文章编号:1004-0609(2016)-12-2573-07

苛刻热循环对Sn2.5Ag0.7Cu0.1RExNi/Cu钎焊界面及接头性能的影响

郭兴东1, 2,张柯柯1, 2,邱然锋1,石红信1,王要利1,马 宁1

(1. 河南科技大学 材料科学与工程学院,洛阳 471023;

2. 河南科技大学 有色金属共性技术河南省协同创新中心,洛阳 471023)

摘 要:采用SEM、EDS、XRD等对苛刻热循环下Sn2.5Ag0.7Cu0.1RExNi/Cu钎焊界面IMC及接头性能进行研究。结果表明:苛刻热循环下Sn2.5Ag0.7Cu0.1RExNi/Cu钎焊界面IMC由(Cu,Ni)6Sn5和Cu3Sn相组成;随热循环周期的增加,钎焊接头的界面IMC (Cu,Ni)6Sn5形态由波浪状转变为局部较大尺寸的“笋状”,IMC平均厚度和粗糙度增大,相应接头剪切强度降低。添加适量Ni 0.05%(质量分数)的钎焊接头界面IMC平均厚度和粗糙度最低,接头剪切强度最高。在100热循环周期内,随热循环周期增加,Sn2.5Ag0.7Cu0.1RE0.05Ni/Cu钎焊接头剪切断口由呈现钎缝处的韧性断裂向由钎缝和IMC层组成以韧性为主的韧-脆混合断裂转变。

关键词:无铅钎料;苛刻热循环;接头;金属间化合物;性能

中图分类号:TG425 文献标志码:A

随着人们环保意识的增强,电子信息产品无铅化已成为其发展的必然趋势[1-2]。Sn-Ag-Cu系钎料合金因其较好的润湿性和综合性能,被认为是Sn-Pb系钎料的最佳替代品之一[3-4],并成功地开发出微电子连接商用Sn3.8Ag0.7Cu无铅钎料,我国开发出独具特色的Sn-Ag-Cu-RE系无铅钎料合金。为进一步降低无铅钎料的制造成本,人们在保证无铅钎料具有良好润湿性的同时,借助于合金化方法降银并提高钎料合金的强韧性,以获得具有较高可靠性的焊点,如我国开发出低银高强韧Sn2.5Ag0.7Cu0.1RExNi钎料合金,其中蠕变寿命是目前商用Sn3.8Ag0.7Cu无铅钎料的两倍多,呈现出显著的技术经济优势。但迄今为止,关于微电子连接用Sn-Ag-Cu-RE-Ni系无铅钎料合金焊点可靠性尤其在航空、军工等苛刻环境下焊点可靠性研究却鲜见文献报道。因此,本文作者拟对苛刻热循环下Sn2.5Ag0.7Cu0.1RExNi/Cu钎焊界面IMC及接头性能进行研究,为新型微电子连接用高强韧高可靠性无铅钎料的设计开发提供实验依据。

1 实验

1.1 实验材料

采用99.9%以上纯度的Sn、Ag、Cu、Ni及富含Ce和La的混合RE,在真空度为5×10-3 Pa的非自耗电炉(ZHW-600A型)中先制备Cu-RE中间合金,再取一定量的中间合金与Sn、Ag、Cu、Ni制备实验用Sn2.5Ag0.7Cu0.1RExNi(x=0,0.05,0.1,质量分数,%)钎料合金;母材选用纯度为99.9%的紫铜板;焊剂为商用CX600水洗钎剂。

