摩擦轧压表面处理及退火处理中纯钛的微观组织与织构演化

来源期刊:中国有色金属学报(英文版)2012年第11期

论文作者:施梅勤 高山善匡 马淳安 渡部英男 井上博史

文章页码:2616 - 2627

关键词:钛;摩擦轧压表面处理;强烈塑性变形;择优取向;再结晶;结构演化;超细晶粒

Key words:titanium; friction roll surface processing; severe plastic deformation; preferred orientation; recrystallization; texture evolution; ultra-fine grains

摘 要:通过一种新的摩擦轧压表面处理工艺(FRSP)对纯钛板材表面进行加工,引入的应变沿材料厚度方向成梯度分布。采用光学显微镜、X射线衍射对FRSP加工后的纯钛的微观组织进行观察发现在钛材表面形成了超微细晶粒,且具有明显织构,其方向与FRSP的加工方向有关。另外,对FRSP处理后的钛材在不同温度和时间下进行退火处理,通过EBSD研究织构的形成及其在退火过程中的演变规律。结果表明:在低温退火过程中,钛板材表层主要存在FRSP后形成的织构,而原有的典型轧制织构减少,可见,通过FRSP及后续退火可有效地控制钛材表面的微观组织与织构。

Abstract: Commercial purity and high purity titanium sheets were initially strained by a new technique, named as friction roll surface processing (FRSP). Severe strain was imposed into the surface layer and strain gradient was formed through the thickness of the sheet. The microstructure and texture in as-strained state were investigated by optical microscopy and X-ray diffraction technique. On the surface of the sheets, ultra-fine grains were found to have a sharp texture with a preferred orientation strongly related to the FRSP direction. The evolution of microstructure and crystallographic texture of FRSPed samples during recrystallization were also studied by electron back-scattered diffraction (EBSD) technique after being annealed at selected temperatures and time. The results indicated that the preferred orientations resulting from FRSP and annealing in the surface layer were formed during rolling and its recrystallization textures were reduced by FRSP. In addition, the texture evolved stably without change in main components during the annealing.

Trans. Nonferrous Met. Soc. China 22(2012) 2616-2627

SHI Mei-qin1, Yoshimasa TAKAYAMA2, MA Chun-an1, Hideo WATANABE2, Hirofumi INOUE3

1. State Key Laboratory Breeding Base of Green Chemistry Synthesis Technology, College of Chemical Engineering and Materials Science, Zhejiang University of Technology, Hangzhou 310032, China;

2. Department of Mechanical and Intelligent Engineering, Graduate School of Engineering, Utsunomiya University, Utsunomiya 321-8585, Japan;

3. Department of Materials Science, Graduate School of Engineering, Osaka Prefecture University, Sakai 599-8531, Japan

Received 8 October 2011; accepted 5 April 2012

Abstract: Commercial purity and high purity titanium sheets were initially strained by a new technique, named as friction roll surface processing (FRSP). Severe strain was imposed into the surface layer and strain gradient was formed through the thickness of the sheet. The microstructure and texture in as-strained state were investigated by optical microscopy and X-ray diffraction technique. On the surface of the sheets, ultra-fine grains were found to have a sharp texture with a preferred orientation strongly related to the FRSP direction. The evolution of microstructure and crystallographic texture of FRSPed samples during recrystallization were also studied by electron back-scattered diffraction (EBSD) technique after being annealed at selected temperatures and time. The results indicated that the preferred orientations resulting from FRSP and annealing in the surface layer were formed during rolling and its recrystallization textures were reduced by FRSP. In addition, the texture evolved stably without change in main components during the annealing.

Key words: titanium; friction roll surface processing; severe plastic deformation; preferred orientation; recrystallization; texture evolution; ultra-fine grains

1 Introduction

Properties of metals and alloys depend on both their microstructure and texture developed during producing process. In order to optimize the final properties, it is necessary to understand the whole metallurgical phenomena which occur during the producing process. Many earlier studies presented the development of microstructure and texture for FCC and BCC metals and alloys during deformation and subsequent recrystallization [1-5]. In contrast, far fewer works on hexagonal metals and alloys have been reported.

Titanium and titanium-based alloys have been widely used in various engineering and medical fields. Especially, pure titanium gives an outstanding advantage in biomedical applications owing to its corrosion resistance, high inertness and biocompatibility. There have been some efforts to elucidate the mechanism and enhance its mechanical properties through a variety of techniques. Microstructure and texture evolution in titanium after cold-rolling and subsequent annealing have been investigated to know the deformation mechanism [6-8]. The characteristics of titanium at the different recrystallization stages were also studied [9,10]. On the other hand, severe plastic deformation (SPD) is used to improve strength of pure titanium by producing the ultrafine-grained microstructure. SPD is a recent approach to fabrication of bulk nanostructured metals and alloys. By using SPD, the resulted nanocrystalline materials exhibited some unique structural characteristics and novel properties which were fundamentally different from those of the conventional ones with general grain structure [11]. Several attempts have been successfully applied to titanium [12-14]. High ultimate tensile strength and ductility were obtained in titanium billets which were processed using equal channel angular extrusion followed by conventional cold rolling [14]. These studies on recrystallization during and after SPD have been performed to understand the formation of ultrafine grained microstructure in titanium. Besides forming the ultrafine grained microstructure, another possibility of SPD is to make a preferred orientation [15-18]. It has been reported that basal α slip was dominant in CP-Ti when deformation proceeds during ECAP via route A (in which there is no rotation of the sample between passes) at 350 °C [19]. However, DHEDA et al [20] found that ECAP resulted in more random textures within commercially pure titanium after the sample was subjected to one pass of ECAP at room temperature. Effect of SPD on texture evolution of material after deformation and annealing is still under the investigation. Furthermore, some properties such as corrosion resistance, fatigue and formability strongly depend on the microstructure in the surface layer. Therefore, more attention should be paid to the importance of the microstructure control on the surface layer sufficiently.

We recently proposed a new severe straining technique, named friction roll surface processing (FRSP), to control the microstructure and texture on the surface layer in commercial purity titanium [21,22]. As a result, the formation of a unique preferred orientation that is strongly related to the FRSP direction was found. In the present study, FRSP and annealing were applied to surface modification in commercial purity and high purity titanium sheets. The work focuses on the development of FRSP recrystallization texture and its relationship to the original texture during annealing. The differences in microstructure and texture formed between the commercial purity and high purity titanium sheets are also discussed.

