8.5%TiBw/Ti复合材料的强度从842 MPa提高到1030 MPa。需要指出的是,随着变形量的增加,TiB晶须的断裂程度也增加,这一点对复合材料的力学性能是不利的。

关键词:钛基复合材料;轧制变形;反应热压;网状结构;拉伸性能

(Edited by HE Xue-feng)

Foundation item: Projects (51101042, 51271064) supported by the National Natural Science Foundation of China; Project (HIT. NSRIF. 201131) supported by the Fundamental Research Funds for the Central Universities, China; Projects (2012T50327, 2011M500653) supported by the China Postdoctoral Science Foundation; Project supported by the Postdoctoral Science Foundation of Heilongjiang Province, China

Corresponding author: GENG Lin; Tel: +86-451-86418836; Fax: +86-451-86413922; E-mail: ljhuanghit@yahoo.com.cn