冷轧带钢板形屈曲变形失稳限的有限元分析

王 澜1,曹建国1,贾生晖2,曾 彤2

(1. 北京科技大学 机械工程学院,北京,100083;

2. 武汉钢铁(集团)公司,湖北 武汉,430083)

摘 要:采用ANSYS有限元仿真分析方法研究冷轧宽带钢板形屈曲失稳特性。利用ANSYS的几何非线性求解模块,建立宽薄带钢二维有限元模型,分析不同形式载荷、厚宽比和张应变下的屈曲失稳过程,计算板形屈曲变形失稳限。分析结果表明:边中复合浪的临界失稳载荷最大,中浪的较大,边浪的最小;边中复合浪的屈曲半波长为板宽的50%~60%,中浪与单边浪为80%左右,对称双边浪约为70%;在同样载荷下,随着厚宽比或张应变的增加,临界失稳限呈增长趋势,并且复杂浪形的临界失稳限增长速度明显大于简单浪形的增长速度。

关键词:冷连轧机;带钢;屈曲;有限元分析

中图分类号:PG335.11 文献标识码:A 文章编号:1672-7207(2007)06-1157-05

Finite element analysis of shape buckling load for cold rolled strips

WANG Lan1, CAO Jian-guo1, JIA Sheng-hui2, ZENG Tong2

(1. School of Mechanical Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Wuhan Iron and Steel Company, Wuhan 430083, China)

Abstract: The behavior of the cold rolled strip buckling was studied using the ANSYS finite element method. Based on the geometrical non-linear solution module of the ANSYS, the two-dimensional finite element model was developed to analyze the process of buckling with the different kinds of loads, the different ratios of strip width to gauge and tensile strain. Then the buckling load was figured out. The results show that the biggest buckling load appears in the center buckle with edge wave, the smallest appears in the side long edge, and the long center ranks the middle. The half buckling wavelength of the center buckle with edge wave is 50%-60% of width, the long center and the single-side long edge is round 80%, the symmetrical dual-side long edge is about 70%. With the same kind of loads, the buckling load keeps growing while the ratio of strip width to gauge or the tensile strain increases, and the complex grows obviously faster than the simple one.

Key words: tandem cold rolling mill; strip; buckling; finite element analysis

确定冷轧带钢板形屈曲失稳限,即轧后带材产生板形缺陷的临界条件,是建立冷轧带钢板形控制目标模型的理论基础。在冷轧薄板轧制过程中,在张力作用下,带钢内部原存在的纵向纤维不均匀延伸导致带材上有的部分受拉应力作用,有的部分受压应力作用,当压缩部分的压应力超过一定临界值时,该部分的带材会出现受压失稳,带材产生某种形式的板形屈曲变形,带材出现翘曲浪形。带钢产生板形屈曲的根本原因是带钢各条纵向纤维长度不相等(沿宽向的不均匀轧制或延伸所致),且达到屈曲临界条件。运用薄板弹性小位移理论,根据能量原理和变分法可以求解各种板形应力形式下的屈曲发生界限[1-10],但不能得到关于屈曲临界条件的显式表达式,必须通过数值计算才能求得各种工况下的屈曲临界应力[11]。1 700 mm冷连轧机是我国引进的第1套现代化冷连轧机,2004年3月完成了以“酸轧联机”为主要内容的技术改造,目前年生产50万t以上的新规格电工钢板,该轧机仍采用改造前板形控制目标系统,不能反映生产实际的变 化[12-16]。因此,本文作者采用大型通用有限元分析软件ANSYS建立薄板有限元模型,施加相应的边界条件和载荷,计算了轧后带材的屈曲失稳限,这对于建立大量生产电工板的板形控制目标具有实用价值。

1 板形屈曲变形的有限元模型

1.1 建 模

由于这里研究的对象是宽薄带钢,其厚度仅为0.5 mm,与宽度、长度相比很小,因此,利用ANSYS提供的二维壳单元shell63来建模,厚度作为实参数直接输入[17]。模型宽度等于带材原来的宽度,长度等于带材发生屈曲后的半波长L。单元划分时保证每个单元面积不大于20 mm×20 mm。薄板模型具体参数为:宽度b=1 300 mm;计算参数为:弹性模量E=2.1×1011 N/m2,泊松比μ=0.28。

1.2 确定边界条件与载荷

采用第1类车比雪夫多项式系表示的板形应力作为计算中的外载,具体表达式如下:T1(x)=x; T2(x)=2x2-1;T4(x)=8x4-8x2-1。冷轧带钢板形应力分布模式如图1所示。

