Article ID: 1003-6326(2005)06-1303-06

Hydroxyapatite coating on pretreated CoNiCrMo prosthesis

WANG Tao(汪 涛)1, A. Dorner-Reisel2

(1. College of Materials Science and Technology,

Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China;

2. Institute of Ceramic Materials, Technische Universitt Bergakademie Freiberg,

Freiberg 09596, Germany)

Abstract: In order to improve the quality of the bio-active coating on medical grade CoNiCrMo substrate, hydroxyapatite(HA) coatings were produced via low-temperature dip-coating route on substrates treated using various surface pre-treating methods. The surface and cross-sectional morphologies of HA coatings were observed by SEM, as well as the bonding strength between coatings and substrates after different pre-treatments were characterized according to ASTM C633. The low-temperature HA dip-coating method with the substrate merely oxidized at 600℃ can provide a high quality HA coating for CoNiCrMo, of which the bonding strength reaches (58±5)MPa, higher than that of the clinically used HA coatings on Ti-alloys produced via plasma spray route, as well as a HA coating with full crystallinity and high phase-purity, which is more in-vivo stable than plasma sprayed HA coating.

Key words: bonding strength; coating; Co-alloys; hydroxyapatite CLC

number: TQ174 Document code: A

1 INTRODUCTION

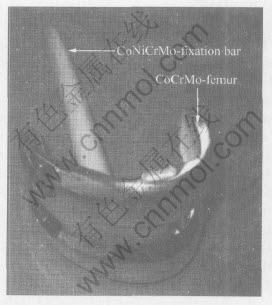

Co-alloys are important metallic medical materials for tribologically loaded knee, hip joints and their fixation parts, as shown in Fig.1, due to excellent mechanical, tribological and corrosion-resistant properties[1]. A bioactive ceramic coatings, especially hydroxyapatite(HA) coating, on metallic prostheses is a promising approach for improving its osteoconductivity and bone-bonding ability[2-11]. Nowadays, some plasma sprayed HA and other bioceramic coatings on metallic implants have been widely used in orthopaedic operations[1, 12-17]. Unfortunately, due to the ultra-high temperature and cooling rate, the plasma spray coating technique induces a partial decomposition of HA into the phases, e.g. TCP(Ca3(PO4)2) and TTCP(Ca4(PO4)2O), which are less in vivo stable, and naturally lead to the early failure of the HA coating[1, 12, 17]. Whereas, the low-temperature coating techniques are beneficial to obtaining a pure crystalline HA layer, which can provide a longer duration for bio-degradation[1, 12, 17]. Recently, a number of low-temperature coating techniques, such as biomineralization in simulated body fluid[2-8], sol-gel process[9-11, 18], have been reported for synthesizing HA coatings on metallic substrates, primarily for the purpose of enhancing osteoconductivity or bone bonding characteristics of bone-interfacing implants with a longer life time.

Fig.1 Metallic knee prosthesis of CoNiCrMo alloy for bone fixation and CoCrMo-femur tribological loading

However, the peeling of bioactive ceramic coatings from the metallic substrates can happen even after heat treatment during the low-temperature coating process[2], which restricts the orthopaedic applications of bio-active coatings prepared via low-temperature routes. The peeling stress is generated along the interface between coating and substrates due to the difference between metals and ceramics in the coefficient of thermal expansion(CTE), as well as the insufficient mechanical interlocking or chemical interaction between the coating and the substrate[2, 18]. So an intermediate layer between metal and HA is useful to improve the interfacial bonding condition due to the effectiveness in CTE reduction[2-8]. Nowadays, alkali and heat treatments are found effective for producing the intermediate layer for the subsequent HA coating on Ti, Ta alloys and stainless steels[2-8]. Although, Co-alloys are used as tribologically loaded components and fixation parts in close bone contact, the HA coating on Co-alloys, especially improving the bonding strength using an intermediate layer, are rarely reported.

In order to study the feasibility of various surface pre-treating methods to conventionally used CoNiCrMo substrate, several substrate pre-treating conditions are applied in the present study. Subsequently, the effect of intermediate layer is assessed by observing the morphology and measuring the bonding strength of the dip-coated HA layer on the substrate with and without pre-treatment.

