Influence of solidification mode on pore structure of directionally solidified porous Cu-Mn alloy

JIANG Guang-rui, LI Yan-xiang, LIU Yuan

Key Laboratory for Advanced Manufacturing by Materials Processing Technology,

Department of Mechanical Engineering, Tsinghua University, Beijing 100084, China

Received 26 March 2010; accepted 21 June 2010

Abstract: By the directional solidification of metal-gas eutectic method (GASAR), porous Cu-Mn alloy with oriented pores was fabricated successfully. The variation of pore structure was studied by experiments. The results show that the pore structure is primarily dependent on the solidification mode (planar, columnar cellular, columnar dendritic, equiaxed dendritic), which is controlled by the solidification process. By numerical simulation, it is noted that along with solidification, the solidification mode of the alloy transforms from cellular to columnar dendritic and finally to equiaxed dendritic. Through increasing melt temperature and mold preheating, the range of equiaxed dendrite could be decreased, which helps to extend the region of oriented pore structure.

Key words: porous Cu-Mn alloy; solidification mode; GASAR process; metal-gas eutectic

1 Introduction

Based on the solubility difference of gas between liquid and solid metals, regular porous metals with oriented pores could be fabricated by directional solidification of molten metals saturated with gas (such as hydrogen), which is called directional solidification of metal-gas eutectic method, or GASAR process[1-3]. Compared with traditional fabrication methods for porous metals, this process allows an effective control of porosity, pore size and orientation. A porous metal with oriented pore structure shows promising mechanical and functional properties.

Although there have been many studies on the GASAR process, most all of these studies have shown that it is easy to fabricate porous metals with oriented pores[4-7] but hard to get similar porous alloys[8-10], which have more important potentials than porous pure metals in industry. A few studies have shown that oriented pore could not be formed by columnar dendritic solidification[8-13], which is an usual solidification mode for alloys[14]. However, Jamgotchian and TRIVEDI[15] found that oriented bubbles could also be formed between columnar dendrites in succinonitrile- acetone alloys. These indicate that solidification mode affects pore structure greatly, which had not been studied thoroughly.

In this work, porous Cu-33.7%Mn (mass fraction) alloy, which is convenient for study as a single-phase alloy with small solidification interval[16], was fabricated successfully to get oriented porous structure with a columnar dendritic solidification mode. Then relationship between the pore structure and the solidification mode of the alloy was studied by experiments and numerical simulation. Based on this study, Cu-Mn alloy with other compositions and more other alloys will be researched by GASAR process furthermore.

2 Experimental

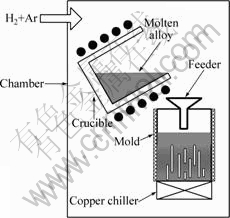

A self-developed apparatus for fabrication of porous alloys by directional solidification was utilized, as shown in Fig.1. It consists of a magnesia crucible (105 mm in inside-diameter and 180 mm in height) surrounded by a induction coil and a stainless steel mold with a water-cooled copper chiller at the bottom. These are all installed in a high-pressured chamber. Electrolytic manganese (99.8%) and electrolytic copper (99.95%) were melted in the crucible. In order to suppress the evaporation of manganese during smelting in vacuum,

Fig.1 Schematic diagram of apparatus for GASAR process

some argon was introduced into the chamber before smelting. When the charge was melted, a mixture of high-purity 99.99% hydrogen (0.1 MPa) and high-purity 99.99% argon (0.3 MPa) was introduced into the chamber and the temperature of the melt (T0) was monitored to 1 346 K by a tungsten-rhenium thermo- couple for 30 min. Meanwhile, the mold temperature (Tmold) was increased to 1 273 K. Then, the melt was poured into the mold through a feeder and was directionally solidified upwards from the water-cooled copper chiller.

