文章编号:1004-0609(2015)06-1721-09

基于分子动力学理论制备含氮磷硼酸酯添加剂及其摩擦学性能

熊 桑,孙建林,徐 阳,严旭东

(北京科技大学 材料科学与工程学院,北京 100083)

摘 要:利用分子动力学(MD)理论设计合成了一种新型含氮磷硼酸酯极压抗磨添加剂NBPE,分别采用元素分析仪和红外光谱仪(FTIR)对分子结构进行表征。采用热重分析法(TG)和饱和蒸汽法分别考察化合物的热稳定性与水解稳定性;采用四球摩擦磨损试验机考察NBPE的含量对润滑油摩擦学性能的影响;利用立式万能摩擦磨损试验机研究不同润滑条件下钢-铜摩擦副的摩擦磨损性能;利用扫描电子显微镜(SEM)观察试样表面磨痕形貌,利用能谱分析仪(EDS)分析磨斑表面附着物组成。结果表明:NBPE是一种具有良好热稳定性、水解稳定性和优异的极压、抗磨性的润滑油添加剂;添加剂在金属表面发生摩擦化学反应形成摩擦化学产物是提高其极压、抗磨性能的根本原因;当润滑油中NBPE的含量为0.15%(质量分数)时,润滑油具有最佳的极压、抗磨性能,其油膜强度提高了148%,磨斑直径降低了23.2%;在钢-铜摩擦过程中,摩擦因数和铜磨损率分别降低了59.4%和45.2%,获得光洁度较好的铜表面。

关键词:硼酸酯;摩擦;磨损;钢-铜摩擦副;分子动力学

中图分类号:TG335.12 文献标志码:A

Preparation of nitrogen- and phosphorus-containing boric acid ester additive based on molecular dynamics theory and its tribology properties

XIONG Sang, SUN Jian-lin, XU Yang, YAN Xu-dong

(School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: A new extreme pressure and anti-wear additive of nitrogen- and phosphorus-containing boric acid ester (NBPE) was designed and synthesized by molecular dynamics method and characterized by infrared spectroscopy and element analysis. The thermal stability and hydrolytic stability of compounds were examined by thermogravimetric analyzer and saturated steam method, respectively. The effect of the NBPE lubricants content on the tribological behavior was investigated using four-ball friction and wear tester. The friction and wear properties of copper-steel friction pairs under different lubrication oils were measured by vertical universal test machine. The surface morphologies of the grinding crack were observed by scanning electron microscopy (SEM), and the composition of its surface attachments was analyzed by energy dispersive spectrometry (EDS). The results show that NBPE has good thermal stability and hydrolytic stability, and it also exhibits excellent extreme pressure, anti-wear properties as additives in lubricating oils. The lubricant exhibits excellent extreme pressure and wear-resistance attribute to the tribochemical reaction of nitrogen-containing boric acid ester with the sliding surface. When the content of NBPE is 0.15% (mass fraction), it has the best extreme pressure and anti-wear performance, the maximum non-seizure load (pB) value is increased by 148% and the wear scar diameter is decreased by 23.3%. In steel-copper friction process, the coefficient of friction and the wear rate of copper are also reduced by 59.4% and 45.2%, respectively. And a good copper surface can be obtained.

Key words: boric acid ester; friction; wear; copper-steel friction pair; molecular dynamics

硼酸酯用作铜加工润滑油减摩、抗磨添加剂的研究始于20 世纪60 年代,在基础油中加入0.5%~4.0% (质量分数)的硼酸酯,摩擦因数可减少5%~50%,同时可提高油品的热氧化稳定性[1]。20世纪90 年代初,王永刚等[2]将 S、P、N 等活性元素引入到硼酸酯分子中,分别与B原子形成较稳定的配位键,合成多功能型含氮硼酸酯润滑油添加剂,这在一定程度上提高了其抗磨减摩性能。沈光球等[3]在硼酸酯分子中引入配位键从而降低B的缺电子性为出发点,制备的含氮硼酸酯中苯环提供π 键与含氮杂环提供孤对电子,从而提高硼酸酯的水解性,同时具有紧凑的分子结构、良好的热稳定性,分子结构中兼具不同的官能团和不同的活性元素,作为润滑油添加剂(如极压抗磨剂、防锈剂、抗氧剂和金属碱活剂等)具有广阔的应用前景[4-5]。