带材发生屈曲变形的过程中,在计算中假定外载荷保持不变,即忽略失稳过程中的应力松弛现象。对不同的载荷形式采用不同的约束方式分别进行约束。对同一种载荷形式也要尝试不同的约束条件,进行多次试算,以最符合实际情况的约束作为最终可采用的约束。图2所示为中浪形式模型载荷图。

2 计算与分析

由于冷轧薄板结构的特殊性,当?σcr<<σs时,已经发生失稳变形,因此,不必考虑材料的非线性特点[13-14]。计算中的主要参数有轧件宽度、厚度及截取的半波长L。根据实践经验,半波长L一般在宽度的0.25~1.25之间变动,因此,在这个范围内分别截取不同的长度进行求解,以找到最小临界失稳限及半波长。ANSYS提供的分析结构屈曲失稳的技术是通过逐渐增加载荷的非线性静力分析方法来获得结构发生失稳的临界载荷。在计算中,如果模型的原始状态为平坦的,并且所加载荷也在平面内,将不会产生屈曲变形,也不会得到屈曲结果[18-20]。所以,在计算前,通过对平坦的板带模型加入适当静态初始位移,使模型产生预变形,从而达到屈曲变形的目的。利用非线性计算中的BUCKLING模块求解出薄板模型在不带张力情况下的屈曲失稳限。中浪形式模型屈曲变形如图3所示。

1—1/4浪;2—边中复合浪;3—左侧边浪;

4—右侧边浪;5—中浪;6—双侧边浪

图1 冷轧带钢板形应力分布模式

Fig.1 Shape of cold rolled strip strain

图2 中浪形式载荷图

Fig.2 Loads of long center

2.1 临界失稳限的计算与分析

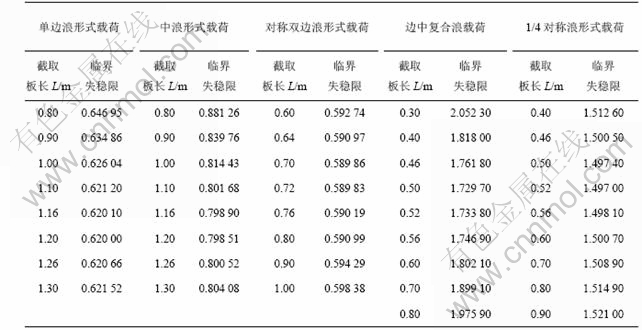

0.5 mm×1 300 mm规格冷轧薄板的5种浪形的临界失稳限计算结果如表1和图4所示。

表1 冷轧带钢不同浪形的临界失稳限计算结果

Table 1 Buckling load results of different strip waves

图3 中浪形式屈曲变形图

Fig.3 Buckling of long center

1—单边浪形式载荷;2—中浪形式载荷;3—对称双边浪

形式载荷;4—边中复合浪载荷;5—1/4对称浪形式载荷

图4 冷轧带钢5种典型浪形的临界失稳限

Fig.4 Buckling load of five typical waves

2.1.1 不同形式载荷对临界失稳限的影响

从计算出的各种屈曲失稳限可以看出(见图4),不同的浪形有不同的临界失稳限,复合浪的临界失稳限相对较大, 中浪的临界失稳限次之,边浪的临界失稳限较小。即在同样大小的残余内应力下,边浪最易生成,而复合浪最不易生成。

2.1.2 不同形式载荷对屈曲半波长的影响

单边浪与中浪的屈曲半波长相对较大,为板宽的80%左右,对称双边浪屈曲半波长约为板宽的70%,复合浪的屈曲半波长最小,为板宽的50%~60%。这与复合浪多为短波,中、边浪多为长波的实际情况也相吻合。

2.2 张应力对临界失稳限的影响

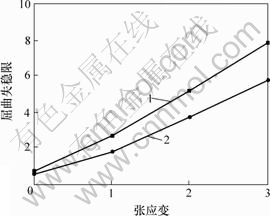

中浪和对称双边浪为例,薄板模型在带张力情况下的屈曲失稳限,计算结果如图5所示。

从图5可见,在对中浪、对称双边浪施加张应变后,浪形的临界失稳限明显增大,并且临界失稳限的增加与张应变的增加呈线性关系。因此,在线轧制时,施加合理的张应力,提高临界失稳限,可以有效防止带材在线屈曲。

