胶结充填开采两端固定岩梁模型及梁式断裂分析

李石林1, 2, 3,冯涛2, 3,朱卓慧1, 2

(1. 中南大学 资源与安全工程学院,湖南 长沙,410083;

2. 湖南科技大学 能源与安全工程学院,湖南 湘潭,411201;

3. 湖南科技大学 煤炭资源清洁利用与矿山环境保护湖南省重点实验室,湖南 湘潭,411201)

摘要:考虑采空区胶结体在强度形成区内对顶板的支撑载荷与距离工作面长度呈线性关系,基于垮落法两端固定梁模型,建立胶结充填开采两端固定岩梁力学模型,得到岩梁剪切力、弯矩分布和两端支座反力的表达式;提出充填开采极限跨距概念,从岩梁抗拉、抗剪强度推导出极限跨距表达式;提出充填开采工作面极限推进速度概念,并推导出其表达式。应用模型和概念公式对某矿2414工作面进行计算。研究结果表明:充填开采时,岩梁最大剪切力、弯矩位于煤壁处,与垮落法开采相比,剪切力和弯矩更小;增加支柱(架)的支撑力,可减小岩梁两端剪切力和弯矩;按抗拉和抗剪强度计算充填开采极限跨距分别为24.6 m和85.8 m,胶结体须在12.5 d内形成抵抗上覆岩层载荷的强度;岩梁剪切力和弯矩分布均为非对称性;煤壁处的支座反力、弯矩分别为采空区侧岩梁端2.28和1.49倍;充填开采有利于采空区后部沿空巷道的维护。

关键词:充填开采;胶结;力学模型;极限跨距;推进速度

中图分类号:TD323 文献标志码:A 文章编号:1672-7207(2014)08-2793-06

Mechanical model of rock beam with both ends fixed and force analysis of roof fracture in cemented filling mining

LI Shilin1, 2, 3, FENG Tao2, 3, ZHU Zhuohui1, 2

(1. School of Resources and Safety Engineering, Central South University, Changsha 410083, China;

2. School of Mining and Safety Engineering, Hunan University of Science and Technology, Xiangtan 411201, China;

3. Hunan Province Key Laboratory of Coal Resources Clean-utilization and Mine Environment Protection,

Hunan University of Science and Technology, Xiangtan 411201, China)

Abstract: A new mechanical model of rock beam with both ends fixed in cemented filling mining was established during the combined action of coal body, pillar (support) and backfill. Based on the mechanical model of rock beam with both ends fixed in caving mining, the relationship between the supporting effect of backfill on roof and the distance from the working face was considered to be a linear relation in the new model. The expressions of shear stress distribution, moment distribution and support reaction of two ends in beam were deduced. The new concept of limit span of roof was given, and its calculating formulas were deduced from tensile and shear strength of rock. The new concept of ultimate advance speed of work face for cemented filling mining was given, and its calculating formula was deduced. Parameters related to a mine working face 2414 were calculated by applying new model and concept formula. The results show that the positions of the maximum shear stress and moment are located in the coal wall place. The maximum shear stress and moment by cemented filling method are much smaller than the one by caving method. Increasing holding power of the pillar (support) can reduce the shear force and bending moment at both ends of the rock. Limit spans in terms of tensile and shear strength in filling mining are 24.6 m and 85.8 m, respectively. Cemented body should form the strength which can resist the load from overlying strata within 12.5 d. The stress distribution at stope is changed greatly. The distributions of shear stress and moment are asymmetry, and their values reduce significantly compared with those of the caving mining method. The values of support reaction and bending moment at coal wall place are respectively 2.28 and 1.49 times that of gob side. Advanced supporting and roof management should be strengthened at filling mining working face. Filling mining is favorable for maintaining the retaining roadways along gob.