目前,国内外学者着重研究开发性能较好的极压、抗磨添加剂以及能够替代二烷基二硫代磷酸锌ZDDP的“无锌”、“无硫”或“低磷”多功能润滑油添加剂[6-7]。新型有效的多功能添加剂是极压抗磨活性元素和杂环官能团结合在同一分子内的含N杂环衍生物[8]。从成本控制及摩擦学性能综合考虑,氮磷硼酸酯衍生物用作ZDDP替代物的研究最为广泛。然而,在金属加工润滑领域,润滑油中的添加剂通常是通过试错法或是凭借经验筛选,缺乏理论指导。近年来,金属缓蚀剂的选择常借助于分子动力学理论,宋晓岚等[9]采用密度泛函量子化学计算方法,明确了2-氨基-5-巯基-1, 3, 4-噻二唑(简称AMT)与Cu形成的缓蚀膜层是Cu(Ⅰ)与AMT中的7N和2S原子分别形成共价键和配位键相互交错而成。李酽等[10]研究表明,12种N-芳基-α-氨基苄基膦酸的缓蚀效率与分子的量子化学计算结果有很好的相关性。

本文作者尝试利用分子动力学理论模拟添加剂分子粘附于铁/铜表面,计算分子与金属表面的吸附能,并确定其吸附方式,通过合理的分子设计,引入具有极压抗磨作用的活性元素以及含N、B杂环,制备出一种具有良好的热稳定性、水解稳定性和优异的极压、抗磨性的含氮硼酸磷酯润滑油添加剂。通过四球和立式万能摩擦磨损试验机研究添加剂的摩擦磨损性能,使用扫描电子显微镜(SEM)和能谱仪(EDS)分别观察和分析试样表面磨痕形貌与元素组成,研究钢-铜摩擦副的磨损形式,为改善润滑油性能的机理、添加剂的选择提供理论依据。

1 实验

1.1 理论计算

添加剂分子与金属表面的相互作用采用分子动力学模拟(MD)方法。选取晶体Fe/Cu(110)晶面为吸附表面,计算过程中“冻结”表面体系中所有原子,吸附分子保持与金属表面自由相互作用。模拟中使用Materials Studio 6.1软件包中Discover模块COMPASS力场对体系进行优化,通过Supercell(3×3)增大表面面积,使用分层模建工具将添加剂分子加入到表面上,运行分子动力学计算分子与金属表面的吸附能[11]。

1.2 添加剂的制备

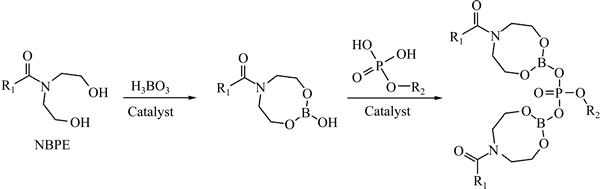

所用添加剂是以二羟基磷酸酯EAPT、硼酸HBO3以及长链烷基羟基酰胺ANH为原料,试剂均为化学分析纯。添加剂合成步骤如下:在250mL圆底烧瓶中加入20.0 g(0.1 mol)的长链烷基羟基酰胺,加入甲苯溶解,再加入0.10 mol 硼酸和质量分数为0.5%催化剂,加热分水回流,分水量约为4.00 mL,得到中间产物含氮硼衍生物BECN。在中间产物中加入EAPT,加热回流,随着反应的进行,生成越来越多的沉淀物,然后继续加热回流反应5 h直到沉淀量不再增加,将沉淀物过滤,再减压蒸除溶剂得到浅黄色黏稠液体,真空干燥3h即得到产品24.4 g(产率97.6%),将产品记为NBPE,其制备工艺路线及所用添加剂的分子结构如图1所示。