The ingots with 80 mm in diameter and about 120 mm in height are obtained. The ingot of porous Cu-Mn alloy was firstly sectioned into two parts along the centre axis, and then one part was cut into several pieces at different heights. Pore structure images on the longitudinal

section and transverse sections were obtained by a scanner and average pore diameter (D) on the transverse sections was evaluated through an image analysis system. Microstructure of the ingot at different heights along the centre axis and at different radii at the height of 50 mm was obtained through an optical microscope. The specimens were etched with a copper-ammonium chloride solution.

3 Results and discussion

3.1 Characterization of pore structure

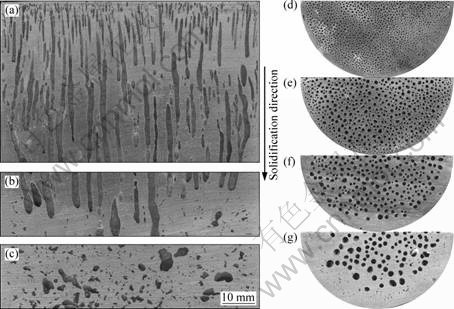

Fig.2 shows the pore structure of the ingot on the longitudinal section and transverse sections at different heights (H), which illustrates the variation of the pore morphology along with the solidification process. 1) At the bottom of the ingot, pores grow up directionally (Fig.2(a)). With increasing the solidification height, oriented pores gradually become irregularly aligned, and finally interrupted at height about 70 mm (Fig.2(b)). On the upper part of the ingot, no oriented pores exist (Fig.2(c)). 2) Oriented pores are interrupted first in the outside area of the ingot and gradually extend to the central region (Figs.2(d)-(g)). 3) Pore number decreases along the solidification direction, while pore diameter increases.

3.2 Influence of solidification mode on pore structure

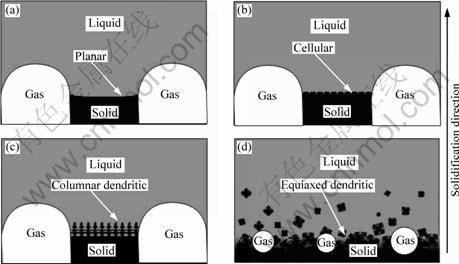

According to the difference of solid-liquid interface morphology, the solidification mode of single phase alloy could be divided into four kinds: planar (P), cellular (C), columnar dendritic (D) and equiaxed

Fig.2 Pore structures of porous Cu-Mn alloy on longitudinal section (a, b, c) and transverse sections (d, e, f, g) at different heights: (a) 0-50 mm; (b) 60-80 mm;(c) 100-120 mm; (d) 10 mm; (e) 30 mm; (f) 50 mm; (g) 70 mm (pH2=0.1 MPa, pAr=0.3 MPa, T0=1 346 K, Tmold=1 273 K)

dendritic (E), which correspond to four kinds of microstructures.

