超声凝固法制备细晶AC7A Al-Mg合金

来源期刊:中国有色金属学报(英文版)2016年第4期

论文作者:W. KHALIFA Y. TSUNEKAWA

文章页码:930 - 937

关键词:Al-4.5Mg 合金;超声熔体处理;晶粒细化;金属间化合物

Key words:Al-4.5Mg alloy; ultrasonic melt treatment; grain refining; intermetallics

摘 要:通过超声熔体处理技术制备细晶AC7A锭坯,为后续变形提供原料。采用直接或间接超声技术对熔融合金进行超声振动处理。研究浇铸温度(740~660 °C)、处理时间(12~2 min)等参数的影响。超声处理从液态延续到半固态。结果表明,两种超声熔体处理技术都能获得理想的显微组织。适宜的熔体处理条件如下:处理时间2~3 min,对于间接超声处理技术,浇铸温度为660~615 °C,对于直接超声处理技术,浇铸温度为660~635 °C。沿铸锭高度方向3个位置的显微组织为非枝晶α(Al)细晶,晶粒大小为几百微米,而传统铸锭的晶粒大小为几千微米。超声处理可使金属间化合物细化,形貌得到改善。讨论和分析超声处理改变铸锭显微组织的机理。

Abstract: The objective of the current study was to investigate the use of ultrasonic melt treatment technology in the production of grain-refined billets of the AC7A alloy, which was intended for subsequent use as a feedstock in forming operations. The experiments included the application of ultrasonic vibrations to the molten alloys via direct and indirect techniques. Several process parameters such as pouring temperatures (several temperatures between 740 and 660 °C), and treatment time (from 12 min down to 2 min) were investigated. The experiment included continuous ultrasonic treatment from the liquid to the semisolid states. The results showed that both treatment techniques were viable for producing billets with the desirable microstructural characteristics. The optimum treatment conditions were the short treatment time (2 to 3 min), from about 660 °C down to 615 °C for the indirect treatment technique, and from 660 °C to 635 °C for the direct treatment technique. The resulting microstructures, at three positions along the height of the ingot, were characterized by fine, non-dendritic α(Al) grains in the order of a hundred microns, as compared to few thousands of microns for the conventional cast ingots. The intermetallic particles were also refined in size and modified in morphology by the ultrasonic treatment. The operating mechanisms by which the ultrasonic vibrations altered the ingot microstructures were discussed and analyzed.

Trans. Nonferrous Met. Soc. China 26(2016) 930-937

W. KHALIFA1, Y. TSUNEKAWA2

1. Faculty of Engineering, Cairo University, Giza 12613, Egypt;

2. Toyota Technological Institute, 2-12-1, Hisakata, Tempaku, Nagoya 468-8511, Japan

Received 8 May 2015; accepted 17 October 2015

Abstract: The objective of the current study was to investigate the use of ultrasonic melt treatment technology in the production of grain-refined billets of the AC7A alloy, which was intended for subsequent use as a feedstock in forming operations. The experiments included the application of ultrasonic vibrations to the molten alloys via direct and indirect techniques. Several process parameters such as pouring temperatures (several temperatures between 740 and 660 °C), and treatment time (from 12 min down to 2 min) were investigated. The experiment included continuous ultrasonic treatment from the liquid to the semisolid states. The results showed that both treatment techniques were viable for producing billets with the desirable microstructural characteristics. The optimum treatment conditions were the short treatment time (2 to 3 min), from about 660 °C down to 615 °C for the indirect treatment technique, and from 660 °C to 635 °C for the direct treatment technique. The resulting microstructures, at three positions along the height of the ingot, were characterized by fine, non-dendritic α(Al) grains in the order of a hundred microns, as compared to few thousands of microns for the conventional cast ingots. The intermetallic particles were also refined in size and modified in morphology by the ultrasonic treatment. The operating mechanisms by which the ultrasonic vibrations altered the ingot microstructures were discussed and analyzed.

