文章编号: 1004-0609(2005)06-0929-06

机械与热综合活化法制备超细WC-Co粉末

刘紫兰, 李 强, 张钦钊, 黄向东

(福州大学 材料科学与工程学院, 福州 350002)

摘 要: 研究了WO3、 Co3O4和石墨混合粉末经高能球磨活化后再分步进行还原和碳化反应制备超细WC-Co粉末的过程。 结果表明: 球磨30h后, 粉末粒径达到70~100nm。 450~700℃温度范围内球磨粉在流动H2和Ar混合气体中经2h还原时, 随着还原温度的升高, WO3还原反应顺序为WO3→WO2.9→WO2.72→WO2→W, 700℃时可实现完全还原; Co3O4在450℃完全还原为Co, 随着温度的进一步升高和时间的延长, Co与W反应转变为Co3W; 最终还原产物由W、 Co、 Co3W和石墨组成; 在700~1000℃温度范围内还原粉在流动Ar中碳化时, 随着碳化温度的升高, 碳化反应按W(Co3W)→Co6W6C→Co3W3C→W2C→WC的顺序进行, 在900℃下还原粉在2h内可完全碳化, 得到WC颗粒尺寸约为200~300nm的WC-Co复合粉末。

关键词: WC-Co; 高能球磨; 还原; 碳化

中图分类号: TF123.3; TF123.7 文献标识码: A

Synthesis of ultrafine WC-Co composites by

integrated mechanical and thermal activation process

LIU Zi-lan, LI Qiang, ZHANG Qin-zhao, HUANG Xiang-dong

(School of Materials Science and Engineering,

Fuzhou University, Fuzhou 350002, China)

Abstract: Synthesis of ultrafine WC-Co powders was investigated using WO3, Co3O4 and graphite powders as starting materials by high energy ball milling followed by reduction and carburization. The results show that particle sizes of powder mixtures milled 30h are in the range of 70-100nm. When the milled mixture is reduced in a flowing gas mixture of H2 and Ar at different temperatures ranging from 450 to 700℃ for 2h, the reaction sequence of WO3 to W appears as WO3→WO2.9→WO2.72→WO2→W with the increase of temperature, and WO3 reduction completes at 700℃. Reduction reaction of Co3O4 to Co can be finished in 2h at 450℃ and the reduced Co keeps reacting with W to transform into Co3W with the increase of reduction temperature and time. The final product of reduction reaction is composed of W, Co, Co3W and graphite. The reduced mixture is carburized in a flowing Ar in temperature range of 700-1000℃, carburization reaction takes place following the routine W(Co3W)→Co6W6C→Co3W3C→W2C→WC, and the carburization reaction completes at 900℃ in 2h. The size of the WC grain in the final WC-Co composite powders is in the range of 200-300nm.

Key words: WC-Co; high energy ball milling; reduction; carburization

超细及纳米结构WC-Co材料比对应常规粗晶材料具有更高的硬度、 耐磨性以及更好的硬度和韧性的组合[1]。 制备超细及纳米结构WC-Co粉末是制备纳米块体材料的关键, 近年来成为各国致力研究的热点之一, 并取得了令人鼓舞的进展, 所涉及的主要制备方法有: 机械合金化法[2, 3]、 机械与热综合活化法[4]、 热化学合成法[5, 6]、 原位渗碳还原法[7]、 等离子体法[8]和共沉淀法[9]等。

机械与热综合活化法是合成超细及纳米粉体的一条新方法, 其优点是, 由于在室温下机械活化引入非常高的缺陷密度, 与常规反应相比, 高温合成反应的温度低, 反应时间短。 应用该工艺已成功制备了超细及纳米结构碳化物(如SiC, TiC, WC)、 氮化物(如Si3N4, CrN, TiN)以及WC-Co复合粉末[4, 10-12]。 其中Ban和Shaw[4]以WO3、 石墨和CoO的摩尔比为1∶2.4∶0.7的混合粉为原料, 研究了经过机械球磨活化后在流动的氢气和氩气混合气体中进行还原和碳化的反应过程, 认为碳化过程中, 石墨和氢气形成的甲烷气体裂解出的活性C原子参与碳化, 然而由于WO3和石墨配比相对WC化学计量成分大大过量, 并且反应在流动气氛中进行, 生成的甲烷气体随气流不断排出, 因此无法确定完全碳化所需的石墨含量和产物成分, 碳化反应难以控制。 本文作者以WO3, Co3O4和石墨为原料, 研究WO3和石墨按形成WC所需的化学计量比配比的混合物在Ar气保护下经高能球磨机碾磨后, 分步进行还原和碳化反应来制备超细WC-Co复合粉末过程中的反应机制及其优化工艺。

