聚合物水泥基复合填缝料浸水后剪切性能

王志航1,白二雷1,许金余1, 2,刘高杰3,朱从进4

(1. 空军工程大学 航空工程学院,陕西 西安,710038;

2. 西北工业大学 力学与土木建筑学院,陕西 西安,710072;

3. 中国海警局直属第三局,广东 广州,510006;

4. 中国人民解放军 94921 部队,福建 晋江,362200)

摘要:针对机场道面填缝料承受剪切荷载与面临浸水作用的实际工作环境,对聚合物水泥基复合填缝料(PCJS)进行浸水试验、干湿循环试验和剪切试验,测试剪切强度、剪切韧度、峰值应变和断裂伸长率等指标,研究PCJS浸水后的剪切性能。结合SEM与MIP试验结果,分析不同浸水时间和干湿循环次数对PCJS微观形貌和孔隙结构的影响。研究结果表明:PCJS持续浸水后剪切性能劣化,浸水1 d时剪切强度损失率为6.64%,剪切韧度保持率为91.14%,峰值应变和断裂伸长率分别增大了11.73%和14.32%。PCJS干湿循环次数较少时(5次和10次),剪切性能优化,当干湿循环次数较多时(15次和20次),剪切性能劣化;水分子促使PCJS内部分子结构发生降解断裂和未水化的水泥发生二次水化反应。持续浸水和干湿循环导致PCJS的微观形貌劣化,裂缝增加,大孔增多,剪切性能劣化;当干湿循环较少时,使得PCJS孔径分布更均匀,平均孔径减小,剪切性能优化。

关键词:填缝料;复合材料;浸水;剪切

中图分类号:TU528 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2021)07-2416-10

Shear performance of polymer cement-based composite joint sealant after immersion in water

WANG Zhihang1, BAI Erlei1, XU Jinyu1, 2, LIU Gaojie3, ZHU Congjin4

(1. School of Aviation Engineering, Air Force Engineering University, Xi′an 710038, China;

2. College of Mechanics and Civil Architecture, Northwest Polytechnic University, Xi′an 710072, China;

3. The Third Bureau of China Maritime Police Bureau, Guangzhou 510006, China;

4. Unit 94921, People's Liberation Army of China, Jinjiang 362200, China)

Abstract: Aiming at the actual working environment where the airport pavement joint sealant was subjected to shear load and facing water immersion, the polymer-cement based composite joint sealant (PCJS) was subjected to water immersion test, dry and wet cycle test and shear test, and by testing the shear strength, shear toughness, peak strain and elongation at break, the shear performance of PCJS after immersion in water was studied. Combined with the results of SEM and MIP experiments, the effects of different immersion time and the number of wet and dry cycles on the microscopic morphology and pore structure of PCJS were analyzed. The results show that the shear performance of PCJS deteriorates after continuous immersion in water. When the immersion time in water is 1 d, the shear strength loss rate is 6.64%, the shear toughness retention rate is 91.14%, and the peak strain and elongation at break increase by 11.73% and 14.32% respectively. When the number of PCJS wet and dry cycles is small (5 times and 10 times), the shear performance is optimized, and when the number of wet and dry cycles is large (15 times and 20 times), the shear performance is deteriorated. Water molecules promote degradation and fracture of the internal molecular structure of PCJS and secondary hydration of unhydrated cement. Continuous water immersion and dry-wet cycles lead to deterioration of PCJS's microscopic appearance, increased cracks, increased macropores, and degraded shear performance. When there are fewer dry-wet cycles, the PCJS pore size distribution is more uniform, the average pore size is reduced, and the shear performance is optimized.

Key words: joint sealant; composite material; water immersion; shear

在机场建设施工中,需要设置各种形式的接缝,减小由温度或湿度变化引起的翘曲或收缩应力,避免水泥混凝土道面板发生破坏[1-3]。而在缝槽内,使用填缝料对接缝进行密封和防水[4-5]。机场运营过程中,在飞机轮载作用下,道面板接缝缝槽产生竖向位移,填缝料受到剪切应力的作用[6]。大量研究和实际经验表明,道面板破坏通常与填缝料失效有关[7-8]。

目前,常用的填缝料有聚氨酯、聚硫和硅酮类[9-11],而研究较多且具有广阔应用前景的是聚合物水泥复合填缝料(PCJS)[12-14]。PCJS是一种通过聚合物与水泥共混,加入无机填料和功能性助剂,经过聚合物成膜和水泥水化的交互反应生成的复合材料,这类材料能够兼具无机水泥基材料耐久性强、强度高、价廉环保与有机聚合物材料黏结强度高、柔韧性好等优点[15-16]。韩思聪等[17]利用苯丙乳液、水泥、填料和助剂制备了一种填缝料,系统研究了填缝料的配比设计。刘高杰等[18]研究了粉液比对苯丙乳液水泥基复合填缝料剪切性能的影响,发现当粉液质量比为0.35~0.40时,填缝料剪切性能最佳。WANG等[19]采用3种外加助剂和纳米氧化铝对苯丙乳液水泥基复合填缝料进行改性,给出了外加助剂和纳米氧化铝的合理掺量。孟博旭等[20]研究了VAE乳胶粉掺量对苯丙乳液水泥基复合填缝料剪切性能的影响,发现乳胶粉的掺加能改善填缝料的剪切性能。彭光等[21]研究了硅烷偶联剂改性PCJS的力学性能及孔隙结构,发现硅烷偶联剂可以细化PCJS孔隙结构,当掺量(质量分数)为0.2%时,PCJS力学性能最佳。

