挤压态Mg–Dy–Zn合金板材的压缩各向异性

来源期刊:中国有色金属学报(英文版)2016年第2期

论文作者:罗晓梅 毕广利 姜静 李明 李荣广 李元东 马颖 郝远

文章页码:390 - 397

关键词:Mg-Dy-Zn合金;显微组织;织构;LPSO相;压缩各向异性

Key words:Mg-Dy-Zn alloy; microstructure; texture; LPSO phase; compressive anisotropy

摘 要:研究挤压态Mg-2Dy-0.5Zn (摩尔分数,%)合金板材的压缩各向异性。合金主要由α-Mg、(Mg, Zn)xDy 相和大量沿挤压方向分布的长周期有序堆垛(LPSO)结构相组成。压缩实验测试结果表明,合金呈明显的压缩各向异性。平行于挤压方向(ED)合金试样的压缩强度显著高于板材横向(TD)及与挤压方向成45°角的合金试样的压缩强度。ED方向合金试样的压缩屈服强度(CYS)、最大压缩强度(UCS)和压缩应变分别为274.65 MPa, 518.94 MPa 和12.93%。合金压缩各向异性主要与LPSO相的分布以及变形晶粒中 //ED类型织构的形成有关。

Abstract: Compressive anisotropy of extruded Mg-2Dy-0.5Zn (mole fraction, %) alloy sheet was investigated. The alloy sheet was mainly composed of α-Mg, (Mg, Zn)xDy phase and a large number of long period stacking ordered (LPSO) phases distributed along the extrusion direction. The compressive experimental results show that the alloy sheet exhibits an obvious compressive anisotropy. The compressive strength of the specimen in the extrusion direction (ED) is higher than those of the specimens in the transverse direction (TD) and 45° inclined to the extrusion direction. The compressive yield strength (CYS), ultimate compressive strength (UCS) and compressive strain of the specimen in the ED are 274.65 MPa, 518.94 MPa and 12.93%, respectively. The compressive anisotropy is mainly attributed to the distribution of LPSO phase and formation of fiber texture in the deformed grains.

Trans. Nonferrous Met. Soc. China 26(2016) 390-397

Xiao-mei LUO1,2, Guang-li BI1,2, Jing JIANG1,2, Ming LI1,2, Rong-guang LI3, Yuan-dong LI1,2, Ying MA1,2, Yuan HAO1,2

1. State Key Laboratory of Advanced Processing and Recycling of Nonferrous Metals, Lanzhou University of Technology, Lanzhou 730050, China;

2. Key Laboratory of Nonferrous Metal alloys and Processing, Ministry of Education, Lanzhou University of Technology, Lanzhou 730050, China;

3. School of Mechanical Engineering, Shenyang University of Chemical Technology, Shenyang 110142, China

Received 25 March 2015; accepted 17 November 2015

Abstract: Compressive anisotropy of extruded Mg-2Dy-0.5Zn (mole fraction, %) alloy sheet was investigated. The alloy sheet was mainly composed of α-Mg, (Mg, Zn)xDy phase and a large number of long period stacking ordered (LPSO) phases distributed along the extrusion direction. The compressive experimental results show that the alloy sheet exhibits an obvious compressive anisotropy. The compressive strength of the specimen in the extrusion direction (ED) is higher than those of the specimens in the transverse direction (TD) and 45° inclined to the extrusion direction. The compressive yield strength (CYS), ultimate compressive strength (UCS) and compressive strain of the specimen in the ED are 274.65 MPa, 518.94 MPa and 12.93%, respectively. The compressive anisotropy is mainly attributed to the distribution of LPSO phase and formation of  fiber texture in the deformed grains.

fiber texture in the deformed grains.

Key words: Mg-Dy-Zn alloy; microstructure; texture; LPSO phase; compressive anisotropy

1 Introduction

Magnesium alloys have attracted considerable interest due to their low density, high specific strength and stiffness [1-3]. However, the tensile strength of conventional magnesium alloys is relatively low compared with that of other metallic materials, such as Al and Fe alloys. It is reported that the addition of rare earth (RE) elements could effectively enhance the high-temperature tensile strength of Mg-RE alloy by precipitation strengthening from some strengthening phases, such as β' (cbco) and β'' (DO19) phases [4]. Moreover, a long period stacking ordered (LPSO) phase has been proposed as a new strengthening phase in Mg-RE-Zn alloy. The LPSO phase has high hardness, excellent plasticity and good coherent interface with Mg matrix [5,6]. The Mg-RE-Zn alloys containing LPSO phase fabricated by extrusion, rolling and forging exhibit a good combination of tensile strength and ductility at room and elevated temperatures [7-10]. Although the above hot working process could significantly refine grain, disperse LPSO phase and further enhance mechanical properties, the formation of texture, mechanical anisotropy and yield asymmetry limit the development and application of Mg alloy sheet.