2 EXPERIMENTAL

The CoNiCrMo substrates were mechanically polished to a 1μm finish washed with acetone and distilled water in an ultrasonic cleaner. The intermediate layers on CoNiCrMo for HA coating were produced by alkali treatments and oxidation pre-treatments. The alkali pre-treatments were performed by soaking these substrates in 10mol/L NaOH at 60℃ for 24h[2]; and Ca(OH)2 saturated solution at 80℃ for 36h, which could be used to provide a similar surface morphology with NaOH treatment[14]. After the alkali pre-treatment, the substrates were gently washed with distilled water and then dried at 40℃ for 24h in air. In order to avoid the degradation of CoNiCrMo at over-elevated temperature, the pre-treated substrates were successively heated to a moderate temperature, 600℃ for 1h at a slow heating rate of 5℃/min, and then cooled to room temperature in the furnace.

In order to verify the effect of intermediate layer produced by pre-treatments, a HA dip-coating procedure was necessary. Ca(NO3)2·4H2O and (NH4)2HPO4,at a Ca/P ratio of 1.67, were used as the precursors of HA sol for dip-coating. The sol was aged and washed with distilled water until the pH value of waste water was neutral. The substrates with and without pre-treatment were dip-coated in HA sol at a withdraw rate of 4mm/s, dried at 150℃ for 15min and heated at 500℃ for 15min at the heating rate of 5℃/min. All coating procedures were repeated 10 times in order to obtain a considerable thickness.

Grazing incident XRD was used to identify the phase purity of the dip-coated HA on different pre-treated CoNiCrMo substrates. Then the morphologies of HA coatings were also studied using scanning electron microscopy(SEM) method. The improving effects of pre-treatments were evaluated using SEM images by comparison of the crack and pore features in the HA coatings on the substrates with and without pre-treatment. The bonding strength of the HA coatings on different intermediate layers were measured after the adhesion testing standard ASTM C633. The coated substrates were fixed onto a pair of testing bars of d11mm×60mm by araldite glue on a V-shaped block with a uniaxial pressure of 40MPa. And the tensile tests were carried out with a material testing machine.

3 RESULTS AND DISCUSSION

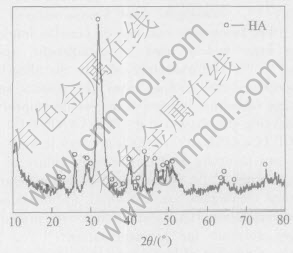

Fig.2 shows the grazing incidence XRD pattern of the dip-coated HA layers on the un-pretreated, alkali pretreated and merely oxidized substrates, which were detected as monophase full crystallinity HA. The monophase full crystallinity HA is much more in-vivo stable than TCP, TTCP as well as amorphous calcium phosphate phases, the decomposition products of plasma sprayed HA coating resulting from the ultra-high temperature and cooling rate[1, 12, 17]. The morphologies of the substrates with or without pretreatments were observed using SEM, as displayed in Fig.3, respectively.

