文章编号:1004-0609(2015)-05-1256-08

等温时效对In-3Ag/Cu焊接界面组织演变特征的影响

马运柱,罗辉庭,李永君,刘文胜,黄国基

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:通过加速温度时效方法针对电子器件可靠性评估中等温时效对In-3Ag焊料显微观组织和剪切性能的影响进行研究。采用扫描电镜(SEM)、能量色散仪(EDS)和X射线衍射(XRD)分别对焊点基体及其与铜基板界面金属间化合物层的组织结构进行观察和分析,采用力学试验机测试焊点的剪切强度,并通过SEM观察分析其断裂特征。结果表明:随着等温时效时间延长,基体中二次相AgIn2显著长大,由颗粒状转变为大块状;界面IMC层(成分为(Ag,Cu)In2)的厚度逐渐增加,其生长由组元扩散速率控制;焊点剪切强度呈下降趋势,由焊后的5.94 MPa降至时效1000 h后的2.35 MPa;在100 ℃分别时效100、250、500和750 h后,焊点剪切失效均呈焊料内部韧性断裂模式,时效1000 h后,断裂模式转变为韧脆混合断裂。

关键词:In-3Ag焊料;金属间化合物;等温时效;剪切性能;钎焊

中图分类号:TG425.1 文献标志码:A

Effects of isothermal aging on In-3Ag/Cu interface microstructure evolution characteristics

MA Yun-zhu, LUO Hui-ting, LI Yong-jun, LIU Wen-sheng, HUANG Guo-ji

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The effects of isothermal aging on the microstructure and shear property of In-3Ag solder were investigated by accelerated temperature aging. Scanning electricity microscope (SEM), energy dispersive spectrometer (EDS) and X-ray diffractometer (XRD) were used to observe and analyze the intermetallic compound (IMC) layer microstructure and the composition of solder joint. The mechanical testing machine was used to test the shear strength of solder joint, and the shear fractography was measured by SEM. The results show that, with the isothermal aging time increases, the quadratic phase AgIn2 in solder matrix grows prominently, and the shape changes from grain to blocky ship. The thickness of (Ag,Cu)In2 layer increases gradually, which is controlled by component diffusion rate. The shear strength of solder joints decreases with isothermal aging time increases, and it decreases from 5.94 MPa after soldering to 2.35 MPa after 1000 h aging. The fracture type is ductile fracture in solder matrix after being aged at 100 ℃ for 100, 250, 500 and 750 h, respectively. After being aged for 1000 h, the fracture type belongs to the toughness-brittleness fracture mode.

Key words: In-3Ag solder; intermetallic compound; isothermal aging; shear property; soldering

热连接是焊点连接的主要任务之一,随着电子行业向高密度、细间距和高集成化发展。焊点尺寸越来越小,封装结构越加复杂,焊点需要承受更大的负载,因此散热性能成为影响电子产品可靠性的一个关键因素。在电子产品的使用和服役过程中,器件产生的热量使封装焊点处于一个长期时效的热环境中。长时间的时效会提高原子的扩散能力,焊点的显微组织及力学性能将产生显著的变化,特别是对于焊点与金属基板间界面化合物层,长时间的时效会导致其过度生长,由于自身的硬脆性和生长过程中原子不等量扩散引发的柯肯达尔孔洞等,使其极易成为受力断裂时裂纹扩展的萌生地,因此,对焊点等温时效后的界面组织及焊接性能进行研究是十分必要的。

国内外关于等温时效对Sn基焊料微观组织和力学性能的影响报道较多[1-3],如LEJUSTE等[2]研究时效处理对Sn-3.0Ag-0.4Cu-7.0In/Cu界面组织的影响,不同时效条件下的界面IMC层均为Cu3(Sn,In)与Cu6(Sn,In)5组成的双层结构,界面组织中In组元的存在强烈影响了Cu3(Sn,In)相的生长激活能。LIN等[3]研究60 ℃下等温时效对In-Sn焊料与化学镀Ni-P层之间的界面反应,结果表明,Ni原子通过扩散与In-Sn焊料生成In3Ni2界面IMC层,随着时效时间的延长,In3Ni2层的生长阻碍了In-Sn焊料与化学镀Ni-P层之间的进一步反应。但关于等温时效对In基焊料的显微组织和剪切性能的影响却鲜见报道。与Sn基焊料相比,In基焊料具有熔点低、延展性好、疲劳寿命长和能抑制Ag或Au溶蚀等优点,In-3Ag焊料能够有效降低焊点服役过程中由于热失配所产生的残余应力,可应用于微光机电系统中的气密性封装。其在LED、热敏元件和分步焊接工艺中具有非常重要的应用价 值[4-6]。本文作者着重对在100 ℃下等温时效不同时间后In-3Ag/Cu焊点基体、基体与铜基板之间界面的显微组织、成分及剪切强度进行分析和测试,并对断裂机制进行研究。