上述已有研究探索了PCJS的制备方法、力学性能和改性机理,为PCJS在机场道面接缝工程中的应用进行了初步验证[22-25]。但是在实际使用过程中,PCJS常需面临复杂多变的环境因素[26]如雨水浸泡与自然风干[27-28]。因此,有必要探索PCJS持续浸水和干湿循环后的性能。

基于填缝料承受剪切荷载与面临浸水作用的实际工作环境,本文作者在已有试验基础上[17-21, 28],通过浸水试验和干湿循环试验对PCJS进行浸水处理,然后采用电子剪切试验设备研究不同浸水时间和干湿循环次数对PCJS剪切性能的影响,并结合SEM试验和MIP试验讨论PCJS浸水后剪切性能变化的微观机理。

1 试验

1.1 试验材料

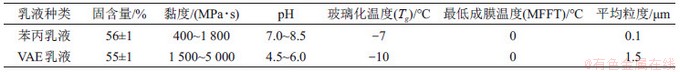

制备PCJS的原材料可分为固体组分和液体组分两大类,固体组分包括水泥和无机填料,液体组分包括聚合物乳液和功能性助剂。聚合物乳液有苯丙乳液和VAE乳液,主要技术指标如表1所示。水泥为陕西蓝田尧柏牌P.O 42.5级水泥,主要技术指标如表2所示。无机填料为滑石粉和重质碳酸钙,功能性助剂为消泡剂、分散剂、成膜助剂、增塑剂以及硅烷偶联剂。

表1 聚合物乳液主要技术指标

Table 1 Main technical indicators of polymer emulsion

表2 水泥主要技术指标

Table 2 Main technical indicators of cement

1.2 试件制备

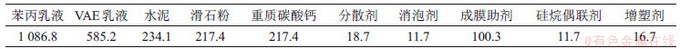

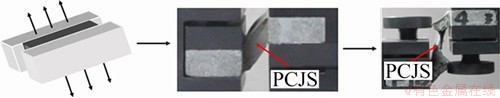

表3所示为聚合物水泥复合填缝料配合比。根据表3所示配合比制备PCJS,然后根据图1所示流程制备PCJS试件。

表3 聚合物水泥复合填缝料配合比

Table 3 Mixture ratio of polymer cement composite joint filler kg/m3

PCJS制备流程如下:1) 将苯丙乳液与VAE乳液边倒入混料机中,搅拌5 min,而后加入分散剂,搅拌均匀,制成聚合物乳液混合液;2) 将消泡剂、增塑剂、硅烷偶联剂和成膜助剂依次加入聚合物乳液混合液,搅拌10 min,制成PCJS液体组分;3) 将滑石粉和重质碳酸钙依次加入水泥中,搅拌均匀,制成PCJS固体组分;4) 将固体组分缓缓加入液体组分中,同时缓慢搅拌,避免固体组分被液体组分包裹成团黏附于混料机内壁或沉淀于底部,再快速搅拌10 min,使固体组分彻底地均匀分散于液体组分中,最终制成PCJS。

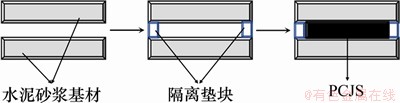

图1 PCJS试件的制备流程

Fig. 1 Preparation processes of PCJS specimen

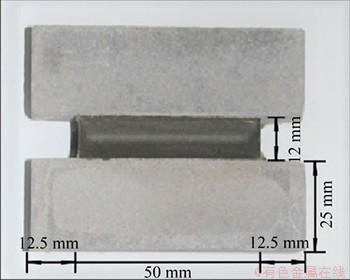

PCJS试件的制备流程如图1所示。具体步骤如下:1) 利用制备好的水泥砂浆试块作为黏结基材,将2块水泥砂浆基材置于试验平台;2) 将隔离垫块置于水泥砂浆基材两端;3) 采用挤出器将新制备的PCJS缓缓地注入水泥砂浆基材与隔离垫块形成的空腔内。标准试验条件养护28 d,制得如图2所示PCJS试件。

图2 PCJS试件

Fig. 2 PCJS test piece

1.3 试验方法

1.3.1 浸水试验

将养护28 d后的PCJS试件在常温下放入水中浸泡,浸泡时间为1,7,15和30 d,浸泡至规定时间后取出,擦干表面水分后立即进行剪切试验。

1.3.2 干湿循环试验

将养护28 d后PCJS试件在常温下放入水中浸泡12 h,再放入干燥箱内烘干12 h,记为1次干湿循环。PCJS试件干湿循环次数为5,10,15和20,干湿循环后立即进行剪切试验。