Key words: Al-4.5Mg alloy; ultrasonic melt treatment; grain refining; intermetallics

1 Introduction

Aluminum alloys with magnesium as the major alloying element are used in a wide variety of applications in automotive body structures, trains, shipbuilding and cryogenic applications, because of their excellent properties such as high strength, good formability, corrosion resistance and weldability. In general, these alloys offer the best combination of strength and corrosion resistance of all Al alloys. These alloys are non-heat treatable alloys, and their strength is derived mainly from Mg solid solution strengthening. Mg has a substantial solid solubility in aluminum (solid solubility of Mg is about 2% at 200 °C). In order to obtain strength levels approaching those of the precipitation hardening alloys such as Al-Cu and Al-Zn-Mg alloys, high Mg levels are required [1,2]. Such high levels of Mg pose processing challenges and can increase the susceptibility of the alloys to stress corrosion cracking due to the formation of continuous b phase (Al3Mg2) at the grain boundaries [3-5].

Grain refinement offers several advantages to cast and wrought alloys such as better distribution of porosity and second phase particles, improved surface finish and machinability, greater fatigue strength and better pressure tightness [4,6]. In ingot and DC casting, grain refinement greatly facilitates the DC casting by reducing tendency of ingot cracking, and provides improved mechanical properties and several other beneficial effects [7]. The general problem with grain refinement is that it appears to be very inefficient, with at best approximately 1 % of added particles successfully nucleating grains. Therefore, a key issue is to develop better refining methods [6].

Melt treatment with high-intensity ultrasonic vibrations is attracting more attention because of its ability to refine and modify the alloy microstructure. High-intensity ultrasonic waves (e.g., above 80 W/cm2) generate important effects on liquids, i.e., cavitation and acoustic streaming, causing microstructure refining, degassing of liquid metals, and dispersive effects for homogenizing. Cavitations could produce an implosive impact, strong enough to break up the clustered fine particles and disperse them more uniformly in liquids [8].

Ultrasonic treatment (UST) was used for microstructure refinement in the aluminum alloys [9]. From our previous studies, it was found that short ultrasonic treatments in the liquid state provide fine non-dendritic structure in hypoeutectic Al-Si alloys. The ultrasonic treatment showed potential effects in refining the primary silicon and Fe-intermetallic phases in hypo- and hyper-eutectic Al-Si alloys, as well [10,11]. This effect superseded that of phosphorous addition (50×10-6) in both Si-particle refining and its effect on wear resistance [12]. It was also found that the use of ultrasonic vibrations in the production of billets for thixocasting is beneficial, since the UST produces much slower-growing aluminum grains during soaking treatment, with a uniquely very small amount of entrapped eutectic, giving a merit of better formability in the semisolid state [13]. The ultrasonically-treated thixocast parts showed a highly uniform nondendritic microstructure with better mechanical properties than the untreated billets [14,15].

The current work was carried out to investigate the use of ultrasonic treatment in the production of fine grained billets of alloy AC7A, which can be used for semi-solid forming operations. It is worth mentioning here that alloying additions have different effects on the response of alloy to the grain refining process. Therefore, the current work investigated the effect of ultrasonic treatment on the Al-Mg alloy system, which has not been studied before. In addition, the capability of the ultrasonic treatment was shown by processing larger amount of liquid metal than the earlier works. The grain size and morphology of the primary and secondary phases are of prime importance for this purpose. These objectives were achieved through metallographic studies on optical and electron microscopes.

2 Experimental

The JIS-AC7A (Al-4.5Mg alloy) was used in this study. Ingots of this alloy were melted in a resistance furnace at 750 °C, and then allowed to cool down to pouring temperature. The ultrasonic treatment was carried out during continuous cooling of the alloy using two techniques. The first was pouring of molten alloy into the crucible mold for ultrasonic treatment, as shown in Fig. 1. The crucible capacity was about 1.3 kg of molten metal, and was made of austenitic stainless steel 304, and kept at room temperature upon pouring in all experiments.