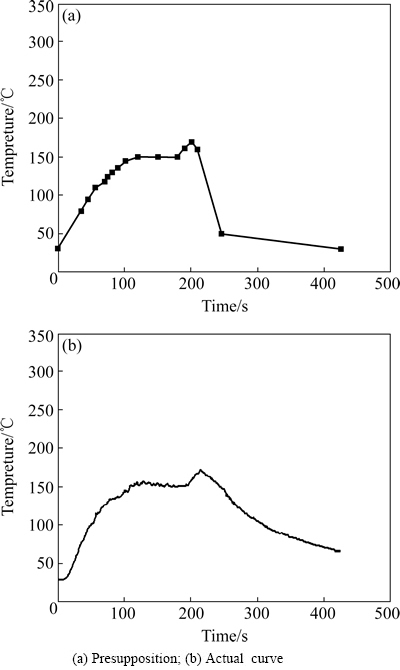

1 实验

实验原料选用纯度大于99.95%(质量分数)的单质金属In和Ag,按In-3Ag名义成分(质量比)配料,采用ZGJL-0.01-50-4型真空感应熔炼炉熔炼后浇入铜模中成型为d15 mm的柱状In-3Ag焊料合金。经轧机轧制成焊料薄片后将其剪成质量约0.2 g的圆片,在乙醇中超声清洗3 min后吹干待焊。助焊剂为松香型助焊剂(RMA型)。用SiC砂纸打磨25 mm×25 mm×0.5 mm紫铜板,然后用无水乙醇清洗,以去除其表面氧化膜。根据In-3Ag合金和助焊剂的特点,设计的回流接曲线如图1(a)所示,活化区保温温度为150 ℃,保温时间为1 min,回流区升温速度为1 ℃/s,液化区峰值温度为170 ℃。图1(b)所示为在钎焊过程中焊机绘制的实际工艺曲线。从图中曲线可以看出,在150 ℃保温段,曲线有轻微波动,这是由焊机控温误差造成的,但基本符合预设曲线。将助焊剂均匀涂覆于焊料圆片上,使用北京七星天禹TYR108N-C台式回流焊机进行钎焊。

图1 焊接回流曲线

Fig. 1 Reflux curve of welding

将铜板沿焊点中心纵向剪开,将其镶成金相试样,经过打磨、抛光、清洗、吹干后使用HCl+FeCl3饱和溶液与无水乙醇按体积比1:4配制成腐蚀液腐蚀铜板,用35%HF+10%HNO3+55%H2O(体积分数)腐蚀液腐蚀In-3Ag/Cu焊点截面。将腐蚀后的试样,采用JSM- 6360LV型扫描电镜观察腐蚀后试样截面IMC层形貌并采集图样,使用EDS能谱分析系统测算焊点组织成分。为了定量分析等温时效对界面IMC的作用效果,参照文献[7-8]中的方法,对界面IMC厚度值做测量,具体如下:每种焊料纵截面试样在1500倍的扫描电镜下选择不同的连续视野照相,采用专业图像软件计算照片中IMC层的总面积S和横向长度L,两者相除,得IMC层厚度值d,统计5张照片,求得平均值,得出界面IMC层最终厚度值。

将等温时效后的In-3Ag/Cu焊点基体用35%HF+ 10%HNO3+55%H2O(体积分数)腐蚀液腐蚀至露出界面反应产物,经超声清洗、烘干后采用JSM-6360LV型扫描电镜观察腐蚀后试样横截面IMC层形貌并采集图样,采用Oxford INCA300型X射线衍射仪对腐蚀后试样进行物相分析。

