Trans. Nonferrous Met. Soc. China 22(2012) s769-s774

Wear characteristics of V shape diamond tool for micro prism pattern with Al alloys

Eun-Suk PARK1, 2, Tae-Jin JE1, 2, Hwan-Jin CHOI1, 2, Eun-Chae JEON 2, Myung-Chang KANG3

1. Nano-Mechatronics, University of Science &Technology, Daejeon 305-350, Korea;

2. Division of Nano-Mechanical Systems, Korea Institute of Machinery and Materials, Daejeon 305-343, Korea;

3. National Core Research Center for Hybrid Materials Solution, Pusan National University, Busan 609-735, Korea

Received 21 May 2012; accepted 1 November 2012

Abstract: The ultra-precision machining process using a single crystal diamond tool has been mainly used for machining molds of optical components. Since the micro patterns of various shapes having excellent surface roughness can be machined by using ultra-precision machine tools, the micro pattern on a large light guide plate (LGP) is mainly machined using a diamond tool. The tool wear occurs due to long machining distances and time while machining a large-area LGP mold. The deformation and dimensional error of micro pattern are caused by tool wear, as a result, the light efficiency of LGP declines. The characteristics of tool wear should be analyzed in order to precisely machine large-area LGP mold from all sorts of materials. The experiments were performed in order to compare wear characteristics of a V90° diamond tool using Al3003, 5052, 6061 and 7075. The prism pattern of depth 10 μm was machined in order to analyze characteristics of tool wear according to machining distances (0.5, 1 and 1.5 km). The effects of tool wear on pattern shape were analyzed by applying overlapped cutting depths (Rough machining is (10+8+7) μm and Finish machining is (5+3+2+1) μm) by continuously machining a prism pattern of W shape of 25 μm in depth.

Key words: diamond tool wear; Al alloys; micro prism pattern; planer

1 Introduction

Recently display industries have been dramatically grown with immersion into the high-speed information age and increased for large-area slim displays high specifications. Light guide plate (LGP) which compensates light uniformity is a core optical component of displays. Large-area LGPs are manufactured with variously patterned molds based on ultra-precision machining process using a diamond tool because of the ease of machining various micro pattern shapes, and better surface roughness than other processes [1-4]. Problems such as mass of workpiece, long machining time and tool wear occur when machining large-area molds. Al alloy is widely used as light materials due to mass of workpiece in the case of machining large-area mold. Therefore, study on machining Al alloy mold has been carried out [5-7]. Also deformation and dimensional errors of the pattern occur by tool wear during machining large-area mold [8-11]. The causes of diamond tool wear are the chemical components and mechanical properties of materials and long machining distances etc [12,13], therefore, it is important to analyze the characteristics of diamond tool wear according to the different kinds of materials. The wear characteristics of V90° diamond tool were compared for various kinds of Al alloys (Al3003, 5052, 6062 and 7075) and machining distances (0.5, 1.0 and 1.5 km) using planer in this study. The selected Al alloys were considered to be used for the large-area molds of LGP in display industries.

2 Expectation of tool wear according to machining distances and deformation of prism pattern by tool wear

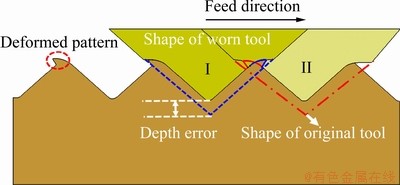

The more machining distance is increased when the value of tool wear at the side is larger and edge is increased. The dimensional error occurs according to the value of tool wear. The cutting force is decreased due to decreased cutting area caused by tool wear from machining long distances. The unexpected deformation and dimensional error of pattern occur. The deformation of pattern (--------) generated by the first machining (I) is eliminated and the deformation of pattern (-·-·-) is generated by the second machining (II), as shown in Fig.1, during continuous machining of a W shape prism pattern due to cutting depths. Effect of tool wear on pattern shape by due to overlapped cutting depth is shown in Fig. 1.

Fig. 1 Effect of tool wear on pattern shape by due to overlapped cutting depth

3 Machining system and experimental methods

The ultra precision planer system can control four- axis movement with 5 nm accuracy. The cutting force of X, Y and Z-axis was measured by tool dynamometer. V90° single crystal diamond tool whose back relief angle is 3° and side relief is 1° was manufactured.

Fig. 2 Experimental methods for experiments

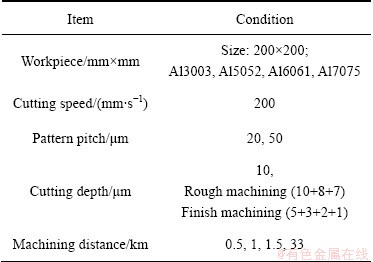

The experiments were performed in order to compare characteristics of diamond tool wear as shown in Fig. 2. The prism patterns having depth 10 μm and pitch 20 μm were machined in order to analyze characteristics of diamond tool wear according to machining distances (0.5, 1.0 and 1.5 km) as shown in Fig. 2(a). The prism patterns of W shape were continuously machined in order to analyze the effect of tool wear on the pattern by application of overlapped cutting depths (Rough machining is (10+8+7) μm and Finish machining is (5+3+2+1) μm) as shown in Fig. 2(b). Detailed experimental conditions are listed in Table 1. The machined micro pattern was replicated by UV resin in order to analyze machined surface and shape of pattern using SEM and microscope.