所得产物均用薄层层析色谱(TLC)验证其纯度。

图1 添加剂NBPE制备工艺路线

Fig. 1 Preparation pathway of additive NBPE

在Nexus 670型傅立叶红外分光光谱仪(FTIR)合成对产物的主要官能团进行鉴定,测试时使用KBr涂膜;C、H、O、N元素分析在PE 2400-Ⅱ型元素分析仪上进行(Perkin-Elmer,Inc.,USA),测试方法参照《YJ/T 017—1996 元素分析仪方法通则》;用库仑法测定S元素的含量,测试方法按SH/T 0303—92标准(添加剂中硫含量测定法)进行;用比色法测定P元素的含量,测试方法按SH/T 0296—92标准(添加剂和含添加剂润滑油的磷含量测定法)进行;用电感耦合等离子体-原子发射光谱法ICP/AES)测定B元素的含量,测试方法按GB/T 17476—1998标准进行。

1.3 新型添加剂制备润滑油的热稳定性测试

EAPT、BECN和新型添加剂NBPE与国内低硫加氢的铜轧制基础油[12]以一定的工艺制备润滑油,其热分解温度用WCR-2C型热重分析(TG)测试。测试条件如下:测试温度从室温以10 ℃/min升温到600 ℃,氮气保护,流速60 mL/min,样品20 mg。

1.4 新型添加剂的水解稳定性测试

采用饱和水蒸气法[5]考察NBPE与商用的含硼添加剂硼化高分子量聚异丁烯丁二酰亚胺T161B的水解稳定性。其具体操作如下:往装有150 g油样的试管中加入浓度为0.5%(质量分数)的添加剂,溶解后将试管放到200 mL的盛水烧杯中,并保鲜膜密封,将其放入烘箱(温度(50±2) ℃,相对湿度95%以上)。每隔1 h观察一次样品并记录,若发现样品不再透明或者出现沉淀,则意味着添加剂已经水解。

1.5 四球摩擦学性能测试

按GB/T 12583—1998标准测试不同含量(0.05%、0.10%、0.15%、0.20%,质量分数)的NBPE润滑油的最大无卡咬负荷(pB值),测试条件如下:转速(1760±40) r/min、室温25 ℃、时间10 s,试验所用钢球均为GCr15标准钢球。四球法测其摩擦因数与磨斑直径试验条件如下:载荷(392±5) N,转速(1200±5) r/min,室温25 ℃,时间30 min。

1.6 钢-铜摩擦副的摩损性能测试

在MM-W1A立式万能型摩擦磨损试验机上采用不同润滑介质进行盘-盘磨损形式,自动采集摩擦因数,测试条件如下:转速为(200±2) r/min,接触压力为0.2 MPa,室温25 ℃,时间30 min,材料是d 50 mm的Gr15轴承钢磨盘与d 60 mm的紫铜圆片试样。铜的耐磨性采用测量盘试样摩擦前后的质量损失,按式(1)计算磨损率m[13]:

(1)

(1)

式中:Δm为磨损质量损失,mg;N为施加在盘试样上的轴向力,N;l为磨损行程,m;ρ为材料的密度,g/mm3。

1.7 钢球、铜磨损表面分析

摩擦磨损试验结束后,将钢球及磨盘浸在石油醚、丙酮中,并用超声波清洗2次,每次15 min,四球试验后下试球作为OLYMPUS激光共交显微镜的试验样;下试球与立式万能磨损后的铜板作为德国EVO18扫描电子显微镜(SEM)以及能谱仪(EDS)的试验样。