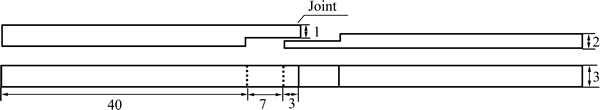

剪切试验参照JISZ3198-5无铅钎料试验方法[9], 剪切试样如图2所示,材料为紫铜板,采用搭接方式钎焊,使用Instron3369型力学试验机测试焊料剪切性能。剪切强度由公式τ=Fs/A计算得出,其中τ为剪切强度,MPa;Fs为最大剪切载荷,N;A为剪切实验前搭接面积,mm2。

2 结果与讨论

2.1 等温时效对焊点微观组织的影响

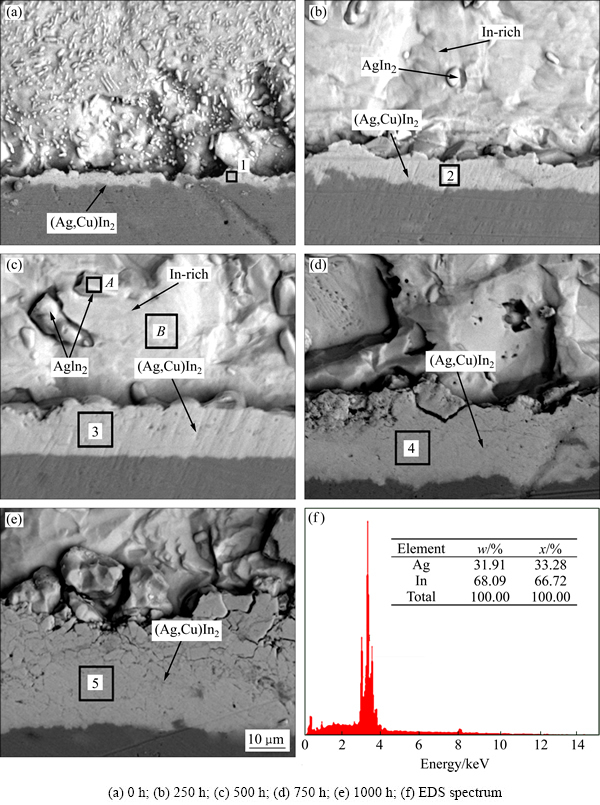

图3所示为100 ℃时等温时效不同时间所得焊点微观组织的SEM像。由图3可看出,用EDS分析图3(c)中区域A、B的成分,A区域化合物成分为Ag33.28%、In66.72%(摩尔分数),结合In-Ag相图,此相应为AgIn2相。而区域B为富In相,通过EDS进一步分析图3中各相成分,分析得等温时效不同时间后焊点基体均为富In相,而二次相成分为AgIn2。如图3所示,焊后试样基体中二次相大多呈小颗粒状,基体中的AgIn2二次相随着时效时间的延长,其尺寸逐渐变大。其长大机理与早期研究中二次相随着回流次数增加尺寸出现长大现象的机理相同[10],为奥斯特瓦尔德熟化机理(Ostwald ripening),即较大尺寸的AgIn2二次相以较小尺寸AgIn2二次相的重新溶解为条件进一步长大,从而使二次相的数目下降,而尺寸则明显长大[11-12]。