1.2 实验方法及条件

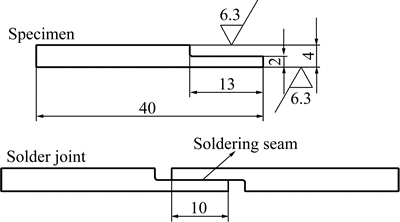

将制备的钎料合金轧制成10 mm×20 mm×0.1 mm的薄带,在自行研制的箱式钎焊炉内进行搭接钎焊试验,试样形状尺寸如图1所示。参照文献[5]选用钎焊工艺参数:钎焊温度270 ℃,钎焊时间240 s。焊后在SM-KS-50-CC型微连接接头可程式快速温变试验箱中进行接头热循环试验,其热循环试验参数如下:极限温度-40~125 ℃,升降温速率15 ℃/min,高低温各保温10 min,循环周期数为0、20、50、60、80、100。热循环试验后的钎焊试样经打磨、抛光后4%(体积分数)硝酸酒精溶液腐蚀,用JSM-5610LV型扫描电镜观察接头组织形貌,必要时进行EDS能谱成分分析;钎焊后采用尺寸为8 mm×70 mm×4 mm剪切试样,在AG-I250kN型万能试验机上室温条件下进行拉伸,拉伸速度为1 mm/min,借助于D8 ADVANCE型X衍射仪对钎焊接头界面进行物相分析。为保证剪切强度接头测试结果的准确性,取5个不同试样的算术平均值作为剪切强度值。

图1 钎焊试样形状及尺寸

Fig. 1 Configuration and dimension of specimen for soldering (Unit: mm)

图2 接头界面粗糙度示意图

Fig. 2 Schematic diagram of roughness of solder joints

参照文献[6]中关于微连接焊点界面厚度、粗糙度的评估方法(界面IMC粗糙度测量示意图见图2),利用AutoCAD软件测量观察界面IMC面积,根据等积法原理求得界面IMC的平均厚度。以平均厚度线作为粗糙度测量基准线(见图2中虚线),测量选定区域界面IMC的峰值到基准线间的距离,代入式(1)计算选定区域的界面粗糙度。为减小测量误差,以5次随机测量区域的平均值作为测量结果。

(1)

(1)

式中:Rrms为粗糙度,μm;N为选定区域测量点的个数;Zi为所测量选定区域的IMC峰值到测量基准线间的距离,μm。

2 结果与分析

无铅钎焊接头界面区IMC层在服役环境中的成长及其形态与接头可靠性密切相关。因此,有必要研究苛刻热循环下Sn2.5Ag0.7Cu0.1RExNi/Cu钎焊接头界面IMC的生长行为、接头性能及其断裂机制。

2.1 Sn2.5Ag0.7Cu0.1RExNi/Cu苛刻热循环钎焊接头界面金属间化合物

图3所示为Sn2.5Ag0.7Cu0.1RExNi/Cu苛刻热循环接头界面SEM像和XRD谱,钎焊接头界面金属间化合物(见图3(a)中A、B点)EDS分析结果如表1所列。由图3和表1可知,钎焊接头由钎缝、界面区和母材3部分组成。钎缝由初生相β-Sn和共晶组织组成,其共晶组织包括颗粒状β-Sn+Cu6Sn5、针状β-Sn+Ag3Sn二元共晶组织以及β-Sn+Cu6Sn5+Ag3Sn三元共晶组 织[7]。接头界面IMC形成于钎缝和Cu基体之间,分为两层:一层为靠近钎缝侧颜色较浅的(Cu,Ni)6Sn5(见图3(a)中A),向钎缝内不规则生长,厚度一般4~5.5 μm;一层为靠近Cu基体侧平且颜色较深厚度小于1 μm的Cu3Sn[8](见图3(a)中B)。Ni和Cu具有相同的晶体结构,钎料熔化过程中Ni原子置换出Cu6Sn5中部分Cu形成了(Cu,Ni)6Sn5相[9]。界面IMC层中Cu3Sn相生成量较少,可能是由于Cu6Sn5相的生长驱动力高于Cu3Sn相[10]和(Cu,Ni)6Sn5抑制Cu3Sn相的生长驱动力。接头界面处IMC内存在少量气孔、裂纹等缺陷。无铅焊点界面IMC作为连接的基础,其几何形态、尺寸与微连接焊点可靠性密切相关[11],在此,重点考虑苛刻热循环对接头界面界面金属间化合物尤其是(Cu,Ni)6Sn5的影响。

表1 图3(a)中焊点界面EDS分析结果

Table 1 EDS results of solder joint interface shown in Fig. 3(a)