Therefore, mechanical anisotropy of Mg alloys, besides their hexagonal structure, is mainly related to their texture and microstructure. The previous literatures have demonstrated that the addition of RE elements could not only weaken texture, but also enhance mechanical properties of the alloy by solution strengthening, grain refinement and precipitating strengthening [11-14]. However, the preferred orientation of a large number of strengthening phases containing those elements also results in mechanical anisotropy. Recently, the mechanical anisotropy of Mg alloys containing LPSO phase has been widely investigated [11,15-17]. The preferred orientation of LPSO phase in Mg matrix causes the formation of mechanical anisotropy. The investigation of HAN et al [11] indicated that the compressive strength of the extruded Mg-10Gd-2Y-0.5Zn-0.3Zr alloy specimen with 0°orientation is higher than that of specimen with 45° orientation due to difficult shear deformation across LPSO phase. The similar results are also obtained in extruded Mg-9RY-4Zn (RY: Y-rich misch metal) alloy [15] and Mg-7Y-5Zn (mole fraction, %) alloy [16]. However, there are few reports on the mechanical anisotropy of Mg-Dy-Zn alloy containing LPSO phase.

Therefore, in this paper, an extruded Mg-2Dy-0.5Zn (mole fraction, %) alloy sheet was prepared, the compressive anisotropy of the alloy sheet was investigated, and the corresponding effect of LPSO phase on compressive anisotropy of the extruded alloy was also discussed.

2 Experimental

The experimental Mg-2Dy-0.5Zn alloy sheet was prepared from pure Mg, Zn and Mg-20%Dy (mass fraction) master alloy in a graphite crucible under an anti-oxidizing flux. The melts were homogenized at 750 °C for 0.5 h and then poured into a water-cooling mould at 720 °C. The ingot was homogenized at 525 °C for 10 h and extruded into a sheet with a width of 50 mm and a thickness of 7 mm. The extrusion process with extrusion ratio of 17:1 was carried out at 360 °C and a heating speed of 3 mm/s.

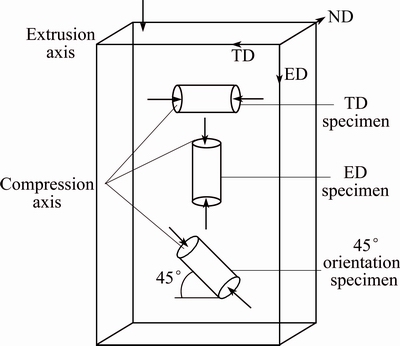

The microstructure, phase structure and composition of the extruded alloy sheet were characterized by optical microscopy (OM) (Olympus GX71), scanning electron microscopy (SEM) (JSM-5600) with energy dispersive X-ray spectroscopy (EDS). Specimens for microstructure observations were firstly ground on 400, 600, 800 and 1000 grit SiC papers and etched after polishing in a solution of picric and 2% nitric acid for about 50 s. Texture measurements were executed on a Rigaku D/max 2500 PC X-ray diffractometer with Cu Kα radiation. The specimens for texture examination were ground on 2000 grit SiC paper, and then polished mechanically. Compressive tests were carried out in an Instron-type tensile testing machine (Instron 1211) at room temperature with a strain rate of 1×10-1 s-1. In order to analyze the compressive anisotropy of the alloy sheet, the cylindrical specimens with sizes of 6 mm in diameter and 12 mm in length were cut from the alloy sheet using electric spark linearly cutting along the extrusion direction (denoted as ED specimen), across the extrusion direction (denoted as TD specimen), and 45° inclined to the extrusion direction (denoted as 45° orientation specimen), respectively, as shown in Fig. 1. In addition, ED, TD and ND (normal direction) of extruded alloy sheet were denoted in Fig. 1. The lateral and fracture surfaces of compressive specimens were also observed by SEM.