1 实验

实验原料为WO3粉(纯度≥99.8%, 粒度≤30μm)、 Co3O4粉(纯度≥98.5%, 粒度≤30μm)和石墨粉(纯度≥99.85%, 粒度≤30μm)。 WO3和石墨按WC化学计量配比, 其摩尔比为1∶1, Co3O4按WC-10%Co的成分设计配料。 配制后的混合粉末和磨球一起装入磨罐, 先抽真空后充入氩气, 球料比为10∶1, 磨球为两种尺寸的不锈钢球, 其直径分别为6mm和10mm。 球磨在QM-1SP行星式球磨机上进行, 球磨机转速为500r/min。 原料经高能球磨后在管式炉中进行还原碳化反应。 还原反应在流动H2和Ar混合气体中进行, 还原温度范围在450~700℃之间, 还原时间2h。 还原后的粉末在流动Ar中进行碳化反应, 碳化温度取700~1000℃。

粉末的相结构分析在Shimadzu XD-5A X射线衍射仪上进行, 采用Cu Kα辐射, 管电流20mA, 管电压35kV。 球磨和反应过程各阶段粉末形貌表征采用Philips XL-30 ESEM 型扫描电子显微镜, 粉末晶粒尺寸的测定采用定量金相分析方法。

2 结果与分析

2.1 球磨过程粉末形貌和相结构的变化

WO3、 Co3O4和石墨的混合粉末球磨前后的X射线衍射谱如图1所示。 随着球磨时间的延长, WO3、 Co3O4和石墨的衍射峰都呈明显变化, 主要表现为衍射强度的不断下降和衍射峰的逐渐宽化。 衍射强度下降和衍射峰宽化的主要原因是, 在高能球磨的过程中, 粉末在碾磨罐中不断被磨球碰撞, 经过反复变形, 焊合和断裂, 导致晶粒的不断细化, 引入了大量的缺陷, 造成严重晶格畸变。 其中石墨的衍射峰变化最为显著, 衍射强度大大下降。 这是因为石墨晶体具有层状微观结构, 在平面内是共价键, 而层与层之间是结合力较弱的分子键, 很容易破坏层片之间的结合, 在高能球磨的机械力作用下, 伴随着碳原子六角层面的移动、 重排、 断键及交联[13]。

图1 WO3、 Co3O4和石墨混合粉末经不同时间球磨后的X射线衍射谱

Fig.1 XRD patterns of WO3-Co3O4-graphite powder mixture milled for different time

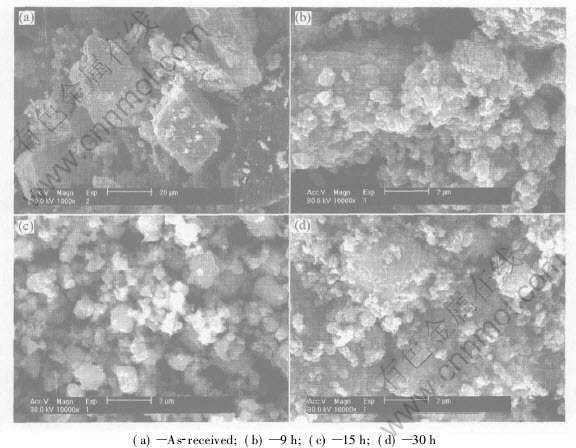

WO3、 Co3O4和石墨的混合粉末经不同时间球磨后对应的SEM像如图2所示。 经过9h的球磨, 粉末的粒度从20μm迅速降低到300~500nm, 球磨到15h后, 粉末粒度降低到100~200nm, 继续球磨至30h, 粉末的粒度为70~100nm。 可见, 随着球磨时间的延长, 粉末的平均粒径不断减小, 但细化作用不断减弱, 粉末细化的速率越低, 晶格畸变越严重。 因为随着粉末粒度变小, 单位体积的表面自由能增加, 被粉碎物料的颗粒强度增大, 断裂能提高, 粉碎所需机械应力相应增加[14]。 当粉碎到 一定程度后, 颗粒之间的作用力加大, 导致颗粒聚集。 当两过程达到平衡时, 粉碎达到平衡, 即达到粉碎极限[15]。 因此, 球磨时间并非越长越好, 一方面粉末的制备效率下降, 另一方面磨罐和磨球易引起铁元素的污染, 对后续的烧结工序带来不利的影响。