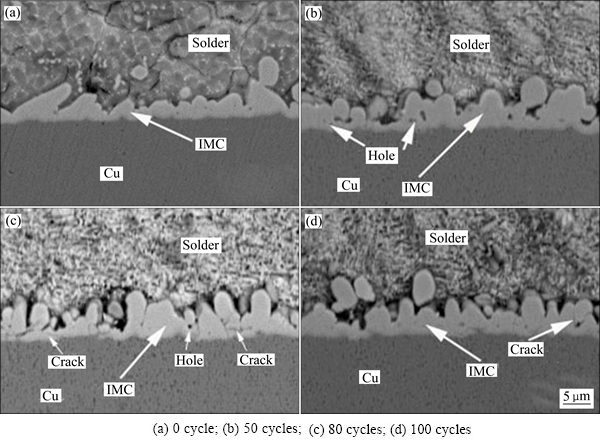

图4所示为苛刻热循环对Sn2.5Ag0.7Cu0.1RE- xNi/Cu接头界面IMC的影响。由图4可知,低热循环周期下接头界面IMC成长较慢,波浪状IMC形态均匀,无裂纹、空洞等缺陷(见图4(a));当循环周期大于50周时,界面化合物IMC生长加快,局部出现较大尺寸的“笋状”,甚至产生空洞等现象(见图4(b))。随着热循环周期数增加,接头界面IMC层逐渐变厚,界面中(Cu,Ni)6Sn5相逐步长大并粗化,生长前沿部分不断向钎缝内部不规则长大。由于界面金属间化合物和钎缝热膨胀系数不相同,在接头应力作用下界面产生显微裂纹、空洞等(见图4(c)和(d))。对比图4可知,热循环过程接头遭受高低温度循环作用,导致接头界面金属间化合物粗化,在接头应力循环作用下产生开裂失效等。热循环初期,界面处连续致密的(Cu,Ni)6Sn5相阻碍了钎缝中Sn、Ni原子与基板上Cu原子间的相互扩散,抑制了界面Cu3Sn金属间化合物的生长,形成了薄且平的形貌特征。热循环50周期以后,界面化合物生长速率有所加快,一方面可能是由于界面处扇贝状(Cu,Ni)6Sn5之间的凹槽是Cu原子向(Cu,Ni)6Sn5颗粒与钎料界面处扩散的快速通道,Cu原子通过凹槽快速扩散至扇贝状颗粒与钎料界面处与Sn、Ni原子发生反应;另一方面可能是由于钎料在热循环条件下发生了动态再结晶,促使钎料中的Sn、Ni原子快速扩散至钎料/(Cu,Ni)6Sn5界面处与Cu原子发生反应,从而加快了界面化合物的生长[12]。

图3 Sn2.5Ag0.7Cu0.1RE0.05Ni/Cu接头界面SEM像及XRD分析结果

Fig. 3 SEM image and XRD results of Sn2.5Ag0.7Cu0.1RE0.05Ni/Cu solder joint interface

图4 苛刻热循环对Sn2.5Ag0.7Cu0.1RE0.05Ni/Cu接头界面IMC的影响

Fig. 4 SEM images of Sn2.5Ag0.7Cu0.1RE0.05Ni/Cu solder joint interface in different thermal cycling

苛刻热循环对Sn2.5Ag0.7Cu0.1RExNi/Cu(x=0, 0.05, 0.1, %)接头界面粗糙度及IMC层的平均厚度影响如图5所示。由图5可见,钎焊点界面金属间化合物平均厚度一般为3~ 5 μm;随热循环周期次数的增加,界面IMC层的平均厚度及粗糙度不断增加;Sn2.5Ag0.7Cu0.1RE0.05- Ni/Cu钎焊接头界面粗糙度及IMC层的平均厚度明显低于不添加Ni和添加0.1%Ni(质量分数)的Sn2.5Ag- 0.7Cu0.1RExNi/Cu钎焊接头的,这表明适量添加Ni能够抑制苛刻热循环条件下Sn2.5Ag0.7Cu0.1RExNi/Cu钎焊接头界面IMC的生长、降低界面粗糙度,改善接头组织形态。这可能是由于添加的Ni在Sn基焊料中的溶解度小,Ni-Sn金属间化合物反应生成速率小,添加适量的Ni增加了界面元素的扩散阻力,降低了钎焊界面IMC的生成速率,抑制了IMC的快速长大[1]。