2 Experimental

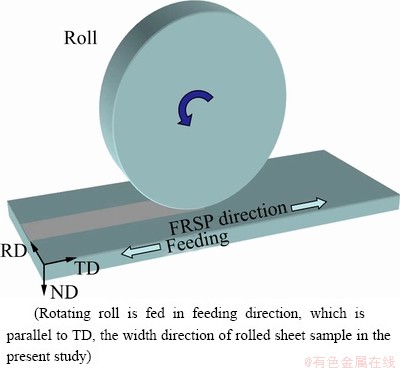

FRSP [21] is a straining technique which enables to make ultrafine grains with a strong preferred orientation in surface layer. The schematic illustration of FRSP is displayed in Fig. 1. Fixed rolls with dimensions of d70 mm×10 mm and d70 mm×5 mm, which were made of tool steel SK3, rotated at 48 r/min. The indentation of roll plunged into samples was selected as 0.2 mm. The feeding speed of sample was set at 14 mm/min. The directions of roll rotation and sample feeding were defined as shown in Fig. 1. FRSP was carried out as follows: First, the interface where the roll and the sample just touched was located, and was regarded as the reference plane at which the indentation was zero. Then, the roll was placed in the given indentation without contacting with the sample. After rotating the roll, the sample was moved forward until the entire surface was treated. This procedure resulted in making the working plane lower than the reference plane and led to a great amount of friction.

Fig. 1 Schematic illustration of friction roll surface processing (FRSP)

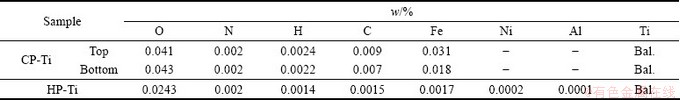

Commercial purity titanium (CP-Ti) sheet (grade 1) with an average grain size of 30 mm was used in the present study. In order to investigate the effect of purity, high purity titanium (HP-Ti) with an average grain size of 100 mm was processed by FRSP also. The chemical compositions of the two kinds of titanium sheets are listed in Table 1. The as-received CP-Ti sheet was initially cold rolled to a thickness of 1 mm and subsequently annealed at 800 °C for 1 h. HP-Ti sheet was initially cold rolled to a thickness of 1 mm and subsequently annealed at 700°C for 0.5 h. Samples with dimensions of 60 mm×20 mm×1 mm were machined from the titanium sheets. In our previous study [20], three types of samples, marked as RD, TD and RD+45° treated samples were studied. FRSP was conducted with the FRSP direction parallel to the rolling direction (RD), transverse direction (TD) and the direction rotated by 45° from RD to TD, respectively. In the present study, FRSP was conducted with the processing direction parallel to the transverse direction (TD) of sample, namely, TD sample was chosen to be studied in more detail. This is because in TD sample the textures formed by FRSP and annealing can be identified easily from the textures formed by rolling and annealing. The sample feeding direction, FRSP direction and the reference direction of the rolled sheet are also sketched in the figure.

Table 1 Chemical compositions of titanium samples used

Morphologies of FRSP treated samples were observed by optical microscopy. The specimens were first ground by emery papers of grade 400 to 1200, then on a polishing cloth with a liquid suspension of 0.3 μm alumina, and finally etched at room temperature for 5 s in a solution of 6 mL HF, 3 mL C3H6O3 and 1 mL HNO3. The cross sections of samples were then examined by optical microscopy. Global textures of surface layers on the sample were measured as incomplete pole figures for diffraction planes (0002) and  using X-ray diffraction (XRD; Rigaku RINT-2500HK/PC, Cu Kα, 40 kV, 100 mA) to reveal the textures of deformed materials. The data were corrected by quasi-normalization and a standard sample was titanium powder.

using X-ray diffraction (XRD; Rigaku RINT-2500HK/PC, Cu Kα, 40 kV, 100 mA) to reveal the textures of deformed materials. The data were corrected by quasi-normalization and a standard sample was titanium powder.

FRSP treated sheets were annealed in argon at 550, 600 and 650 °C for 20-500 min for CP-Ti and at 360, 400, 440 and 480 °C for 60 min for HP Ti, and then air cooled.

Crystallographic textures of annealed samples were evaluated using a scanning electron microscope/electron back scatter diffraction pattern technique (SEM/EBSD; HITACHI S-3500H, TSL orientation image microscopy system) after electropolishing. The electropolishing was carried out at -50 °C and 14 V for 10 min in a solution containing 5%H2SO4+ 95%CH3OH (volume fraction). The scan areas were on the cross sections of ND-RD plane. Microstructure and texture evolution through the thickness of sample were investigated from the processed surface to center of the sample, the area was 600 μm×600 μm and the step size was 5 μm. In order to study the surface layer carefully, a smaller area of 200 μm×200 μm was examined starting from the processed surface using a step size of 1 μm.

3 Results and discussion

3.1 Strain distribution

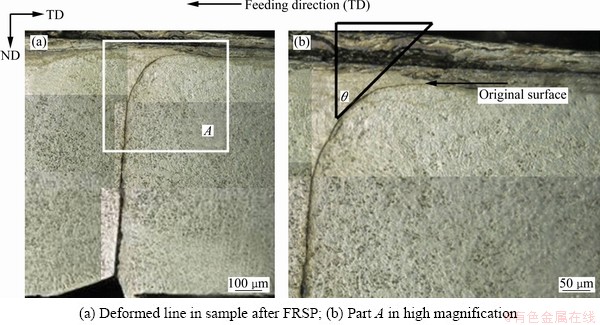

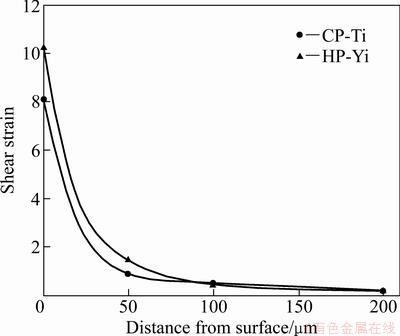

For the purpose of evaluating the strain distribution through the thickness of the FRSP treated samples, shear strain measurement was carried out by the embedded-pin method [23]. The experimental method and results of CP-Ti were reported in the earlier published paper [22]. Shear strain measurements were also carried out on HP-Ti sample in the same way. As displayed in Fig. 2, the deformed line which was the boundary between pin and outside materials indicates the gradient of strain along the thickness of the FRSP treated sample. In the figure, the original surface of the right side material is shown by an arrow. Shear strain was measured with considering the surface of right side as the real surface. At a position of x=0, the shear strain was determined by the extrapolation of the slope of the deformed line near the surface. Comparison in shear strain between the two types of titanium samples is displayed in Fig. 3. Higher strain with a value of 10.26 was imposed beneath the surface in HP-Ti. These strains fall off drastically to 1.43 when the thickness is 50 μm. The strain distribution in the depth direction for HP-Ti is concentrated to the surface compared with CP-Ti. This is due to the difference in ductility between the two samples.