3 Results

3.1 Microstructures

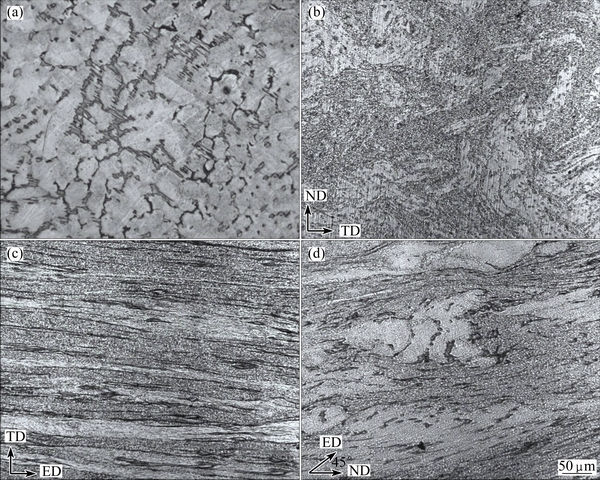

Figure 2 shows the optical microstructures of Mg-2Dy-0.5Zn alloy in the as-cast and extruded states. According to our previous investigations [8,18,19], the as-cast alloy consists of α-Mg dendrite, reticular Mg8ZnDy phase, cubic Mg2Dy phase and lamellar 18R type LPSO phase distributed along the dendrite boundary (see Fig. 1(a) in Ref. [19]. During the high-temperature homogenization (525 °C, 10 h) before hot extrusion, parts of lamellar 18R type LPSO phases transfer into the fine stripe-like 14H type phases in the grain interior and some fine (Mg, Zn)xDy phases precipitate in the Mg matrix [8]. In addition, sufficient dynamic recrystallization (DRX) occurs in the ED, TD and 45° direction, as shown in Figs. 2(b), (c) and (d), respectively. The DRX regions mainly distribute along the lamellar 18R LPSO phase because the LPSO phase could act as an effective nucleation site. These different distributions of DRX grains also suggest that the LPSO phase behaves as different orientations along the ED, TD and 45° direction. The grains are obviously refined due to the occurrence of DRX during extrusion process. The average grain size is about 3 μm [8,14,18].

Fig. 1 Specimen orientations with respect to extruded sheet geometry

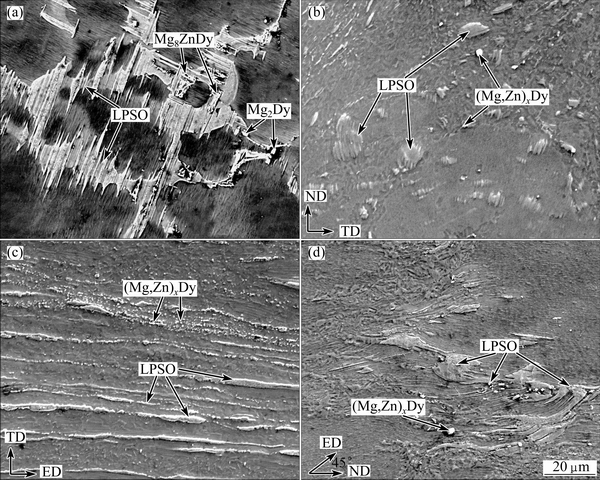

By careful observation in Fig. 3(a), the lamellar 18R type LPSO phase and small amounts of Mg8ZnDy and Mg2Dy particles precipitate at the dendrite grain boundary. After extrusion, these particles are crushed and dispersedly distribute in the Mg matrix. It is worth noting that the 18R type LPSO phase arranges along the ED and parallels to each other, as seen in Fig. 3(c), whereas the phase randomly distributes in α-Mg matrix and parts of them occur to bend in the TD and 45° direction, as shown in Fig. 3(b) and (d), respectively. For Fig. 3(b), the ED is perpendicular to the paper. These different distributions of LPSO phase in α-Mg matrix along the ED, TD and 45° direction suggest that the alloy would exhibit the compressive anisotropy.

Fig. 2 Optical microstructures of as-cast alloy (a) and extruded alloy sheet in TD (b), ED (c) and 45° direction (d)

Fig. 3 SEM images of as-cast alloy (a) and extruded alloy sheet in TD (b), ED (c) and 45° direction (d)

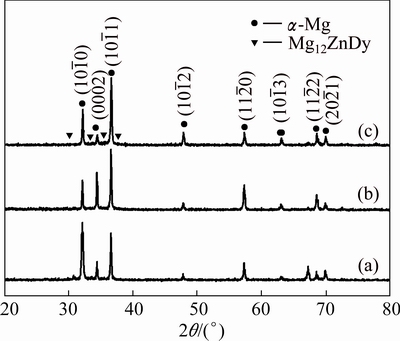

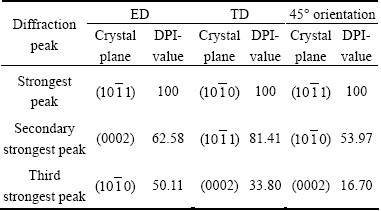

Figure 4 displays the XRD patterns of extruded alloys in the ED, TD and 45° direction, respectively. The corresponding diffraction peak intensity (DPI) of α-Mg is shown in Table 1. It can be seen that the alloy is mainly composed of diffraction peaks of α-Mg and LPSO phase. The diffraction peaks of Mg8ZnDy and Mg2Dy phases are not indexed due to their small amount. It is noted that the DPI-values of  , (0002) and

, (0002) and  crystal planes of α-Mg vary with the orientation of alloy. The DPI-values of (0002) plane in the ED, TD and 45° direction are 62.58, 33.80 and 16.70, respectively (see Table 1). The DPI-value of (0002) plane in the ED is the highest, indicating that (0002) crystal planes of most grains have a trend parallel to the ED of as-extruded alloy after hot extrusion [15]. In the same way, the