Table 1 Experimental conditions

4 Results and discussion

4.1 Analysis of characteristics of tool wear according to machining distances

The tool wear was compared according to machining distances and Al alloys in Fig. 3 after machining the prism pattern under the experimental condition in Fig. 2(a). The correlation of tool wear to machining distances was confirmed by the measured dimensional error of machined prism pattern. The longer the machining distance is, the more tool wear is severe. The tool wear of approximately 1.2 μm occurred after machining 1.5 km regardless of the types of Al alloys, as shown in Fig. 4. The amount of tool wear is linearly proportional to the machining distance.

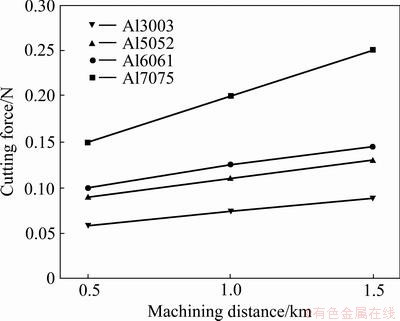

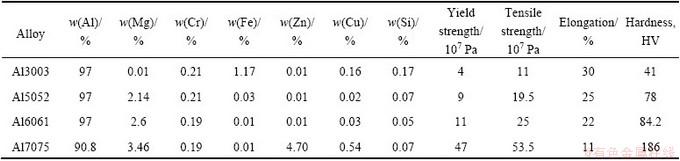

The cutting force was compared according to types of Al alloys and machining distances shown in Fig. 5. The cutting force is high when Al alloys have high hardness as shown in Table 2. It is expected that cutting force would be decreased by the decreased cutting area resulting from tool wear. But it is confirmed that cutting force is only slightly increased due to wearing of the tool edge while machining long distance. The worn tool edge more strongly influences cutting force, than the decreases cutting area.

Fig. 3 Dimensional errors of machined pattern according to Al alloy and machining distances

Fig. 4 Comparison of tool wear after machining 1.5 km

Fig. 5 Comparison of cutting force according to Al alloys and machining distances

4.2 Analysis of effect of tool wear on pattern

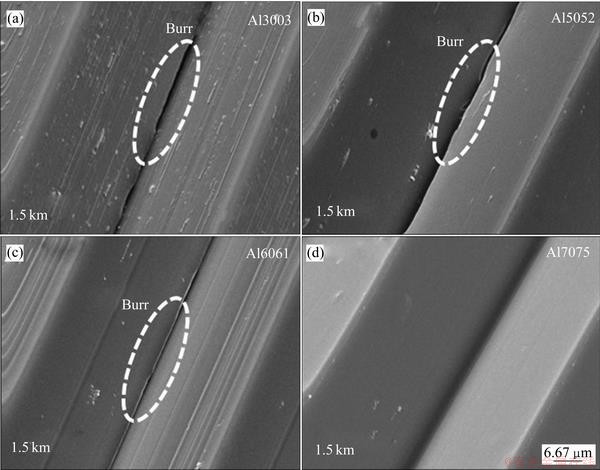

The tool wear and machined surface were compared according to Al alloys in Fig. 6 after the prism pattern of W shape was continuously machined under the experimental condition in Fig. 2(b). The tool wear of approximately 1.2 μm occurs regardless of types of Al alloys under the same experimental conditions in Fig. 2(a). The burr occurs at the top part of the pattern in the case of Al3003, Al5052 and Al6061 but there is no burr in the case of Al7075. The burr which is formed at the top part of the prism pattern can be reduced due to low elongation in the case of Al alloys having high hardness. The measured surface roughness was compared with standard deviation according to Al alloys in Fig. 7.

Table 2 Chemical components and mechanical properties of Al alloys

Fig. 6 Comparison of machined surface according to Al alloys after application of overlapped cutting depth

Fig. 7 Comparison of surface roughness of Al alloys

The surface roughness of Al7075, which has the highest hardness of the Al alloys, is low, but Al3003 which has the lowest hardness of the Al alloys is high.