1.3.3 剪切试验

参考GB/T 13477—2002“建筑密封材料试验方法”与GJB 6951—2010“军用机场水泥混凝土道面接缝材料施工技术规程”对PCJS试件进行剪切试验。采用HS-3001B型电子剪切试验设备对PCJS试件进行剪切试验,将试件装入剪切试验夹具中,采用5 mm/min的剪切速度将PCJS剪切至破坏,在剪切过程中,相应的应力-应变数据由试验设备信息采集终端自动记录。剪切试验示意图如图3所示。

图3 剪切试验示意图

Fig. 3 Schematic diagram of shear test

1.3.4 微观试验

使用COXI EM-30型扫描电镜对试件进行SEM试验,分析PCJS的微观形貌;借助Pore Master-33型压汞仪进行MIP试验,分析PCJS的孔隙结构。微观试验所用试样均取自浸水或干湿循环处理后未进行剪切试验的试件。SEM试验试样取样位置在试件中间。

2 结果与分析

2.1 浸水时间对PCJS剪切性能的影响

PCJS的剪切性能指标包括剪切强度、剪切韧度、峰值应变和断裂伸长率[29-31]。剪切强度是PCJS在剪切荷载作用下应力-应变曲线上的峰值应力,表征PCJS能承受的最大剪切荷载。剪切韧度是PCJS剪切应力-应变曲线与横轴所包含的面积,表征PCJS在整个剪切过程中所吸收的能量。峰值应变和断裂伸长率是PCJS在剪切过程中的变形指标,峰值应变是PCJS达到剪切强度时的应变,断裂伸长率是PCJS剪切破坏时伸长量与原始宽度的比值。

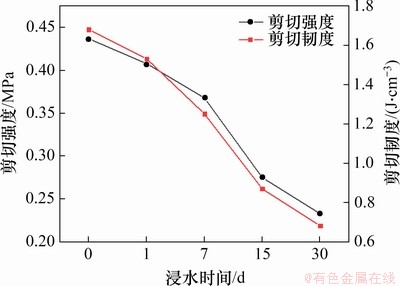

2.1.1 浸水时间对剪切强度和剪切韧度的影响

浸水时间对PCJS剪切强度和剪切韧度的影响规律如图4所示。从图4可以看出:随着浸水时间增加,PCJS的剪切强度和剪切韧度均不断减小,且减小趋势逐渐变缓;当PCJS浸水1 d时,剪切强度损失率为6.64%;当PCJS浸水7 d时,剪切强度损失率达到15.80%,强度损失较小;当浸水时间增加至15 d和30 d时,剪切强度损失率分别为34.25%和46.68%,强度损失较大;当PCJS浸水1,7,15和30 d时,剪切韧度保持率分别为91.14%,74.48%,51.75%和40.57%。PCJS浸水后,剪切强度和剪切韧度下降主要有三方面的原因[32-33]。一是增塑,水分子易与聚合物大分子网络中的极性基团形成氢键,导致聚合物分子之间的氢键和其他次价键被破坏,削弱了分子间的作用力,分子间的相互摩擦力减弱,分子链间距离增大,从而使得聚合物塑性增加,引起复合材料模量下降,进而造成PCJS剪切强度和韧度降低。二是水解,水分子与聚合物大分子中易水解的基团(如酯基、羧基、羟基等)发生化学反应,使聚合物大分子链断裂而水解降解,导致PCJS性能劣化。三是软化和溶胀,水分子进入PCJS内部,使得聚合物分子链柔顺性改变,易引起聚合物的软化和溶胀。因此,在以上作用的综合影响下,随着浸水时间的增加,PCJS浸水后的剪切强度和剪切韧度不断降低。

图4 浸水时间对PCJS剪切强度与剪切韧度的影响

Fig. 4 Effect of immersion time on PCJS shear strength and shear toughness

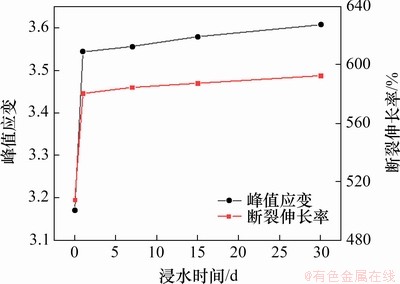

2.1.2 浸水时间对峰值应变和断裂伸长率的影响

浸水时间对PCJS峰值应变和断裂伸长率的影响规律如图5所示。从图5可以看出:PCJS的峰值应变和断裂伸长率随浸水时间的增加而不断增大;当PCJS浸水1 d时,PCJS的峰值应变迅速增大,增大了11.73%,而后随浸水时间的增加缓慢增大;浸水30 d时,PCJS的峰值应变增大13.75%。PCJS断裂伸长率随浸水时间的变化趋势与峰值应变随浸水时间的变化趋势基本一致。浸水1 d和30 d时,PCJS的断裂伸长率分别增大14.32%和16.71%。由于增塑、水解、软化和溶胀三者的共同作用,导致浸水后PCJS内部聚合物分子链变得更加柔软,因此,在受到较小外力后即可产生较大的形变,从而使得PCJS的峰值应变和断裂伸长率随浸水时间的增加而不断增大。