2.3 厚宽比对临界失稳限的影响

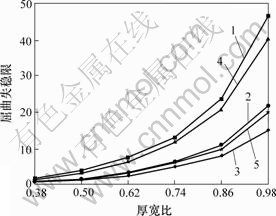

薄板5种浪形在不同厚宽比(比例数量级为10-3)的情况下计算结果的屈曲失稳限如图6所示。

1—中浪;2—对称双边浪

图5 薄板临界失稳限与张应变的关系

Fig.5 Relationship between buckling load and tensile strain of thin plate

1—边中复合浪;2—中浪;3—对称双边浪;

4—1/4浪;5—单边浪

图6 薄板临界失稳限与厚宽比的关系

Fig.6 Relationship between buckling load and ratio of width to gauge of thin plate

从图6可以看出,随着厚宽比的增大,临界失稳限呈显著增加趋势,并且在增加的厚宽比相同时,复合浪形比中浪、边浪等简单浪形的临界失稳限增加的速度更快,其曲线的斜率明显大于其他2种浪形斜率。因此,厚度越大的薄板越不易发生屈曲,厚宽比是影响薄板临界失稳限的重要因素。

3 结 语

a. 冷轧带钢临界失稳除了与材料性质E和μ相关外,不同的浪形对应不同的临界失稳限及屈曲半波长,并且复合浪最不易发生屈曲,中浪、边浪较易发生 屈曲。

b. 在带钢屈服极限内,临界失稳限随张应变的增加呈线性增长。

c. 临界失稳限随厚宽比的增加而增大,并且在增加相同厚宽比的情况下,边浪、中浪、复合浪的曲线变化斜率依次增大。

d. 基于本模型计算结果可为冷轧硅钢板形控制目标的建立提供理论依据。

参考文献:

[1] 杨 荃. 冷轧带钢屈曲理论与板形控制目标的研究[D]. 北京: 北京科技大学机械工程学院, 1992.

YANG Quan. Study on the buckling theory of cold rolled strip and shape controlled target[D]. Beijing: School of Mechanical Engineering, University of Science and Technology Beijing, 1992.

[2] 杨 荃, 陈先霖. 轧制带材的屈曲理论及其在冷轧机板形控制中的应用[J]. 冶金设备, 1994(83): 1-5.

YANG Quan, CHEN Xian-lin. Bucking theory and its use in shaping control of cold rolling mill[J]. Metallurgical Equipment, 1994(83): 1-5.

[3] 林振波, 连家创. 冷轧带材形判别模型的有限条分析[J]. 东北重型机械学院学报, 1996, 20(3): 207-210.

LIN Zhen-bo, LIAN Jian-chuang. Finite strip method research on shape discriminant model of cold rolled strip[J]. Journal of Northeast Heavy Machinery Institute, 1996, 20(3): 207-210.

[4] 张清东, 刘赟赟, 周晓敏, 等. 带钢在连续退火过程中的板形屈曲变形原因分析[J]. 上海金属, 2005, 27(4): 27-29, 33.

ZHANG Qing-dong, LIU Yun-yun, ZHOU Xiao-min, et al. Research on strip profile buckling deformation during continuous annealing process[J]. Shanghai Metals, 2005, 27(4): 27-29, 33.

[5] 林振波, 张 波, 连家创, 等. 冷轧带材板形判别模型的分析与讨论[J]. 钢铁, 1995, 30(8): 39-43.

LIN Zhen-bo, ZHANG Bo, LIAN Jian-chuang, et al. Analysis and discussion of shape discriminant model of cold rolled strip[J]. Iron and Steel, 1995, 30(8): 39-43.

[6] 张清东, 陈先霖, 陈宝官. 冷轧带钢翘曲浪形的变形分析[J]. 轧钢, 1996, 2(1): 9-12.

ZHANG Qing-dong, CHEN Xian-lin, CHEN Bao-guan. Analysis on the shape deformation of on-line buckled strip[J]. Steel Rolling, 1996, 2(1): 9-12.

[7] GUO Ren-min. Computer model simulation of strip and shape control[J]. Iron and Steel Engineer, 1986, 21(11): 35-42.

[8] Nappez C, McDermott R C. Control of strip flatness in cold rolling: A global approach[J]. Iron and Steel Engineer, 1997, 23(4): 42-45.

[9] 孙 林, 张清东, 陈先霖, 等. 中板轧机板形控制性能的研 究[J]. 钢铁, 2002, 37(1): 34-38.

SUN Lin, ZHANG Qing-dong, CHEN Xian-lin, et al. Research on profile and flatness control characteristics of plate mill[J]. Iron and Steel, 2002, 37(1): 34-38.

[10] 张清东, 陈先霖, 何安瑞, 等. 冷轧宽带钢板形检测与自动控制[J]. 钢铁, 1999, 23(10): 69-73.