2 结果与讨论

2.1 理论计算

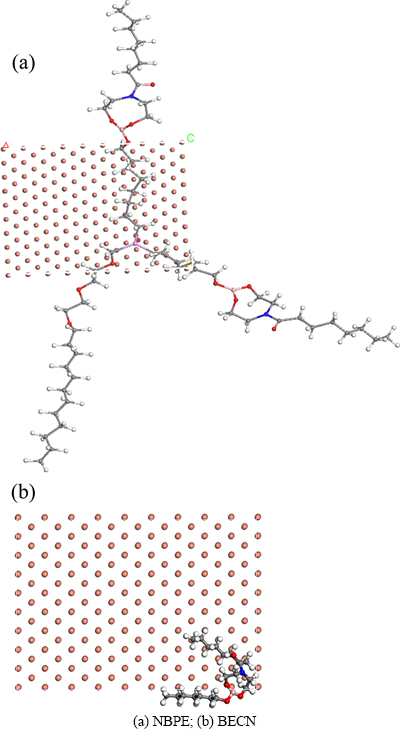

图2 添加剂在Cu(110)晶面的吸附构型

Fig. 2 Adsorption configurations of additives on Cu (110) crystal plane

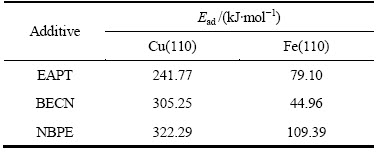

吸附能是分子与金属的相互作用强弱的重要衡量指标,其值越大,分子与金属的相互作用越强。添加剂EAPT、BECN以及NBPE与金属表面的吸附能如表1所列。NBPE与Cu/Fe表面的相互作用明显高于其余两种分子的,其吸附膜在Cu/Fe(110)晶面上的吸附能在44~330 kJ/mol之间,均大于40 kJ/mol,可形成NBPE—Fe或 NBPE—Cu的化学键,属于化学吸附。钢-铜摩擦过程中添加剂分子均易粘着于铜表面或发生化学反应,形成一层稳定润滑薄膜。

表1 添加剂在金属不同晶面上的吸附能平均值

Table 1 Statistic average values of adsorption energies (Ead) on metal surface for additives

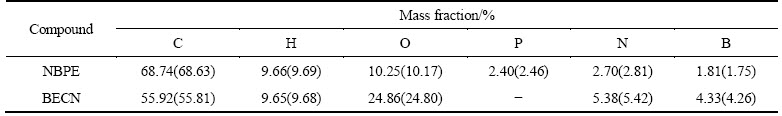

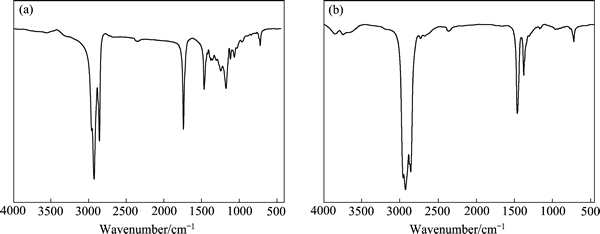

2.2 合成添加剂的表征

表2为合成的硼酸酯添加剂的元素分析结果。可以看出,NBPE与BECN元素分析结果和理论值接近,均在误差范围之内。表3与图3为NBPE和BECN的红外数据与谱图,目标产物的主要官能团均得到了体现。

2.3 新型添加剂制备润滑油的热稳定性

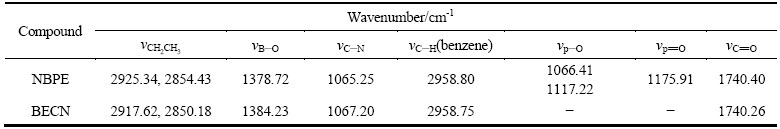

图4所示为采用不同添加剂制备的润滑油的TG曲线。从图4可以看到,3种产物的质量损失温度都在160 ℃以上,说明所合成的产物均具有较好的热稳定性,并且含NBPE润滑油的热稳定性最好。3种润滑油在280 ℃的蒸发量相近,恒温30 min后,3种润滑油蒸发过程均结束,根据最终残留量判断,含BECN(0.74%)与NBPE(0.42%)润滑油的退火清净性相当,含EAPT(0.27%)润滑油的稍好。

表2 合成化合物的元素分析测试结果(括号内数值为计算值)

Table 2 Elemental measured results of synthesized compound (Data in parentheses are calculated values)

图3 NBPE与BECN 的红外光谱

Fig. 3 FTIR spectra of NBPE(a) and BECN(b)