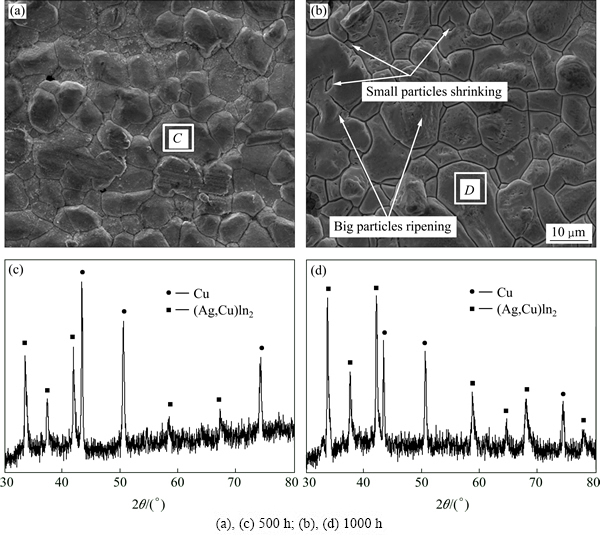

图4所示为等温时效不同时间后In-3Ag/Cu焊点界面处金属间化合物的顶视图和XRD谱。从图3还可以看出,焊后试样界面IMC为致密层状结构;时效250 h后,界面IMC层有所长大,但结构变化不大,仍为致密层状结构;时效500 h后,界面IMC层继续长大;时效750 和1000 h后,界面IMC生长趋势不变,但IMC层出现裂纹,其原因是随进一步时效的进行,界面IMC层中较大的晶粒通过吞并小晶粒不断长大[13](晶粒成熟长大和缩小的痕迹如图4(b)所示),使得界面IMC层由连续的细晶粒层逐渐长大成粗晶粒层。在等温时效及冷却过程中,Cu基板与IMC层热膨胀系数的不同引起大晶粒层发生断裂。通过EDS分析,等温时效不同时间后,In-3Ag/Cu焊点界面IMC的成分如表1所列,时效250、500、750和1000 h后In-3Ag/Cu焊点界面IMC层中元素摩尔比均为n(Ag+Cu):n(In)=1:2,等温时效500 与1000 h后,焊点界面IMC的XRD物相分析结果可确定界面化合物的晶体结构与AgIn2一致,属于I4/mcm(140)空间群、四方结构(见图4(c)和(d))。由于Ag和Cu原子半径相近(Cu为0.1278 nm,Ag为0.14444 nm),且均为面心立方结构,故Cu原子取代AgIn2中的部分Ag原子位置较容易,不会发生晶格畸变生成新相,故界面IMC层成分为(Ag,Cu)In2。与前面研究中不同回流次数下界面IMC层成分变化规律一致[10]。

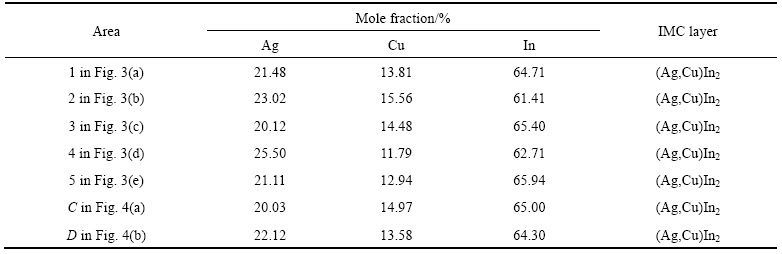

采用专业图像软件对焊点界面IMC厚度进行测量,其结果如图5所示,焊后界面IMC厚度为3.63 μm;时效250和500 h后,界面IMC厚度有所增加,分别为7.14和12.08 μm;时效750和1000 h,后界面IMC厚度继续增加,分别为21.07和29.00 μm。

图2 剪切试样示意图

Fig. 2 Schematic diagram of shear specimens (Unit: mm)

图3 等温时效不同时间后In-3Ag/Cu焊点界面纵向形貌以及图(c)的EDS谱

Fig. 3 Typical morphologies of IMCs formed at In-3Ag/Cu substrate interface after isothermal aging for different times and EDS spectrum of Fig. 3(c)

焊接时焊点中形成的界面IMC层在多次回流和时效过程中会不断长大。影响界面IMC层生长速率的因素有原子在IMC中的扩散速度和界面IMC的反应速度两种。其中速度较小的将成为界面IMC生长的控制因素,即当反应速度小于扩散速度时,反应速度是IMC生长的控制因素。当扩散速度小于反应速度时,扩散速度是化合物生长的控制因素。根据SCHAEFER等[14]提出的模型,IMC生长厚度与时效时间的关系如下式所示:

(1)

(1)

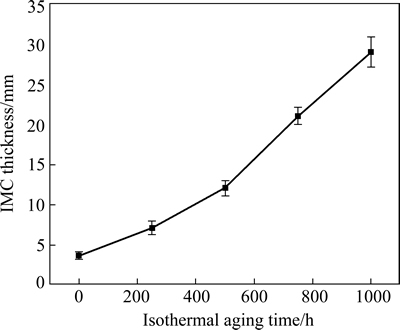

式中:τ为时效后IMC层厚度值;τ0为焊后IMC层厚度值;t为时效时间;K为IMC层长大系数。n值反映了界面IMC层生长模式,当界面IMC层长大由组

元的扩散速率控制时,n≈0.5;当由界面反应速率控制时,n≈1;当n为0.5~1时,界面IMC的生长是混合因素控制。K值代表界面IMC层的生长速度,K值越大表明在相同的生长模式下,界面IMC层的厚度增加得越快,n值由公式(2)求出:

(2)

(2)

以ln(τ-τ0)值为纵坐标,lnt值为横坐标作图,求n值,如图6所示,得出n=0.6011,接近0.5,表明In-3Ag焊料在等温时效过程中界面IMC层的生长是以组元扩散控制为主。

图4 等温时效不同时间后In-3Ag/Cu焊点界面处金属间化合物的顶视图和XRD谱

Fig. 4 Top views ((a), (b)) and XRD patterns ((c), (d)) of IMCs formed at In-3Ag/Cu interface after isothermal aging for different times

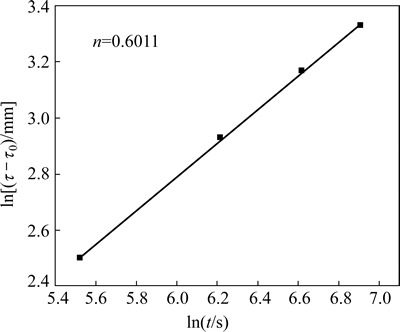

表1 等温时效不同时间后In-3Ag/Cu焊点界面IMC的EDS分析结果

Table 1 EDS analysis results of IMCs formed at In-3Ag solder/Cu interface after isothermal aging for different times

2.2 等温时效对焊点力学性能的影响

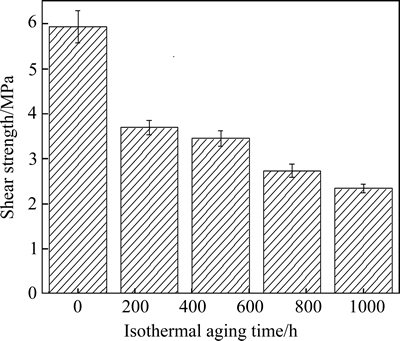

In-3Ag/Cu焊点接头在100℃下等温时效250、500、750和1000 h后,每种各取3个试样,取剪切强度的平均值,其结果如图7所示。从图7中可以观察到,随着时效时间增加,焊点剪切强度呈下降趋势。焊后所得试样剪切强度最大,约为5.94 MPa;时效250 和500 h后,剪切强度依次为3.70和3.46 MPa;时效750 h后,剪切强度继续下降,为2.74 MPa;时效 1000 h后剪切强度降到最低,仅为2.35 MPa。

图5 等温时效对金属间化合物厚度的影响

Fig. 5 Effects of isothermal aging time on IMC thicknesses

图6 In-3Ag/Cu界面IMC厚度与时效时间的关系曲线

Fig. 6 Relationship between isothermal aging time and IMC layer thickness at In-3Ag/Cu interface

