Influence of heat treatment on microstructure and damage tolerance property in Ti-6Al-2Zr-1Mo-1V

FAN Rong-hui(范荣辉), ZHU Ming(朱明), HUI Song-xiao(惠松骁),

LI De-fu(李德富), SHEN Jian(沈健)

General Research Institute for Nonferrous Metals, Beijing,100088, China

Received 15 July 2007; accepted 10 September 2007

Abstract: The influence of heat treatment on the microstructure and damage tolerance property of Ti-6Al-2Zr-1Mo-1V titanium alloy was investigated. The large-thickness Ti-6Al-2Zr-1Mo-1V titanium alloy plate was produced by β-processing, following with duplex anneal in (α+β) phase field and β anneal, respectively. The fatigue crack propagation rate(da/dN) test and the fracture toughness(KⅠC) test of Ti-6Al-2Zr-1Mo-1V were performed. The results show that the annealing in (α+b) phase field, with increasing anneal temperature, prior β grain size and α colony size of Ti-6Al-2Zr-1Mo-1V remained constant approximately, α lamella mean size increases gradually; KⅠC increases and da/dN decreases respectively; when annealing in b phase field, prior β grain size and α colony size increases sharply, da/dN decreases drastically. β anneal is better than anneal in (α+β) phase field as to improve the damage tolerance property of Ti-6Al-2Zr-1Mo-1V.

Key words: Ti-6Al-2Zr-1Mo-1V ; microstructure ; crack propagation rate; fracture toughness

1 Introduction

The study of damage tolerance property(fracture toughness and fatigue crack growth rate) in titanium alloys has received considerable interest[1-6] because of their important use in aerospace applications due to their high specific strength (strength/density).The damage tolerance property of titanium alloys, however, is complicated by the changes in the microstructures that occur by even small changes in heat treatment that in turn result in changes in their properties. It has been proved that β working(deformation or annealing in β phase field) and reducing the content of interstitial elements(C,N,O, etc) can improve damage tolerance property of titanium alloys[7].

It has been known that Ti-6Al-2Zr-1Mo-1V exhibits good comprehensive mechanical property, workability and weldability. In this paper, the content of oxygen, carbon and nitrogen of Ti-6Al-2Zr-1Mo-1V were reduced to extra-low inerstitial(ELI) grade, and the microstructure characteristic parameters and damage tolerance property of Ti-6Al-2Zr-1Mo-1V, in different heat treatment conditions(including β annealing), were examined. The interrelationships of heat treatments, microstructures and damage tolerance property were discussed. And the comparison of damage tolerance property between Ti-6Al-2Zr-1Mo-1V and Ti-6Al-4V ELI had also been performed.

2 Experimental

The Ti-6Al-2Zr-1Mo-1V plate was received in such hot working history as: three vacuum arc meltings to obtain the billet of 720 mm in diameter, forging to plate of 300 mm thickness, and first rolling at 1 050 ℃ (ε ≈ 75%, in β phase field),then second rolling at 950 ℃ (ε ≈ 60%, in (α+b) phase field ), at last obtaining the plate with the dimension of 80 mm×2 000 mm×L mm.

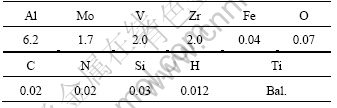

The b transformation point Tβ of Ti-6Al- 2Zr-1Mo-1V was 970 ℃ measuring by metallographic method. The chemical composition of Ti-6Al-2Zr- 1Mo-1 V used for this study was shown in Table 1.

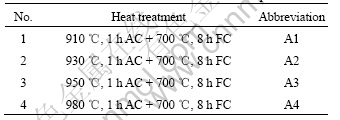

In order to study the influence of heat treatment on microstructure and damage tolerance property of Ti-6Al-2Zr-1Mo-1V, annealing in β phase field anddouble anneal in α+b phase field were performed respectively. The different heat treatments were listed in Table 2.

Table 1 Chemical composition of Ti-6Al-2Zr-1Mo-1V (mass fraction, %)

Table 2 Heat treatments of Ti-6Al-2Zr-1Mo-1V plate

For double anneal in α+b phase field in this paper, secondary anneal was set at 700 ℃, 8 h FC constantly. And secondary anneal had little effect on the mechanical property of Ti-6Al-2Zr-1Mo-1V plate actually[8-11]. In this study , the interrelationship of heat treatment, microstructure and damage tolerance property were investigated primarily.