表3 NBPE与BECN的红外数据

Table 3 Infrared analyses of NBPE and BECN

图4 润滑油的TG曲线

Fig. 4 TG curves of rolling oil

2.4 新型添加剂的水解稳定性

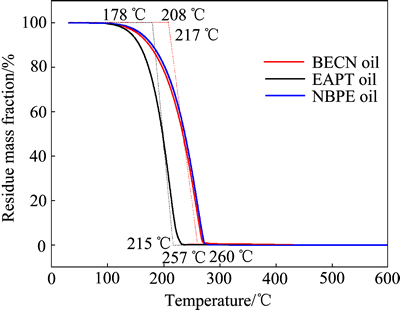

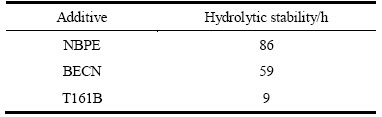

NBPE、BECN与T161B的水解稳定性测试结果如表4所示。含氮硼酸酯衍生物的水解稳定性均大于T161B的水解稳定性,这说明新型添加剂NBPE具有良好的水解稳定性,且NBPE的水解稳定性是T161B的9倍。

表4 NBPE的水解稳定性

Table 4 Hydrolytic stability of NBPE

2.5 新型添加剂的油膜承载能力、抗磨性能及磨斑形貌

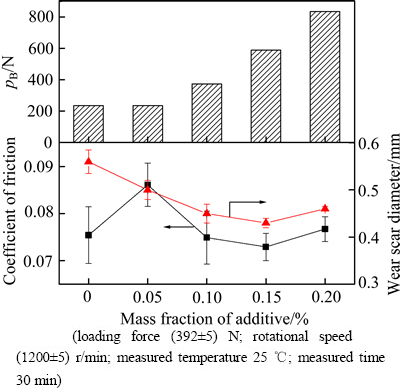

图5所示为润滑油的油膜承载能力和抗磨性能随添加剂含量的变化曲线,图6所示为添加NBPE磨斑的SEM与EDS分析。从图5可以看出,新型添加剂NBPE的油膜承载能力,在低浓度(小于0.05%)下,NBPE的最大无卡咬负荷(pB值)相当;在高浓度(大于0.05%)下,基础油的承载能力显著提高。一方面,在极压状态下摩擦表面的压力、温度很高,添加剂分子中活性元素N、P和金属表面发生摩擦化学反应,生成硬度小、易剪切的有机含氮金属络合物或磷酸盐无机反应膜,添加剂的极压性能与其分子结构中活性元素的含量相关[14]。另一方面,含氮杂环结构紧凑,N的原子半径小、电负性高,当吸附于金属表面时,其分子之间易形成氢键,使横向引力增加,从而提高油膜强度。

图5 润滑油摩擦学性能随添加剂含量的变化曲线

Fig. 5 Variations of tribological performance with additive concentration

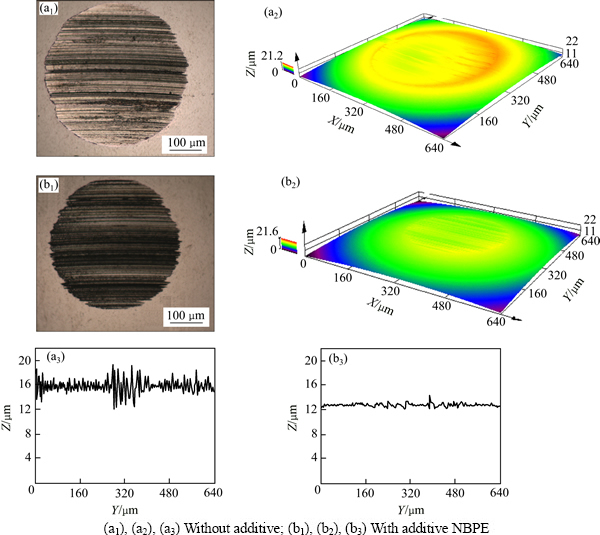

在基础油中加入添加剂NBPE后,磨斑直径显著减小。当润滑油中添加的NBPE质量分数为0.15%时,油膜强度提高了148%,磨斑直径最小,比不添加NBPE时分别减小了23.2%和27.9%。因为硼酸酯在摩擦过程中分解,在金属表面形成由部分硼酸酯组成的含硼吸附层,且吸附能力很强,可避免摩擦副间的直接接触,从而减少摩擦与磨损[15]。由于含硼吸附层与反应膜组成的复合边界润滑膜起到更好的抗磨作用。添加剂的减摩性能与其自身的层状结构关系很大,硼酸酯与金属表面形成易剪切的吸附层起到了“化学抛光”的作用[16],摩擦因数减小,且其层与层之间的排列方向与相对滑动方向相平行,这使摩擦副的滑动变得更容易。图7所示为无添加剂与含0.15% (质量分数)NBPE试油润滑下磨斑的 2D、3D 形貌图以及垂直于磨斑的剖面轮廓图。由图7可以看出,无添加剂润滑的磨斑表面有大量深的犁沟,由于摩擦表面生成的油膜抗剪切力很低,表面微凸体以及摩擦过程中产生的游离而坚硬的磨屑粒子对钢球表面进行犁削;添加NBPE的试油润滑时,磨斑表面的沟槽少且浅,表面相对光滑且分布均匀。