图5 不同热循环周期下Sn2.5Ag0.7Cu0.1RExNi/Cu(x=0, 0.05, 0.1, %)接头界面粗糙度及IMC层的平均厚度

Fig. 5 Roughness and IMC average thickness of Sn2.5Ag0.7Cu0.1RExNi/Cu (x=0, 0.05, 0.1, %) solder joint interface in different thermal cycling

2.2 Sn2.5Ag0.7Cu0.1RExNi/Cu苛刻热循环下钎焊接头性能

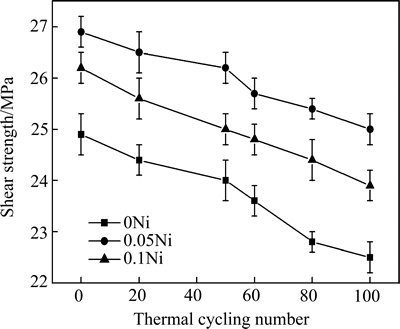

苛刻热循环下Sn2.5Ag0.7Cu0.1RExNi/Cu接头剪切强度如图6所示。由图6可知,随苛刻热循环周期的增加,Sn2.5Ag0.7Cu0.1RExNi/Cu接头剪切强度下降;添加适量的Ni能抑制苛刻热循环钎焊接头剪切强度的降低。在低热循环周期即热循环小于50周时,钎焊接头剪切强度下降幅度较小;当热循环大于50周时,钎焊接头剪切强度呈快速下降。这与无铅焊点界面区IMC的成长及其形态与接头可靠性密切相关研究结果吻合,由图4和5可知,苛刻热循环对Sn2.5Ag0.7Cu0.1RExNi/Cu接头界面IMC的影响可见,随热循环周期的增加,接头界面IMC层平均厚度和界面粗糙度增大,接头剪切强度降低;添加适量Ni(0.05%)IMC层平均厚度和界面粗糙度增大最低,其接头剪切强度最高。

图6 苛刻热循环对Sn2.5Ag0.7Cu0.1RExNi/Cu接头剪切强度影响

Fig. 6 Shear strength of Sn2.5Ag0.7Cu0.1RExNi/Cu(x=0, 0.05, 0.1, %)solder joint in different thermal cycling

苛刻热循环下Sn2.5Ag0.7Cu0.1RExNi/Cu接头剪切断口SEM像如图7所示。从图7可见,经100热循环周期后(见图7(d));A点成分以Sn元素为主,属钎缝区域(见图7(e));B点成分反映其为界面IMC层(Cu,Ni)6Sn5(见图7(f)),这表明苛刻热循环钎焊接头断裂部分发生在钎缝内、部分发生在界面IMC层。在0~100热循环周期,Sn2.5Ag0.7Cu0.1RE0.05Ni/Cu钎焊接头剪切断口均有一定量的抛物线韧窝,这是由于钎焊接头受剪切力作用时,钎缝和界面区发生塑性变形,组织显微裂纹等缺陷会导致显微空穴的形成,在变形量增大时,空穴聚集长大,并最终相互连通形成在断口上呈现出剪切韧窝断裂特征。随着热循环周期的增加,剪切断口中发生在焊缝中蜂窝状韧窝断口呈韧性断裂减少,断口中短而平的断裂小刻面增多,该断裂更多是发生在接头界面的IMC层如(Cu,Ni)6Sn5中,且刻面周围存在明显的撕裂棱,断口呈脆性断裂特征。经热循环100周期后,接头在IMC层与钎缝的结合面发生断裂,断口上观察到山峰状韧窝及部分撕裂棱,韧窝数量减少,尺寸变大,深度变浅,甚至出现层片状光滑的脆断区。这表明随着热循环周期的增加断口呈韧性断裂逐渐向以韧性为主的韧-脆混合断裂转变。