图5 浸水时间对PCJS峰值应变与拉伸断裂伸长率的影响

Fig.5 Effect of water immersion time on PCJS peak strain and tensile elongation at break

2.2 干湿循环对剪切性能的影响

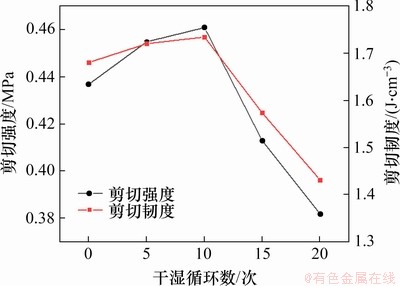

2.2.1 干湿循环次数对剪切强度和剪切韧度的影响

干湿循环次数对PCJS剪切强度和剪切韧度的影响规律如图6所示。从图6可以看出:随着干湿循环次数的增加,PCJS的剪切强度和剪切韧度均呈现先增大后减小的趋势;干湿循环10次时,PCJS的剪切强度和剪切韧度均最大,与干湿循环前相比,分别增大了5.50%和3.21%;干湿循环15次时,PCJS的剪切强度和剪切韧度均比干湿循环前的小;干湿循环30次时,PCJS的剪切强度损失率为12.59%,剪切韧度保持率为85.19%。在干湿循环初期(即干湿循环次数较少时),PCJS内部未水化的水泥与渗入的水分发生二次水化反应[25],因此,PCJS的剪切强度和剪切韧度稍有增大;而随着干湿循环次数的增加,PCJS在干湿环境交替作用下,水浸泡作用导致其内部损伤不断累积,水泥二次水化的增强作用逐渐被水浸泡的削弱作用所掩盖,因此当达到一定干湿循环次数后,PCJS剪切强度和剪切韧度均显著下降。

图6 干湿循环次数对PCJS剪切强度与剪切韧度的影响

Fig.6 Effect of number of dry and wet cycles on shear strength and shear toughness of PCJS

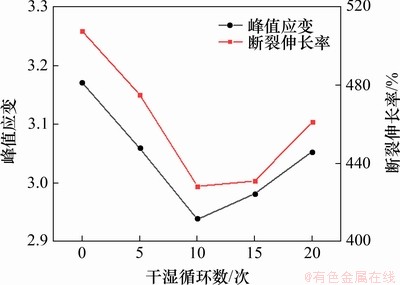

2.2.2 干湿循环次数对峰值应变和断裂伸长率的影响

干湿循环次数对PCJS峰值应变和断裂伸长率的影响规律如图7所示。从图7可以看出:随着干湿循环次数的增加,PCJS峰值应变和断裂伸长率先减小后增大;干湿循环10次时,PCJS峰值应变和断裂伸长率均最小,分别减小了7.35%和15.63%;在干湿循环初期,水泥二次水化的增强作用占主导地位,导致PCJS刚性增大,因此,峰值应变和断裂伸长率减小。在干湿循环后期,水浸泡的削弱作用占据主导,PCJS柔性增强,因此,峰值应变和断裂伸长率增大。

图7 干湿循环次数对PCJS峰值应变与断裂伸长率的影响

Fig.7 Effect of number of dry and wet cycles on peak strain and elongation of PCJS

3 微观机理分析

3.1 微观形貌分析

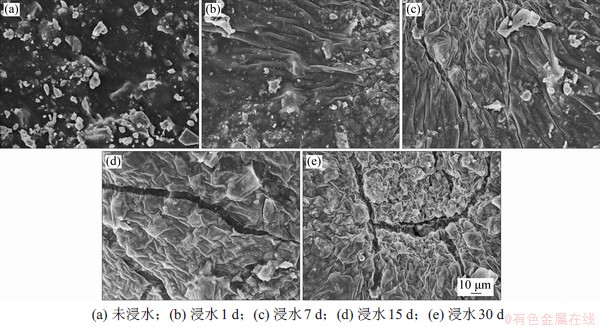

3.1.1 不同浸水时间时的微观形貌

不同浸水时间时PCJS的微观形貌如图8所示,放大倍数为1 000倍。从图8可以看出:浸水1 d时,PCJS的微观形貌出现明显条状褶皱;浸水7 d时,条状褶皱数量增多且部分褶皱间出现裂纹;浸水15 d时,条状褶皱发展为无规则的交错网状褶皱且裂纹宽度和深度变大;浸水30 d时,后交错网状褶皱更加密集且相互交错贯通的宽大裂纹分布其间。分析表明,浸水作用可使PCJS的微观形貌产生褶皱和裂纹,且浸水时间越长,PCJS微观形貌破坏越严重,说明水分子可促使PCJS内部分子结构发生降解断裂,从而导致PCJS剪切性能劣化。