3.2 Microstructure of processed material

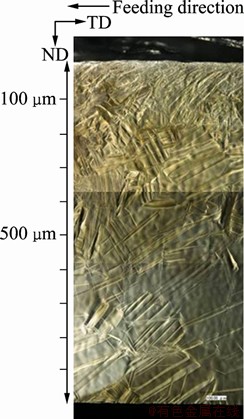

The optical micrographs on the ND-TD cross-section of the TD sample (CP-Ti) after FRSP are shown in Fig. 4. Change in microstructure is observed depending on the distance from the processed surface. The microstructure is correspondent with the strain distribution. In the surface layer, to a depth of about 150 μm, lamellar microstructures with an inclination about 20°-25° to TD can be observed in the figure. In the second layer from a depth of 150 μm to 500 μm, there are many deformation twins formed, which implies a lower strain than that in the first layer. In the case of rolled titanium deformation, twinning was found in all grains at a very early stage [24]. The absence of additional twinning during the large deformation of titanium has been discussed as being the result of the reduced grain size introduced by prior twinning [6]. Therefore, almost no deformation twins can be observed near the surface of FRSP treated sample. In the rest part of the samples, equiaxed grains remains without deformation. This gradually changed microstructure through thickness of sample is consistent with the strain gradient formed after FRSP.

Fig. 2 An example of embedded-pin of HP-Ti after FRSP

Fig. 3 Comparison of strains imposed by FRSP in HP-Ti and CP-Ti

Similar change was found in HP-Ti sample also. Figure 5 shows the image of HP-Ti sample after FRSP. Material flow along shear strain is observed in the vicinity of the surface. There is a significant difference in the second layer between the two types of titanium samples. In the HP-Ti sample, much more deformation twins can be observed in the second layer. And the depth of the second layer in HP-Ti reaches up to the bottom of the sample. It is well known that twinning is more easily activated when increasing grain size and decreasing impurity content [25]. The propensity for twin formation was significantly reduced as the grain size decreased [25]; small grain size was found to impede the deformation twinning [26,27]. Grain size of CP-Ti is 30 μm, which is much smaller than that of HP-Ti, 100 μm. Moreover, the difference in effect of impurity on critical resolved shear stress (CRSS) in each slip system should be considered.

Fig. 4 Optical micrograph showing microstructure character- istics along depth in CP-Ti sample after FRSP

Fig. 5 Optical micrograph showing microstructure character- istics along depth in HP-Ti sample after FRSP

In our previous paper [22], the TEM images described the surface features associated with the severe strain imposed during FRSP. The microstructure in the surface zone was fragmented down to the elongated nanostructure consisting of ultra fine grains of 110 nm × 50 nm due to the severe strain. For HCP metals, it was known that the transition of strain accommodation from twinning to dislocation slip with increasing strain was responsible for the grain refinement in titanium [28], magnesium, and zirconium [29] during the process of equal channel angular pressing (ECAP), and surface mechanical attrition treatment (SMAT) [30]. Sliding friction under a large load in FRSP should be especially effective for the formation of ultra fine grains with 100 nm scale in the surface layer, since it can cause a large shear stress, which is a necessary condition for the generation of severe plastic deformation. The ultra fine grained material was produced by processes similar to those involved in the early stages of mechanical alloying, which were commonly done in a high energy ball mill [31]. Therefore, a large amount of shear strain was probably introduced in the surface region by large friction between the roll and the sample during FRSP without lubrication. The grains were sheared, resulting in an oblate grain structure with long axes of grains inclined to the FRSP direction. Moreover, grain fragmentation set in [32] and the grain subdivision continued to refine with the increase of strain. This process led to the formation of new ultra-fined grains.

3.3 Texture of deformed material

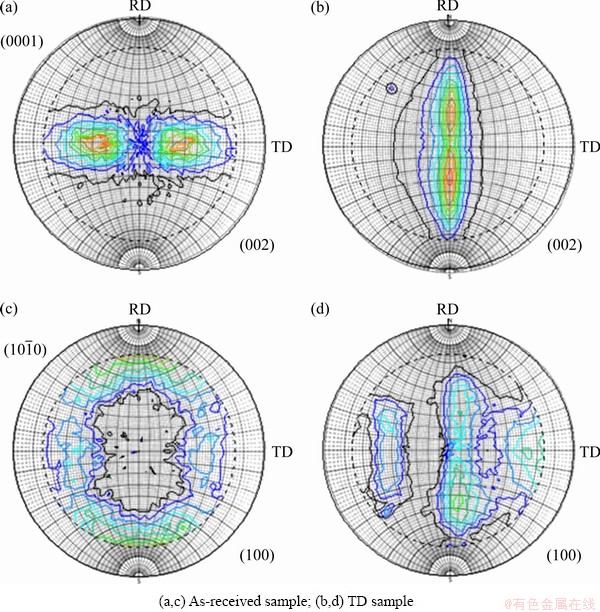

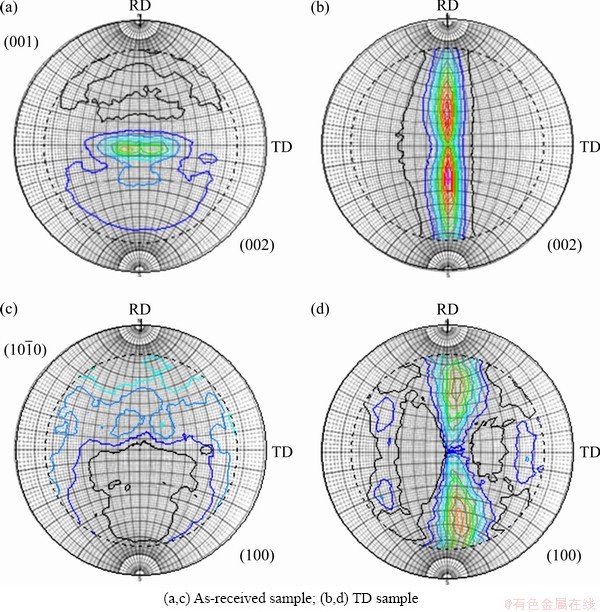

The normalized pole figures of the CP-Ti and HP-Ti after FRSP measured by XRD are presented with Polar net in Figs. 6 and 7, respectively. It has been proved that FRSP has a deformation mechanism different from general cold-rolling. After FRSP,  was found to align along RD in the