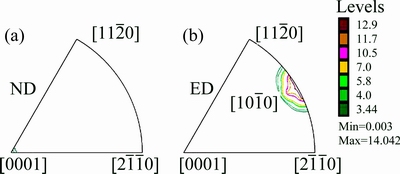

crystal planes of α-Mg vary with the orientation of alloy. The DPI-values of (0002) plane in the ED, TD and 45° direction are 62.58, 33.80 and 16.70, respectively (see Table 1). The DPI-value of (0002) plane in the ED is the highest, indicating that (0002) crystal planes of most grains have a trend parallel to the ED of as-extruded alloy after hot extrusion [15]. In the same way, the  plane of most grains is parallel to the TD of as-extruded alloy. Figure 5 shows the inverse pole figures (IPFs) of alloy referring to the normal direction (ND) and ED. The component of

plane of most grains is parallel to the TD of as-extruded alloy. Figure 5 shows the inverse pole figures (IPFs) of alloy referring to the normal direction (ND) and ED. The component of  //ED is dominant fiber texture with a maximum intensity of 14.042. The texture is a typical fiber texture of Mg alloy resulted from an extrusion deformation [20,21]. YAMASAKI et al [22] have reported that the deformed grains in Mg97Zn1Y2 alloy show a strong fiber texture with the basal plane parallel to the ED. Therefore, for the present alloy sheet, the fiber texture mainly arises from a large amount of deformed grains [17,22].

//ED is dominant fiber texture with a maximum intensity of 14.042. The texture is a typical fiber texture of Mg alloy resulted from an extrusion deformation [20,21]. YAMASAKI et al [22] have reported that the deformed grains in Mg97Zn1Y2 alloy show a strong fiber texture with the basal plane parallel to the ED. Therefore, for the present alloy sheet, the fiber texture mainly arises from a large amount of deformed grains [17,22].

Fig. 4 XRD patterns of extruded alloy sheet in TD (a), ED (b) and 45° direction (c)

Table 1 XRD analysis of strong diffraction peaks of extruded alloy sheets

Fig. 5 Inverse pole figures of extruded alloy sheet referring to normal direction (ND) (a) and extrusion direction (ED) (b)

3.2 Compressive properties

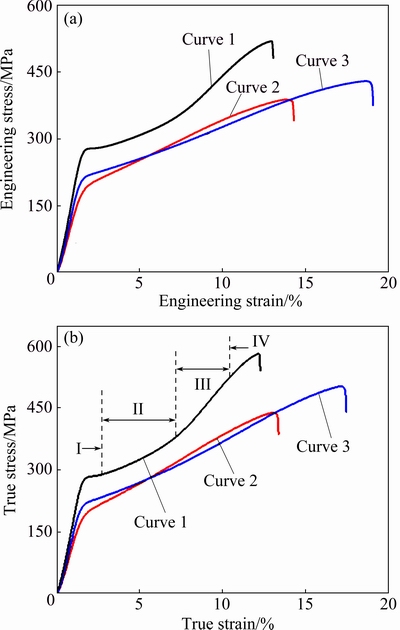

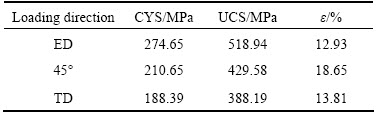

Figure 6(a) shows typical engineering compressive stress-strain curves of extruded alloy sheet in three different directions. The corresponding compressive yield strength (CYS), ultimate compressive strength (UCS) and elongation (ε) are listed in Table 2. It can be seen from Fig. 6(a) and Table 2 that the compressive strength varies with different orientations of compressive specimen. The alloy exhibits an obvious compressive anisotropy. The CYS and UCS of the alloy sheet in the ED are higher than those of alloy in the TD and 45° direction. The values of CYS, UCS and ε of the alloy in the ED are 274.65 MPa, 518.94 MPa and 12.93%, respectively.

Fig. 6 Engineering compressive stress-strain (a) and true stress-strain (b) curves of extruded alloy sheet in ED (Curve 1), TD (Curve 2) and 45° direction (Curve 3), respectively

Table 2 Room-temperature compressive mechanical properties in three orientation specimens of extruded alloy sheet

Additionally, it can be seen from the true stress- strain curves (see Fig. 6(b)) that the alloy sheet in the ED exhibits more obvious work hardening behavior than that in the TD and 45° direction. Interestingly, an S-shape strain hardening response only occurs in the ED as compared with other two directions. Generally, the occurrence of the hardening response is mainly related to the formation of twining. The similar experimental results are also reported in other Mg alloys [23,24].