图8 不同浸水时间时PCJS的微观形貌

Fig. 8 Micromorphology of PCJS for different immersion time

图9 不同干湿循环次数时PCJS的微观形貌

Fig. 9 Microscopic morphology of PCJS at different wet and dry cycles

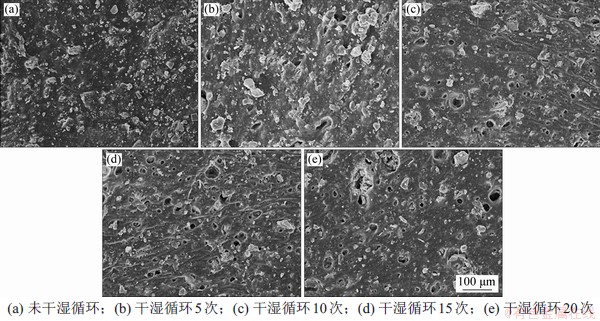

3.1.2 不同干湿循环次数时的微观形貌

不同干湿循环次数时PCJS的微观形貌如图9所示,放大倍数为300倍。从图9可以看出:干湿循环5次时PCJS的微观形貌中可见部分无机填料脱离聚合物膜,并且出现少数孔隙;干湿循环10次时,细小孔隙数量增加且出现部分较大孔隙;干湿循环15次时,总体上孔隙数量明显增多且孔径变大;干湿循环20次时,部分包裹无机填料和水泥水化产物的聚合物膜破裂出现明显大孔隙。分析表明,干湿循环作用可使PCJS微观形貌产生孔隙,且干湿循环次数越多,PCJS微观形貌中孔隙数量越多且孔径越大。这主要是由于干湿循环作用引起PCJS内部聚合物膜破裂,导致包裹于聚合物膜中的无机填料和水泥水化产物逐渐溶解、散失,从而形成孔隙;干湿循环次数越多,聚合物膜越易破裂,造成无机填料和水化产物散失越多,因此,孔隙数增多且孔径变大。

3.2 孔隙结构分析

3.2.1 浸水时间对孔隙结构的影响

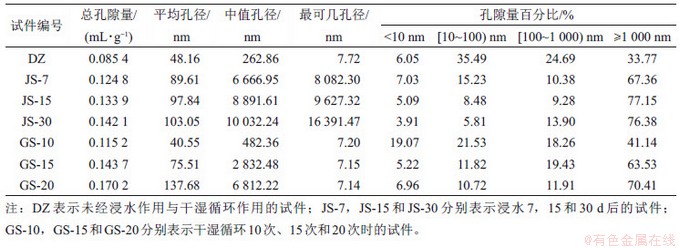

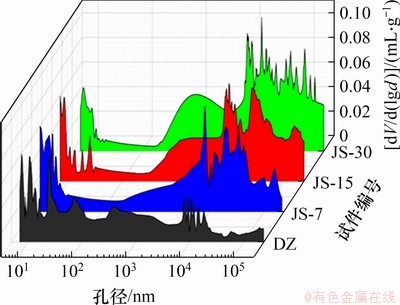

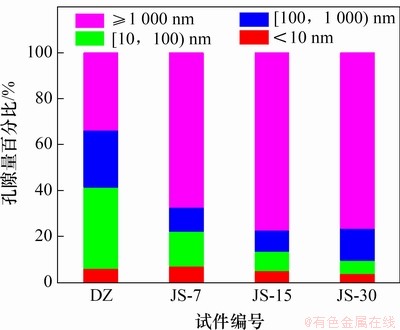

浸水时间和干湿循环次数对PCJS孔隙结构参数的影响如表4所示。不同浸水时间时PCJS的孔径分布微分曲线如图10所示,浸水时间对PCJS孔隙量百分比的影响规律如图11所示。

表4 浸水时间和干湿循环次数对PCJS孔隙结构参数的影响

Table 4 Effect of soaking time and number of wet and dry cycles on pore structure parameters of PCJS

从表4、图10和图11可以看出:经浸水作用后,PCJS的总孔隙量和特征孔径(平均孔径、中值孔径和最可几孔径)均明显增大;随着浸水时间的增加,总孔隙量和特征孔径不断增大;随着浸水时间的增加,PCJS的孔径分布微分曲线逐渐向大孔径方向偏移,大孔(≥1 000 nm)百分比明显增大,孔隙结构不断减弱,其中,浸水30 d时,PCJS的总孔隙量为0.142 1 mL/g,增加66.39%,平均孔径增大113.97%,大孔百分比达到了76.38%。由此可见,浸水作用会导致PCJS的孔隙量、孔径尺寸及大孔数量增加,这主要归因于水分子引起的聚合物分子溶胀软化和水解降解,致使聚合物分子链断裂,从而造成PCJS内部产生裂纹,进而引起PCJS剪切性能劣化。

图10 不同浸水时间时PCJS的孔径分布微分曲线

Fig. 10 Differential curve of pore size distribution of PCJS for different immersion time