was found to align along RD in the  pole figure of the RD sample [20]. This is different from the texture with

pole figure of the RD sample [20]. This is different from the texture with  parallel to RD, which is well known for titanium subjected to cold-rolling [7]. Figure 6 shows the pole figures of as-received and TD samples of CP-Ti. As displayed in Fig. 6(a), (0001) pole figure of the as-received one indicates that the basal poles are tilted 30°-40° away from the ND toward the TD, thereby exhibiting a TD-split texture (

parallel to RD, which is well known for titanium subjected to cold-rolling [7]. Figure 6 shows the pole figures of as-received and TD samples of CP-Ti. As displayed in Fig. 6(a), (0001) pole figure of the as-received one indicates that the basal poles are tilted 30°-40° away from the ND toward the TD, thereby exhibiting a TD-split texture ( or

or  ({rolling plane}

({rolling plane}

The formation of preferred orientations after sliding was already reported in various metals [33-37].

Fig. 6 Pole figures showing difference in texture of CP-Ti sample before and after FRSP

Fig. 7 Pole figures showing difference in texture of HP-Ti samples before and after FRSP

Considerable plastic deformation was produced by friction forces in the surface layers of metallic objects. This caused a preferred orientation of the crystallites in a particular direction with a large amount of strain. However, the stability and component of textures were different according to the metals, and the mechanism of texture formation has not been given or clearly explained. HEILMANN et al [37] explained that the special orientation was the result of the rotation of the lattice. This rotation is about the transverse axis normal to the sliding direction and parallel to the sliding interface. This indicates that the material at a given depth on each side of the boundary rotates by the same angle and about the same axis during sliding. They also suggested the sliding process must involve more than a simple shear parallel to the sliding interface because a simple shear cannot provide the observed rotation. The simplest rotation requires two slip systems, but to generate a three- dimensional cell network, a third system may also be needed. KOCKS and CHANDRA [38] described the deformation in a slotted die in which the material was constrained in a way similar to that found in a sliding system. They reported that three slip systems were sufficient to give the observed deformation. Therefore, it is reasonable to expect that two or three slip systems have operated during sliding to produce the observed rotations and substructure. There has been continuing interest in the nature of crystallographic textures generated by sliding. Several researchers have reported that sliding creates well-defined textures. It has been reported [39,40] that for hexagonal metals, sliding tends to produce an alignment of basal slip plane (0001) parallel to the worn surface. In our study, the strong texture developed near the surface of sample without lubricant by FRSP. Both CP-Ti and HP-Ti exhibited sharp shear texture after FRSP. The slip direction has the inclination to become parallel to process direction. Therefore, the FRSP texture was strongly related to the processing direction, namely, TD direction in the case of TD sample. Comprehensive explanation of the mechanism will be presented after using FRSP on FCC and BCC metals in the future.

3.4 Microstructure and texture evolution during annealing

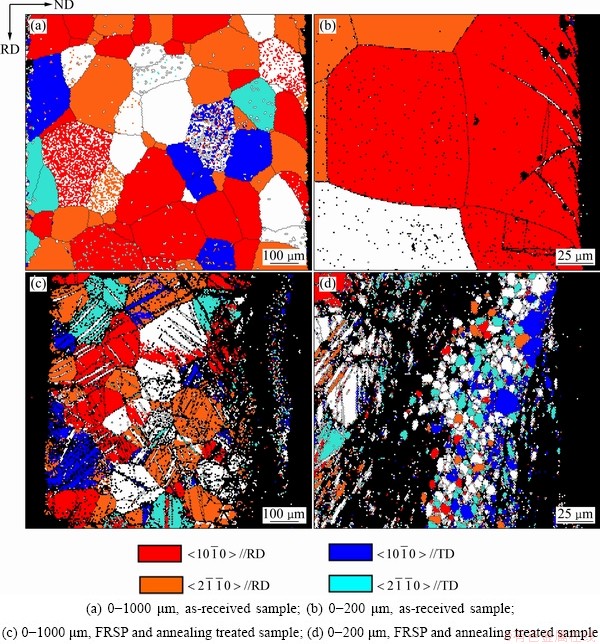

Microstructures of ND-RD cross sections in as- received and FRSP treated samples of CP-Ti are displayed in Fig. 8 as image quality (IQ) maps in which each point in the scan is shaded according to its image quality of EBSD analysis. Because the strain imposed by plastic deformation still remained, the areas that have not undergone recrystallization give rise to poorer Kikuchi patterns and, thus, appear with a darker contrast in the IQ map. On the contrary, the recrystallized grains of lower dislocation density appeared with much brighter contrast with high image quality. The image quality was already applied to analyzing fraction of recrystallized volume [41] though it might not be completely correspondent to dislocation density in each analyzing point. The as-received one (Fig. 8(a)) exhibits an almost strain free state in equiaxed grains of 30 μm while the gradient contrast showing strain imposed in thickness direction appeared in the FRSP treated sample (Fig. 8(b)).