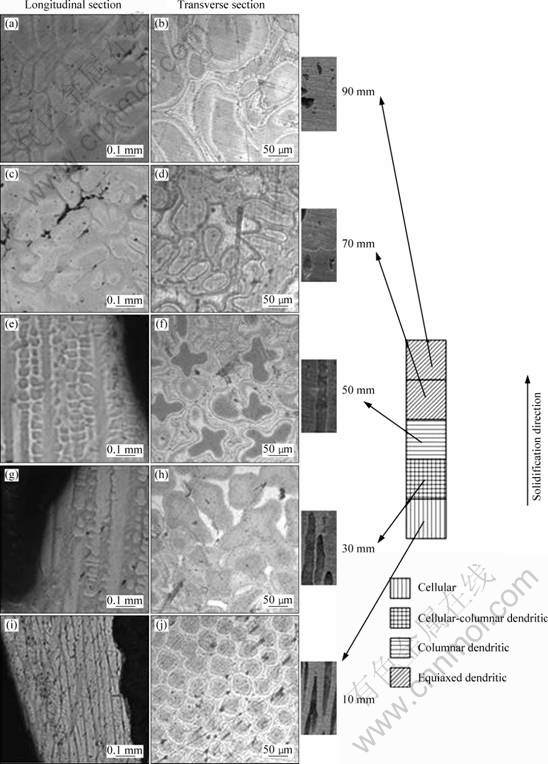

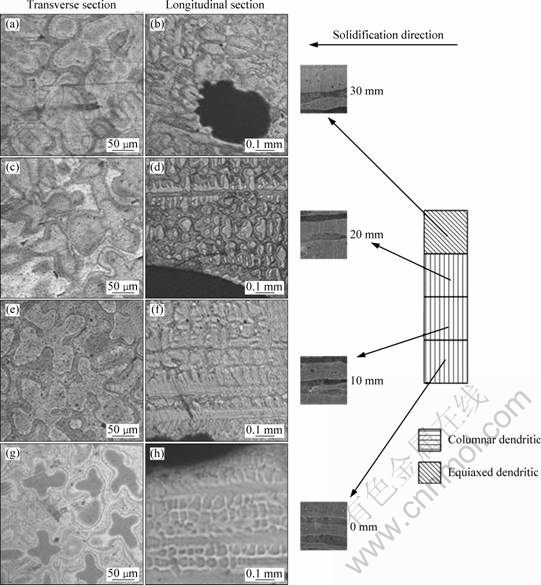

The microstructures of the ingot on the transverse and the longitudinal sections at different heights in the centre area are shown in Fig.3, from which it is found that the microstructures vary with the increase of height. At the beginning stage (10 mm), it is a cellular structure. It starts to become columnar dendrites at the height of 30 mm. The secondary dendritic arms appear at a height of 50 mm. It becomes equiaxed dendritic structure at the height of 70 mm. Similarly, microstructures both parallel to and perpendicular to the solidification direction at different radii at the height of 50 mm are shown in Fig.4.

Fig.3 Microstructures and pore morphologies at different heights (r=0 mm)

Fig.4 Microstructures and pore morphologies at different radii (H=50 mm)

It is found that the microstructure close to the centre (r=0-20 mm) is columnar dendrite and transforms to equiaxed dendrite at outside region (r=30 mm).

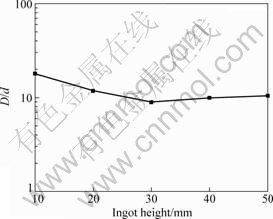

By comparing the microstructure with the pore morphology at the same height and the same radius, as shown in Fig.3 and Fig.4, it is found that pore growth direction is parallel to the solidification direction coupled with cellular and columnar dendritic microstructure (H<70 mm, r=0-20 mm) and oriented pores are interrupted when equiaxed dendritic structure appears (H>70 mm, r>30 mm). Furthermore, it is found that cellular and primary dendrite arm spacing is always about one tenth of the average pore diameter at the same height, as shown in Fig.5.

It is found in our experiments that oriented pore structure could be formed with cellular and columnar dendritic solidification, as shown in Fig.3 and Fig.4,

Fig.5 Ratio of pore diameter (D) to cellular and primary dendrite arm spacing (d) at different heights

which is interrupted only with the appearance of equiaxed dendrite. The reason is that the average pore diameter is larger than the cellular and primary dendrite arm spacing in our experiment, which means that cellular and columnar dendritic morphology of solid-liquid interface could be regarded as roughly planar and does not disturb the directional growth of big pores aside. Thus, oriented pores could be formed with planar, cellular and columnar dendritic solidification modes and no oriented pores can form accompanying the equiaxed dendrites, as shown in Fig.6.

3.3 Simulation of solidification mode

For a selected alloy, its solidification mode is determined by the solidification process which could be numerically simulated. Although the GASAR solidification is a cooperative growth of two phases (a solid phase and a gas phase), it has been found that pores do not significantly affect the solidification of solid[17]. To simplify simulation, two assumptions are made:

1) No fluid flow and convection occur in the melt;

2) Thermodynamic properties, boundary conditions and initial conditions are isotropic.

Under these two assumptions, the temperature distribution in the ingot and the chiller can be regarded as being axisymmetrical and described with the following unsteady-state heat transfer equation in cylindrical coordinate system:

(1)

(1)

where ρ is density; c is specific heat; and λ is thermal conductivity.