Fig.2 Grazing incidence XRD pattern of HA coating

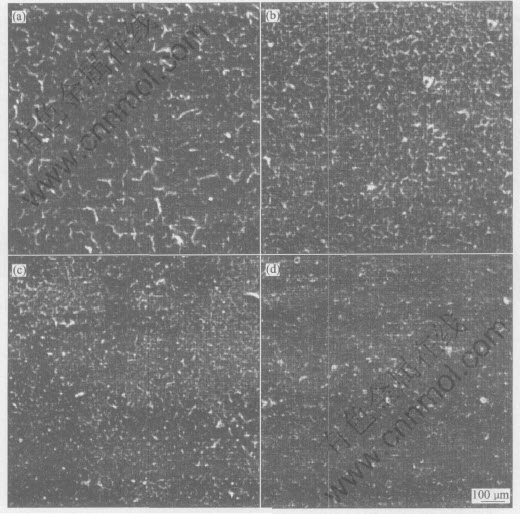

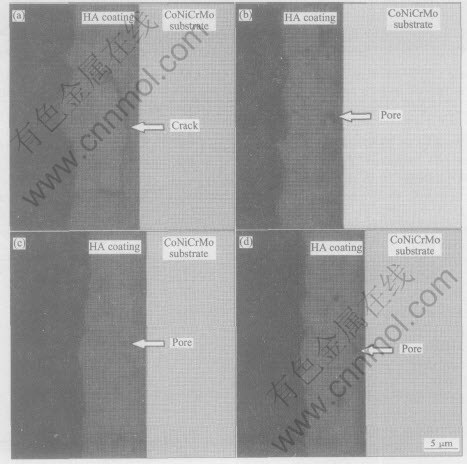

The HA coating on the untreated CoNiCrMo substrate (Fig.3(a)) is full of the networks of long crack, which is attributed to the great difference of CTE between HA ceramic and metallic substrate. Whereas the HA coatings on the alkali-treated substrates (Figs.3(b) and (c)) show a different morphologies, less and smaller cracks. It suggests that the alkali pretreatments are effective

Fig.3 SEM images of HA dip-coatings on untreated CoNiCrMo substrate(a), 10mol/L NaOH treated and 600℃ heated substrate(b), saturated Ca(OH)2 treated and 600℃ heated substrate(c), and merely oxidized substrate(d)

to improve the quality of HA coating on CoNiCrMo substrate. As reported previously[18], a mountain-like morphology, with the height of 175-189nm, was obtained on the surface of CoNiCrMo substrate after the alkali pre-treatment of either 10mol/L NaOH at 60℃ for 24h or saturated Ca(OH)2 solution at 80℃ for 36h, succeeded with oxidation at 600℃. By comparison of Figs.3(b) and (c), the HA coating on Ca(OH)2 pretreated substrate is better than that on the NaOH pretreated one, in both crack length and density. Although, the alkali pre-treatment can improve the quality of HA coating on CoNiCrMo substrate, the alkali pretreatments need a great amount of alkali chemicals, which could be harmful to the environment. Furthermore, the post treatment of the waste alkali solution will result in extra expenses as well as further pollutions.

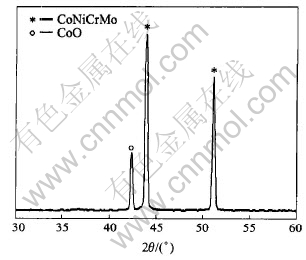

Additionally, it is noticeable that the HA coating on the directly oxidized CoNiCrMo substrate presents a crack-free morphology, which looks better than the HA coatings on the substrates with alkali-treatment and without any treatment. The reasons for such a phenomenon can be concluded as the well crystallized oxide CoO layer on the oxidized CoNiCrMo substrate as shown in Fig.4, which could greatly reduce the CTE difference between HA layer and CoNiCrMo substrate. The topographic images of the as-

Fig.4 Grazing incidence XRD pattern of CoNiCrMo substrate merely oxidized at 600℃

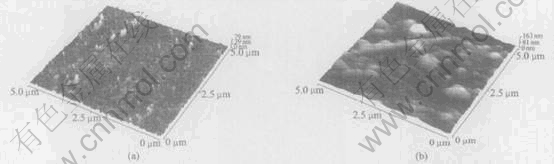

polished CoNiCrMo substrate and the substrate merely oxidized at 600℃ are illustrated in Fig.5, which show the peak-like surface of untreated CoNiCrMo substrate is replaced with a thick layer of oxidization product after oxidization at 600℃.

In brief, the crack densities of the HA coatings decrease along the sequence of no pre-treatment, NaOH pre-treatment, Ca(OH)2 pre-treatment and direct oxidation. Among these methods, direct oxidation is an environment friendly method, which doesnt need any special chemical reagent and produce any harmful by-product.

Furthermore, the cross sections of the HA coatings were also observed by SEM, as shown in Fig.6, which exhibit a similar result with the morphology observations. In the HA coating on the untreated CoNiCrMo substrate, there are a lot of vertical and parallel cracks. Whereas only several pores are found in the HA coating on the directly oxidized substrate. The coating quality of the cross section varies with the same sequence as the results of morphological observation in Fig.3.