Fig. 1 Setup for ultrasonic treatment of solidifying alloy

The experimental system used for the indirect introduction of ultrasonic vibrations into the melt was designed and manufactured by Branson Ultrasonics Corporation. The consumable parts were the vertical guide plate and the crucible horns, and these were 254.5 mm in length, and 70 mm in width for the vertical guide plate; and 70, 80 and 155 mm for the bottom outside diameter, top outside diameter and outside height of the horn, respectively. The amplitudes of the vibrations were 60 μm at the end of the horizontal guide rode, 47 μm at the middle of vertical guide plate and about 25 μm at the bottom of the treatment crucible. The vibrations were, thus, transferred to the solidifying alloy through the bottom and walls of the crucible horn. Treatment continued during solidification. The ultrasonic system provided a power of 2 kW, and a frequency of 19.5 kHz.

The second technique was direct application of ultrasonic vibrations into the molten bath in alumina crucible, and then pouring into metallic mold. In this experiment, alloy pieces were melted in alumina crucibles using resistance furnace. When melt temperature reached about 30 °C above the specified treatment temperature, the crucible was transferred to the ultrasonic treatment setup. The UST setup consisted of an electric resistance furnace, an ultrasonic source and a horn, an adjustable-height stand, a crucible containing the molten sample, and a thermocouple. The ultrasonic horn and the treatment furnace were kept at the same temperature of the melt. The horn was lowered down and immersed in the melt to a depth of 5-10 mm. The furnace temperature was adjusted so that the system cooled down to the specified treatment temperature. Then, the ultrasonic vibrations were turned on for the specified treatment period. After treatment, the melt was cast directly into the steel mould kept at room temperature. Treatment time was adjusted so that melt temperature was just below the liquidus temperature (liquidus temperature of this alloy as obtained by thermal analysis was 638 °C). The optimum experiment was ultrasonic treatment from 660 to 635 °C within 3 min, then casting in a mold of the same dimensions as the crucible horn shown above. For each experiment, with direct or indirect application of ultrasonic vibrations, 1.3 kg of the alloy was remelted.

Of prime interest in this study is the effect of ultrasonic melt treatment on the size and morphology of primary Al and intermetallic particles in the commercial AC7A alloy. To do this, the ultrasonic vibrations were turned on before pouring and continued for different treatment time during solidification. The pouring temperature varied from 740 to 660 °C, ultrasonic vibrations continued down to 585 °C for up to 12 min (see Fig. 2). Treatment time varied between 12 and 2 min. A treatment between 660 and 615 °C took 2-3 min. The changes in the size and morphology of the Fe-intermetallic phases were also considered.

Specimens for microstructure investigation were cut from the treated and untreated cast billets in three positions: bottom, middle and top (Fig. 1(b)). The internal dimensions of the crucible horn used in these experiments were 65 mm for bottom diameter, 74 mm for top diameter, and 150 mm for depth. The sampling areas were taken at midpoints between the ingot surface and ingot centerline, at the three vertical locations shown in Fig. 1(b). The thermocouple tip was placed at the sample position of the middle section of the ingot. The microstructure study was to evaluate the effect of ultrasonic treatment on the primary phase size and morphology and on the intermetallic phases. Optical microscope and scanning electron microscope with EDS analyzer were used for this purpose.

3 Results and discussion

The purpose of the current work was to assess the use of ultrasonic treatment (UST) in the production of grain refined billets of alloy AC7A for semi-solid forming. This includes the investigation of molten metal ultrasonic treatment on the grain size and morphology of the α(Al) and the intermetallic phases in the studied alloy.

Fig. 2 Cooling curves during ultrasonic treatment

Billets cast at temperatures of 750 °C and lower have coarse dendritic structures. With the application of ultrasonic treatments, the microstructures increasingly showed finer and less dendritic structures. Figure 3 shows the microstructures of cast billets at different positions: top, middle and bottom, and at different pouring temperatures, and treatment time. The micrographs in Fig. 3 were from the ingots cast with indirect application of UST. The untreated billet cast at 680 °C shows large dendritic microstructure in the three positions as can be seen from Figs. 3(a)-(c) (grain sizes estimated as few thousands of microns). The application of ultrasonic treatment during identical casting conditions caused the microstructure to be finer and less dendritic, as can be seen from Figs. 3(d)-(f).