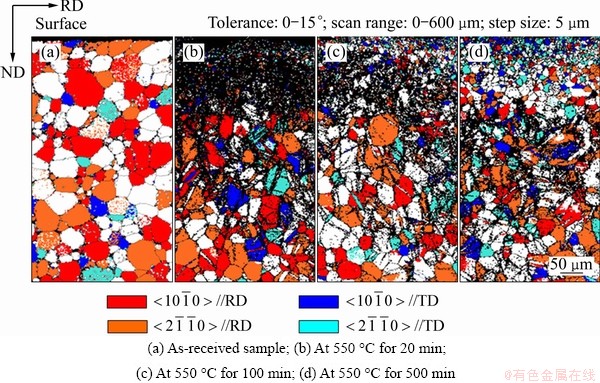

Figure 9 shows the evolution of the crystallographic texture in CP-Ti during recrystallization at 550 °C with various time of 20, 100 and 500 min. The maps demonstrated the microstructure gradient of samples along ND direction after annealing. Heterogeneous microstructures were found in different layers. For instance, after annealing at 550 °C for 20 min, uniform fine grains appeared in the surface layer sited with a depth of about 50 μm. In the narrow layer, finer recrystallization nuclei should be formed though they might not be detected easily. However, the deeper layer has a wide black area representing non-analyzable points with confidence indices not more than 0.1 because the strain was still stored in the area. This state might be regarded as the start of recrystallization in CP-Ti after FRSP. In this stage, heavily deformed part in the sample undergoes heterogeneous recrystallization in which strain-free grains were initiated preferentially in the regions of high stored energy. The depth where the black area was extended showed the limit of strain generated by FRSP.

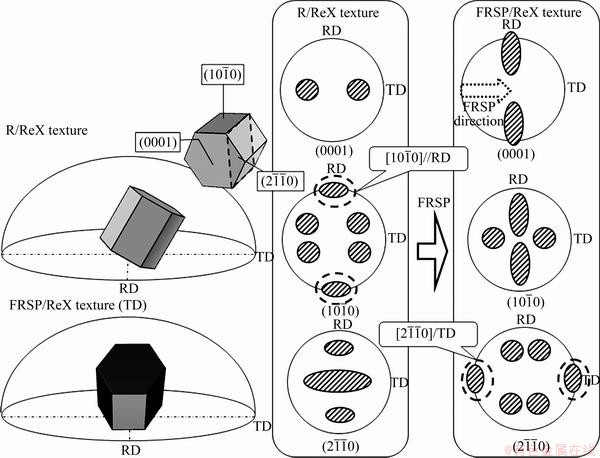

Since the slip direction, which is  for titanium, has the inclination to become parallel to process direction during the FRSP, the FRSP recrystallization texture formed in the TD sample was strongly related to the TD direction. To distinguish and investigate the texture evolution during FRSP and annealing, the original texture and the texture formed by FRSP and annealing were analyzed by their characteristic components respectively. The original texture consisting of rolling and its recrystallization ones is characterized by

for titanium, has the inclination to become parallel to process direction during the FRSP, the FRSP recrystallization texture formed in the TD sample was strongly related to the TD direction. To distinguish and investigate the texture evolution during FRSP and annealing, the original texture and the texture formed by FRSP and annealing were analyzed by their characteristic components respectively. The original texture consisting of rolling and its recrystallization ones is characterized by and

and  which is called R/ReX texture below. The newly formed texture consisting of FRSP and its recrystallization ones is characterized by

which is called R/ReX texture below. The newly formed texture consisting of FRSP and its recrystallization ones is characterized by  and

and  , which is named as FRSP/ReX texture. Schematic illustration of the difference between the rolling and FRSP/ReX textures are displayed in Fig. 10. The four texture components were analyzed within the scan area of 600 μm along ND direction, and the directions maps were displayed in Fig. 9 also. Obviously, at 550 °C the FRSP/ReX texture (blue and sky blue grains) evolves with high fractions in the surface layer whereas larger grains with the rolling and its recrystallization textures (red and orange grains) remain with high fractions in the center layer. There is a sharp transition from the surface to the center of samples. The main components vary through the thickness and the differences are rather significant. Moreover, the distribution of texture components is not changed with the increase of annealing time. Size and spatial distributions of non-indexed grains are not changed either.

, which is named as FRSP/ReX texture. Schematic illustration of the difference between the rolling and FRSP/ReX textures are displayed in Fig. 10. The four texture components were analyzed within the scan area of 600 μm along ND direction, and the directions maps were displayed in Fig. 9 also. Obviously, at 550 °C the FRSP/ReX texture (blue and sky blue grains) evolves with high fractions in the surface layer whereas larger grains with the rolling and its recrystallization textures (red and orange grains) remain with high fractions in the center layer. There is a sharp transition from the surface to the center of samples. The main components vary through the thickness and the differences are rather significant. Moreover, the distribution of texture components is not changed with the increase of annealing time. Size and spatial distributions of non-indexed grains are not changed either.

Fig. 8 IQ maps showing cross sections of CP-Ti samples

Fig. 9 Direction maps showing evolution of R/ReX and FRSP/ReX textures in CP-Ti sample during annealing at 550 °C