After heat treatment, the samples were taken from each plate, the microstructure characteristic parameters were measured by the Secant Method. Then, the room temperature tensile tests were conducted on AG-501CNE stretch test machine, fracture toughness tests were conducted on MTS-810-500KN test machine, fatigue crack growth rate tests were conducted on MTS-810-25KN test machine respectively.

3 Results and discussion

3.1 Microstructure

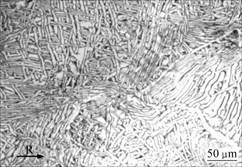

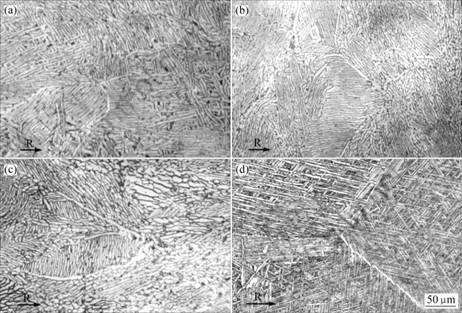

The microstructure of Ti-6Al-2Zr-1Mo-1V plate in the as-received condition was shown in Fig.1. The microstructure of Ti-6Al-2Zr-1Mo-1V samples after different heat treatments were shown in Fig.2.

The microstructure of Ti-6Al-2Zr-1Mo-1V plate in the as-received condition is typical lamella microstructure, containing a discontinuous prior b boundary (Fig.1). Because anneal in (α+b) phase field had little effect on the type of microstructure of (α+b) titanium alloy, the microstructures of anneal in (α+b) phase field (Fig.2(a), Fig.2(b), Fig.2(c)) are similar to that in the as-received condition(Fig.1). The microstructure in b anneal condition(Fig.2(d)) is typical acicular widmanstatten structure, which containing a continuous prior b boundary and acicular a lamella aligned disorderly.

Fig.1 Microstructure of Ti-6Al-2Zr-1Mo-1V plate in as- received condition (T-R direction, R: rolling)

Fig.2 Microstructures of Ti-6Al-2Zr-1Mo-1V after different heat treatments (T-R direction): (a) A1; (b) A2; (c) A3; (d) A4

3.2 Tensile properties

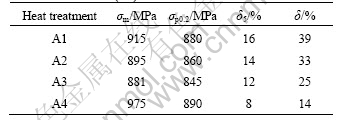

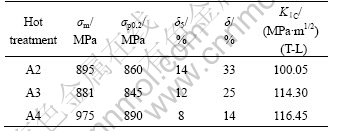

The tensile property of Ti-6Al-2Zr-1Mo-1V plate in different heat treatment conditions was shown in Table3. It can be observed from Table1 that annealing in (α+b) phase field, with anneal temperature increasing, both strength (σm, σp0.2) and plasticity(δ5, δ) decreased; and annealing at 10 ℃ above b transition point, strength property of Ti-6Al-2Zr-1Mo-1V was higher than that annealing in (α+b) phase field apparently, the tensile strength (σm) reached to 975 MPa; but plasticity decreased drastically , comparing with that annealing in (α+b) phase field.

Table 3 Influence of heat treatments on tensile behaviour of Ti-6Al-2Zr-1Mo-1V(RT)

3.3 Fracture toughness and fatigue crack growth rate

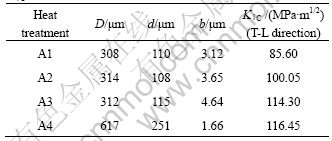

In different heat treatment conditions, the micro- structure characteristic parameters (Prior β grain size(D), α colony size(d), α lamella mean size(b) and fracture toughness were shown in Table 4. It can be observed from Table 4 that while annealing in (α+b) phase field, with anneal temperature increasing, prior β grain size and α colony size of Ti-6Al-2Zr-1Mo-1V remained constant approximately, but α lamella mean size increased gradually, and fracture toughness also increased in certain degree. It can be illustrated that the increasing of α lamella mean size was a beneficial factor for improving the fracture toughness of Ti-6Al-2Zr-1 Mo-1V [12-15]; while annealing at 10 ℃ above b transition point, prior β grain size and α colony size of Ti-6Al-2Zr-1Mo-1V increased sharply, KⅠC reached to 116.45 MPa?m1/2, which was equivalent to that annealing at 950 ℃, the upper temperature in (α+b) phase field.