At lower pouring temperature, i.e., 660 °C, the ultrasonic treatment for 2-3 min during continuous cooling (Figs. 3(g)-(i)), modifies the microstructure to a much finer grains (in the order of a hundred microns), with completely non-dendritic globular morphology (Figs. 3(g)-(i) and (j)-(l)). It is obvious that the ultrasonic treatment at lower temperatures is more efficient than treatments at higher temperatures (Figs. 3(d-f) and (j-l)). This may be explained by the larger undercooling experienced at lower pouring temperatures, which might lead to higher nucleation rates.

Fig. 3 Microstructures of ultrasonic-treated and untreated billets

Fig. 4 Microstructures of ultrasonic-treated billets with direct application of ultrasonic vibrations into molten alloy from 660-635 °C within 3 min

Figure 4 shows the microstructure of ingots treated by direct application of ultrasonic vibrations into the molten alloy. It is obvious that the size and morphology of the aluminum grains are comparable to those produced by indirect ultrasonic treatment shown in Fig. 3, especially the low temperature treatment shown in Figs. 3(j)-(l). It is believed that casting the molten or semi-solid alloy after UST into a cold mold would enhance the refinement process. However, it is worth mentioning here that it was easier to carry out and control the indirect ultrasonic treatment than the direct treatment, even though both of them produced similar microstructures. In a conclusion to this point, one can say that both treatment techniques are viable for producing billets with the desirable microstructural characteristics.

Fig. 5 Size and morphology of intermetallic phases

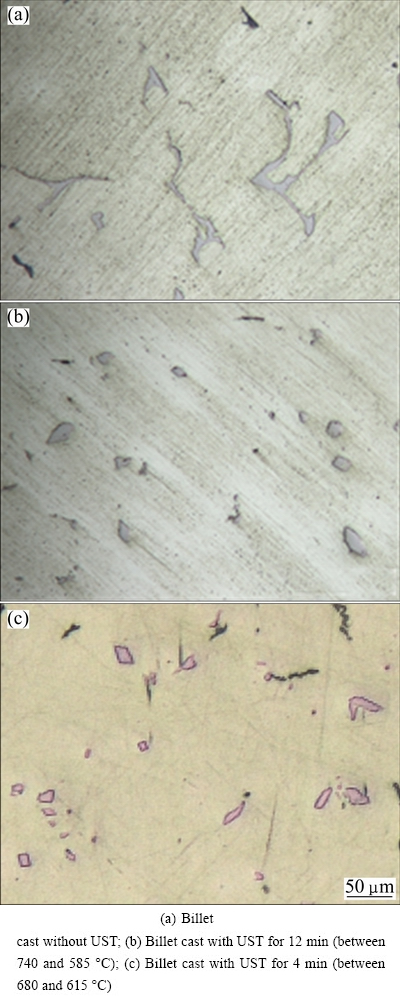

The intermetallic particles were also affected by ultrasonic treatment during solidification. Figure 5 shows these results. The intermetallic particles exhibit large dendritic shape in the untreated condition, and extend over long paths at the grain boundaries, see Fig. 5(a), while in the ultrasonically-treated billets, the second phase particles are much finer and less dendritic, as can be seen from Figs. 5(b) and (c). It is worth mentioning here that the intermetallic particles were refined in size and modified in shape in all the ultrasonic-treated ingots, even though the UST treatment ended at higher temperatures (i.e., 635 °C and 615 °C) before the start of intermetallic phase formation (i.e., they form at 607 °C, see Fig. 2(a)). The formation temperature of the second phase particles was identified by the second derivative method. It can be concluded here that the intermetallic particles were refined in size and modified in morphology by the ultrasonic treatment.