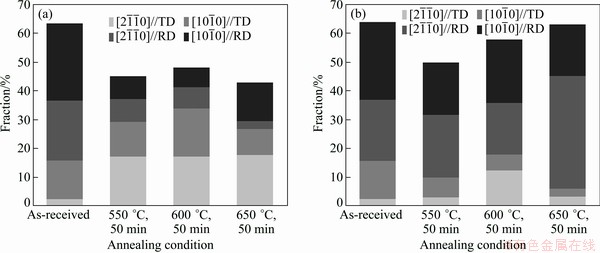

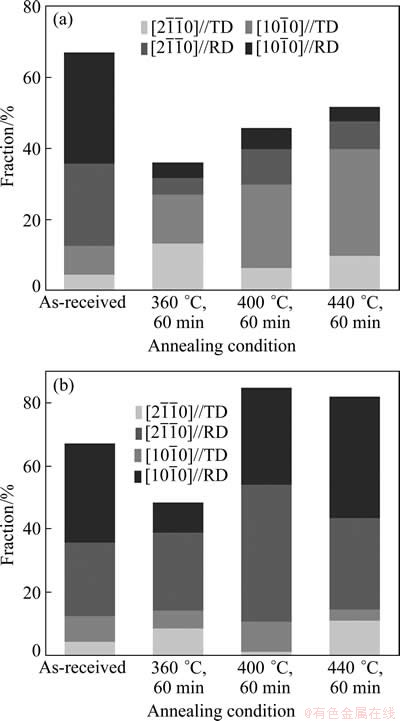

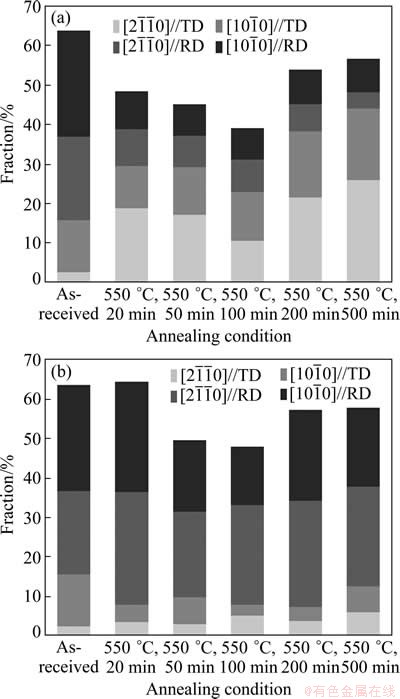

The fractions of texture components as a function of annealing temperature are shown in Fig. 11 for CP-Ti. Figures 11(a) and (b) show the analyzed results of surface (0-50 μm from the surface) and center (400-600 μm) layers, respectively. The total fractions of four components in the center layer, which correspond to the as-received sample, increase gradually with annealing temperature (see Fig. 11(b)). As a whole, fraction of  component corresponding to rolling recrystallization texture tends to rise up after higher temperature annealing. On the other hand, in the surface layer the component with

component corresponding to rolling recrystallization texture tends to rise up after higher temperature annealing. On the other hand, in the surface layer the component with  , which is one of FRSP/ReX texture components, increases remarkably after annealing though effect of the annealing temperature is not clear. After annealing at a higher temperature of 650 °C for 50 min, the different texture components can still be observed in different layers. The FRSP/ReX texture components are the main ones in the surface of sample, as displayed in Fig. 11(a). The grains in the center layer having R/ReX texture components grew preferentially, as shown in Fig. 11(b).

, which is one of FRSP/ReX texture components, increases remarkably after annealing though effect of the annealing temperature is not clear. After annealing at a higher temperature of 650 °C for 50 min, the different texture components can still be observed in different layers. The FRSP/ReX texture components are the main ones in the surface of sample, as displayed in Fig. 11(a). The grains in the center layer having R/ReX texture components grew preferentially, as shown in Fig. 11(b).

Recrystallization that happened at lower temperature in HP-Ti is not only because of its higher purity but also the severe strain imposed in HP-Ti, as discussed above. Figure 12 shows the microstructural evolution and texture distribution of TD sample after FRSP and annealing at 360 °C for 60 min. For whole sample, the scan area of EBSD is 0-1000 μm with a step size of 5 μm. Detailed analyses were carried out in a scan area of 0-200 μm with a step size of 1 μm. The notable change in grain size is observed on the sample along ND. Fine grained microstructure was obtained in the surface layer about 50 μm sample; the grains with the same size as the as-received one remained on the rest part of sample. FRSP and R/ReX texture components were given by assigned color. A distinguished FRSP/ReX texture can be found in the surface of sample which is different from the texture of as-received one. The rest part of the sample still has the original texture even though the twins can be confirmed in the grain. It is obviously that fine grains holding sharp FRSP/ReX texture appeared after FRSP and subsequent annealing. Fractions of FRSP and R/ReX texture components against annealing temperature are also compared in Fig. 13. The total fraction of four components in the surface layer increase gradually with annealing temperature also in HP-Ti (Fig. 13(b)). However, it is worth to mention that  component evolves considerably compared with that in CP Ti. The explanation and mechanism are investigated below.

component evolves considerably compared with that in CP Ti. The explanation and mechanism are investigated below.

Fig. 10 Schematic illustration of difference between R/ReX and FRSP/ReX textures

Fig. 11 Relationship between rolling and FRSP texture components and annealing temperature for CP-Ti annealed for 50 min (The directions  and

and  represent R/ReX texture while

represent R/ReX texture while  and

and  do FRSP/ReX texture) with analysis area of for as-received one of 0-1000 mm, and for FRSP treated and annealed samples of 0-50 mm (a) and 400-600 μm from surface

do FRSP/ReX texture) with analysis area of for as-received one of 0-1000 mm, and for FRSP treated and annealed samples of 0-50 mm (a) and 400-600 μm from surface

Fig. 12 Direction maps showing R/ReX and FRSP/ReX textures on TD cross section perpendicular to FRSP direction in HP Ti TD sample after FRSP and annealing at 360 °C for 60 min

Fig. 13 Relationship between rolling and FRSP texture components and annealing temperature for HP-Ti annealed for 60 min (The directions  and

and  represent R/ReX texture while

represent R/ReX texture while  and

and  do FRSP/ReX texture) with analysis area of 0-1000 mm for as-received, 0-50 mm (a), 400-600 mm (b) from surface for FRSP treated and annealing samples

do FRSP/ReX texture) with analysis area of 0-1000 mm for as-received, 0-50 mm (a), 400-600 mm (b) from surface for FRSP treated and annealing samples

After FRSP process, i.e. at the deformed state, the new FRSP texture was given into the surface of sample, therefore both FRSP and R/ReX texture components coexist in the surface layer where the severe strain was stored. After annealing at the low temperature, the grains which hold four texture components with more fraction of FRSP/ReX texture components and less fraction of R/ReX ones appeared in the surface layer. It suggests that the preferred orientations resulting from FRSP and annealing were formed while R/ReX was reduced by FRSP. The preferred orientations by FRSP remained distinctly after annealing and the components of the texture tended to increase with the annealing temperature and time. The transition from deformation to recrystallization texture mainly takes place only during the growth in hexagonal materials [42,43].

The ratio of main texture components of  and

and  in the surface and inside layers of the FRSP treated CP-Ti was not changed drastically during annealing at 550 °C though fractions of them were changed in Fig. 14. Besides, the size of grains in the surface layer did not change either. After FRSP and annealing at a lower temperature, only stored strain in certain oriented area was removed, and the finer grains with FRSP texture could be maintained. The FRSP/ReX texture can be controlled by the operating conditions of FRSP, such as FRSP direction and indentation depth. FRSP and subsequent annealing can be a promising way to make the fine grains with preferred orientation in the surface layer of materials.

in the surface and inside layers of the FRSP treated CP-Ti was not changed drastically during annealing at 550 °C though fractions of them were changed in Fig. 14. Besides, the size of grains in the surface layer did not change either. After FRSP and annealing at a lower temperature, only stored strain in certain oriented area was removed, and the finer grains with FRSP texture could be maintained. The FRSP/ReX texture can be controlled by the operating conditions of FRSP, such as FRSP direction and indentation depth. FRSP and subsequent annealing can be a promising way to make the fine grains with preferred orientation in the surface layer of materials.