图11 浸水时间对PCJS孔隙量百分比的影响

Fig. 11 Effect of soaking time on percentage of PCJS porosity

3.2.2 干湿循环次数对孔隙结构的影响

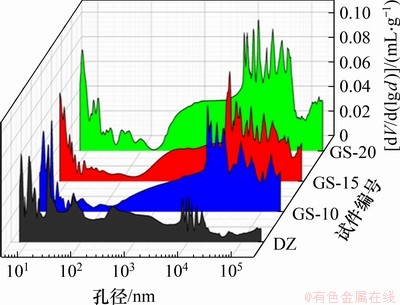

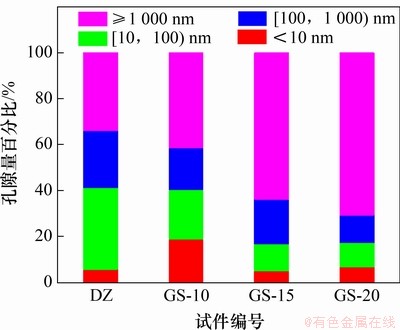

图12所示为不同干湿循环次数时PCJS的孔径分布微分曲线。图13所示为干湿循环次数对PCJS孔隙量百分比的影响。从表4、图12和图13可以看出:经干湿循环后,PCJS的总孔隙量、中值孔径和大孔百分比明显增大;且随着干湿循环次数的增加,总孔隙量、中值孔径和大孔百分比不断增大;随着干湿循环次数的增加,PCJS的平均孔径先减小后增大,最可几孔径不断增大,孔径分布微分曲线逐渐向大孔径方向偏移;干湿循环10次时,PCJS的平均孔径最小,中孔径(10~1 000 nm)百分比减小,小孔径(<10 nm)和大孔径百分比增大。这主要是因为干湿循环次数较少时,促进了PCJS内部未水化的水泥颗粒二次水化,在一定程度上使得孔径分布更均匀,从而PCJS的抗剪性能有一定提升。干湿循环次数较大时,PCJS的孔隙结构不断劣化,主要是由于包裹或覆盖于聚合物膜结构中的无机填料和水泥水化产物随着聚合物膜结构在浸水作用下的溶胀软化和水解降解而不断暴露、脱落并丧失最终形成孔隙,且干湿循环次数越大,孔隙数量越多,孔径尺寸变大,PCJS剪切性能劣化越明显。

图12 不同干湿循环次数时PCJS的孔径分布微分曲线

Fig. 12 Differential curve of pore size distribution of PCJS at different wet and dry cycles

图13 干湿循环次数对PCJS孔隙量百分比的影响

Fig .13 Effect of the number of dry and wet cycles on percentage of PCJS porosity

4 结论

1) PCJS持续浸水后剪切性能劣化,且浸水时间越长,劣化程度越大。当PCJS浸水1 d和30 d时,剪切强度损失率分别为6.64%和46.68%,剪切韧度保持率分别为91.14%和40.57%。由于水分子可促使PCJS内部分子结构发生降解断裂,致使PCJS浸水后软化,峰值应变和断裂伸长率不断增大。

2) 当干湿循环次数较少时,PCJS内部未水化的水泥与渗入的水分发生二次水化反应,剪切性能优化,剪切强度、韧度增大,峰值应变和断裂伸长率减小。当干湿循环次数较多时,浸水作用导致PCJS内部损伤不断累积,水泥二次水化的增强作用逐渐被浸水的削弱作用所掩盖,剪切性能劣化,剪切强度、韧度减小,峰值应变和断裂伸长率增大。

3) SEM 试验和MIP试验结果从微观层面解释了浸水时间和干湿循环对PCJS剪切性能的影响机制。持续浸水和干湿循环导致PCJS的微观形貌劣化,裂缝增加,大孔增多;当干湿循环较少时,PCJS孔径分布更均匀,平均孔径减小。

参考文献:

[1] 张献民, 刘小兰, 张子文. 基于振动特性的机场刚性道面传荷性能[J]. 北京航空航天大学学报, 2018, 44(9): 1787-1796.

ZHANG Xianmin, LIU Xiaolan, ZHANG Ziwen. Rigid pavement load transfer ability of airport based on vibration characteristics[J]. Journal of Beijing University of Aeronautics and Astronautics, 2018, 44(9): 1787-1796.

[2] WANG Dongya, FEI Weishui. Joint issue discussion on cement concrete pavement[J]. Advanced Materials Research, 2013, 671/672/673/674(2): 1179-1182.

[3] LIU Zhonggen, LI Jingnan, CAO Guobin. The treatment technology of void beneath cement concrete pavement bottom in cold area[J]. Advanced Materials Research, 2014, 1049/1050: 339-341.

[4] LIU Zhonggen, XU Fuming, CAO Goubin. Study on cement concrete pavement treatment methods of common damage diseases[J]. Applied Mechanics and Materials, 2014, 716/717: 307-309.

[5] 王洁宁, 赵晓鹏. 机场安全热点本体建模及智能划分研究[J]. 中国安全科学学报, 2016, 26(5): 47-52.

WANG Jiening, ZHAO Xiaopeng. Research on ontology modeling and intelligent partitioning of airport security hotspots[J]. Chinese Journal of Safety Science, 2016, 26(5):47-52.

[6] 袁捷, 刘文博. 民用机场水泥混凝土道面接缝嵌缝材料性能指标分析[J]. 公路交通科技, 2016, 33(9): 7-13.

YUAN Jie, LIU Wenbo. Analysis on performance index of joint sealant material for civil airport cement concrete pavement[J]. Journal of Highway and Transportation Research and Development, 2016, 33(9): 7-13.