图7 不同热循环周期下Sn2.5Ag0.7Cu0.1RE0.05Ni/Cu接头剪切断口SEM像及A、B点成分分析结果

Fig. 7 SEM images of Sn2.5Ag0.7Cu0.1RE0.05Ni/Cu solder joint shear fracture in different thermal cycling and EDS results of points A and B

2.3 分析与讨论

Sn2.5Ag0.7Cu0.1RExNi/Cu钎焊接头经不同苛刻热循环,接头受不均匀热、力作用会导致界面区组织不规则成长。界面化合物IMC的生长主要依靠原子扩散进行[13]。在热循环条件下Cu原子通过晶界、位错、空位、缺陷等穿过界面IMC 与钎料基体中界面处的Sn原子进行反应生成(Cu,Ni)6Sn5层,使(Cu,Ni)6Sn5层明显加厚[14],局部的快速生长使得出现界面IMC“笋状”[15],界面IMC的形态由波浪状演变为局部较大尺寸的“笋状”,导致界面IMC厚度及粗糙度不断增加。无铅焊点界面IMC属于硬脆相,影响着接头区组织性能的连续性,其形态、尺寸的改变势必降低钎焊接头的强度和韧性并最终影响接头可靠性。接头在热循环作用下,一定程度上导致钎缝组织的粗化,界面IMC尺寸变大、形态粗化,这使钎焊接头的性能及可靠性降低。在接头热循环作用下,钎焊接头断面上韧窝数量逐渐减少,出现撕裂棱甚至层片状光滑的脆断区,表现出接头断口由韧性断裂向以韧性为主的韧-脆混合断裂特征的转变,使接头可靠性降低。因此,应寻求减少界面IMC成长的有效途径以改善钎焊接头的可靠性。

Sn2.5Ag0.7Cu0.1RE钎料合金中添加适量Ni,可以细化组织、改善钎料润湿性及性能[16]。Ni晶格点阵与Cu的相近,原子序数也与Cu的相近,在实际的电子封装及焊后的服役条件下,Ni晶格起到结晶核心的作用,可以减小焊点界面IMC的晶粒尺寸。由于Ni在Sn基焊料中的溶解度小,Ni-Sn金属间化合物反应生成速率小,添加适量的Ni能增加界面元素的扩散阻力,从而抑制热循环过程中接头界面IMC的过快生长,减缓热循环过程中剪切强度的降低,进而提高接头的可靠性。鉴于Ni元素能够抑制界面IMC快速生长,因此,可以向钎料合金中加入适量的Ni来提高钎焊接头热循环条件下的可靠性。

3 结论

1) 苛刻热循环下Sn2.5Ag0.7Cu0.1RExNi/Cu钎焊界面IMC由(Cu,Ni)6Sn5和Cu3Sn相组成。随热循环周期增加,钎焊接头界面IMC (Cu,Ni)6Sn5形态由波浪状转变为局部较大尺寸的“笋状”,IMC平均厚度和粗糙度增大,相应接头剪切强度降低。添加适量Ni (0.05%)的钎焊接头界面IMC平均厚度和粗糙度最低,接头剪切强度最高。

2) 在100热循环周期内随热循环周期增加,Sn2.5Ag0.7Cu0.1RE0.05Ni/Cu钎焊接头剪切断口由呈现钎缝处的韧性断裂向由钎缝和IMC层组成以韧性为主的韧-脆混合断裂转变。

REFERENCES

[1] SUGANUMA K. 无铅钎焊技术[M]. 宁晓山, 译. 北京: 科学出版社, 2004: 138-152.

SUGANUMA K. Lead-free soldering technology[M]. NING Xiao-shan, transl. Beijing: Science Press, 2004: 138-152.

[2] STELLER A, PAPE U, BLAIR L. Solder joint reliability in automotive applications: New assessment criteria through the use of EBSD[J]. Solid State Phenomena, 2010, 160: 307-312.