3.3 Surface and fracture observation

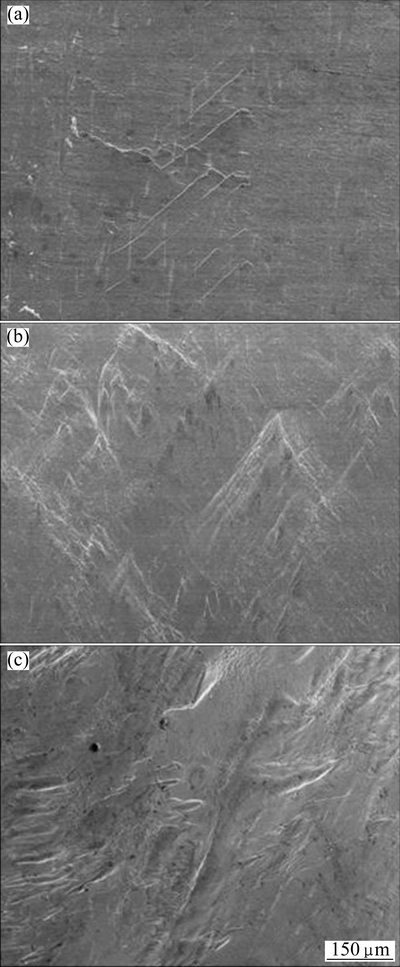

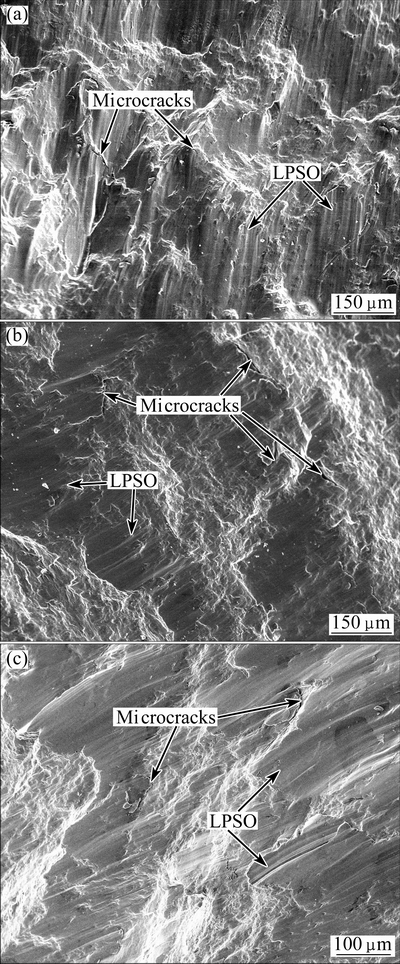

Extensive slip bands throughout the entire lateral surface are observed for the three compressive samples as shown in Fig. 7. Parts of slip bands are parallel to each other, intersect and form a 45° angle with its loading axis in the ED specimen (see Fig. 7(a)). These slip bands also appear on lateral surface of compressive sample in the TD and 45° direction (see Figs. 7(b) and (c)). In addition, there are plentiful convex shape kinks present in the 45° specimens (Fig. 7(c)). Figure 8 shows the fracture morphologies of compressive specimens in the ED, TD and 45° direction, which could provide partial explanations of different compressive strains in the three directions. A great number of shining tearing ridges and cleavage planes could be observed in fracture surface, which suggests that the alloy suffers relatively large plastic deformation before the compressive fracture. Some cracks form at the interface between α-Mg matrix and LPSO phase for the compressive specimens in the ED and TD (Figs. 8(a) and (b)). The formation of these cracks is related to a large stress concentration [14]. Bent LPSO phases with some kinks are observed on fracture surface as shown in Fig. 8(c).

4 Discussion

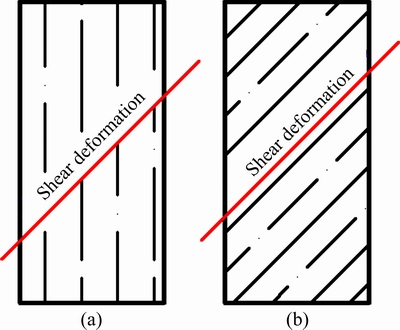

The compressive anisotropy of the extruded alloy sheet during compressive test in the TD, ED and 45° direction is mainly related to the texture of α-Mg grains and the distribution of lamellar LPSO phase. The grain orientation and distribution of LPSO phase vary in the above three directions. Firstly, as for lamellar LPSO phase, it is noted that most lamellar LPSO phases distribute along the ED as shown in Figs. 2 and 3. The affecting modes of the phase on compressive properties in the ED and 45° direction are shown in Fig. 9. It can be seen that the phase is more difficult to be sheared in the ED as compared with that in the 45° direction. The strengthening role of the phase in the ED is similar to that of fiber in composite materials. During compression, the load would transfer from the soft α-Mg matrix to the hard LPSO phase. Therefore, the LPSO phase in the ED also occurs to deform during compression, whose deformation mode is mainly  basal slip [21,25,26]. According to the previous investigations [25,27,28], the LPSO phase is in hard orientation in the ED due to small Schmid factor (SF) [28]. The activity of the basal slip is more difficult for the phase in the ED than TD and 45° direction, hence, the higher UCS and YCS of the alloy in the ED are obtained (see Fig. 6). Conversely, the shear deformation is easy to occur across the phase in the 45°direction [11,15]. Thus, the strengthening role of LPSO phase is small, the main strengthening role arises from strengthening of α-Mg matrix with nanometer between two LPSO phases [15,29].

basal slip [21,25,26]. According to the previous investigations [25,27,28], the LPSO phase is in hard orientation in the ED due to small Schmid factor (SF) [28]. The activity of the basal slip is more difficult for the phase in the ED than TD and 45° direction, hence, the higher UCS and YCS of the alloy in the ED are obtained (see Fig. 6). Conversely, the shear deformation is easy to occur across the phase in the 45°direction [11,15]. Thus, the strengthening role of LPSO phase is small, the main strengthening role arises from strengthening of α-Mg matrix with nanometer between two LPSO phases [15,29].