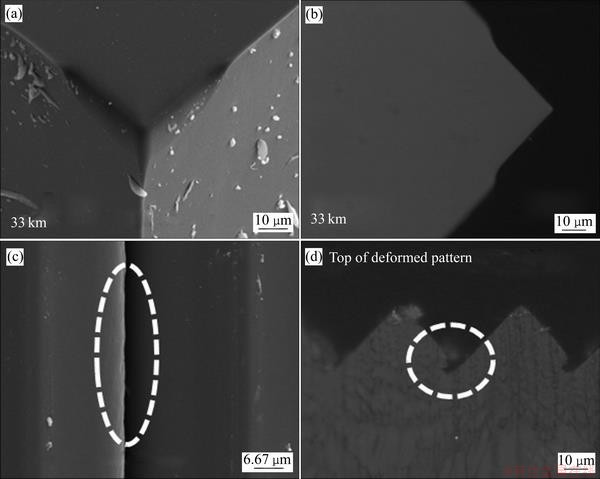

The tool wear and shape of the pattern were indicated as shown in Fig. 8 after machining 33 km by the application of overlapped cutting depths. The tool wear of approximately 6 μm occurred but tool wear rate was slightly different despite differences in machining distances (1.5 and 33 km) because the sharp tool edge is worn out easily. However, tool wear becomes beyond a critical machining distance at which the tool edge is worn out significantly. The severe burr and expected deformation of the pattern resulted from side wear of the tool, and the bottom part of the pattern was machined into an R shape by the edge wear of the tool.

5 Conclusions

1) The similar tool wear (approximately 1.2 μm) occurs regardless of the type of Al alloys and it is conformed that tool wear is proportional to machining distance.

2) The amount of burr and surface roughness are minimized when machining high hardness Al alloy.

3) The tool wear was similar regardless of overlapped cutting depths if total machining distance is the same; therefore, tool wear is more influenced by machining distance than cutting depth.

4) The burr is observed at the top part of the pattern from tiny tool wear when machining 1.5 km by the application of overlapped cutting depths. The severe burr and the deformation of pattern occurs at the top part of pattern after severe tool wear after machining 33 km.

Fig. 8 Tool wear and machined surface after machining 33 km

References

[1] EZILARSAN C, SENTHIL K V S, VELAYUDHAM A, PALANIKUMAR K. Modeling and analysis of surface roughness on machining of Nimonic C-263 alloy by PVD coated carbide inset [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(9): 1986-1994.

[2] PARK C H, SONG C K. Ultra precision machine tools for machining the large surface micro feature [J]. KSPE, 2005, 22(5): 7-14.

[3] JE T J, JEON E C, PARK S C, CHOI D S, WHANG K H, KANG C. Improvement of machining quality of copper-plated roll mold by controlling temperature variation [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(s1): 37-41.

[4] PARK E S, JE T J, CHOI H J, JEON E C. Analysis on planer machining characteristics of stamp using diamond cutting tool [J]. KSPE, 2010, 11: 81-82.

[5] FENG LI, WEI P Z, XING L C, QIANG J Z, JING C W, QIAO Z Z. Mechanical properties, corrosion behaviors and microstructures of 7075 aluminum alloy with various aging treatment [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(4): 755-762.

[6] LI J F, PENG Z W, LI C X, JIA Z Q, CHEN W J, ZHENG Z Q. Mechanical properties, corrosion behaviors and microstructures of 7075 aluminum alloy with various aging treatments [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(4): 755-762.

[7] NOUARI M, LIST G, GIROT F, COUPARD D. Experimental analysis and optimization of tool wear in dry machining of aluminum alloys [J]. Wear, 2003, 255: 1359-1368.

[8] DING X, LIU K. Ultra-precision of micro-channels on Ni-copper: Effects on diamond cutter tool wear and workpiece surface finish [J]. SIMTech Technical Reports, 2009, 10(4): 209-215.

[9] PARK E S, CHOI H J, JE T J. Effect of tool wear for machining micro pattern on large surface [J]. KSPE, 2011: 195-19.

[10] PRAMANIK A, NEO K S, RAHMAN M. Cutting performance of diamond tools during ultra-precision turning of electroless-nickel plated die materials [J]. Journal of Materials Processing Technology, 2003, 140(1-3): 308-313.

[11] FU Z X, XIAN L A. Effects of titanium coating on property of diamond [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(4): 715-719.

[12] SHIMADA S, INAMURA T, HIGUCHI M, TANAKA H, IKAWA N. Suppression of tool wear in diamond turning of copper under reduced oxygen atmosphere [J]. CIRP annals-Manufacturing Technology, 2000, 49(1): 21-24.

[13] UDDIN M S, SEAH K H W, RAHMAN M, LI X P, LIU K. Performance of single crystal diamond tools in ductile mode cutting of silicon [J]. Journal of Materials Processing Technology, 2007, 185(1-3): 24-30.

(Edited by CHEN Can-hua)

Corresponding author: Tae-Jin JE; Tel: +82-42-868-7142; E-mail: jtj@kimm.re.kr; Myung-Chang KANG; Tel: +82-51-510-2361; E-mail: kangmc@pusan.ac.kr

DOI: 10.1016/S1003-6326(12)61802-0