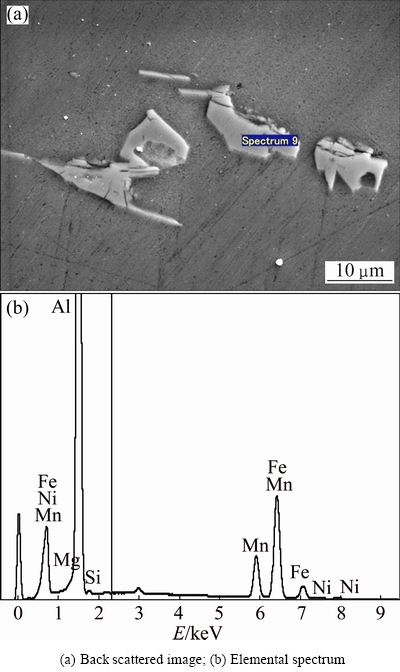

The EDS microanalysis shows that these particles are iron intermetallic particles (see Fig. 6), with an analysis of Al4.7Fe1.0Mn0.35. The matrix distant from these particles contains 5.24% Mg, 0.23% Mn and traces of Fe and Si. The refinement of the intermetallic phase particles will likely reduce the hot-tearing susceptibility of the products according to Saveiko’s theory, which relates the force to cause a tear to the area of coverage of the dendrites by the interdendritic liquid [16].

Fig. 6 EDS analysis of refined intermetallic particles

The current study showed clearly that the melt treatment by ultrasonic vibrations during solidification has potential effects on both primary and second phases, so that fine and nondendritic particles are formed. This microstructure is optimum for obtaining highly refined microstructure upon reheating to the semisolid state before thixoforming. Therefore, the UST can be used for the billet preparation for thixoforming of the Al-4.5%Mg alloys.

The question that might rise in mind now is on the mechanism of microstructure modification by ultrasonic treatment. The mechanism of ultrasonic treatment in liquid metals is based mainly on two phenomena: cavitation and acoustic streaming. The observed microstructure modification is a cumulative result of both phenomena.

The cavitation is the formation and expansion of bubbles in the melt and collapse of these bubbles as the horn vibrates back and forth in the melt. This produces high pressures on melt layers in direct contact with collapsing bubbles [8]. This effect happens in very short cycles of time. The microstructure is refined ahead of the vibrating surface [17]. This might cause formation of precipitate solid crystals at some temperatures above the liquidus temperature, according to Clausius-Clapeyron equation. These tiny solid crystals are well distributed in the melt via acoustic streaming, and can grow to mature crystals with further cooling, and may vanish depending on the melt condition and temperature. However, the evidence of crystal formation and survival via this mechanism in liquid metals does not exist. However, recent reports of isothermal holding of pure aluminum melt after ultrasonic melt treatment showed that a loss of nucleation potency occurred with isothermal holding [17]. Another indirect observation of a highly refined Al-Si microstructure was observed in the overflow area at the end of solidification [18]. These observations may support in part the above mechanism.

The cavitation is more extensive in viscous liquidus and therefore more extensive at low superheat temperatures (near to the liquidus temperature), since metal viscosity increases near to melting temperature [19]. It was also reported that the cavitation threshold of aluminum decreases with decreasing the melt temperature [20], and hence the cavitation ability and intensity increase at low superheat temperature. This explains in part the inefficiency of ultrasonic treatment when applied at higher superheat temperatures (Figs. 3(d)-(f) and (j)-(l)). In addition, this may be also attributed to the thermal condition in which the nucleated grains are difficult to survive.

The cavitation has other effects on the liquid metals, such as degassing effects [21]. Degassing of liquid metals includes the solute gas atoms and the adsorbed gas atoms on the non-metallic inclusions and solid particles existing in the liquid metals. Removal of gas atoms from the surface of these solid particles improves wetting of these particles with the liquid phase and hence improves their nucleation potency. This can explain in part the refining effect of UST when applied only in the liquid state, and still showing grain refining effects.

In the current study, there is no experiment using ultrasonic treatment in only the liquid state. However, the continuous cooling treatments comprised a part of treatment in the liquid state and a part during solidification. This is why the refining mechanism of the liquid treatment is still important to explain the results of the current study.