Fig. 7 SEM images of lateral surface of compressive specimens of extruded alloy sheet in ED (a), TD (b) and 45° direction (c)

Fig. 8 Fracture morphologies of compressive specimens of extruded alloy sheet in ED (a), TD (b) and 45° direction (c)

Fig. 9 Affecting modes of lamellar LPSO phase on compressive mechanical properties in ED (a) and 45° direction (b)

Additionally, the LPSO phase in the 45° direction is in the soft orientation. The typical kinking forms on the later surface of compressive specimen (see Fig. 7(c)). The formation of the kinking could inhibit the crack propagation, thus improving the ductility of alloy [16,29]. The corresponding ductile fracture also reflects good compressive strain for the alloy sheet in the 45° direction (see Fig. 8(c)). The alloy exhibits higher UCS and YCS in the ED and good compressive strain in the 45° direction (see Fig. 6). Secondly, most α-Mg deformed grains exhibit a typical  //ED fiber texture according to the IPFs in Fig. 5. Those grains are in hard orientation where the basal slip is difficult to operate in the ED and TD due to its small Schmid factor [21,22]. Therefore, in order to better deform, twinning and some latent non-basal slip systems should be activated, such as prismatic and pyramidal slips. The corresponding slip lines in Fig. 7 also conform that the non-basal slip systems are activated. The S-shape plastic stress-strain curve in the ED should be related to the formation of twinning. The deformation mode can be classified into four stages with different strain-hardening rates (SHRs) as seen in Fig. 6(b). At stage I, the SHR initially decreases up to about 2.5%. This mainly arises from the predominant basal slip over extension twinning. At stage II, the SHR slowly increases in a strain range from 2.5% to 7.2%, and the extensive twinning rapidly increases before it begins to coarsen with increasing strain. The whole deformation is accommodated by the extension twining [30,31]. At stage III, the SHR rapidly increases in a strain range from 7.2% to 10.4%, where the slip dominance within twins plays a role in increasing SHR. At stage IV, the SHR gradually decreases after a strain of 10.4% and finally rupture. This is attributed to the double-twining of extension twining. Therefore, the plastic stress-strain curve shows an S-shape in the ED [23,24]. Conversely, the basal slip is easy to be activated in the 45° direction due to its large Schmid factor. In addition, the alloy in the 45° direction also exhibits high compressive strength due to the strengthening role of fine stripe-like LPSO phase in α-Mg DRX grains through blocking dislocation movements.

//ED fiber texture according to the IPFs in Fig. 5. Those grains are in hard orientation where the basal slip is difficult to operate in the ED and TD due to its small Schmid factor [21,22]. Therefore, in order to better deform, twinning and some latent non-basal slip systems should be activated, such as prismatic and pyramidal slips. The corresponding slip lines in Fig. 7 also conform that the non-basal slip systems are activated. The S-shape plastic stress-strain curve in the ED should be related to the formation of twinning. The deformation mode can be classified into four stages with different strain-hardening rates (SHRs) as seen in Fig. 6(b). At stage I, the SHR initially decreases up to about 2.5%. This mainly arises from the predominant basal slip over extension twinning. At stage II, the SHR slowly increases in a strain range from 2.5% to 7.2%, and the extensive twinning rapidly increases before it begins to coarsen with increasing strain. The whole deformation is accommodated by the extension twining [30,31]. At stage III, the SHR rapidly increases in a strain range from 7.2% to 10.4%, where the slip dominance within twins plays a role in increasing SHR. At stage IV, the SHR gradually decreases after a strain of 10.4% and finally rupture. This is attributed to the double-twining of extension twining. Therefore, the plastic stress-strain curve shows an S-shape in the ED [23,24]. Conversely, the basal slip is easy to be activated in the 45° direction due to its large Schmid factor. In addition, the alloy in the 45° direction also exhibits high compressive strength due to the strengthening role of fine stripe-like LPSO phase in α-Mg DRX grains through blocking dislocation movements.

5 Conclusions

1) Mg-2Dy-0.5Zn alloy sheet is mainly composed of α-Mg, (Mg, Zn)xDy and a large number of lamellar LPSO phases distributed along the ED. Sufficient DRX of the alloy occurs after extrusion and parts of DRX grains contain fine stripe-like shape LPSO phase.

2) The alloy sheet exhibits an obvious compressive anisotropy in the ED, TD and 45° direction. The YCS, UCS and ε are 274.65 MPa, 518.94 MPa and 12.93% in the ED, and 188.39 MPa, 388.19 MPa and 13.81% in the TD, 210.65 MPa, 429.58 MPa and 18.65% in the 45° direction after compressive tests, respectively.

3) The compressive anisotropy is mainly attributed to the distribution of LPSO phase and formation of  //ED fiber texture in the deformed grains.

//ED fiber texture in the deformed grains.

References

[1] MORDIKE B, EBERT T. Magnesium: Properties-applications- potential [J]. Materials Science and Engineering A, 2001, 302: 37-45.