Key words: filling mining; cementing; mechanical model; limit span; advance speed

胶结充填开采技术在国内外矿山已得到广泛推广,但该开采条件下采场矿山压力与岩层控制的,其作用规律和机理等尚不清晰,有待进一步研究。陈绍杰等[1]提出了条带煤柱膏体充填开采覆岩时空结构模型,陈杰等[2]提出了矸石充填采煤覆岩移动的弹性地基梁模型,常庆粮等[3]研究了膏体充填开采覆岩稳定性[3],马超等[4]研究了煤矿充填巷采中煤柱与充填体耦合作用力学机理,李永明[5]研究了水体下急倾斜煤层充填开采采场围岩的控制机理。另外,钱鸣高等[6-14]建立了垮落法开采条件下几种不同的顶板结构力学模型。既有充填开采力学模型和研究大多以弹性基础梁为基础,视充填体为线性弹性地基,未考虑煤体、支架和充填体对顶板的联合作用,也未考虑充填体强度形成的时空特性问题,造成研究结果与现场实际偏离较大。针对上述不足,本文作者以垮落法两端固定梁为基础[7],将强度形成过程中胶结充填体对顶板的支撑载荷与距离工作面长度简化为线性关系,考虑顶板与煤体、支柱(架)和胶结体的耦合作用,提出胶结充填开采两端固定梁力学模型,并进行力学分析与计算,在此基础上提出充填开采极限跨距和工作面极限推进速度概念。

1 胶结充填采场顶板力学模型

1.1 顶板力学模型

在胶结充填开采中,覆岩作用的载荷通过顶板岩层分散地作用在煤体、支柱(架)和采空区充填体上,采空区上覆岩层的移动变形因充填材料的支撑作用而得到有效阻止,上覆岩层出现小型弯曲带和裂隙带,一般不发生贯穿性断裂,有良好的连续性,比传统垮落法开采产生的移动变形小得多[3]。充入采空区中的胶结体材料随着工作面的向前推进,在终期强度形成前,强度将随时间推移而增大,逐渐能抵抗上覆岩层施加的作用力。胶结充填开采采场内,顶板、煤体、支柱(架)和充填体形成耦合支护结构。

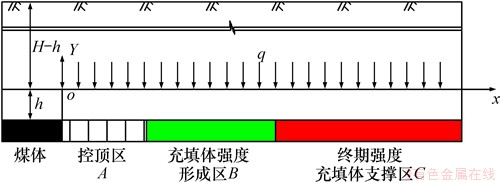

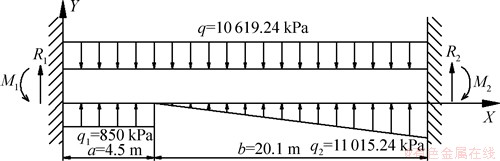

基于上述因素,并假设顶板在胶结体充入前没有弯曲下沉,充填体全部接顶,以垮落法开采的两端固定梁为基础,建立“煤体-支柱(架)-胶结体”联合作用下的胶结充填开采顶板岩梁力学模型,如图1所示。图1中工作面煤层埋深为H,厚度h的煤层顶板为弹性,岩梁上覆岩层厚度为(H-h),岩梁在控顶区范围内由支柱(架)支撑,控顶区之外的采空区顶板由胶结体充填材料支撑,充填区因胶结体充填材料强度形成特性分为充填体强度形成区和终期强度充填体支撑区。

图1 胶结充填开采条件下岩梁力学模型

Fig. 1 Mechanics model of rock beam in cemented filling mining

1.2 模型力学分析

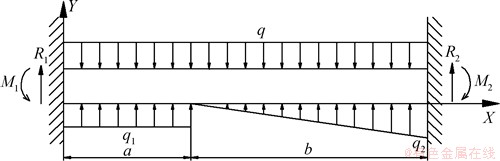

选取图1中煤层煤壁处至充填体强度形成区(B)与终期强度充填体支撑区(C)交界面之间上覆厚度h、单位宽度的顶板为研究对象,将该段顶板视为一端由工作面煤壁、另一端由终期强度充填体支撑的两端固定弹性梁,岩梁受到上覆岩层载荷、采场支柱(架)及充填体支撑作用,岩梁受力分析如图2所示。图2中,l为支柱(架)控顶区宽度a与充填体强度形成区宽度b之和;R1和R2分别为岩梁两端的支座反力;M1和M2分别为岩梁两端的弯矩;q为(H-h)厚度的上覆岩层重力作用对岩梁产生均布载荷;q1为支柱(架)控顶区A对岩梁产生均布支撑作用力;q2为胶结体在能完全抵抗上覆岩层载荷而不发生塑性破坏时对岩梁的支撑作用力。在工作面正常推进情况下,胶结充填材料强度在刚充入控顶区后部采空区时可视为0 MPa,在强度形成区内随时间而增大,即随距离工作面的长度增长而增大。充填体强度的变化,将导致其对上覆顶板支撑载荷的变化。将强度形成区内充填体对顶板的支撑载荷与距离工作面的长度简化为线性关系。