Table 4 Influence of heat treatments on microstructure and KⅠC of Ti-6Al-2Zr-1Mo-1V

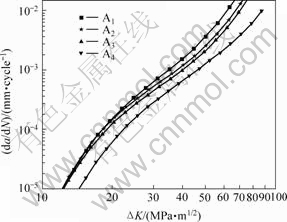

Fatigue crack growth rate(da/dN) curves of Ti-6Al-2Zr-1Mo-1V in different heat treatment conditions, at room temperature and under the atmosphere condition, were shown in Fig.3. When annealing in (α+b) phase field, with anneal temperature increasing, α lamella mean size increased gradually, and fatigue crack growth rate da/dN decreased gradually. When annealing at 10 ℃ above b transition point, fatigue crack growth rate da/dN decreased drastically comparing with that annealing in (α+b) phase field. Thus, it can be proved that b anneal was favorable to improve the damage tolerance property of Ti-6Al-2Zr-1Mo-1V compared with (α+b) phase field anneal[16-20], and increasing annealing temperature in (α+b) phase field would also benefit the damage tolerance property of Ti-6Al-2Zr-1Mo-1V [21-23].

Fig.3 Influence of heat treatment on fatigue crack growth rate of Ti-6Al-2Zr-1Mo-1V (R=0.1, RT, AT)

3.4 Ti-6Al-2Zr-1Mo-1V and Ti-6Al-4VELI

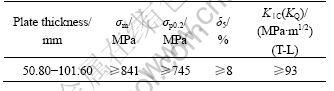

In 1981, US issued aerospace material specification- AMS4905A-titanium alloy, damage-tolerance grade plate 6Al-4V beta annealed, which the latest version is AMS4905C, issued in 2004. This specification defined many technology requirements, including the chemical composition range, heat treatments, basic mechanical property requirements and so on. The tensile properties of Ti-6Al-4VELI and Ti-6Al-2Zr-1Mo-1V plate were shown in Table 5 and Table 6 respectively.

Comparing the comprehensive property of Ti-6Al- 2Zr-1Mo-1V and Ti-6Al-4VELI, it can be observed from Table 5 and Table 6, when annealing at 10 ℃ above b transition point, the strength(σm and σp0.2)and fracture toughness (KⅠC) of Ti-6Al-2Zr-1Mo-1V were obviously better than that of Ti-6Al-4VELI defined in AMS4905C; when annealing at 930 ℃ and 950 ℃, the upper temperature in (α+b) phase field, the strength and fracture toughness of Ti-6Al-2Zr-1Mo-1V were equivalent to which of Ti-6Al-4VELI defined in AMS4905C.

Table 5 Tensile properties of Ti-6Al-4VELI plate specified in AMS4905C

Table 6 Tensile properties of Ti-6Al-2Zr-1Mo-1V plate

4 Conclusions

1) Ti-6Al-2Zr-1Mo-1V annealing in (α+b) phase field, with anneal temperature increasing, prior β grain size and α colony size remained constant approximately, α lamella mean size increased gradually; KⅠC increased and da/dN decreased respectively. Increasing of α lamella mean size was beneficial to improve damage tolerance property of Ti-6Al-2Zr-1Mo-1V.

2) Ti-6Al-2Zr-1Mo-1V annealing at 10 ℃ above b transition point, the microstructure was transformed into acicular widmanstatten structure, prior β grain size and α colony size increased sharply, da/dN decreased drastically. b anneal was better than (α+b) phase field anneal for damage tolerance property of Ti-6Al-2Zr- 1Mo-1V.

3) Annealing in b phase field, the damage tolerance (KⅠC, da/dN) of Ti-6Al-2Zr-1Mo-1V was obviously better than that of Ti-6Al-4VELI defined in AMS4905C.

References

[1] SEN I, TAMIRISAKANDALA S, MIRACLE D B, RAMAMURTY R. Microstructural effects on the mechanical behavior of B-modified Ti-6Al-4V alloys[J]. Acta Materialia, 2007, 55(15): 4983-4993.

[2] SADANANDAA K, VASUDEVAN A K. Fatigue crack growth behavior of titanium alloys[J]. International Journal of Fatigue, 2005, 27: 1255-1266.

[3] VADIRAJ A, KAMARAJ M. Damage characterization of unmodified and surface modified medical grade titanium alloys under fretting fatigue condition[J]. Mater Sci Eng A, 2006, 416: 253-260.

[4] SESHACHARYULU T, MEDEIROS S C, MORGAN J T, MALAS J C, FRAZIER W G, PRASAD Y V R K. Hot deformation and microstructural damage mechanisms in extra-low interstitial (ELI) grade Ti-6Al-4V[J]. Mater Sci Eng A,2000, 279(1/2): 289-299

[5] SAUER C, L?TJERING G. Influence of α layers at β grain boundaries on mechanical properties of Ti-alloys[J]. Mater Sci Eng A, 2001, 319/321: 393-397.