[2] PENG Q M, DONG H W, WANG L D, WU Y M, WANG L M. Microstructure and mechanical property of Mg-8.31Gd- 1.12Dy-0.38Zr alloy [J]. Materials Science and Engineering A, 2008, 477: 193-197.

[3] ZHANG J, LENG Z, LIU S, LI J, ZHANG M, WU R. Microstructure and mechanical properties of Mg-Gd-Dy-Zn alloy with long period stacking ordered structure or stacking faults [J]. Journal of Alloys and Compounds, 2011, 509: 7717-7722.

[4] GAO X, HE S, ZENG X, PENG L, DING W, NIE J. Microstructure evolution in a Mg-15Gd-0.5Zr (wt.%) alloy during isothermal aging at 250 °C [J]. Materials Science and Engineering A, 2006, 431: 322-327.

[5] ONO A, ABE E, ITOI T, HIROHASHI M, YAMASAKI M, KAWAMURA Y. Microstructure evolutions of rapidly-solidified and conventionally-cast Mg97Zn1Y2 alloys [J]. Materials Transactions, 2008, 49: 990-994.

[6] LEE J, SATO K, KONNO T J, HIRAGA K. Stabilization of stacking faults and a long period stacking phase dispersed in α-Mg crystalline grains of Mg-0.7at%Zn-1.4at%Y alloy [J]. Materials Transactions, 2009, 50: 222-225.

[7] ZHANG L, ZHANG J, LENG Z, LIU S, YANG Q, WU R, ZHANG M L. Microstructure and mechanical properties of high-performance Mg-Y-Er-Zn extruded alloy [J]. Materials & Design, 2014, 54: 256-263.

[8] BI G L, FANG D Q, ZHAO L, LIAN J S, JIANG Q, JIANG Z H. An elevated temperature Mg-Dy-Zn alloy with long period stacking ordered phase by extrusion [J]. Materials Science and Engineering A, 2011, 528: 3609-3614.

[9] ITOI T, INAZAWA T, YAMASAKI M, KAWAMURA Y, HIROHASHI M. Microstructure and mechanical properties of Mg-Zn-Y alloy sheet prepared by hot-rolling [J]. Materials Science and Engineering A, 2013, 560: 216-223.

[10] NODA M, MATSUMOTO R, KAWAMURA Y. Forging induces changes in the formability and microstructure of extruded Mg96Zn2Y2 alloy with a long-period stacking order phase [J]. Materials Science and Engineering A, 2013, 563: 21-27.

[11] HAN X, XU W, YUAN L, SHAN D. The influences of long period stacking order phase and texture on compressive behavior of an extruded magnesium alloy [J]. Materials Science and Engineering A, 2013, 568: 246-255.

[12] CHINO Y, KADO M, MABUCHI M. Enhancement of tensile ductility and stretch formability of magnesium by addition of 0.2 wt%(0.035 at%) Ce [J]. Materials Science and Engineering A, 2008, 494: 343-349.

[13] ZOU G, CAI X, FANG D, WANG Z, ZHAO T, PENG Q. Age strengthening behavior and mechanical properties of Mg-Dy based alloys containing LPSO phases [J]. Materials Science and Engineering A, 2015, 620: 10-15.

[14] BI G L, LI Y D, HUANG X F, CHEN T J, LIAN J S, JIANG Z H, MA Y, HAO Y. Deformation behavior of an extruded Mg-Dy-Zn alloy with long period stacking ordered phase [J]. Materials Science and Engineering A, 2015, 622: 52-60.

[15] LENG Z, ZHANG J, CUI C, SUN J, LIU S, WU R, ZHANG M. Compression properties at different loading directions of as-extruded Mg-9RY-4Zn (RY: Y-rich misch metal) alloy with long period stacking ordered phase [J]. Materials & Design, 2013, 51: 561-566.

[16] GARCES G,  M, MORRIS D, JIMENEZ J, PEREZ P, ADEVA P. The role of extrusion texture on strength and its anisotropy in a Mg-base alloy composed of the long-period- structural-order phase [J]. Intermetallics, 2014, 55: 167-176.

M, MORRIS D, JIMENEZ J, PEREZ P, ADEVA P. The role of extrusion texture on strength and its anisotropy in a Mg-base alloy composed of the long-period- structural-order phase [J]. Intermetallics, 2014, 55: 167-176.

[17] JONO Y, YAMASAKI M, KAWAMURA Y. Effect of LPSO phase-stimulated texture evolution on creep resistance of extruded Mg-Zn-Gd alloys [J]. Materials Transactions, 2013, 54: 703-712.

[18] BI G L, FANG D Q, ZHANG W C, SUDAGAR J, ZHANG Q X, LIAN J S, JIANG Z H. Microstructure and mechanical properties of an extruded Mg-2Dy-0.5 Zn alloy [J]. Journal of Materials Science and Technology, 2012, 28: 543-551.

[19] BI G L, FANG D Q, ZHAO L, ZHANG Q X, LIAN J S, JIANG Q, JIANG Z H. Double-peak ageing behavior of Mg-2Dy-0.5 Zn alloy [J]. Journal of Alloys and Compounds, 2011, 509: 8268-8275.