Fig.5 AFM topographies of as-polished CoNiCrMo substrate(a) and substrate merely oxidized at 600℃(b)

Fig.6 SEM images of cross section of HA dip-coatings on untreated CoNiCrMo substrate(a), 10mol/L NaOH treated and 600℃ heated substrate(b), saturated Ca(OH)2 treated and 600℃ heated substrate(c), and directly oxidized substrate(d)

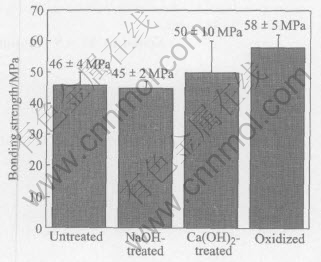

The measured bonding strengths of HA coatings on the substrates treated under different treating conditions are plotted in Fig.7. The bonding strengths of the HA coatings on the pre-treated substrates increase with the same sequence of the coating qualities. Direct oxidation provides the highest average boding strength, whereas NaOH treatment results in the lowest value. The average bonding strength of the HA coating on substrate merely oxidized at 600℃ reaches (58±5)MPa, higher than the reported values of the plasma sprayed HA coatings on Ti-alloys[15-17]. Furthermore, according to the proposed standards, the shear strength should be 22-29MPa and the minimum tensile strength should be 51MPa for the clinically available HA coating[18]. This suggests that the HA sol-gel coating route with a direct oxidation pre-treatment is suitable for providing a coating bonding strength higher than that of plasma spray coating route for CoNiCrMo substrate, the high crystallinity and phase-purity of HA coating, which is more in-vivo stable than those produced via plasma spray route.

Fig.7 Measured bonding strengths of HA coatings on CoNiCrMo substrates under different pretreating conditions

It is noticeable that there is an abnormal value measured with the samples of untreated condition. The measured bonding strength of the HA coating on the untreated CoNiCrMo substrate was a little bit higher that that of NaOH sample. Such an abnormal result could attribute to the morphological features of HA coating. There are a lot of crack network along and within the HA coating on the untreated substrate, which could be the penetrating channels for the epoxy resin to fill into during the gluing process under a pressure up to 40MPa. Naturally, the epoxy network reinforced HA coating is believed to be able to provide a higher bonding strength.

4 CONCLUSIONS

1) The surface pre-treatments are effective for improving the quality of HA coating on CoNiCrMo. The crack-eliminating effects of pre-treatments can be ranged decreasingly as direct oxidation at 600℃, alkali pre-treatment by saturated Ca(OH)2+oxidation at 600℃, as well as alkali pre-treatment of 10mol/L NaOH+oxidation at 600℃.

2) According to ASTM C633 tests, the bonding strength of the HA dip-coating on CoNiCrMo substrate merely oxidized at 600℃ reaches (58±5)MPa, which is higher than that of the clinically used HA coatings on Ti-alloys produced via plasma spray route.

3) The HA dip-coating on CoNiCrMo substrate merely oxidized at 600℃ is of full crystallinity and high phase-purity, which is more in-vivo stable than those produced via plasma sprayed HA coating.

4) The direct oxidation pre-treating method can produce a best coating quality and highest average bonding strength among these surface pre-treating methods, more importantly, which is also an environmentally friendly and cost-saving route.

ACKNOWLEDGEMENT

Financial support from the German Academic exchange service(DAAD) is gratefully acknowledged. The authors thank Mr. P. Handschin (Sulzer Orthopaedics Ltd., Switzerland) for providing the medical grade Co alloy

REFERENCES

[1]Kohn D H, Ducheyne P. Materials for Bone and Joint Replacement, Materials Science and Technology—A Comprehensive Treatment. Vol. 14. Medical and Dental Materials[M]. Cahn R W, Haasen P, Kramer E J. New York: VCH Publishers Inc, 1992. 41-42.

[2]Lin F, Hsu Y, Lin S, et al. The effect of Ca/P concentration and temperature of simulated body fluid on the growth of hydroxypatite coating on alkali-treated 316L stainless steel [J]. Biomaterials, 2002, 23(19): 4029-4038.

[3]Kato H, Nakamura T, Nishiguchi S, et al. Bonding of alkali- and heat-treated tantalum implants to bone [J]. J Biomed Mater, 2000, 53(1): 28-35.