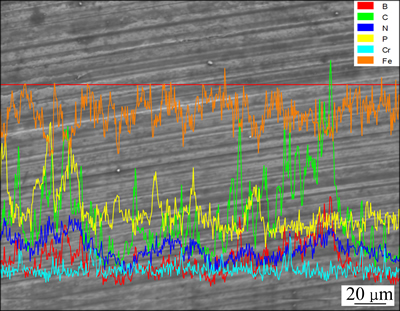

图6 添加NBPE磨斑的SEM与EDS谱分析

Fig. 6 SEM and EDS of wear scar with additive NBPE

图7 两种润滑条件下磨斑表面的2D、3D形貌以及垂直于磨斑的剖面轮廓图

Fig. 7 Optical micrographs((a1), (b1)), 3D morphologies((a2), (b2)) and cross-section outline maps((a3), (b3)) of wear scars on steel balls with two lubricants

2.6 新型添加剂对钢-铜摩擦副的磨损性能分析

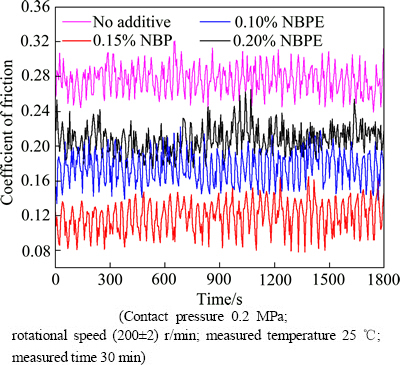

接触压力为0.2 MPa、转速为200 r/min时,在4种润滑条件下,铜-钢摩擦副的摩擦因数随磨损时间的变化曲线如图8所示。从图8可以看出,摩擦因数与添加剂的含量非线性相关,当润滑油中添加NBPE的含量0.15%(质量分数)时,摩擦副的摩擦因数最小,其平均摩擦因数为0.112,比无添加剂润滑的条件下的平均摩擦因数0.276降低了59.4%。图9所示为不同质量分数的NBPE润滑条件下相应的铜板磨损率。无添加剂润滑条件下试样剧烈磨损;而添加0.15%(质量分数)NBPE润滑油,试样磨损率明显下降,比无添加剂润滑时的降低了45.22%。而NBPE的含量大于0.15%时,活性元素含量过高,因化学作用直接侵蚀金属,在机械应力作用下其吸附膜破裂而失效,导致材料磨损加剧[17]。

图8 铜-钢摩擦副摩擦因数随磨损时间的变化曲线

Fig. 8 Variations of coefficient of friction of copper-steel friction pair with wearing time

图9 添加不同NBPE润滑条件下铜磨损率的变化

Fig. 9 Variation of wear rate of copper under different lubricating conditions adding different NBPE

2.7 铜磨痕的表面形貌

图10所示为使用无添加剂与添加0.15%(质量分数)的NBPE润滑油摩擦后的铜表面形貌。图10(a)中,铜摩擦表面有明显的犁沟与严重的擦伤。钢的凸峰在光滑的铜表面产生剪切变形并不断累积,在粘着磨损和磨粒磨损机制的交替作用下,在表面缺陷处产生应力集中生成疲劳裂纹,正应力循环导致裂纹不断横向扩展,达到某临界尺寸时,裂纹上的材料断裂以鳞片状的形式剥落下来,如图10(c)所示。对图10(c)的区域进行能谱分析,其结果如图10(d)所示,铜表面凹坑存在大量的碳元素,这进一步验证了无添加剂时,摩擦副间油膜的承载能力低,摩擦过程油膜迅速破裂,造成其剧烈磨损,磨损率最大(见图9)。铜-钢磨损过程是由微凸体变形、磨粒和微凸体犁沟以及表面粘着综合作用的结果。从图10(b)可以看出,随着NBPE的添加,铜表面相对光滑,仅部分出现轻微的犁沟,处于边界润滑状态,试样表面的磨损程度得到明显改善。这主要是由于NBPE在摩擦过程中对其所承受的侧向剪切力和法向载荷力等破坏力起支撑、转移、分散和润滑作用[17],从而使铜的磨损减轻。