ZHANG Qing-dong, CHEN Xian-lin, HE An-rui, et al. Automatic measurement and control of flatness of wide cold-rolled steel strip[J]. Iron and Steel, 1999, 23(10): 69-73.

[11] 顾云周, 张 杰, 陈先霖, 等. 高效实用的板带变形求解方 法[J]. 北京科技大学学报, 2002, 23(3): 333-335.

GU Yun-zhou, ZHANG Jie, CHEN Xian-lin, et al. High efficient simulation for strip deformation in strip rolling[J]. Journal of University of Science and Technology Beijing, 2002, 23(3): 333-335.

[12] 曹建国, 顾云舟, 张 杰, 等. 1 700 mm冷轧带钢轧机板形控制能力研究[J]. 钢铁研究, 2002(3): 16-19.

CAO Jian-guo, GU Yun-zhou, ZHANG Jie, et al. Study on controllability of profile and flantness at 1 700 mm tandem cold rolling mill[J]. Research on Iron & Steel, 2002(3): 16-19.

[13] 贾生晖. 变凸度冷连轧机辊形及板形研究[D]. 北京: 北京科技大学机械工程学院, 2005.

JIA Shen-hui. Study on roll contour and strip flatness of variable crown tandem cold rolling mills[D]. Beijing: School of Mechanical Engineering, University of Science and Technology Beijing, 2005.

[14] 卿伟杰. 武钢1700冷连轧机组板形控制目标的设定[D]. 北京: 北京科技大学机械工程学院, 2000.

QIN Wei-jie. Study on the target shape in the automatic flatness control of wisggo 1 700 mm five-stand cold tandem rolling mill[D]. Beijing: School of Mechanical Engineering, University of Science and Technology Beijing, 2000.

[15] 贾生晖, 尹晓青, 曹建国, 等. 冷连轧机板形控制对策的仿真分析[J]. 冶金设备, 2002, 10(135): 20-23.

JIA Sheng-hui, YIN Xiao-qing, CAO Jian-guo, et al. Simulation of flatness control method on tandem cold rolling mill[J]. Metallurgical Equipment, 2002, 10(135): 20-23.

[16] 贾生晖, 张 杰, 曹建国, 等. 冷连轧机硅钢板形控制目标的改进[J]. 北京科技大学学报, 2002, 24(3): 303-305.

JIA Shen-hui, ZHANG Jie, CAO Jian-guo, et al. Flatness target curve for non-tropism silicon steel rolling in 5-stand tandam cold rolling mill[J]. Journal of University of Science and Technology Beijing, 2002, 24(3): 303-305.

[17] 李黎明. ANSYS有限元分析实用教程[M]. 北京: 清华大学出版社, 2005.

LI Li-ming. Finite element analysis practicality tutorial of ansys[M]. Beijing: Tsinghua University Press, 2005.

[18] 张凤鹏, 黄宝宗, 牛晚扬, 等. 非线性复合材料层板分层屈曲及后屈曲分析[J]. 东北大学学报, 2000, 21(3): 343-346.

ZHANG Feng-peng, HUANG Bao-zong, NIU Wan-yang, et al. Buckling and postbuckling analysis of nonlinear composite laminates with delamination[J]. Journal of Northeastern University, 2002, 21(3): 343-346.

[19] 田晓耕, 沈亚鹏, 高坚新. 压电板屈曲和后屈曲的有限元分析[J]. 固体力学学报, 2000, 21(2): 123-130.

TIAN Xiao-geng, SHEN Ya-peng, GAO Jian-xin. Buckling and post-buckling analysis of piezoelectric plates using finite element method[J]. Acta Mechanica Solid Asinica, 2000, 21(2): 123-130.

[20] 曾晓辉, 柳春图, 杨丽敏. 面板局部屈曲的船体双层板架整体屈曲分析[J]. 海洋工程, 2001, 19(3): 60-67.

ZENG Xiao-hui, LIU Chun-tu, YANG Li-min. Overall buckling analysis of double-wall shipgrillage considering post buckling behavior of flange[J]. Ocean Engineering, 2001, 19(3): 60-67.

收稿日期:2007-03-10;修回日期:2007-05-08

基金项目:国家自然科学基金重点资助项目(59835170);北京科技大学科技发展专项基金资助项目(20050311890)

作者简介:王 澜(1978-),男,浙江长兴人,工程师,从事板形控制、板带轧制技术及自动化研究

通信作者:曹建国,男,博士,副教授;电话:010-62332835;E-mail: geocao@me.ustb.edu.cn