图2 WO3、 Co3O4和石墨混合粉末经不同时间球磨后的SEM像

Fig.2 SEM images of WO3-Co3O4-graphite powder mixtures milled for different time

2.2 还原过程

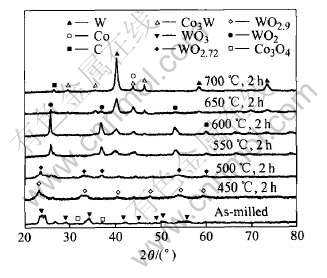

图3所示为WO3、 Co3O4和石墨的混合粉末经30h球磨后在不同温度下还原2h得到的X射线衍射谱。 可以看出, 球磨粉经450℃还原后, Co3O4的衍射峰已经完全消失, Co的衍射峰相应出现, 这表明, 在450℃下还原2h, Co3O4已经还原完全。 事实上, 在传统钴粉的制备过程中, Co3O4在200℃左右开始还原[16], 并随着温度的升高, 还原反应速度加快。

三氧化钨还原成钨粉是一个十分复杂的过程, 需经过生成一系列中间氧化物阶段, 主要包含以下几种氧化钨: 黄色的WO3、 蓝色的WO2.9、 紫色的WO2.72和褐色的WO2[17]。 实验表明, 还原温度为450℃时, 在X射线衍射谱中, WO3的衍射峰已经

图3 球磨30h的混合粉末在流动H2和Ar混合气体中经不同温度还原(保温2h)后的X射线衍射谱

Fig.3 XRD patterns of WO3-Co3O4-graphite powder mixtures milled for 30h followed by reduction at different temperatures for 2h in flowing H2 and Ar mixture

完全消失, 相应出现WO2.9的衍射峰, 该过程的反应式为

10WO3(s)+H2(g)=

10WO2.9(s)+H2O(g)

还原温度500℃时, WO2.9的衍射峰消失, 出现WO2.72的衍射峰和微弱的WO2的衍射峰, 该温度下的反应为

50/9WO2.9(s)+H2(g)=

50/9WO2.72(s)+H2O(g)

还原温度分别为550, 600和650℃时, 其X射线衍射谱中, 主要是W和WO2的衍射峰。 其中, WO2的衍射峰强度随还原温度的升高先逐渐增强, 而后逐渐减弱, 650℃还原得到的粉末衍射图谱中仅有少量的WO2存在。 在550℃还原时W的衍射峰开始出现并随温度升高逐渐增强, 这表明在此温度范围内, 发生WO2.72向WO2转变的同时也发生WO2还原成W的转变。 两个转变过程可表述为

25/18WO2.72(s)+H2(g)=

25/18 WO2(s)+H2O(g)

1/2 WO2(s)+H2(g)=1/2 W(s)+H2O(g)

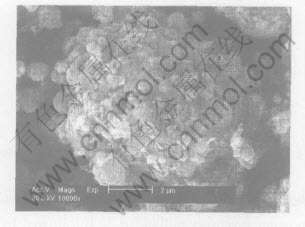

当700℃还原时, WO2完全转变为W。 而用传统制备方法, 还原温度通常在800~990℃之间[17], 与其相比, 经机械球磨活化后的还原温度大大下降, 还原温度的降低有利于形成超细还原W粉, 这与Ban和Shaw[4]的研究结果一致。 700℃还原得到粉末的SEM像如图4所示, 粉末颗粒的平均尺寸约为100~200nm。 在450~700℃的温度范围内, 随着还原温度的升高, WO3的主要转变顺序可表述为:

WO3→WO2.9→WO2.72→WO2→W

图4 球磨30h后经700℃还原2h后 混合粉末的SEM像

Fig.4 SEM image of powder mixture reduced at 700℃ for 2h after 30h milling

值得注意的是, 在600℃还原粉末的X射线衍射谱中, 出现了微弱Co3W的衍射峰, 当还原温度为700℃时, 该衍射峰更加明显。 这是因为在该温度范围内, WO2还原为W的反应进行的同时, 已还原出的W粉和Co粉形成钨钴化合物, 并随温度升高, 反应增强。 Ban和Shaw[4]的工作中也报道了Co3W化合物的形成, 这与W-Co二元相图[18]的预测结果一致。