图10 铜摩擦磨损后的SEM像及其相应区域的EDS分析

Fig. 10 SEM images of copper after friction and wear with two lubricants and corresponding EDS analyses

3 结论

1) 利用分子动力学理论设计制备的含氮磷硼酸酯NBPE是一种具有良好的热稳定性、水解稳定性和优异的极压、抗磨性的润滑油添加剂;当润滑油中添加0.15%(质量分数)的NBPE时,轧制油具有最佳的极压、抗磨性能,其油膜强度提高了148%,磨斑直径降低了23.2%,并在钢-铜摩擦过程中,摩擦因数和铜磨损率分别降低59.4%和45.2%。

2) 分子动力学理论计算表明,氮磷硼酸酯在金属表面有较高的吸附能,其在摩擦表面形成了由含硼吸附层、有机含氮金属络合物和磷酸盐无机反应膜组成的润滑膜,在摩擦过程中,对其所承受的侧向剪切力和法向载荷力等破坏力起支撑、转移、分散和润滑作用,这是提高含氮磷硼酸酯添加剂承载能力和减摩抗磨性能的根本原因。说明采用分子动力学的方法设计和选择金属加工用新型添加剂具有良好的应用前景。

REFERENCES

[1] WANG Song, YUE Wen, FU Zhi-qiang, WANG Cheng-biao, LI Xing-liang, LIU Jia-jun. Study on the tribological properties of plasma nitrided bearing steel under lubrication with borate ester additive[J]. Tribology International, 2013, 66: 259-264.

[2] WANG Yong-gang, LI Jiu-sheng, REN Tian-hui. Tribological study of a novel borate ester containing dialkylthiophosphate group as multifunctional additive[J]. Industrial Lubrication and Tribology, 2009, 61(1): 33-39.

[3] 沈光球, 郑 直, 万 勇, 曹立礼, 岳奇贤, 孙天健.有机硼酸酯添加剂的水解稳定性及摩擦特性[J]. 清华大学学报(自然科学版), 1999, 39(10): 97-100.

SHEN Guang-qiu, ZHENG Zhi, WAN Yong, CAO Li-li, YUE Qi-xian, SUN Tian-jian. Hydrolytic stability and triboligical properties of organic borate esters as lubricant additives[J]. Journal of Tsinghua University (Science and Technology), 1999, 39(10): 97-100.

[4] YAN Jin-can, ZENG Xiang-qiong, HEIDE E V D, REN Tian-hui. The tribological performance and tribochemical analysis of novel borate esters as lubricant additives in rapeseed oil[J]. Tribology International, 2014, 71: 149-157.

[5] MENDELSON L T. Lubricating compositions. US Patent 4892670[P]. 1990.

[6] 徐 振, 杨福旺, 程 思, 闫婷婷, 张晨曦, 衣守志. 含硫、氮的硼酸酯添加剂的制备及摩擦学性能[J]. 现代化工, 2014, 34(11): 73-77.

XU Zhen, YANG Fu-wang, CHENG Si, YAN Ting-ting, ZHANG Chen-xi, YI Shou-zhi. Preparation and tribology properties of borate ester lubricating additive containing S and N[J]. Modern Chemical Industry, 2014, 34(11): 73-77.

[7] 任朋飞, 李为民, 段伟娜. 新型含氮磷酸酯添加剂的合成及摩擦学性能研究[J]. 润滑与密封, 2011, 36(12): 41-44.

REN Peng-Fei, LI Wei-ming, DUAN Wei-na. Synthesis and tribological properties of new nitrogen-containing phosphate additives[J]. Lubrication Engineering, 2011, 36(12): 41-44.