When ultrasonic treatment continues during solidification, additional effect exists. This is the dendrite arm breaking of the growing crystals due to cavitation and streaming. These fragments, hence, do inoculate the melt with solid phase fragments which plays a role in grain refinement as these grow as separate crystals. Many researchers believe in this classical explanation. However, in the current continuous cooling treatments, the solidifying melts show much less dendritic grains as can be seen from Figs. 3 and 4. It is believed that the efficient mixing in the liquid due to the acoustic streaming led to a state in the melt of substantially low undercooling, which did not favor the formation of dendritic grains, but rather caused the formation of non-dendritic equiaxed grains. This may explain the grain refinement and globular nature of the primary phase observed in the current work, since UST was applied during solidification.

The only remaining part of this discussion is to explain the mechanism of intermetallic particle refinement in the current study (Figs. 5 and 6). It might be questionable as how the intermetallic refinement occurred while the intermetallic compound started to form at about 607 °C, whereas the ultrasonic treatment terminated at 615 °C and 635 °C for the indirect and the direct treatments, respectively. Actually, the intermetallic particle refinement happened due to indirect effects. These compounds usually form late during solidification, since they contain high concentration of solute elements, which are rejected to the liquid phase during solidification due to the solute redistribution between the solid and liquid phases. The solute elements accumulate during solidification and their concentrations reach substantially high level at the last liquid to solidify. The areas where the enriched liquid exists are the grain boundaries and the interdendritic regions. The number of these liquid pockets decreases and their relative sizes increases in un-grain refined alloys, while in the grain-refined alloys, such as those investigated in the current study, these areas are numerous and their sizes are very fine, as can be seen in the comparison of Figs. 3(a)-(c) and (j)-(l). Thus, intermetallic particles in the grain-refined alloys are much finer than those forming in un-grain-refined melts. Thus, the ultrasonic grain refining of the primary phase indirectly extends to cause refinement of the intermetallic phases.

4 Conclusions

1) Both direct and indirect ultrasonic treatment techniques are viable for producing billets with the desirable microstructural characteristics.

2) The optimum treatment conditions were the short treatment time (2 to 3 min), from 660 to 615 °C for the indirect treatment technique, and from 660 to 635 °C for the direct treatment technique.

3) The resulting microstructures, at three positions along the height of the ingot, were characterized by fine, non-dendritic α(Al) grains in the order of a hundred microns, as compared to few thousands of microns for the conventional cast ingots.

4) The intermetallic particles were also refined in size and modified in morphology by the ultrasonic treatment.

5) The operating mechanisms by which the ultrasonic vibrations altered the ingot microstructures were discussed and analyzed.

References

[1] KOJIMA Y, TAKAHASHI T, KUBO M, MORINAGA T. Decrease of ductility in Al-10 Pct Mg alloys during long-term natural aging [J]. Metallurgical Transactions A, 1981, 12: 1113-1117.

[2] HAMANA D, NEBTI S, HAMAMDA S. Effect of the zirconium addition on the microstructure of Al+8 wt% Mg alloy [J]. Scripta Metallurgica, 1990, 24: 2059-2064.

[3] MONDOLFO L. Aluminum alloys: Structure and properties [M]. Boston: Butterworths, 1976.

[4] POPOVIC M, ROMHANJI E. Stress corrosion cracking susceptibility of Al-Mg alloy sheet with high Mg content [J]. Journal of Materials Processing Technology, 2002, 125-26: 275-280.

[5] KAO P, WANG L. Effect of grain boundary precipitates on the mechanical behavior of Al-5 wt% Mg alloy [J]. Scripta Metallurgica, 1988, 22: 335-338.

[6] GREER A. Grain refinement of aluminum alloys [C]//Proceedings of Solidification of Aluminum Alloys. Charlotte: TMS, 2004: 131-145.

[7] KIMURA R, HATAYAMA H, SHINOZAKIA K, MURASHIMA I, ASADA J, YOSHIDA M. Effect of grain refiner and grain size on the susceptibility of Al-Mg die casting alloy to cracking during solidification [J]. Journal of Materials Processing Technology, 2009, 209: 210-219.

[8] ABRAMOV O, LOBOV L. Ultrasound in liquid and solid metals [M]. Boca Raton, Florida: CRC Press, 1994.

[9] BRODOVA I, POPEL P, ESKIN G. Liquid metal processing: Applications to aluminum alloy production [M]. London: Taylor & Francis, 2002.