[3] 孟工戈, 李 丹, 李正平, 王彦鹏, 陈雷达. 时效对SnCuSb/Cu钎焊接头抗剪强度与断口特征的影响[J]. 焊接学报, 2010, 31(6): 85-89.

MENG Gong-ge, LI Dan, LI Zheng-ping, WANG Yan-peng, CHEN Lei-da. Effects of aging on shearing strength and fracture surface characteristics of SnCuSb/Cu soldering joint[J]. Transactions of the China Welding Institution, 2010,31(6): 85-89.

[4] 王俭辛, 薛松柏, 韩宗杰, 汪 宁, 禹胜林. 温度与镀层对Sn-Cu-Ni无铅钎料润湿性能的影响[J]. 焊接学报, 2006, 27(10): 53-56.

WANG Jian-xin, XUE Song-bai, HAN Zong-jie, WANG Ning, YU Sheng-lin. Effect of temperature and coatings on Sn-Cu-Ni lead-free solder wettability[J]. Transactions of the China Welding Institution, 2006, 27(10): 53-56.

[5] 李臣阳, 张柯柯, 王要利, 赵 恺, 杜宜乐. Ni元素对Sn2.5Ag0.7Cu0.1RE/Cu无铅微焊点界面IMC和力学性能的影响[J]. 焊接学报, 2012, 33(11): 39-42.

LI Chen-yang, ZHANG Ke-ke, WANG Yao-li, ZHAO Kai, DU Yi-le. Effect of Ni on interfacial IMC and mechanical properties of Sn2.5Ag0.7Cu0.1RE/Cu solder joints[J]. Transactions of the China Welding Institution, 2012, 33(11): 39-42.

[6] YU D Q, WANG L. The growth and roughness evolution of intermetallic compounds of Sn-Ag-Cu/Cu interface during soldering reaction[J]. Journal of Alloys and Compounds, 2008, 458(1/2): 542-547.

[7] WANG Yao-li, ZHANG Ke-ke, LI Chen-yang, HAN Li-juan. The morphology and evolution of Cu6Sn5 at the interface of Sn-2.5Ag-0.7Cu-0.1RE/Cu solder joint during the isothermal aging[J]. Materials Science Forum, 2012, 704: 685-689.

[8] ZHANG Ning, SHI Yao-wu, GUO Fu, LEI Yong-ping, XIA Zhi-dong, CHEN Zhen-hua, TIAN Li. Comparison of drop performance between the Sn37Pb and the Sn3.8Ag0.7Cu solder joints subjected to drop test[J]. Journal of Materials Science: Materials in Electronics, 2011, 22: 292-298.

[9] LIN Kwang-lung, SHIH Po-cheng. IMC formation on BGA package with Sn-Ag-Cu and Sn-Ag-Cu-Ni-Ge solder balls[J]. Journal of Alloys and Compounds, 2008, 452(2): 291-297.

[10] LIU Ping, YAO Pei, LIU Jim. Evolutions of the interface and shear strength between SnAgCu–xNi solder and Cu substrate during isothermal aging at 150 ℃[J]. Journal of Alloys and Compounds, 2009, 486(1/2): 474-479.

[11] 王要利, 张柯柯, 李臣阳, 衡中皓. RE对SnAgCu钎料合金及焊点性能的影响[J]. 材料热处理学报, 2011, 32(12): 35-37.

WANG Yao-li, ZHANG Ke-ke, LI Chen-yang, HENG Zhong-hao. Effect of RE on properties of SnAgCu solder alloy and its joints[J]. Transaction of Materials and Heat Treatment, 2011, 32(12): 35-37.

[12] PANG J H L, PRAKASH K H, LOW T H. Isothermal and thermal cycling aging on IMC growth rate in Pb-free and Pb-based solder interfaces[C]// The Ninth Intersociety Conference on Thermal and Thermomechanical Phenomena In Electronic Systems. Piscataway: IEEE, 2004: 109-115.

[13] 许媛媛, 闫焉服, 李 帅, 葛 营. 循环周期对Sn3.0Ag0.5Cu/Cu钎焊接头界面化合物的影响[J]. 材料热处理学报, 2015, 36(1): 93-98.