图2 胶结充填开采两端固定岩梁受力分析

Fig. 2 Force analysis of rock beam with both ends fixed in cemented filling mining

因为工作面后部采空区中支柱(架)和充填体的介入,顶板岩梁成为非对称弹性梁,依据结构力学方法[15-17],可得支座反力R1和R2为

(1)

(1)

由式(1)可知,由于支架和充填体的支撑作用,岩梁两端的支座反力均小于垮落法开采时对称梁两端的支座反力(ql/2)[7],工作面煤壁处和后部沿空留巷处的矿压将减小,有助于减少片帮、顶板管理和巷道维护。加大支柱(架)的支撑力,可减小支座反力。

取岩梁内任一截面,其剪切力Qx表达式为

(2)

(2)

分析式(2)可知,岩梁在[0,l]内最大剪切力发生在梁端煤壁处,即x=0时有最大值,Qmax=Q(0)=R1。

取岩梁内任意一截面,其弯矩Mx表达式为

(3)

(3)

式(3)中,M1由结构力学求解为

(4)

(4)

分析式(3)可知,岩梁在[0,l]内最大弯矩Mmax位于煤壁处,即x=0时有最大值,Mmax=M(0)=M1。由式(4)可知,在胶结充填开采条件下岩梁最大弯矩比全部垮落法的小(-ql2/12)[7],加大支柱(架)的支撑力,可减小弯矩。但因煤壁处往往不能抵抗住固端弯矩,将在该处将出现塑性铰,煤壁被压酥,弯矩将向跨间转移,跨间弯矩变大。

2 充填开采极限跨距

在充填过程中,设计的材料强度不足、充填不及时、充填体强度形成缓慢等因素会导致老顶断裂。在充填开采过程中,老顶达到初次断裂时的跨距称为充填开采极限跨距。掌握充填开采老顶的极限跨距,对充填采场顶板来压、岩层移动控制、工作面推进速度、充填步距、充填体强度设计等具有重要的作用。应用材料力学方法,从岩梁抗拉和抗剪强度极限2个方面研究充填开采极限跨距。

已知梁内任意点的正应力为[7]

(5)

(5)

式中:Mx为该点所在断面的弯矩;yx为该点离断面中性轴的距离;Iz为对称中性轴的断面矩。

取梁为单位宽度,则梁的断面矩 (其中,h为老顶岩层的厚度)。因而任意点的正应力为

(其中,h为老顶岩层的厚度)。因而任意点的正应力为 ,最大拉应力为

,最大拉应力为 。若以最大拉应力作为岩层断裂的依据,则当

。若以最大拉应力作为岩层断裂的依据,则当 时,岩层在该处的正应力达到该处的抗拉强度极限,岩层将在该处断裂,形成的极限跨距LlT可用式(6)求解:

时,岩层在该处的正应力达到该处的抗拉强度极限,岩层将在该处断裂,形成的极限跨距LlT可用式(6)求解:

(6)

(6)

将式(4)和 代入式(6),简化得到充填开采极限跨距LlT的求解公式:

代入式(6),简化得到充填开采极限跨距LlT的求解公式:

(7)

(7)

岩梁任意点的剪应力为

(8)

(8)

式中:Qx为该点的剪切力;h为岩层厚度。

最大剪应力 发生在矩形断面梁的中性轴上,即yx=0,因此,

发生在矩形断面梁的中性轴上,即yx=0,因此, 。若以最大剪应力作为岩层断裂的依据,最大剪切力发生在梁的煤壁端,

。若以最大剪应力作为岩层断裂的依据,最大剪切力发生在梁的煤壁端, 。当

。当 达到岩石极限强度

达到岩石极限强度 时,形成的极限跨距

时,形成的极限跨距 可用下式求解:

可用下式求解:

(9)

(9)

将式(1)代入式(9),简化得到LlS求解公式:

(10)

(10)

对于某个确定的工作面,式(8)和(10)中的RT,RS,q,q2和h为已知数,在支柱(架)型号与支护方式选定后,q1和a也为已知数,因此,这2个方程为一元四次方程。

3 充填开采工作面极限推进速度

胶结充填工作面向前推进时,虽然采空区得到了胶结体的支撑作用,但当推进速度过快时,控顶距与胶结体强度形成区宽度之和大于充填开采极限跨距,因采空区中的胶结体强度尚未形成能抵抗上覆岩层载荷的强度而造成塑性破坏,将导致顶板破断。充填工作面在正常推进下,能保证顶板不破断的工作面最大推进速度称为充填开采工作面极限推进速度。掌握工作面极限推进速度对充填开采工作面的采煤工艺、充填工艺设计等具有理论指导作用。极限跨距与工作面极限推进速度关系如下:

(11)

(11)

式中:vm为工作面极限推进速度,m/d;a为控顶距,m;t为工作面胶结体形成能支撑上覆岩层载荷的强度所需要的时间,d;L为极限跨距,m。

由式(11)可知,对于某个确定工作面,L和a可视为固定值,vm随t的缩短而增大。因此,可通过改变胶结体形成能支撑上覆岩层载荷的强度所需要的时间(t)来改变极限推进速度,从而改变工作面产量,t可通过改变充填材料类型和配比来实现。当充填材料类型和配比确定时,t为固定值,可依据极限跨距来制定工作面的极限推进速度,从而指导生产。

4 工程算例

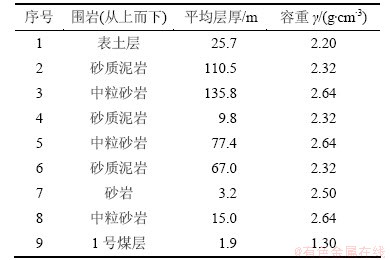

湖南某煤矿“三下”呆滞资源量大,在采用煤矸石胶结充填开采技术试采2414工作面。该面开采1号煤层,平均煤层厚度为1.9 m,煤层倾角为15°,平均开采深度444.4 m,直接顶和老顶为15 m的长石石英中粗粒砂岩,顶板坚硬,完整性好,上覆各岩层力学计算参数见表1。所采工作面为综采长壁工作面,走向长度为650 m,倾斜长度为110 m,日推进1.6 m,控顶距4.5 m,支撑掩护式支架支护强度为0.85 MPa,充填开采法管理顶板,胶结体为以煤矸石为骨料、添加水泥和粉煤灰的充填材料。依据上述研究可知:a=4.5 m;q1=850 kPa; =10 619.24 kPa;

=10 619.24 kPa; =11 015.24 kPa。

=11 015.24 kPa。

表1 各岩层力学计算参数

Table 1 Mechanical calculation parameters of rock stratum

煤层顶板岩层的抗剪强度RS为33 MPa,抗拉强度RT为10 MPa,按式(7)和(9)计算其极限跨距有效值,按抗拉强度计算,LlT=24.6 m,按抗剪强度计算,LlS=85.8 m。

取LlT为充填开采极限跨距,由式(11)可知:

(12)

(12)

即工作面胶结体必须在少于12.5 d的时间内形成能支撑上覆岩层载荷的强度,才能确保顶板不破断。胶结体强度形成区宽度为极限跨距与控顶距的差值,

b=L-a (13)

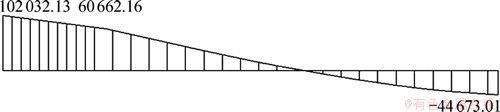

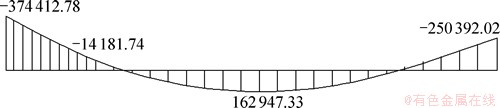

即b=20.1 m。将上述参数代入胶结充填开采两端固定岩梁力学模型(如图3所示),其剪切力分布与弯矩分布分别如图4和图5所示。

由图4和图5可知:胶结充填开采条件下的岩梁剪切力和弯矩为非对称分布;顶板最大剪应力和最大弯矩所在位置仍然在煤壁处,与较垮落法管理顶板开采时相同;岩梁两端的弯矩变化梯度大;煤壁处的支座反力、弯矩分别为采空区侧岩梁端2.28和1.49倍,充填开采有利于采空区后部沿空留巷的维护。

