制备方法和条件对ITO粉体吸波性能的影响

古映莹1,刘雪颖1, 2,秦利平1,吴会永1

(1. 中南大学 化学化工学院,湖南 长沙,410083;

2. 广西工学院科技处,广西 柳州,545006)

摘 要:分别采用化学共沉淀法和水热-煅烧法制备ITO粉体,并通过测定所得ITO 粉体在8~12 GHz频率段的微波吸收率,考察制备条件和制备方法对ITO粉体微波吸收性能的影响。研究表明,采用水热-煅烧法制得的ITO粉体微波吸收性能优于化学共沉淀法得到的ITO粉体微波吸收性能,最大吸收率可达-34 dB,频宽为8.8~10.5 GHz。水热-煅烧法中,水热反应温度影响ITO粉体的微波吸收性能,随水热反应温度的增加,微波吸收率先增大后降低;随煅烧温度的增加,ITO粉体微波吸收率下降。

关键词:ITO;水热-煅烧法;掺杂;微波吸收

中图分类号:O611.4 文献标识码:A 文章编号:1672-7207(2007)03-0486-05

Effects of preparing methods and conditions on microwave absorption performance of ITO nano-powders

GU Ying-ying1, LIU Xue-ying1, 2, QIN Li-ping1, WU Hui-yong1

(1. School of Chemistry and Chemical Engineering, Central South University, Changsha 410083, China;

2. Department of Science, Guangxi University of Technology, Liuzhou 545006, China)

Abstract:ITO nano-powders were prepared separately by co-precipitation method and hydrothermal-sintering process. The effects of preparing methods and conditions on microwave absorption performance of ITO nano-powders were investigated by measuring microwave absorption at 8-12 GHz frequency range. The results show that the microwave absorption performance of ITO nano-powders prepared by hydrothermal-sintering is better than that by co-precipitation method. The best microwave absorption rate is -34 dB and the frequency rang is 8.8-10.5 GHz. In hydrothermal-sintering process, with the hydrothermal temperature rising, the microwave absorption rate of ITO nano-powders gradually increases and then decreases, and with the sintering temperature rising, the microwave absorption reduces.

Key words:ITO; hydrothermal-sintering process; doping; microwave absorption

吸波材料是指能吸收、衰减入射的电磁波,并将其电磁能转换成其它形式的能量(如机械能、电能和热能)耗散掉或使电磁波因干涉而消失的一类材料[1]。经过合理的结构设计、阻抗匹配设计以及采用适当的成型工艺,吸波材料几乎可以完全衰减、吸收所入射的电磁波能量[2-3]。因此,吸波材料在军事和民用方面的应用日益广泛[4-6],其研究也越来越受到各国学者的高度重视[7-11]。

铟锡氧化物(Indium Tin Oxide,以下简称ITO)是一种高简并的N型半导体材料,ITO具有一系列独特性能[12-14],因为掺锡和形成氧空位分布于材料中从而使其导电粒子-载流子浓度N大大增加,电阻率ρ急剧下降,其电导率接近于金属导体电导率[15-16]。雷达波段的电磁波辐射会因与吸波材料电子之间的相互作用而被吸收(雷达波段指的是比红外光波长更长的毫米波和微波波段),雷达波吸收的关键是需要较高的电导率,而ITO材料的霍尔迁移率很小,其高电导率的贡献主要来自于高载流子浓度。因此,在ITO的制备过程中要尽力提高掺杂效率,增加自由载流子数目,以期获得较高雷达波吸收率。本研究分别采用化学共沉淀法和水热-煅烧法考察不同的制备方法和制备条件等因素对ITO粉体雷达波吸收性能的影响。

1 实 验

分别采用化学共沉淀法和水热-煅烧法制备ITO粉体。

a. 化学共沉淀法:将In2(SO4)3溶液和SnCl4溶液按m(In2O3)?m(SnO2)=9?1混合,在70 ℃恒温下反应,匀速滴加Na2CO3溶液,调节pH值到7~8,反应完毕。将得到的凝胶体抽滤、洗涤、干燥,制备出前驱体。将前驱体在不同温度下进行煅烧得到ITO粉体。

b. 水热-煅烧法:将用共沉淀法制备的湿凝胶过滤、洗涤,放入水热高压釜中在一定温度下进行处理,然后将水热反应得到的悬浊液用去离子水过滤洗涤,将过滤得到的产物烘干(温度为80~90 ℃),研磨成粉。以水热反应生成的产物为前驱体在不同温度下进行煅烧得到ITO粉体。