[8] 谢 武, 杨改霞, 何佳正, 苏 冬. 含氮硼酸酯的研究及应用[J]. 材料研究与应用, 2014, 8(4): 215-218.

XIE Wu, YANG Gai-xia, HE Jia-zheng, SU Dong. Research on and application of borate ester containing nitrogen[J]. Materials Research and Application, 2014, 8(4): 215-218.

[9] 宋晓岚, 邱冠周, 王海波, 吴雪兰, 曲选辉. 2-氨基-5-巯 基-1,3,4-噻二唑缓蚀剂结构的密度泛函计算[J]. 中国有色金属学报, 2004, 14(2): 291-297.

SONG Xiao-lan, QIU Guan-zhou, WANG Hai-bo, WU Xue-lan, QU Xuan-hui. Density function theory calculation on structure of 2-aminino-5-mercato-1,3,4-thiadizole inhibitor[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(2): 291-297.

[10] 李 酽, 郭 英, 才 华, 邹云玲. 缓蚀剂构效关系的量子化学研究[J]. 腐蚀与防护, 2007, 28(8): 392-395.

LI Yan, GUO Ying, CAI Hua, ZOU Yun-ling. Quantum chemistry study on the structures-activity relationship of corrosion inhibitor[J]. Corrosion & Protection, 2007, 28(8): 392-395.

[11] NIU Rui-juan, ZHENG Qing-chuan, ZHANG Ji-long, ZHANG Hong-Xing. Molecular dynamics simulations studies and free energy analysis on inhibitors of MDM2–p53 interaction[J]. Journal of Molecular Graphics and Modelling, 2013, 46: 132-139.

[12] 熊 桑, 孙建林. 新型氮磷添加剂对铜箔轧制摩擦学性能与磨损行为的影响[J]. 中国有色金属学报, 2014, 24(9): 2352-2359.

XIONG Sang, SUN Jian-lin. Effect of oil additive containing nitrogen and phosphorus on tribology performance and wear behavior of copper foil during rolling[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(9): 2352-2359.

[13] 刘娜娜, 孙建林, 武 迪, 夏 垒. 不同润滑介质下铜箔摩擦磨损性能研究[J]. 武汉科技大学学报, 2012, 35(6): 444-451.

LIU Na-na, SUN Jian-lin, WU Di, XIA Lei. Friction and wear behaviors of copper foil under different lubrication conditions[J]. Journal of Wuhan University of Science and Technology, 2012, 35(6): 444-451.

[14] YAN Jin-can, ZENG Xiang-qiong, HEIDE E V D, REN Tian-hui, ZHAO Yan-dong. The tribological behavior and tribochemical study of B–N type borate esters in rapeseed oil-compound versus salt[J]. RSC Advances, 2014, 40(4): 20940-20947.

[15] 杨蔚权, 陈波水, 方建华, 王 九. 一种硼氮化改性油酸甲酯的合成及抗磨减摩特性研究[J]. 功能材料, 2015, 46(3): 3135-3138.

YANG Wei-quan, CHEN Bo-shui, FANG Jan-hua, WANG Jiu. Synthesis of a boron nitride modified oil methyl ester and its antiwear friction- reduction research[J]. Journal of Function Materials, 2015, 46(3): 3135-3138.

[16] LI Jian-chang, LI Zhi-peng, REN Tian-hui, ZENG Xiang-qiong, HEIDE E V D. Hydrolytic stability and tribological properties of N-containing heterocyclic borate esters as lubricant additives in rapeseed oil[J]. Tribology International, 2014, 73: 101-107.

[17] 王 顺, 王文中, 胡元中, 王 慧. 点接触润滑粗糙表面滑动摩擦力的预测研究[J]. 摩擦学学报, 2007, 27(2): 152-155.

WANG Shun, WANG Wen-zhong, HU Yuan-zhong, WANG Hui. Prediction of sliding friction force of rough surfaces in lubricated point contact[J]. Tribology, 2007, 27(2): 152-155.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51474025)

收稿日期:2014-11-17;修订日期:2015-03-08

通信作者:孙建林,教授,博士;电话:010-62333768;传真:010-62334743;E-mail: sjl@ustb.edu.cn