2.3 碳化过程

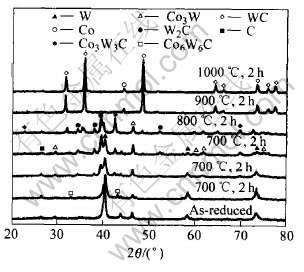

经30h球磨后的Co3O4、 WO3和石墨的混合粉末在700℃还原2h后关闭H2, 在流动的Ar保护下于不同温度和时间下进行碳化反应。 图5给出了还原态粉末分别在700℃碳化1.0, 1.5和2.0h, 以及在800, 900和1000℃分别碳化2h后得到的X射线衍射谱。 当在700℃碳化1h后, 产物的X射线衍射谱中同时存在Co6W6C、 Co3W、 W和石墨的衍射峰。 当碳化1.5h时, Co6W6C的衍射峰强度减弱, 出现W2C和Co3W3C的衍射峰, 继续碳化至2h后, Co6W6C的衍射峰消失, X射线衍射谱中同时存在W2C、 Co3W3C、 Co3W、 W和石墨的衍射峰。 从衍射图的变化可知, 大量W2C形成的同时, 也发现Co的主衍射峰强度下降, 相应的Co3W的衍射峰进一步增强, 这表明在该温度碳化过程中继续发生Co向Co3W的转变。 由此可见, 700℃碳化时随着碳化时间的延长可能发生的反应包括:

6W+C+6Co=Co6W6C

2Co3W+C+4 W=Co6W6C

图5 球磨粉在700℃还原2h后在流动Ar气中经不同温度和时间碳化后的X射线衍射谱

Fig.5 XRD patterns of milled powder mixtures reduced at 700℃ for 2h, followed by carburization at different temperatures and time in flowing Ar

Co6W6C+C=2Co3W3C

Co3W+C+2W=Co3W3C

3Co+W=Co3W

2W+C=W2C

当碳化温度为800℃时, W的衍射强度明显下降, Co继续向Co3W转变, 同时Co3W不断转化为Co3W3C, 相应的Co3W的衍射峰明显减弱, Co几乎耗尽, Co3W3C的衍射峰进一步增强, 转变量增加。 同时衍射图中出现了极弱的WC的衍射峰, 表明在该温度下开始形成WC。 该阶段涉及的反应可表述为

Co6W6C+C=2Co3W3C

Co3W+C+2W=Co3W3C

W+C=WC

随着反应温度的继续升高, 碳化反应进一步进行, 在900℃下碳化2h后, X射线衍射谱中, 仅存在WC和Co的衍射峰和残留极弱的W峰, 碳化反应几达完全。 该阶段的反应包括:

Co3W3C+2WC=3C+3Co

W+C=WC

图6所示为该温度下碳化得到的WC-Co复合粉末的SEM像, WC颗粒尺寸约为200~300nm。 碳化温度达到1000℃时, 碳化完成。

图6 球磨30h后经700℃还原900℃碳化制得的WC-Co复合粉末的SEM像

Fig.6 SEM image of WC-Co composite powders synthesized by 30h milling, reduction at 700℃ for 2h and carburization at 900℃ for 2h

综上所述, 在碳化反应过程中, 反应十分复杂, 涉及多种中间产物, 包括Co3W、 Co6W6C、 Co3W3C、 W2C等化合物。 碳化的主要反应过程可表示为: W(Co3W) →Co6W6C→Co3W3C→W2C→WC, 并且碳化过程中以上多种反应同时进行。 与传统方法制备WC的碳化温度1300~1900℃相比[17], 经机械活化后, 温度略高于900℃可实现完全碳化, 碳化温度大大降低, 有利于形成超细甚至纳米WC。 碳化温度的降低可归因于两个方面, 一方面粉末经球磨还原后, C在W中的分布高度分散和均匀化, 使扩散距离大大缩短, 另一方面Co对碳化反应产生的催化作用不容忽视, 这在没有添加Co3O4的WO3-石墨体系的另一相关研究中得到证明, 该研究发现当碳化时间同样为2h时, 完全碳化的温度为1100℃。

3 结论

1) 混合粉末在球磨过程中, 随着球磨时间的延长, 粉末的平均粒径不断减小, 但细化作用不断减弱, 并发生团聚。 球磨30h后, 粉末粒径达到70~100nm。

2) 球磨粉在流动的H2和Ar混合气体中在450~700℃温度范围内经2h还原时, 形成WO2.9, WO2.72和WO2等一系列中间产物。 随着还原温度的升高, WO3的还原反应顺序为WO3→WO2.9→WO2.72→WO2→W, 700℃时可实现完全还原。 Co3O4在450℃完全还原为Co, 随着温度的进一步升高和时间的延长, 不断转变为Co3W。 球磨粉的还原产物由W, Co, Co3W和石墨组成。