[10] KHALIFA W, TSUNEKAWA T, OKUMIYA M. Effect of ultrasonic melt-treatment on the eutectic silicon and iron intermetallic phases in Al-Si cast alloys [J]. Materials Science Forum, 2010, 638-642: 431-436.

[11] KHALIFA W, TSUNEKAWA T, OKUMIYA M. Effect of ultrasonic treatment on Fe-intermetallic phases in ADC12 Al-Si die cast alloy [J]. Journal of Materials Processing Technology, 2010, 210: 2178-2187.

[12] KHALIFA W, El-HADAD S, TSUNEKAWA Y. Microstructure and wear behavior of solidification sonoprocessed B390 hypereutectic Al-Si alloy [J]. Metallurgical and Materials Transactions A, 2013, 44: 5817-5824.

[13] KHALIFA W, TSUNEKAWA T, OKUMIYA M. Effect of reheating to the semisolid state on the microstructure of the A356 aluminum alloy produced by ultrasonic melt-treatment [J]. Solid State Phenomena, 2008, 141-143: 499-504.

[14] KHALIFA W, El-HADAD S, TSUNEKAWA Y. Microstructure evolution and mechanical properties of sonoprocessed-thixocast AC4C billets [C]//Proceedings of the 71st World Foundry Congress. Bilbao, Spain, 2014.

[15] KHALIFA W, El-HADAD S, TSUNEKAWA Y. Microstructure characteristics and tensile property of ultrasonic treated-thixocast A356 alloy [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(11): 3173-3180.

[16] LIN S, ALIRAVCI C, PEKGULERYUZ M. Hot-tear susceptibility of aluminum wrought alloys and the effect of grain refining [J]. Metallurgical and Materials Transactions A, 2007, 38: 1056-1068.

[17] HUANG Hai-jun, XU Yi-fan, SHU Da, HAN Yan-feng, WANG jun, SUN Bao-de. Effect of ultrasonic melt treatment on structure refinement of solidified high purity aluminum [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2414-2419.

[18] ZHANG Yu-bo, LU Yi-ping, JIE Jin-chuan, FU Ying, ZHONG De-shui, LI Ting-ju. Overflowing phenomenon during ultrasonic treatment in Al-Si alloys [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(11): 3242-3248.

[19] IIDA T, GUTHRIE R. The physical properties of liquid metals [M]. Oxford: Clarendon Press, 1988.

[20] ESKIN G I. Ultrasonic treatment of light alloy melts [M]. Amsterdam: Gordon and Breach Science Publishers, 1998.

[21] PUGA H, BARBOSA J, TUAN N, SILVA F. Effect of ultrasonic degassing on performance of al-based components [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(11): 3459-3464.

W. KHALIFA1, Y. TSUNEKAWA2

1. Faculty of Engineering, Cairo University, Giza 12613, Egypt;

2. Toyota Technological Institute, 2-12-1, Hisakata, Tempakus Nagoya 468-8511, Japan

摘 要:通过超声熔体处理技术制备细晶AC7A锭坯,为后续变形提供原料。采用直接或间接超声技术对熔融合金进行超声振动处理。研究浇铸温度(740~660 °C)、处理时间(12~2 min)等参数的影响。超声处理从液态延续到半固态。结果表明,两种超声熔体处理技术都能获得理想的显微组织。适宜的熔体处理条件如下:处理时间2~3 min,对于间接超声处理技术,浇铸温度为660~615 °C,对于直接超声处理技术,浇铸温度为660~635 °C。沿铸锭高度方向3个位置的显微组织为非枝晶α(Al)细晶,晶粒大小为几百微米,而传统铸锭的晶粒大小为几千微米。超声处理可使金属间化合物细化,形貌得到改善。讨论和分析超声处理改变铸锭显微组织的机理。

关键词:Al-4.5Mg 合金;超声熔体处理;晶粒细化;金属间化合物

(Edited by Yun-bin HE)

Corresponding author: W. KHALIFA; Tel: 20-109-816-3293; E-mail: wkhalifa@eng.cu.edu.eg

DOI: 10.1016/S1003-6326(16)64186-9