Fig. 14 Relationship between rolling, FRSP and their recrystallization texture components and annealing time for CP Ti annealed at 550 °C after FRSP (The directions  and

and  represent R/ReX texture while

represent R/ReX texture while  and

and  do FRSP/ReX texture with analysis area of 0-1000 μm for as-received one, and 0-50 μm (a), 400-600 μm (b) from surface for FRSP and annealing treated samples

do FRSP/ReX texture with analysis area of 0-1000 μm for as-received one, and 0-50 μm (a), 400-600 μm (b) from surface for FRSP and annealing treated samples

4 Conclusions

1) The new straining technique, named FRSP and annealing, was used to make surface modification in commercial purity titanium (CP-Ti) and high purity titanium (HP-Ti).

2) During FRSP, a large plastic strain was imposed into the surface layer and caused grain refinement to form the nanostructure with preferred orientation of shear deformation. The deformation texture of HP-Ti after FRSP became sharper than that of CP-Ti. This was attributed to more strain imposed into the HP Ti sample due to its larger grain size and less impurity. It is also proved that the FRSP texture was strongly related to the processing direction. By optimizing the operating conditions of FRSP and annealing, characteristic textures were formed in the surface layer of sample. The results showed the preferred orientations resulting from FRSP and annealing were formed while R/ReX was reduced by FRSP. Therefore, FRSP and subsequent annealing have an excellent possibility for controlling both microstructure and texture in the surface layer of the materials.

Acknowledgements

The authors gratefully acknowledge support in part by Grant-in-aid for Scientific Research from the Japan Society for Promotion of Science under Contract No. 16560605 and the support of the OSAKA Titanium technologies Co., Ltd. and Kobe Steel, Ltd., for providing the samples.

References

[1] TAVERNIER P H, SZPUNAR J A. Modelling of recrystallization textures [J]. Acta Metallurgica et Materialia, 1991, 39: 549-556.

[2] BALL J, GOTTSTEIN G. Large strain deformation of Ni3Al+B: Part II. Microstructure and texture evolution during recrystallization [J]. Intermetallics, 1993, 1: 191-208.

[3] DOHERTY R D, KASHVAP K, PANCHANADEESWARAN S. Direct observation of the development of recrystallization texture in commercial purity aluminum [J]. Acta Metallurgica et Materialia, 1993, 41: 3029-3053.

[4] DOHERTY R D, CHEN L C, SAMAJDAR I. Cube recrystallization texture-experimental results and modeling [J]. Materials Science and Engineering A, 1998, 257: 18-36.

[5] CALEYO F, BAUDIN T, PENELLE R, VENEGAS V. EBSD study of the development of cube recrystallization texture in Fe-50%Ni [J]. Scripta Materialia, 2001, 45:413-420.

[6] CHUN Y B, YU S H, SEMIATIN S L, HWANG S K. Effect of deformation twinning on microstructure and texture evolution during cold rolling of CP-titanium [J]. Materials Science and Engineering A, 2005, 398: 209-219.

[7] BOZZOLO N, DEWOBROTO N, WENK H R, WAGNER F. Microstructure and microtexture of highly cold-rolled commercially pure titanium [J]. Journal of Material Science, 2007, 42: 2405-2416.

[8] BOZZOLO N, WAGNER F. Textures in hcp titanium and zirconium [C]// ROLLETT A D. Proc ICOTOM 15 Pittsburgh: The American Ceramic Society, 2008: Hexagonal Metals on CD.

[9] WAGNER F, BOZZOLO N, LANDUVT O V, GROSDIDIER T. Evolution of recrystallisation texture and microstructure in low alloyed titanium sheets [J]. Acta Materialia, 2002, 50: 1245-1259.

[10] HAYAMA A O F, SANDIM H R Z. Annealing behavior of coarse-grained titanium deformed by cold rolling [J]. Materials Science and Engineering A, 2006, 418: 182-192.

[11] VALIEY R Z. Nanostructuring of metals by severe plastic deformation for advanced properties [J]. Nature Materials, 2004, 3: 511-516.

[12] YAPICI G G, KARAMAN I, MAIER H J. Mechanical flow anisotropy in severely deformed pure titanium [J]. Materials Science and Engineering A, 2006, 434: 294-302.

[13] ZENG Z P, ZHANG Y S. JONSSON S. Deformation behavior of commercially pure titanium during simple hot compression [J]. Material and Design, 2009, 30: 3105-3111.

[14] FAN Z G, JIANG H, SUN X G, SONG J, ZHANG X N, XIE C Y. Microstructures and mechanical deformation behaviors of ultrafine-grained commercial pure (grade 3) Ti processed by two-step severe plastic deformation [J]. Materials Science and Engineering A, 2009, 527: 45-51.

[15] BEYERLEIN I J, TOTH L S. Texture evolution in equal-channel angular extrusion [J]. Progress in Material Science, 2009, 54: 427-510.

[16] REN T, SHAN D, CHEN Y, LU Y. Surface plastic deformation distribution and microstructural evolution in the compound rolling of Ti-50Al billet [J]. Material and Design, 2010, 31: 3457-3462.

[17] LI S Y. Orientation stability in equal channel angular extrusion. Part II: Hexagonal close-packed materials [J]. Acta Materialia, 2008, 56: 1031-1043.

[18] SUWAS S, BEAUSIR B, TOTH L S, FUNDENBERGER J J, GOTTSTEIN G. Texture evolution in commercially pure titanium after warm equal channel angular extrusion [J]. Acta Materialia, 2011, 59: 1121-1133.

[19] SHIN D H, KIM I, KIM J, KIM Y S, SEMIATIN S L. Microstructure development during equal-channel angular pressing of titanium [J]. Acta Materialia, 2003, 51: 983-996.

[20] DHEDA S S, MOHAMED F A. E. Effect of initial microstructure on the processing of titanium using equal channel angular pressing [J]. Materials Science and Engineering A, 2011, 528: 8179-8186.