3) 还原粉在流动的氩气中在700~1000℃温度范围内经2h碳化过程中, 形成了Co3W, Co3W3C, Co6W6C和W2C等一系列中间产物。 随着碳化温度的升高, 碳化反应的顺序为W(Co3W)→Co6W6C→Co3W3C→W2C→WC。 略高于900℃时可完全碳化。

4) 混合粉末经过30h的球磨后, 在700℃还原后900℃碳化的工艺条件下可得到WC颗粒尺寸约为200~300nm的WC-Co超细复合粉末。

REFERENCES

[1]Suryanarayana C. Nanocrystalline materials[J]. Int Mater Rev, 1995, 40(2): 41-64.

[2]El-Eskandarany M S. Fabrication of nanocrystalline WC and nanocomposites WC-MgO refractory materials at room temperature[J]. J Alloys Comp, 2000, 296(2): 175-182.

[3]Wang G M, Campbell S J. Synthesis and structural evolution of tungsten carbide prepared by ball milling[J]. J Mater Sci, 1997, 32(6): 1461-1467.

[4]Ban Z G, Shaw L L. On the reaction sequence of WC-Co formation using an integrated mechanical and thermal activation process[J]. Acta Mater, 2001, 49(15): 2933-2939.

[5]Fang Z G, Eason J W. Study of nanostructured WC-Co composites[J]. Int J Refractory Metals & Hard Materials, 1995, 13(2): 297-303.

[6]McCandlish L E, Kear B H, Bhatia S J. Spray Conversion Process for the Production of Nanophase Composite Powders[P]. US 5352269. 1994.

[7]Zhu Y T, Manthiram A. A new route for the synthesis of tungsten carbide-cobalt nanocomposites[J]. J Am Ceram Soc, 1994, 77(10): 2777-2778.

[8]Fu L, Cao L H, Fan Y S. Two-step synthesis of nanostructured tungsten carbide-cobalt powders[J]. Scripta Mater, 2001, 44(7): 1061-1068.

[9]Muhammed M, Wahlberg S, Grenthe I. Method of Preparing Powders for Hard Materials[P]. US 5594929. 1997.

[10]Ren R M, Yang Z G, Shaw L L. Nanostructured TiN powder prepared via an integrated mechanical and thermal activation[J]. Mater Sci Eng A, 2000, A286(1): 65-71.

[11]Ren R M, Yang Z G, Shaw L L. Synthesis of nanostructured chromium nitrides through mechanical activation process[J]. Nanostruct Mater, 1999, 11(1): 25-35.

[12]Ren R M, Yang Z G, Shaw L L. Synthesis of nanostructured TiC via carbothermic reduction enhanced by mechanical activation[J]. Scripta Mater, 1998, 38(5): 735-741.

[13]Fukunaga T, Nagano K, Mizutani U, et al. Structural change of graphite subjected to mechanical milling[J]. J Non-Crystalline Solids, 1998, 232-234(2): 416-420.

[14]Zhang X, Wang H, Scattergood R O, et al. Evolution of microstructure and mechanical properties of in situ consolidated bulk ultra-fine-grained and nanocrystalline Zn prepared by ball milling[J]. Mater Sci Eng a, 2003, A344(1-2): 175-181.

[15]Nagumo M. Reaction milling of metals with hydrocarbon or ceramics[J]. Mater Trans JIM, 1995, 36(2): 170-181.

[16]王国栋. 硬质合金生产原理[M]. 北京: 冶金工业出版社, 1988. 41-45.

WANG Guo-dong. Production Principle of Cemented Carbide[M]. Beijing: Metallurgical Industry Press, 1988. 41-45.

[17]Yis S W H, Wang C T. Tungsten Sources, Metallurgy, Properties and Applications[M]. New York: Plenum Press, 1979. 200-300.

[18]虞觉奇, 易文质, 陈邦迪, 等. 二元合金状态图集[M]. 上海: 上海科学技术出版社, 1984. 315.

YU Jue-qi, YI Wen-zhi, CHEN Bang-di, et al. Binary Alloy Phase Diagrams[M]. Shanghai: Shanghai Science and Technology Press, 1984. 315.

(编辑龙怀中)

基金项目: 福建省教育厅资助项目(K02003)

收稿日期: 2004-09-21; 修订日期: 2005-03-14

作者简介: 刘紫兰(1978-), 女, 硕士研究生.

通讯作者: 李 强, 教授, 博士; 电话: 0591-87893593; E-mail: qli@fzu.edu.cn