XU Yuan-yuan, YAN Yan-fu, LI Shuai, GE Ying. Effect of thermal cycles on intermetallic compounds of Sn3.0Ag0.5Cu/Cu soldering joint[J]. Transaction of Materials and Heat Treatment, 2015, 36(1): 93-98.

[14] 王 烨, 黄继华, 张建纲, 齐丽华. Sn-3.5Ag-0.5Cu /Cu界面的显微结构[J]. 中国有色金属学报, 2006, 16(3): 495-499.

WANG Ye, HUANG Ji-hua, ZHANG Jian-gang, QI Li-hua. Microstructure of Sn-3.5Ag-0.5Cu/Cu interface[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(3): 495-499.

[15] 劳邦盛, 高 苏, 张启运. 固-液金属界面上金属间化合物的非平衡生长[J]. 物理化学学报, 2001, 17(5): 453-456.

LAO Bang-sheng, GAO Su, ZHANG Qi-yun. Nonequilibrium growth of intermetallics at the interface of liquid-solid metal[J]. Acta Physico-chimica Sinica, 2001, 17(5): 453-456.

[16] 刘 平, 钟海锋, 龙郑易, 顾小龙. Ni对SAC0307无铅钎料性能和界面的影响研究[J]. 焊接, 2014(5): 27-30.

LIU Ping, ZHONG Hai-feng, LONG Zheng-yi, GU Xiao-long. Effect of Ni on SAC0307 lead-free solder performance and interfaces[J]. Welding & Joining, 2014(5): 27-30.

Effect on interface and property of Sn2.5Ag0.7Cu0.1RExNi/Cu solder joints in severe thermal cycling

GUO Xing-dong1, 2, ZHANG Ke-ke1, 2, QIU Ran-feng1, SHI Hong-xin1, WANG Yao-li1, MA Ning1

(1. College of Materials Science and Engineering, Henan University of Science and Technology, Luoyang 471023, China;

2. Collaborative Innovation Center of Nonferrous Metals, Henan University of Science and Technology, Luoyang 471023, China)

Abstract: The effect of severe thermal cycling on the IMC and mechanical property of Sn2.5Ag0.7Cu0.1RExNi/Cu solder joint was analyzed by SEM, XRD and EDS. The results show that the Sn2.5Ag0.7Cu0.1RExNi/Cu solder joints under severe thermal cycling exhibit duplex intermetallic compounds (IMCs) structure; i.e., a layer of (Cu, Ni)6Sn5 close to the solder and a layer of Cu3Sn adjacent to the Cu substrate. The morphology of the IMC in soldered joints transfers from wavy-shape into larger bamboo shoots with the increasing of thermal cycling, which causes increase of roughness and thickness, as well as decrease of the shear strength. When the Ni adding content of solder alloy is 0.05% (mass fraction), the roughness and average thickness of IMC are the lowest, the shear strength is the highest. Within 100 thermal cycling, the fracture mechanism of the joints exhibits from plastic fracture occured in the solder seam of Sn2.5Ag0.7Cu0.1RE0.05Ni/Cu to ductile-brittle mixed fracture of plastic fracture oriented in the interfacial of IMC and solder seam.

Key words: lead-free solder alloy; severe thermal cycling; solder joints; intermetallic compound(IMC); property

Foundation item: Project(2014DFR50820) supported by the National Science and Technology International Cooperation; Project(U1604132) supported by the National Natural Science Foundation of China; Project (154200510022) supported by the Plan for Scientific Innovation Talent of Henan Province, China

Received date: 2015-12-04; Accepted date: 2016-04-20

Corresponding author: ZHANG Ke-ke; Tel: +86-13837942173; E-mail: zhkekekd@163.com

(编辑 龙怀中)

基金项目:国家国际科技合作专项(2014DFR50820);国家自然科学基金资助项目(U1604132);河南省科技创新杰出人才计划(154200510022)

收稿日期:2015-12-04;修订日期:2016-04-20

通信作者:张柯柯,教授,博士;电话:13837942173;E-mail: zhkekekd@163.com