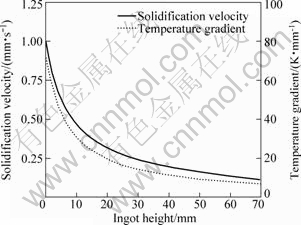

With corresponding boundary conditions and initial conditions, Eq.(1) is numerically solved in ProCAST. Solidification velocity v and temperature gradient GTL at the liquid-solid interface along the central axis are calculated, as shown in Fig.7. It could be found that the solidification velocity and temperature gradient both decrease quickly along with increasing the solidification height, which at the height of 70 mm are about one tenth of the initial values. According to the study in Ref.[18] on the directional solidification of metal-gas eutectic, with decreasing the solidification velocity, as shown in Fig.7, the pore diameter increases, as observed in Fig.2.

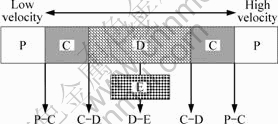

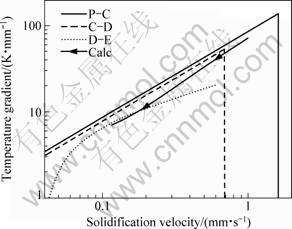

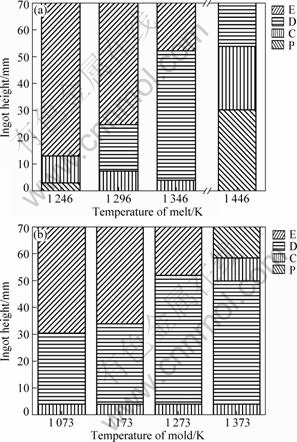

With the variations of the solidification velocity and the temperature gradient at different solidification heights, the solidification mode of the ingot could not be invariable. Possible transitions between the four kinds of solidification modes are shown in Fig.8, which correspond to following three transition criterions: 1) Planar to cellular (P-C), constitutional supercooling criterion at low velocity[19] and absolute stability criterion at high velocity[20]; 2) Cellular to columnar dendritic (C-D), tip stability criterion at low velocity[21] and high velocity[22]; 3) Columnar dendritic to equiaxed dendritic (D-E), heterogeneous nucleation criterion under columnar dendritic solidification[23]. Through comparing the solidification process of the ingot with these criterions, it is found that the solidification mode of the ingot transforms from cellular solidification (C) to columnar dendritic solidification (D) and finally equiaxed dendritic solidification (E), as shown in Fig.9, which agrees with the experimental result. Furthermore, it could be found that the higher the temperatures of melt (T0) and mold (Tmold) are, the less the equiaxed dendritic

Fig.6 Morphologies of pores with different solidification modes: (a) Planar; (b) Cellular; (c) Columnar dendrite; (d) Equiaxed dendrite

Fig.7 Solidification velocity and temperature gradient at liquid-solid interface

Fig.8 Transitions of four solidification modes (P—Planar; C—Cellular; D—Columnar dendritic; E—Equiaxed dendritic)

Fig.9 Transition of solidification modes of ingot

solidification is, as shown in Fig.10, which indicates that the larger the range of oriented pore structure region.

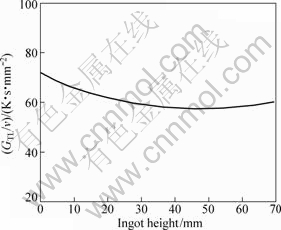

It should be noted that the C-D of the ingot belongs to rapid solidification, as shown in Fig.9. While it is usually thought that the C-D of traditional unidirectional solidification with water-cooled copper chiller is under low-velocity solidification process[24-25]. As transition criterion of C-D at low velocity[19], GTL/v of the solidification process is calculated, as shown in Fig.11. It is found that variation of GTL/v at different heights is so small that the C-D could not be at low velocity. On account of the small solidification interval and approximation to unity of the distribution coefficient of Cu-33.7% (mass fraction) Mn alloy[26], it is possible to get rapid solidified cellular microstructure at relatively low velocity, such as 1 mm/s, which is also observed by Lee et al[27] in directionally solidifying Fe-18Cr-5Al alloy.