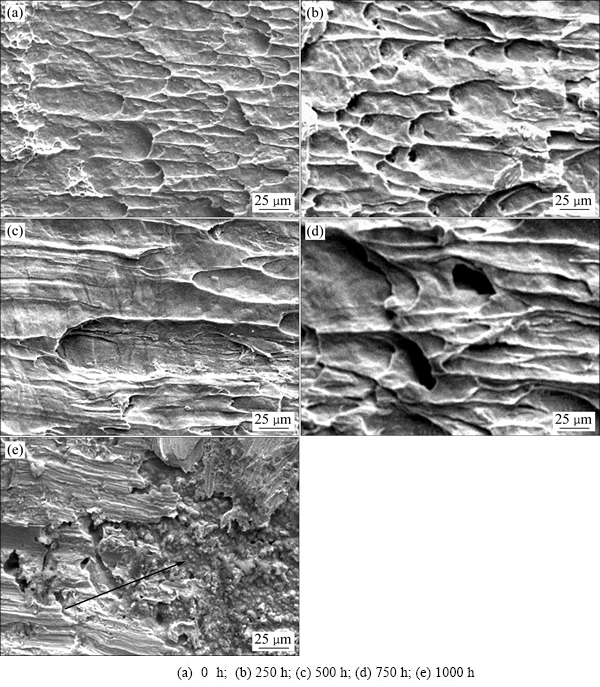

图8所示为100 ℃下等温时效不同时间后焊点剪切断口形貌。由图8可知,焊后焊点剪切断口中的韧窝较小且密集,纹理很细,断裂属于韧性断裂;时效250 h后,断口中韧窝变大,数量减少;时效500 h后,断口中韧窝继续变大变少,出现局部光滑区域;时效750 h后,局部光滑区域所占比例增加,但均为韧性断裂;时效1000 h后,断口中出现局部断面,可以清晰看见界面IMC颗粒出现(图8(e)中箭头所指的凹陷下去的位置为界面IMC层)。即断裂面部分出现在焊料基体中,部分出现在焊料和界面IMC层之间。断裂有发生在焊料基体中的韧性断裂,还有沿着IMC层与焊料基体界面的脆性断裂,断裂方式为韧脆混合断裂。其形成机理与前面研究剪切断口随回流次数增加变化机理一致[10],即韧窝的形成与焊料基体中二次相有关[15-16]。观察图8可知,随着时效时间增加,基体内AgIn2尺寸不断增大,而粗大的二次相使焊点内部受力不均,剪切断口出现比较明显的形变,因此,断口表面出现韧窝尺寸变大的特征,剪切强度也呈下降趋势。当时效时间达到1000 h后,界面IMC明显变厚,其自身的脆性以及界面连接处的薄弱区都会成为剪切断裂源[17-18],断裂方式转变为韧脆混合断裂,剪切强度也降到最低。

图7 等温时效对剪切强度的影响

Fig. 7 Effects of isothermal aging time on shear strengths

3 结论

1) 随着时效时间延长,In-3Ag/Cu焊点界面金属间化合物(Ag,Cu)In2层厚度逐渐增加,生长由组元扩散控制。

2) 随着时效时间延长,焊点剪切强度呈下降趋势,由焊后的5.94 MPa降至100 ℃时效1000 h的2.35 MPa。

3) 时效250、500和750 h后,焊点剪切断裂方式均为焊料内部韧性断裂;而时效1000 h后,断裂面一部分在焊料内部,一部分在焊料和界面化合物层之间,断裂模式转变为韧脆混合断裂。

图8 等温时效不同时间后In-3Ag/Cu剪切断口形貌

Fig. 8 Shear fractographs of In-3Ag/Cu after isothermal aging for different times

REFERENCES

[1] 刘 洋, 孙凤莲. Ni和Bi元素对SnAgCu 钎焊界面金属化合物生长速率的影响[J]. 中国有色金属学报, 2012, 22(2): 460-464.

LIU Yang, SUN Feng-lian. Effect of Ni and Bi addition on growth rate of intermetallic compound of SnAgCu soldering[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(2): 460-464.

[2] LEJUSTE C, HODAJ F, PETIT L. Solid state interaction between a Sn-Ag-Cu-In solder alloy and Cu substrate[J]. Intermetallics, 2013, 36: 102-108.

[3] LIN K L, CHEN C J. The interactions between In-Sn solders and an electroless Ni-P deposit upon heat treatment[J]. Journal of Materials Science: Materials in Electronics, 1996, 7(6): 397-401.

[4] CHUANG T H, JAIN C C, WANG S S. Intermetallic compounds formed in In-3Ag solder BGA packages with ENIG and ImAg surface finishes[J]. Journal of Materials Engineering and Performance, 2009, 18(8): 1133-1139.

[5] LIU Y M, CHUANG T H. Interfacial reactions between In10Ag solders and Ag substrates[J]. Journal of Electronic Materials, 2000, 29(11): 1328-1332.

[6] VIANCO P T, REJENT J A, FOSSUM A F, NEILSEN M K. Compression stress–strain and creep properties of the 52In-48Sn and 97In-3Ag low-temperature Pb-free solders[J]. Journal of Materials Science: Materials in Electronics, 2007, 18(1/3): 93-119.

[7] TSAO L C. Suppressing effect of 0.5wt.% nano-TiO2 addition into Sn-3.5Ag-0.5Cu solder alloy on the intermetallic growth with Cu substrate during isothermal aging[J]. Journal of Alloys and Compounds, 2011, 509(33): 8441-8448.