[20] LI R G, ZHANG H J, FU G Y. Microstructure and mechanical properties of extruded Mg96Zn1Y3 alloy [J]. Materials Characterization, 2014, 98: 107-112.

[21] HAGIHARA K, KINOSHITA A, SUGINO Y, YAMASAKI M, KAWAMURA Y, YASUDA H, UMAKOSHI Y. Plastic deformation behavior of Mg97Zn1Y2 extruded alloys [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(7): 1259-1268.

[22] YAMASAKI M, HASHIMOTO K, HAGIHARA K, KAWAMURA Y. Effect of multimodal microstructure evolution on mechanical properties of Mg-Zn-Y extruded alloy [J]. Acta Materialia, 2011, 59: 3646-3658.

[23] KABIRIAN F, KHAN A S,  T. Visco-plastic modeling of mechanical responses and texture evolution in extruded AZ31 magnesium alloy for various loading conditions [J]. International Journal of Plasticity, 2015, 68: 1-20.

T. Visco-plastic modeling of mechanical responses and texture evolution in extruded AZ31 magnesium alloy for various loading conditions [J]. International Journal of Plasticity, 2015, 68: 1-20.

[24] MA Q, EL-KADIRI H, OPPEDAL A L, BAIRD J C, LI B, HORSTEMEYER M F, VOGEL S C. Twinning effects in a rod-textured AM30 magnesium alloy[J]. International Journal of Plasticity, 2013, 29: 60-76.

[25] HAGIHARA K, YOKOTANI N, UMAKOSHI Y. Plastic deformtion behavior of Mg12YZn with 18R long-period stacking ordered structure [J]. Intermetallics, 2010, 18: 267-276.

[26] HAGIHARA K, SUGINO Y, FUKUSUMI Y, UMAKOSHI Y, NAKANO T. Plastic deformation behavior of Mg12ZnY LPSO-phase with 14H-typed structure [J]. Materials Transactions, 2011, 52: 1096-1103.

[27] HAGIHARA K, FUKUSUMI Y, YAMASAKI M, NAKANO T, KAWAMURA Y. Non-basal slip systems operative in Mg12ZnY long-period stacking ordered (LPSO) phase with 18R and 14H structures [J]. Materials Transactions, 2013, 54: 693-697.

[28] WAN G, WU B L, ZHANG Y D, SHA G Y, ESLING C. Anisotropy of dynamic behavior of extruded AZ31 magnesium alloy [J]. Materials Science and Engineering A, 2010, 527: 2915-2924.

[29] SHAO X, YANG Z, MA X. Strengthening and toughening mechanisms in Mg-Zn-Y alloy with a long period stacking ordered structure [J]. Acta Materialia, 2010, 58: 4760-4771.

[30] JIANG L, JONAS J J, LUO A A, SACHDEV A K, GODET S. Influence of  extension twinning on the flow behavior of AZ31 alloy [J]. Materials Science and Engineering A, 2007, 445-446: 302-309.

extension twinning on the flow behavior of AZ31 alloy [J]. Materials Science and Engineering A, 2007, 445-446: 302-309.

[31] KALIDINDI S R, SALEM A A, DOHERTY R D. Role of deformation twinning on strain hardening in cubic and hexagonal polycrystalline metals [J]. Advanced Engineering Materials, 2003, 5: 229-232.

罗晓梅1,2,毕广利1,2,姜 静1,2,李 明1,2,李荣广3,李元东1,2,马 颖1,2,郝 远1,2

1. 兰州理工大学 省部共建有色金属先进加工与再利用国家重点实验室,兰州 730050;

2. 兰州理工大学 有色金属合金及加工教育部重点实验室,兰州 730050;

3. 沈阳化工大学 机械工程学院,沈阳 110142

摘 要:研究挤压态Mg-2Dy-0.5Zn (摩尔分数,%)合金板材的压缩各向异性。合金主要由α-Mg、(Mg, Zn)xDy 相和大量沿挤压方向分布的长周期有序堆垛(LPSO)结构相组成。压缩实验测试结果表明,合金呈明显的压缩各向异性。平行于挤压方向(ED)合金试样的压缩强度显著高于板材横向(TD)及与挤压方向成45°角的合金试样的压缩强度。ED方向合金试样的压缩屈服强度(CYS)、最大压缩强度(UCS)和压缩应变分别为274.65 MPa, 518.94 MPa 和12.93%。合金压缩各向异性主要与LPSO相的分布以及变形晶粒中 //ED类型织构的形成有关。

//ED类型织构的形成有关。

关键词:Mg-Dy-Zn合金;显微组织;织构;LPSO相;压缩各向异性

(Edited by Wei-ping CHEN)

Foundation item: Projects (51301082, 51464031, 51201158) supported by the National Natural Science Foundation of China

Corresponding author: Guang-li BI; Tel/Fax: +86-931-2973564; E-mail: glbi@163.com

DOI: 10.1016/S1003-6326(16)64127-4