将化学共沉淀法和水热-煅烧法得到的ITO粉体压片,用Swept Amplitude Analyzer仪(惠普 8755C)测试其在8~12 GHz频率段的微波吸收率,考察制备条件和制备方法对ITO粉体微波吸收性能的影响。

2 结果和讨论

2.1 化学共沉淀制备

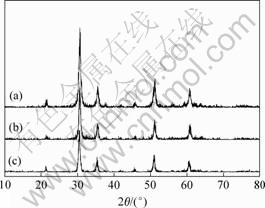

图1所示为采用化学共沉淀法在不同煅烧温度下所得样品的XRD。由图1可知,将共沉淀前驱体在500~800 ℃煅烧均可得到结晶良好的立方结构的ITO粉体。

图1 化学共沉淀法不同煅烧温度所得立方结构ITO粉末的XRD谱

Fig.1 XRD patterns of cubic ITO powders prepared by co-precipitation at different sintering temperature

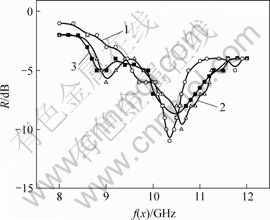

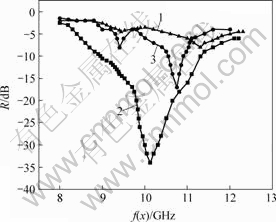

共沉淀法中不同煅烧温度下制备的ITO粉体的微波吸收性能如图2所示。从图中可以看出,在600 ℃煅烧得到的ITO粉体的吸波范围较宽;随着煅烧 温度的升高,ITO粉体的微波吸收能力逐渐增大,到700 ℃时吸收能力最大,这是因为随着煅烧温度的升高,粉体的结晶性能得到改善[17],掺杂反应也进行得更完全,自由载流子数目增加,提高了粉体的电导率,即提高了ITO粉体的微波反射吸收能力,但粉体吸波范围变窄;煅烧温度继续升高,粉体的晶型生长已经完全,粉体的粒径随之长大,对微波的吸收衰减能力反而减弱。

1—600 ℃, 2 h; 2—700 ℃, 2 h; 3—800 ℃, 2 h

图2 不同煅烧温度下ITO粉体微波吸收率

Fig.2 Microwave absorption rate of ITO powders at different sintering temperatures

2.2 水热-煅烧制备

2.2.1 水热条件对ITO粉体吸波性能的影响

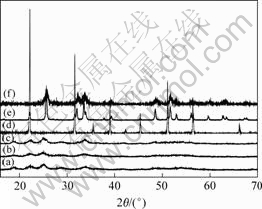

图3所示为水热反应得到的产物的XRD谱。由图3可知,水热反应温度为160~180 ℃时,得到非晶态In(OH)3,200 ℃时得到晶态In(OH)3,220~300 ℃时得到晶态(In1-xSnx)OOH。

(a) 160 ℃, 6 h; (b) 160 ℃, 12 h; (c) 180 ℃, 12 h; (d) 200 ℃, 6 h; (e) 220 ℃, 6 h; (f) 300 ℃, 12 h

图3 不同水热条件下所得样品的XRD谱

Fig.3 XRD patterns of samples prepared under different hydrothermal process conditions

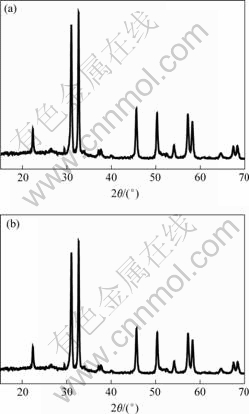

图4所示为以水热反应所得产物为前驱体,在 550 ℃煅烧2 h所得样品的XRD谱。由图4可知,最终产物均为结晶良好的六方结构的ITO粉体。

(a) 200 ℃,水热产物为前驱体;(b) 250 ℃,水热产物为前驱体

图4 水热-煅烧法所得六方结构的ITO的XRD图

Fig.4 XRD patterns of hexagonal sample prepared by hydrothermal-sintering process

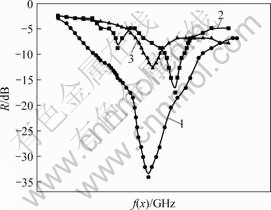

图5所示为水热-煅烧法制备的ITO粉体的微波吸收率与水热反应温度之间的关系曲线,煅烧温度均为450 ℃。从图5可知,水热反应温度为220 ℃时制备的ITO粉体(曲线2)的微波吸波性能最好,最大吸收率可达-34 dB;水热反应温度为250 ℃时制备的ITO粉体(曲线3)次之。水热反应温度为200 ℃时生成的产物是结晶性良好的In(OH)3晶体,当水热反应温度为220 ℃及其以上时所生成的产物为(In1-xSnx)OOH晶体,由于它们在后续的煅烧过程中晶体结构变化不同,因而影响了它们的最终产物(ITO粉体)的性能。