[4]Kokubo T, Miyaji F, Kim H M. Spontaneous formation of bonelike apatite layer on chemically treated titanium metals [J]. J Am Cerm Soc, 1996, 79(4): 1127-1129.

[5]Kim H M, Miyaji F, Kokubo T, et al. Preparation of bioactive Ti and its alloys via simple chemical surface treatment [J]. J Biomed Mater, 1996, 32(3): 409-417.

[6]Miyazaki T, Kim H M, Miyaji F, et al. Bonding strength of apatite layer formed on chemically treated tantalum metal [A]. Ohgushi H, Hastings G W, Yoshikawa T. Bioceramics, Vol. 12, Proceedings of the 12th International Symposium on Ceramics in Medicine [C]. Nara, Japan: World Scientific Publishing Co Pte Ltd, 1999. 113-115.

[7]Kim H M, Miyaji F, Kokubo T, et al. Bonelike apatite formation on porous titanium metal subjected to NaOH and heat treatments [A]. Ohgushi H, Hastings G W, Yoshikawa T. Bioceramics, Vol.12, Proceedings of the 12th International Symposium on Ceramics in Medicine [C]. Nara, Japan: World Scientific Publishing Co Pte Ltd, 1999. 117-119.

[8]Layrolle P, Clemens A, Blitterswijk Van, et al. Biomimetic hydroxyapatite coating on Ti6Al4V induced by pre-calcification [A]. LeGeros R Z, LeGeros J P. Bioceramics, Vol.11, Proceedings of the 11th International Symposium on Ceramics in Medicine[C]. New York, USA: World Scientific Publishing Co Pte Ltd, 1998. 465-467.

[9]Montenero A, Gnappi G, Ferrari F, et al. Sol-gel derived hydroxyapatite coatings on titanium substrate [J]. J Mater Sci, 2000, 35(11): 2791-2797.

[10]Breme J, Biehl V, Hoffman A. Tailor-made composites based on titanium for medical devices [J]. Advanced Engineering Materials, 2000, 2(5): 270-275.

[11]Wen W, Shen G, Han G. Low temerpature preparation of hydroxyapatite coatings on titanium alloy by a sol-gel route [J]. J Mater Sci Lett, 2000,19(24): 2187-2188.

[12]Hench L L. Biomaterials Science—An Introduction to Materials in Medicine [M]. Ratner B D, Hoffman A S, Schoen F J, et al. San Diego: Academic Press, 1996. 82-83.

[13]Lin C, Liu J H, Chen M L, et al. Plasma-sprayed hydroxyapatite-bioactive glass composites on Ti6Al4V [A]. Proceedings of the 17th Annual Conference on Composites and Advanced Ceramic Materials, Vol.14 [C]. Cocoa Beach, FL, USA, 1993. 971-981.

[14]Lin C, Liu J H, Ju M L. Structure and properties of hydroxyapatite-bioactive glass composites plasma sprayed Ti6Al4V [J]. Journal of Materials Science: Materials in Medicine, 1994, 5(5): 279-283.

[15]Ning C Y, Wang Y J, Ye J D, et al. Gradient structure characteristics and properties of bioactive plasma-sprayed coatings [J]. The Chinese Journal of Nonferrous Metals, 2004, 14(S3): 425-428.(in Chinese)

[16]Sun L M, Berndt C C, Gross K A, et al. Material fundamentals and clinical performance of plasma-sprayed hydroxyapatite coatings: a review [J]. J Biomed Mater Res, 2001, 58(5): 570-592.

[17]Ravaglioli A, Krajeweski A. Bioceramics: Materials, Properties, Applications [M]. London: Chapman & Hall Press, 1992. 44-45.

[18]Wang T, Dorner-Reisel A, Mueller E. Preparation of the intermediate layers on CoNiCrMo-alloys using alkaline treatment for improving the bonding of bioceramic coatings [J]. Advanced Engineering Materials, 2003, 5(7): 493-498.

(Edited by YUAN Sai-qian)

Received date: 2005-05-08; Accepted date: 2005-10-20

Correspondence: WANG Tao, Associate Professor, PhD; Tel/Fax: +86-25-84895790; E-mail: taowang@nuaa.edu.cn