[7] 寿崇琦, 张志良, 邢希学, 等. 水泥混凝土路面填缝材料的研究[J]. 公路, 2005, 50(2): 113-115.

SHOU Chongqi, ZHANG Zhiliang, XING Xixue, et al. Research on joint sealants for cement concrete pavement[J]. Highway, 2005, 50(2): 113-115.

[8] PARK T S, LEE K S, LEE S H. Comparison of performance & jet fuel oil resistance of joint sealant materials for airside[J]. Journal of Membrane Science, 2008, 309(1): 120-127.

[9] DAL LAGO B, BIONDINI F, TONIOLO G, et al. Experimental investigation on the influence of silicone sealant on the seismic behaviour of precast facades[J]. Bulletin of Earthquake Engineering, 2017, 15(4): 1771-1787.

[10] 毛俊轩, 潘林, 熊婷. 硅烷改性聚氨酯密封胶与PC粘接性的研究[J]. 化学研究与应用, 2016, 28(11): 1654-1656.

MAO Junxuan, PAN Lin, XIONG Ting. Study of adhesion effect between silylated polyurethane sealant with polycarbonate[J]. Chemical Research and Application, 2016, 28(11): 1654-1656.

[11] QUAN Yiwu, HE Peng, ZHOU Baijie, et al. Modification of polysulfide sealant with polysulfide polythio-urethane-urea[J]. Journal of Applied Polymer Science, 2007, 106(4): 2599-2604.

[12] 徐峰, 刘林军. 聚合物水泥基建材与应用[M]. 北京: 中国建筑工业出版社, 2010: 150-168.

XU Feng, LIU Linjun. Polymer cement-based building materials and applications[M]. Beijing: China Architecture & Building Press, 2010: 150-168.

[13] BAI Erlei. Tensile properties of a flexible polymer-cement composite containing portland cement and VAE emulsion[J]. Ceramics-Silikaty, 2019, 64(1): 92-99.

[14] 许金余, 任韦波, 彭光, 等. 一种VAE乳液水泥基路面填缝材料及其制备方法: 中国, CN106966656A[P]. 2017-07-21.

XU Jinyu, REN Weibo, PENGeng Guang, et al. VAE(vinyl acetate-ethylene copolymer emulsion) emulsion cement-based pavement joint filling material and preparation method: China, CN106966656A[P]. 2017-07-21.

[15] WANG Zhihang, XU Jinyu, MENG Xin, et al. Effect of VAE emulsion and inorganic fillers on the properties of styrene-acrylic emulsion based cement composite joint sealant[J]. Construction and Building Materials, 2021, 286: 122976.

[16] WANG Zhihang, XU Jinyu, MENG Xin, et al. Effect of ultraviolet aging on the bonding and tensile properties of polymer-cement composite[J]. Journal of Renewable Materials, 2021, 9(6): 1157-1168.

[17] 韩思聪, 白二雷, 郭创, 等. 苯丙乳液基水泥复合道面填缝料力学性能研究[J]. 硅酸盐通报, 2018, 37(11): 3398-3404.

HAN Sicong, BAI Erlei, GUO Chuang, et al. Research on mechanical properties of styrene-acrylic emulsion based cement composite pavement joint sealant[J]. Bulletin of the Chinese Ceramic Society, 2018, 37(11): 3398-3404.

[18] 刘高杰, 白二雷, 许金余, 等. 不同粉液比苯丙乳液水泥基复合填缝料剪切性能试验研究[J]. 铁道科学与工程学报, 2020, 17(3): 615-622.

LIU Gaojie, BAI Erlei, XU Jinyu, et al. Shear behavior of styrene-acrylic emulsion cement-based composite joint sealant with different powder-emulsion ratio[J]. Journal of Railway Science and Engineering, 2020, 17(3): 615-622.

[19] WANG Tengjiao, XU Jinyu, ZHU Congjin, et al. Comparative study on the effects of various modified admixtures on the mechanical properties of styrene-acrylic emulsion-based cement composite materials[J]. Materials, 2019, 13(1): E8.

[20] 孟博旭, 许金余, 顾超, 等. VAE乳胶粉掺量对苯丙乳液基水泥复合填缝料拉伸和剪切性能的影响[J]. 硅酸盐通报, 2019, 38(6): 1713-1718.

MENG Boxu, XU Jinyu, GU Chao, et al. Effect of VAE latex powder addition on tensile and shear properties of styrene-acrylate based cement composite joint compound[J]. Bulletin of the Chinese Ceramic Society, 2019, 38(6): 1713-1718.

[21] 彭光, 许金余, 任韦波. 硅烷偶联剂改性苯丙乳液水泥复合材料的力学性能及孔隙结构[J]. 硅酸盐通报, 2018, 37(10): 3076-3081.

PENG Guang, XU Jinyu, REN Weibo. Mechanical properties and pore structure of silane coupling agent modified styrene-acrylic emulsion cement composite material[J]. Bulletin of the Chinese Ceramic Society, 2018, 37(10): 3076-3081.

[22] 任韦波, 许金余, 彭光, 等. 云母粉增强的聚合物水泥复合填缝材料及其制备方法: 中国, CN107010899A[P]. 2017-08-04.