Fig.10 Variation of range of equiaxed dendritic solidification with increasing temperature of melt (a) and mold (b)

Fig.11 Variation of GTL/v with increasing height

4 Conclusions

1) By GASAR process, oriented porous Cu-33.7%Mn alloy is fabricated successfully.

2) The pore growth direction and pore distribution are determined by the solidification mode. When the cellular and primary dendrite arm spacing is less than the pore size, oriented pore structure could be formed with a cellular and columnar dendritic morphology in solid-liquid interface.

3) By increasing the temperatures of melt and mold, the range of equiaxed dendritic solidification could be shortened and the range of oriented pore structure region could be extended.

References

[1] SHAPOVALOV V I. Method of manufacture of porous articles: USA, 5181549 [P]. 1993-06-23.

[2] SHAPOVALOV V I, BOYKO L. Gasar—A new class of porous materials [J]. Advanced Engineering Materials, 2004, 6(6): 407-410.

[3] LIU Yuan, LI Yan-xiang. A theoretical study of Gasarite eutectic growth [J]. Scripta Materialia, 2003, 49(5): 379-386.

[4] NAKAJIMA H, HYUN S K, OHASHI H, OTA K, MURAKAMI K. Fabrication of porous copper by unidirectional solidification under hydrogen and its properties [J]. Colloids and Surfaces A, 2001, 179(2-3): 209-214.

[5] LIU Yuan, LI Yan-xiang, ZHANG Hua-wei. Fabrication of lotus-structure porous magnesium with GASAR process [J]. Acta Metallurgica Sinica, 2004, 40(11): 1121-1126. (in Chinese)

[6] HYUN S K, IKEDA T, NAKAJIMA H. Fabrication of lotus-type porous iron and its mechanical properties [J]. Science and Technology of Advanced Materials, 2004, 5(1-2): 201-205.

[7] HYUN S K, NAKAJIMA H. Fabrication of lotus-structured porous iron by unidirectional solidification under nitrogen gas [J]. Advanced Engineering Materials, 2002, 4(10): 741-744.

[8] IKEDA T, TSUKAMOTO M, NAKAJIMA H. Fabrication of lotus-type porous stainless steel by unidirectional solidification under hydrogen atmosphere [J]. Materials Transactions, 2002, 43(11): 2678-2684.

[9] TAKUYA I, MASAKAZU T, HYUN S K, NAKAJIMA H. Fabrication of lotus-type porous Ni3Al by unidirectional solidification [C]//NAKAJIMA H, KANETAKE N. Porous Metals and Metal Foaming Technology. Kyoto: The Japan Institute of Metals, 2005: 229-232.

[10] PARK J S, SUZUKI S, NAKAJIMA H. Fabrication of lotus-type porous Al-Si alloys using continuous casting technique [C]//LEFEBVRE L P, BANHART J, DUNAND D C. Porous Metals and Metallic Foams. Montreal: DEStech Publications, 2007: 229-232.

[11] ATWOOD R C, SRIDHAR S, ZHANG W L, LEE P D. Diffusion-controlled growth of hydrogen pores in aluminium-silicon castings: In situ observation and modeling [J]. Acta Materialia, 2000, 48(2): 405-417.

[12] LEE P D, HUNT J D. Hydrogen porosity in directionally solidified aluminium-copper alloys: A mathematical model [J]. Acta Materialia, 2001, 49(8): 1383-1398.

[13] MELO M L N M, RIZZO E M S, SANTOS R G. Numerical model to predict the position, amount and size of microporosity formation in Al-Cu alloys by dissolved gas and solidification shrinkage [J]. Materials Science and Engineering A, 2004, 374(1-2): 351-361.

[14] KURZ W, FISHER D J. Fundamentals of solidification [M]. Rockport: Trans Tech Publications, 1986: 1-15.

[15] JAMGOTCHIAN H, TRIVEDI R, BILLIA B. Interface dynamics and coupled growth in directional solidification in presence of bubbles [J]. Journal of Crystal Growth, 1993, 134(3-4): 181-195.