[8] HASEEB A, LENG T S. Effects of Co nanoparticle addition to Sn-3.8Ag-0.7Cu solder on interfacial structure after reflow and ageing[J]. Intermetallics, 2011, 19(5): 707-712.

[9] 王春青, 李明雨, 田艳红, 孔令超. JISZ3198无铅钎料试验方法简介与评述[J]. 电子工艺技术, 2004, 25(2): 47-54.

WANG Chun-qing, LI Ming-yu, TIAN Yan-hong, KONG Ling-chao. Review of JISZ3198: Test method for lead-free solders[J]. Electronics Process Technology, 2004, 25(2): 47-54.

[10] 马运柱, 李永君, 刘文胜, 黄国基. 回流次数对In3Ag焊料微观组织和剪切性能的影响[J]. 材料研究学报, 2012, 26(3): 321-326.

MA Yun-zhu, LI Yong-jun, LIU Wen-sheng, HUANG Guo-ji. Effects of multiple reflows on microstructure and shear properties of In3Ag solder[J]. Chinese Journal of Materials Research, 2012, 26(3): 321-326.

[11] DUTTA I, KUMAR P, SUBBARAYAN G. Microstructural coarsening in Sn-Ag-based solders and its effects on mechanical properties[J]. JOM, 2009, 61(6): 29-38.

[12] 王小京, 祝清省, 王中光, 尚建库. Ag3Sn粗化模型及其对Sn- Ag-Cu焊料蠕变的影响[J]. 金属学报, 2009, 45(8): 912-918.

WANG Xiao-jing, ZHU Qing-sheng, WANG Zhong-guang, SHANG Jian-ku. Modeling of Ag3Sn coarsening and its effect on creep in Sn-Ag-Cu solder[J]. Acta Metallurgica Sinica, 2009, 45(8): 912-918.

[13] TANG Y, LI G Y, PAN Y C. Influence of TiO2 nanoparticles on IMC growth in Sn-3.0Ag-0.5Cu-xTiO2 solder joints in reflow process[J]. Journal of Alloys and Compounds, 2013, 554: 195-203.

[14] SCHAEFER M, FOURNELLE R A, LIANG J. Theory for intermetallic phase growth between Cu and liquid Sn-Pb solder based on grain boundary diffusion control[J]. Journal of Electronic Materials, 1998, 27(11): 1167-1176.

[15] 王玲玲, 孙凤莲, 王丽凤, 刘洋. 回流焊对SnAgCu焊点IMC及剪切强度的影响[J]. 电子元件与材料, 2009, 28(9): 73-76.

WANG Ling-ling, SUN Feng-lian, WANG Li-feng, LIU Yang. Effect of reflow soldering on IMC and shear strength of SnAgCu solder joint[J]. Electronic Components and Materials, 2009, 28(9): 73-76.

[16] 唐 宇. 焊料纳米改性对无铅焊点界面反应及力学性能影响的研究[D]. 广州: 华南理工大学电子与信息学院, 2013: 1-186.

TANG Yu. Influence of nano-modifided solder on interfacial reaction and mechanical property of lead-free solder joints[D]. Guangzhou: South China University of Technology, 2013: 1-186.

[17] 赵 杰, 迟成宇, 程从前. Bi对Sn-3Ag-0.5Cu/Cu无铅钎焊接头剪切强度的影响[J]. 金属学报, 2008, 44(4): 473-477.

ZHAO Jie, CHI Cheng-yu, CHENG Cong-qian. Effect of Bi addition on shear strength of Sn-3Ag-0.5Cu/Cu solder joints[J]. Acta Metallurgica Sinica, 2008, 44(4): 473-477.

[18] LIU P, YAO P, LIU J. Evolutions of the interface and shear strength between SnAgCu-xNi solder and Cu substrate during isothermal aging at 150 ℃[J]. Journal of Alloys and Compounds, 2009, 486(1): 474-479.

(编辑 李艳红)

基金项目:国家配套项目(JPPT-115-2-1057)

收稿日期:2014-09-22;修订日期:2015-01-06

通信作者:马运柱,教授,博士;电话:0731-88877825;E-mail: zhuzipm@CSU.edu.cn