1—200 ℃, 6 h; 2—220 ℃, 6 h; 3—250 ℃, 6 h

图5 ITO粉体的微波吸收率与水热反应温度的关系

Fig.5 Relationship between microwave absorption rate of ITO powders and hydrothermal temperature

(In1-xSnx)OOH晶体与In(OH)3晶体相比,在水热反应过程中Sn离子已部分替代了In离子掺杂进入In2O3的晶格中,它的Sn掺杂结合得比后者要早,在随后的煅烧过程中更进一步加强了In2O3与Sn离子的结合,因此,煅烧过程也是重掺杂过程。而In(OH)3晶体只是在后续的煅烧过程中才发生Sn离子的取代掺杂,所以,前者的自由载流子浓度要比后者的高,即以(In1-xSnx)OOH晶体为前驱体得到的ITO粉体微波吸收性能要好。

2.2.2 煅烧温度对ITO粉体的吸波性能的影响

图6所示为水热反应生成的(In1-xSnx)OOH晶体在不同煅烧温度下制备的ITO粉体的微波吸收曲线。从图6可知,在450 ℃煅烧得到的ITO粉体吸波性能最好,且随温度的升高,ITO粉体的微波反射吸收能力逐渐下降。这是因为在450 ℃ITO粉体晶型生长已经完全,Sn的掺杂完全;随着温度的升高,粉体粒径增加,又降低了ITO粉体的微波吸收能力。

1—450 ℃, 2 h; 2—500 ℃, 2 h; 3—550 ℃, 2 h

图6 ITO粉体的微波吸收率与煅烧温度的关系

Fig.6 Relationship between microwave absorption rate of ITO powders and sintering temperature

2.3 比较不同制备方法的影响

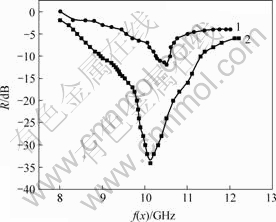

图7所示为共沉淀法和水热-煅烧法制备的ITO粉体的微波吸收率曲线。其中共沉淀法制备的条件为:700 ℃高温煅烧2 h;水热-煅烧法的制备条件为:于220 ℃水热反应6 h,再于450 ℃煅烧2 h。从图7可知,水热-煅烧法制备的ITO粉体比共沉淀法制备的ITO粉体的微波吸收性能更佳,因为前者的Sn掺杂是重掺杂过程:Sn离子在水热过程中就开始掺杂进入In2O3的晶格中,并且在随后的低温煅烧过程更进一步地掺入In2O3的晶格,形成稳定的ITO晶体。它比共沉淀法中只在煅烧过程才发生的Sn掺杂的效果好,即Sn掺杂效率高,产生的自由载流子浓度高,所以微波吸收性能好。

1—共沉淀法(700 ℃, 2 h);

2—水热(220 ℃, 6 h)-煅烧法(450 ℃, 2 h)

图7 不同方法制备的ITO粉体的微波吸收率曲线

Fig.7 Curves of microwave absorption rate of ITO powders prepared by different methods

3 结 论

a. 经220 ℃水热反应6 h,450 ℃煅烧2 h制得的ITO超细粉体有优良的微波吸收性能,最大吸收率可达-34 dB,频宽为8.8~10.5 GHz。

b. 在水热-煅烧法制备ITO粉体前驱体过程中,水热反应温度可影响ITO粉体的微波吸收性能。随水热反应温度的增加,ITO粉体的微波吸收性能先增大后降低;随煅烧温度的增加,ITO粉体微波反射吸收性能下降。

参考文献:

[1] 王 海. 雷达吸波材料的研究现状和发展方向[J]. 上海航天, 1999(1): 55-59.

WANG Hai. Studying status and developing trend of radar wave- absorbing materials[J]. Aerospace Shanghal, 1999(1): 55-59.

[2] 宣兆龙, 易建政, 于 鑫. 雷达波吸收剂的研究现状及发展趋势[J]. 材料科学与工程, 1999, 17(2): 94-97.

XUAN Zhao-long, YI Jian-zheng, YU Xin. Current status and development trend of radar wave absorbent[J]. Materials Science & Engineering, 1999, 17(2): 94-97.

[3] 周克省,刘 归,尹荔松,等. 纳米Fe3O4/BaTiO3复合体系的微波吸收特性[J]. 中南大学学报:自然科学版, 2005, 36(5): 872-876.