[16] GOKCEN N. The Cu-Mn (copper-manganese) system [J]. Journal of Phase Equilibria and Diffusion, 1993, 14(1): 76-83.

[17] BIANCHI M V A, VISKANTA R. The effect of air bubbles on the diffusion-controlled solidification of water and aqueous solutions of ammonium chloride [J]. International Journal of Heat and Mass Transfer, 1999, 42(6): 1097-1110.

[18] LIU Yuan, LI Yan-xiang, WAN Jiang, ZHANG Hua-wei. Metal-gas eutectic growth during unidirectional solidification [J]. Metallurgical and Materials Transactions A, 2006, 37(9): 2871-2878.

[19] TILLER W A, JACKSON K A, RUTTER J W, CHALMERS B. The redistribution of solute atoms during the solidification of metals [J]. Acta Metallurgica, 1953, 1(4): 428-437.

[20] MULLINS W W, SEKERKA R F. Stability of a planar interface during solidification of a dilute binary alloy [J]. Journal of Applied Physics, 1964, 35(2): 444-451.

[21] KURZ W, FISHER D J. Dendrite growth at the limit of stability: Tip radius and spacing [J]. Acta Metallurgica, 1981, 29(1): 11-20.

[22] TRIVEDI R. Microstructure characteristics of rapidly solidified alloys[J]. Materials Science and Engineering A, 1994, 178(1-2): 129-135.

[23] HUNT J D. Steady state columnar and equiaxed growth of dendrites and eutectic [J]. Materials Science and Engineering, 1984, 65(1): 75-83.

[24] ROCHA O L, SIQUEIRA C A, GARCIA A. Cellular/dendritic transition during unsteady-state unidirectional solidification of Sn-Pb alloys [J]. Materials Science and Engineering A, 2003, 347(1-2): 59-69.

[25] ROSA D M, SPINELLI J E, FERREIRA I L, GARCIA A. Cellular/dendritic transition and microstructure evolution during transient directional solidification of Pb-Sb alloys [J]. Metallurgical and Materials Transactions A, 2008, 39(9): 2161-2174.

[26] SCHIEVENBUSCH A, ZINMERNMANN G, LU X L. Morphologies in directionally solidified copper-manganese alloys with compositions near the melting point minimum [J]. Zeitschrift fuer Metallkunde, 1995, 86(9): 614-618.

[27] LEE J H, KIM H C, JO C Y, KIM S K, SHIN J H, LIU S, TREVIDI T. Microstructure evolution in directionally solidified Fe-18Cr stainless steels [J]. Materials Science and Engineering A, 2005, 413-414: 306-311.

凝固模式对定向凝固多孔铜锰合金气孔结构的影响

蒋光锐,李言祥,刘 源

清华大学 机械工程系,教育部先进成形重点实验室,北京 100084

摘 要:采用金属-气体共晶定向凝固工艺(GASAR工艺),制备气孔定向排列的多孔铜锰合金,并研究气孔结构的变化。结果表明:这种变化主要取决于合金的凝固模式(平面凝固、柱状胞晶凝固、柱状枝晶凝固、等轴枝晶凝固),而合金凝固模式由合金的凝固过程决定。通过数值模拟发现,随着合金凝固的进行,合金的凝固模式从胞晶凝固向柱状枝晶凝固过渡,最终变为等轴枝晶凝固。通过升高合金熔体温度和铸型的预热温度,可以缩小等轴枝晶凝固的范围,扩大定向生长气孔的区域。

关键词:多孔铜锰合金;凝固模式;GASAR工艺;金属-气体共晶

(Edited by YANG Hua)

Foundation item: Project(U0837603) supported by the NSFC-Yunnan Joint Foundation of China; Project(2092017) supported by the Natural Science Foundation of Beijing, China

Corresponding author: LI Yan-xiang; Tel: +86-10-62773640; E-mail: yanxiang@tsinghua.edu.cn

DOI: 10.1016/S1003-6326(11)60682-1