图3 2414工作面两端固定岩梁力学模型

Fig. 3 Mechanics model of rock beam with both ends fixed in 2414 backfill mining face

图4 2414充填开采工作面岩梁剪切力分布(单位:kN)

Fig. 4 Shear stress distribution of rock beam in 2414 backfill mining face

图5 2414充填开采工作面岩梁弯矩分布(单位:kN·m)

Fig. 5 Moment distribution of rock beam in 2414 backfill mining face

5 结论

(1) 采空区中支柱(架)与胶结体的介入,使充填开采顶板应力状态与其他开采方法的应力状态差异大。基于煤体、支柱(架)和充填体与顶板的耦合作用及充填体强度形成特性,建立胶结充填开采两端固定岩梁力学模型,提出充填开采极限跨距和工作面极限推进速度概念,为胶结充填开采岩层控制理论的建立提供便利,为充填开采工艺设计提供依据。

(2) 胶结充填开采工作面顶板岩梁剪切力和弯矩为非对称分布,煤壁处的支座反力和弯矩值均比采空区侧岩梁端的大,充填开采有利于采空区后部沿空留巷的维护。

(3) 本研究中将胶结体对顶板的支撑载荷与距离工作面的长度简化为线性关系仍有不足,需进一步考虑其不同时空的增长特性。

参考文献:

[1] 陈绍杰, 郭惟嘉, 周辉, 等. 条带煤柱膏体充填开采覆岩结构模型及运动规律[J]. 煤炭学报, 2011, 36(7): 1081-1086.

CHEN Shaojie, GUO Weijia, ZHOU Hui, et al. Structure model and movement law of overburden during strip pillar mining backfill with cream-body[J]. Journal of China Coal Society, 2011, 36(7): 1081-1086.

[2] 陈杰, 杜计平, 张卫松, 等. 矸石充填采煤覆岩移动的弹性地基梁模型分析[J]. 中国矿业大学学报, 2012, 41(1): 14-19.

CHEN Jie, DU Jiping, ZHANG Weisong, et al. An elastic base beam model of overlying strata movement during coal mining with gangue back-filling[J]. Journal of China University of Mining, 2012, 41(1): 14-19.

[3] 常庆粮, 周华强, 柏建彪, 等. 膏体充填开采覆岩稳定性研究与实践[J]. 采矿与安全工程学报, 2011, 28(2): 279-282.

CHANG Qingliang, ZHOU Huaqiang, BAI Jianbiao, et al. Stability study and practice of overlying strata with paste backfilling[J]. Journal of Mining & Safety Engineering, 2011, 28(2): 279-282.

[4] 马超, 茅献彪, 李强, 等. 煤柱与充填体耦合作用力学机理研究[J]. 煤矿安全, 2011, 12(10): 8-11.

MA Chao, MAO Xianbiao, LI Qiang, et al. The mechanics research of coal pillar and backfill coupling function[J]. Safety in Coal Mines, 2011, 12(10): 8-11.

[5] 李永明. 水体下急倾斜煤层充填开采覆岩稳定性及合理防水煤柱研究[D]. 徐州: 中国矿业大学矿业工程学院, 2012: 44-59.

LI Yongming. Research on stability of overlying strata and reasonable waterproof coal pillar with backfilling mining in steep seam under water body[D]. Xuzhou: China University of Mining and Technology. School of Mines, 2012: 44-59.

[6] 史红, 姜福兴. 采场上覆岩层结构理论及其新进展[J]. 山东科技大学学报(自然科学版), 2005, 24(1): 21-25.

SHI Hong, JIANG Fuxing. Structural theories of overlying strata in longwall faces and their new development[J]. Journal of Shandong University of Science and Technology (Natural Science), 2005, 24(1): 21-25.