REN Weibo, XU Jinyu, PENG Guang, et al. gap filling material and preparation method: China, CN107010899A[P]. 2017-08-04.

[23] 杨宁, 白二雷, 许金余, 等. 苯丙乳液水泥复合材料的拉伸力学性能[J]. 硅酸盐通报, 2018, 37(12): 3744-3750.

YANG Ning, BAI Erlei, XU Jinyu, et al. Tensile mechanical property of styrene-acrylic cement composite material[J]. Bulletin of the Chinese Ceramic Society, 2018, 37(12): 3744-3750.

[24] MENG Boxu, XU Jinyu, GU Chao, et al. Effect of VAE latex powder addition on tensile and shear properties of styrene-acrylate based cement composite joint compound[J]. IOP Conference Series: Earth and Environmental Science, 2019, 242: 032063.

[25] 王志航, 许金余, 张彤, 等. 碳纤维改性聚合物水泥复合填缝材料拉伸力学性能研究[J/OL]. 化工新型材料, 2021(12): 1-10. [2021-06-23].

WANG Zhihang, XU Jinyu, ZHANG Tong, et al. The tensile mechanical properties of carbon fiber modified polymer cement-based composite sealing material[J/OL]. New Chemical Materials, 2021(12): 1-10. [2021-06-23].

[26] 王志航, 许金余, 孟欣, 等. 高温环境下聚合物水泥复合填缝料性能研究[J/OL]. 化工新型材料, 2022(3): 1-13. [2021-06-23].

WANG Zhihang, XU Jinyu, MENG Xin, et al. Research on property of polymer cement composite joint sealant under high temperature environment[J/OL]. New Chemical Materials, 2022(3): 1-13. [2021-06-23].

[27] BAI Erlei, LIU Gaojie, XU Jinyu, et al. Tensile and fixed elongation properties of polymer-based cement flexible composite under water/corrosive solution environment[J]. Materials, 2020, 13(9): 2155.

[28] LOU Chuanxin, XU Jinyu, LIU Sinuo, et al. Effects of external environments on the fixed elongation and tensile properties of the VAE emulsion-cement composite joint sealant[J]. Materials, 2020, 13(14): 3233.

[29] 王腾蛟, 许金余, 朱从进, 等. 灰粉比对苯丙乳液基水泥复合材料静态力学性能及破坏形态的影响[J]. 复合材料学报, 2020, 37(9): 2324-2335.

WANG Tengjiao, XU Jinyu, ZHU Congjin, et al. Effects of cement-powder ratio on static mechanical properties and failure forms of styrene-acrylic emulsion-based cement composites[J]. Acta Materiae Compositae Sinica, 2020, 37(9): 2324-2335.

[30] 朱从进, 白二雷, 许金余, 等. 灰粉比对苯丙乳液基水泥复合填缝料剪切性能的影响[J]. 硅酸盐通报, 2017, 36(8): 2576-2582.

ZHU Congjin, BAI Erlei, XU Jinyu, et al. Effects of cement-powder ratio on shear properties of styrene-acrylic emulsion based cement compound joint sealant[J]. Bulletin of the Chinese Ceramic Society, 2017, 36(8): 2576-2582.

[31] 彭光, 许金余, 任韦波. 聚合物水泥路面填缝材料变形性能研究[J]. 硅酸盐通报, 2017, 36(9): 2894-2899.

PENG Guang, XU Jinyu, REN Weibo. Deformation property of polymer cement pavement joint sealant[J]. Bulletin of the Chinese Ceramic Society, 2017, 36(9): 2894-2899.

[32] 李晓刚, 高瑾, 张三平. 高分子材料自然环境老化规律与机理[M]. 北京: 科学出版社, 2011: 320-328.

LI Xiaogang, GAO Jin, ZHANG Sanping. The natural environment aging law and mechanism of polymer materials[M]. Beijing: Science Press, 2011: 320-328.

[33] 丁苏华. 建筑密封材料的老化试验与耐久性研究[D]. 郑州: 郑州大学, 2006: 115-119.

DING Suhua. Studies on weathering and durability of building sealants[D]. Zhengzhou: Zhengzhou University, 2006: 115-119.

(编辑 杨幼平)

收稿日期: 2020 -12 -26; 修回日期: 2021 -03 -10

基金项目(Foundation item):国家自然科学基金资助项目(51208507,51378497) (Projects(51208507, 51378497) supported by the National Natural Science Foundation of China)

通信作者:许金余,博士,教授,从事结构工程与防护工程研究;E-mail:wzhsongchen@163.com

DOI: 10.11817/j.issn.1672-7207.2021.07.027

引用格式: 王志航, 白二雷, 许金余, 等. 聚合物水泥基复合填缝料浸水后剪切性能[J]. 中南大学学报(自然科学版), 2021, 52(7): 2416-2425.

Citation: WANG Zhihang, BAI Erlei, XU Jinyu, et al. Shear performance of polymer cement-based composite joint sealant after immersion in water[J]. Journal of Central South University(Science and Technology), 2021, 52(7): 2416-2425.