[6] SINHA V, SOBOYEJO W O. An investigation of the effects of colony microstructure on fatigue[J]. Mater Sci Eng A, 2001, 319/321: 607-612

[7] CAO Chun-xiao. Change of material selection criterion and development of high damage-tolerant titanium alloy[J]. Acta Metallurgica Sinica, 2002, 38(suppl): 4-11.

[8] SEMIATIN S L, SEETHARAMAN V, WEISS I. Hot workability of titanium and titanium aluminide alloy-an overview[J]. Mat Sci Eng A,1998, 243: 1-24.

[9] ARI-GUR P, SEMIATIN S L. Evolution of microstructure macrotexture and microtexture during hot rolling of Ti-6Al-4V[J]. Mat Sci Eng A, 1998, 257: 118-127.

[10] SEMIATIN S L, THOMAS J F Jr, DADRAS P. Processing- microstructure relation-ships for Ti-6Al-2Sn-4Zr-2Mo-0.1Si[J]. Metall Trans A, 1983, 14: 2363-2374.

[11] KUBIAK K, SIENIAWSKI J. Development of the microstructure and fatigue strength of two phase titanium alloys in the processes of forging and heat treatment[J]. Journal of Materials Processing Technology, 1998, 78: 117-121.

[12] JONO M, SUGETA A. Crack closure and effect of load variation on small fatigue crack growth behaviour[J]. Fatigue & Fracture of Engineering Materials & Strictires, 1996, 19(2/3): 165-174.

[13] L?TJERING G. Influence of processing on microstructure and mechanical properties of (α+β) titanium alloys[J]. Mater Sci Eng A, 1998, 243: 32-45.

[14] NAKAJIMA K, TERAO K, MIYATA T. The effect of microstructure on fatigue crack propagation of α+β titanium alloys In-situ observation of short fatigue crack growth[J]. Mater Sci Eng A, 1998, A243: 176-181.

[15] SINHA V, SOBOYEJO W O. An investigation of the effects of colony microstructure on fatigue crack growth in Ti-6Al-4V[J]. Mater Sci Eng A, 2001, 319/321: 607-612.

[16] YODER G R, COOLEY Y A, CROOKER T W. Quantitative analysis of microstructural effects on fatigue crack growth in widmanstatter Ti-4Al-4V and Ti-8Al-1Mo-1V[J]. Engineering Fracture Mechanixs, 1979, 11: 805-816.

[17] DOWSON A L, HOLLIS A C. The effect of the alpha phase volume fraction and stress ratio on the fatigue crack growth characteristics of the near-alpha IMI834 Ti alloy[J]. Int J Fatigue, 1992, 14(4): 261-270.

[18] LUTJERING G, GYSLER A, ALBRECHT J. Influence of microstructure on fatigue resistance[C]//FATIGUE’96, EMAS, 1996: 893-904.

[19] AKAHORI T, NIINOMI M, FUKUNAGA K I, INAGAKI I. Effects of microstructure on the short fatigue crack initiation and propagation characteristics of biomedical α+β titanium alloys[J]. Metall Mater Trans A, 2000, A31(8):1949-1958.

[20] SESHACHARYULU T, MEDEIROS S C, FRAZIER W G, et al. Microstructural mechanisms during hot working of commercial grade Ti-6Al-4V with lamellar starting structure[J]. Mater Sci Eng A, 2002, 325: 112-125.

[21] SAXENA V K, RADHAKRISHNAN V M. Effect of phase morphology on fatigue crack growth behavior of α+β titanium alloy-a crack closure rationale[J]. Metallurgical and Materials Trans A, 1998, 29(1): 245-261.

[22] PETERS J O, L?TJERING G. Comparison of the fatigue and fracture of α+β and β titanium alloys[J]. Metallurgical and Materials Transactions, 2001, A32(11): 2805-2818.

[23] IVASISHIN O M, SEMIATIN S L, MARKOVSKY P E, et al. Grain growth and texture evolution in Ti-6Al-4V during beta annealing under continuous heating conditions[J]. Mater Sci Eng A, 2002, A337: 88-96.

Corresponding author: FAN Rong-hui; Tel: +86-10-82241297; Fax: +86-10-62012579; E-mail: fan_ronghui@yahoo.com.cn

(Edited by CHEN Ai-hua)