[7] 钱鸣高, 石平五, 许家林, 等. 矿山压力与岩层控制[M]. 徐州: 中国矿业大学出版社, 2010: 73-78.

QIAN Minggao, SHI Pingwu, XU Jialin, et al. Mining pressure and strata control[M]. Xuzhou: China University of Mining and Technology Press, 2010: 73-78.

[8] 钱鸣高, 缪协兴, 许家林, 等. 岩层控制的关键层理论[M]. 徐州: 中国矿业大学出版社, 2000: 74-95.

QIAN Minggao, MIAO Xiexing, XU Jialin, et al. Key strata theory in ground control[M]. Xuzhou: China University of Mining and Technology Press, 2000: 74-95.

[9] 缪协兴, 钱鸣高. 采场围岩整体结构与砌体梁力学模型[J]. 矿山压力与顶板管理, 1995, 3(4): 3-12.

MIAO Xiexing, QIAN Minggao. Solid structure and model of voussoir beam of face surrounding rock[J]. Ground Pressure and Strata Control, 1995, 3(4): 3-12.

[10] GUO Guangli, ZHA Jianfeng, WU Bin, et al. Study of “3-step mining”subsidence control in coal mining under buildings[J]. Journal of China University of Mining & Technology, 2007, 17(3): 316-320.

[11] Fairhurst C. Stress estimation in rock: A brief history and review[J]. International Journal of Rock Mechanics & Mining Science, 2003, 40(4): 957-973.

[12] 贾喜荣, 翟英达. 采场薄板矿压理论与实践综述[J]. 矿山压力与顶板管理, 1999, 3(4): 22-25.

JIA Xirong, ZHAI Yingda. The review of ground pressure theory of thin slab in coal mining and its application[J]. Ground Pressure and Strata Control, 1999, 3(4): 22-25.

[13] 伍永平, 解盘石, 王红伟, 等. 大倾角煤层开采覆岩空间倾斜砌体结构[J]. 煤炭学报,2010,35(8): 1252-1256.

WU Yongping, XIE Panshi, WANG Hongwei, et al. Incline masonry structure around the coal face of steeply dipping seam mining[J]. Journal of China Coal Society, 2010, 35(8): 1252-1256.

[14] 伍永平, 解盘石, 任世广. 大倾角煤层开采围岩空间非对称结构特征分析[J]. 煤炭学报, 2010, 35(2): 182-184.

WU Yongping, XIE Panshi, REN Shiguang. Analysis of asymmetric structure around coal Face of steeply dipping seam mining[J]. Journal of China Coal Society, 2010, 35(2): 182-184.

[15] 龙驭球, 包世华. 结构力学教程(Ⅱ)[M]. 北京: 高等教育出版社, 2001: 29.

LONG Yuqiu, BAO Shihua. Structural mechanics(Ⅱ)[M]. Beijing: Higher education Press, 2001: 29.

[16] 付建新, 宋卫东, 杜建华, 等. 中深孔开采急倾斜薄矿体采场顶板力学模型及围岩扰动规律研究[J]. 岩石力学与工程学报, 2014, 33(增1): 3277-3282.

FU Jianxin, SONG Weidong, DU Jianhua, et al. Study of stope roof mechanical model and wall rock disturbance law of steeply-inclined thin orebody mining using medium-deep hole[J]. Chinese Journal of Rock Mechanics and Engineering, 2014, 33(S1): 3277-3282.

[17] 杜锋, 白海波. 薄基岩综放采场直接顶结构力学模型分析[J]. 煤炭学报, 2013, 38(8): 1331-1337.

DU Feng, BAI Haibo. Mechanical analysis of immediate roof in fully mechanized top coal caving mining with thin bedrock[J]. Journal of China Coal Society, 2013, 38(8): 1331-1337.

(编辑 赵俊)

收稿日期:2013-08-25;修回日期:2013-10-10

基金项目:国家自然科学基金资助项目(51274095);湖南科技大学煤炭资源清洁利用与矿山环境保护湖南省重点实验室开放基金资助项目(Coal201106)

通信作者:冯涛(1957-),男,河北泊头人,教授,博士生导师,从事复杂煤层开采、岩层控制研究;电话:0731-58290500;E-mail:tfeng@hnust.edu.cn