ZHOU Ke-sheng, LIU Gui, YIN Li-song, et al. Microwave absorbing property of nano-Fe3O4/BaTiO3 composite system[J]. Journal of Central South University: Science and Technology, 2005, 36(5): 872-876.

[4] YANG Zhi-wei, HAN Sheng-hao, YAN Tian-lin, et al. Preparation of ITO films on water-cooled flexible substrate by bias R.F. Magnetron Sputtering[J]. Phys, 2000, 6(49): 1196-1201.

[5] 刘 列, 张明雪, 胡连成. 吸波涂层材料技术的现状和发展[J]. 宇航材料工艺, 1994, 24(1):1-5.

LIU Lie, ZHANG Ming-xue, HU Liang-cheng. Status and developing of wave-absorbing coating materials[J]. Aerospace Materials & Technology, 1994, 24(1): l-5.

[6] 刘 飚, 官建国, 王 琦, 等. 纳米技术在微波吸收材料中的应用[J]. 材料导报, 2003, 17(3): 45-47.

LIU Biao, GUAN Jian-guo, WANG Qi, et al. Nano-technology and its application in microwave absorbing materials[J]. Material Review, 2003, 17(3): 45-47.

[7] 陈利民, 开家钟, 朱雪琴, 等. 纳米γ-(Fe, Ni)合金颗粒的微观结构及其微波吸收特性[J]. 兵器材料科学与工程, 1999, 22(4): 3-6.

CHEN Li-ming, KAI Jia-zhong, ZHU Xue-qin, et al. Microstructure and microwave absorptivity of nanometer γ-(Fe,Ni) alloy particles[J]. Ordnance Material Science and Engineering, 1999, 22(4): 3-6.

[8] Kimura K, Aoyama T. Preparation of crosslinked resin Particle[P]. JP11189607, 1999.

[9] JIAO Huan, LUO Fa, ZHOU Wa-cheng. Dielectric properties of Si/C/N nano powders[J]. Journal of Inorganic Materials, 2002, 17(3): 595-599.

[10] CHEN Wei, CAI Wei-ping, WANG Guo-zhong, et al. Effects of interface interaction on the mie resonance absorption of gold nanoparticles dispersed within pores of mesoporous silica[J]. Applied surface Science, 2001, 174: 51-54.

[11] Yang L, Li G H, Zhang L D. Effect of surface resonance state on the plasmon resonance absorption of Ag nanoparticles embedded in partially oxidized amorphous[J]. Apply Physics Letters, 2000, 76(12): 1537-1539.

[12] 段学臣, 杨向萍. 新材料ITO薄膜的应用和发展[J]. 稀有金属与硬质合金, 1999, 138(3): 58-60.

DUAN Xue-chen, YANG Xiang-ping. Application and development of new material-ITO films[J]. Rare Metals and Cemented Carbides, 1999, 138(3): 58-60.

[13] GU Ying-ying, QIN Li-ping, LIU Xue-ying. Preparation of ITO nano-powders by hydrothermal-calcining process[J]. J Cent South Univ Technol, 2006, 13(4): 389-392.

[14] 张明瑜, 姚吉升, 陈志飞. ITO宽频谱隐身材料的作用机理探讨[J]. 矿冶工程, 2003, 23(1): 67-69.

ZHANG Ming-yu, YAO Ji-sheng, CHEN Zhi-fei. A discussion on mechanism of ITO as multispectral nanocrystalline camouflage material[J]. Mining and Metallurgical Engineering, 2003, 23(1): 67-69.

[15] Tadatsugu M, Yoshihiro T, Shinzo T, et al. Preparation of transparent conducting In4Sn3O12 thin films by DC magnetron sputtering[J]. Thin Solid Films, 1997, 308-309: 13-18.

[16] Tadatsugu M, Yoshihiro T, Takata S, et al. Highly transparent and conductive ZnO-In2O3 thin films prepared by d.c. magnetron sputtering[J]. Thin Solid Films, 1996, 290-291: 1-5.

[17] 张永红,陈明飞. 热处理对制备纳米氧化铟锡(ITO)粉末的影响[J]. 金属热处理, 2003, 28(2): 18-20.

ZHANG Yong-hong, CHEN Ming-fei. Influence of the heat treatment on nanoscale indium-tin oxide powder[J]. Heat Treatment of Metals, 2003, 28(2): 18-20.

收稿日期:2006-08-30

基金项目:国家“十五”攻关西部开发科技行动计划资助项目(2001BA901A09)

作者简介:古映莹(1962-),女,湖南郴州人,教授,从事无机功能材料研究

通讯作者:古映莹,女,教授;电话:13467517387;E-mail: guyy02@163.com