[21] SHI M Q, TAKAYAMA Y, KATO H. Microstructure and mechanical properties of titanium severely strained by means of friction roll processing [J]. Materials Science Forum, 2007, 561-565: 909-912.

[22] SHI M Q, TAKAYAMA Y, UMETSU T, KATO H, WATANABE H, INOUE H. Microstructure refinement and texture evolution of titanium by friction roll surface processing [J]. Materials Transactions, 2009, 50: 210-214.

[23] KAMIKAWA N, SAKAI T, TSUJI N. Effect of redundant shear strain on microstructure and texture evolution during accumulative roll-bonding in ultralow carbon IF steel [J]. Acta Materialia, 2007, 55: 5873-5888.

[24] HUMPHREYS F J, HATHERLY M. Recrystallization and related annealing phenomena [M]. 2nd ed. Oxford: Pergamon Press, 2004: 217-219.

[25] SWALLA D R, NEU R W. Fretting damage assessment of titanium alloys using orientation imaging microscopy [J]. Tribology International, 2006 39: 1016-1027.

[26] SALINAS R A. Grain size effects on the texture evolution of α-Zr [J]. Acta Metallurgica et Materialia, 1995, 43 1995: 485-498.

[27] CHRISTIAN J W, MAHAJAN S. Deformation twinning [J]. Progress in Material Science, 1995, 39: 1-157.

[28] ZHU K Y, VASSEL A, BRISSET F, LU K, LU J. Nanostructure formation mechanism of α-titanium using SMAT [J]. Acta Materialia, 2004, 52: 4101-4110.

[29] CHOI W S, RYOO H S, HWANG S K, KIM M H, SWUN S I, CHAE S W. Microstructure evolution in Zr under equal channel angular pressing [J]. Metallurgical and Materials Transactions A, 2002, 33: 973-980.

[30] WU X, TAO N, HONG Y, LIU G, XU B, LU J, LU K. Strain-induced grain refinement of cobalt during surface mechanical attrition treatment [J]. Acta Material, 2005, 53: 681-691.

[31] RIGNEY D A, FU X Y, HAMMERBERG J E, HOLIAN B L, FALK M L. Examples of structural evolution during sliding and shear of ductile materials [J]. Scripta Materialia. 2003, 49: 977-983.

[32] BEYERLEIN I J, LEBENSOHN R A. TOME C N. Modeling texture and microstructural evolution in the equal channel angular extrusion process [J]. Materials Science and Engineering A, 2003, 345: 122-138.

[33] KRAUSE H, DEMIRCI A H. Texture changes in the running surfaces of face-centred cubic metals as the result of frictional stress [J]. Wear, 1980, 61: 325-332.

[34] KRAUSE H, OCALAN E. The effect of initial orientation on the formation of tribological textures and on the wear behavior of the regions in the proximity of surface layers under continuous sliding motion in tribological systems [J]. Wear, 1986, 108: 337-343.

[35] GODDARD J, HACKER H J, WILMAN H. The surface reorientation caused by unidirectional abrasion on face-centred cubic metals [J]. Proceedings of the Physical Society, 1962, 80: 771-782.

[36] FARHAT Z N. Contribution of crystallographic texturing to the sliding fricition behavior of fcc and hcp metals [J]. Wear, 2001, 250: 401-408.

[37] HEILMANN P, CLARK W A T, RIGNEY D A. Orientation determination of subsurface cells generated by sliding [J]. Acta Metallurgica, 1983, 31: 1293-1305.

[38] KOCKS U F, CHANDRA H. Slip geometry in partially constrained deformation [J]. Acta Metallurgica, 1982, 30: 695-709.

[39] HIRTH J P, RIGNEY D A. The application of dislocation concepts in friction and wear [C]//NABARRO F R. Dislocation in solids, Amsterdam: North-Holland, 1983, 6: 10.

[40] SCOTT V D, WILMAN H. Surface Re-orientation caused on metals by abrasion-its nature, origin and relation to friction and wear [J]. Proceedings of the Royal Society A, 1958, 247: 353-368.

[41] TARASJUK J, GERBER P, BACROIX B. Estimation of recrystallized volume fraction from EBSD [J]. Acta Materialia, 2002 50: 1467-1477.

[42] BOZZOLO N, WAGNER F, DEWOBROTO N, GROSDIDIER T. Recrystallization textures in some hexagonal alloys [J]. Material Science Forum, 2002, 408-412: 901-906.

[43] ZHU K Y, BACROIX B, CHAUYEAU T, CHAUBET D, CASTELNAU O. Texture evolution and associated nucleation and growth mechanisms during annealing of a Zr Alloy [J]. Metallurgical and Materials Transactions A, 2009, 40: 2423-2434.

施梅勤1,高山善匡 2,马淳安1,渡部英男 2,井上博史 3

1. 浙江工业大学 化学工程与材料学院,绿色化学合成技术国家重点实验室培育基地,杭州 310032;

2. Department of Mechanical and Intelligent Engineering, Graduate School of Engineering, Utsunomiya University, Utsunomiya 321-8585, Japan;

3. Department of Materials Science, Graduate School of Engineering, Osaka Prefecture University, Sakai 599-8531, Japan

摘 要:通过一种新的摩擦轧压表面处理工艺(FRSP)对纯钛板材表面进行加工,引入的应变沿材料厚度方向成梯度分布。采用光学显微镜、X射线衍射对FRSP加工后的纯钛的微观组织进行观察发现在钛材表面形成了超微细晶粒,且具有明显织构,其方向与FRSP的加工方向有关。另外,对FRSP处理后的钛材在不同温度和时间下进行退火处理,通过EBSD研究织构的形成及其在退火过程中的演变规律。结果表明:在低温退火过程中,钛板材表层主要存在FRSP后形成的织构,而原有的典型轧制织构减少,可见,通过FRSP及后续退火可有效地控制钛材表面的微观组织与织构。

关键词:钛;摩擦轧压表面处理;强烈塑性变形;择优取向;再结晶;结构演化;超细晶粒

(Edited by YANG Hua)

Corresponding author: SHI Mei-qin; Tel: +86-571-88320143; E-mail: smq@zjut.edu.cn

DOI: 10.1016/S1003-6326(11)61508-2