文章编号:1004-0609(2010)S1-s0664-06

热处理工艺对SP-700钛合金组织性能的影响

张 钢,张丰收

(西部超导材料科技有限公司,西安 710012)

摘 要:为了提高国产SP-700钛合金的性能,对SP-700钛合金热处理的工艺进行研究。采用不同固溶温度、时效温度以及时效时间的处理方法,分析热处理工艺对该钛合金组织和性能的影响。研究结果表明:钛合金强度随着固溶温度的升高而提高,其原因是次生α相的析出量增加;控制时效温度和时效时间,可以控制次生α相的形状和尺寸,从而能获得强度和塑性的最佳匹配;于850 ℃进行固溶处理并采用水冷,然后,在510 ℃或550 ℃时效可使SP-700钛合金获得较好的强度-塑性匹配。

关键词:SP-700钛合金;固溶处理;时效处理;次生α相

中图分类号:TG146.2+3 文献标志码:A

Effect of heat treatment process on structures and properties of

SP-700 titanium alloy

ZHANG Gang, ZHANG Feng-shou

(Western Superconducting Technologies Co., Ltd., Xi’an 710012, China)

Abstract: The heat treatment of SP-700 titanium alloy was studied to improve the property of homemade SP-700 titanium alloy. By using different solutions and aging temperatures as well as aging time, the effects of heat treatment process on microstructure and properties of SP-700 titanium alloy were systematically studied. The results show that the alloy strength increases with solid solution temperature due to the fact that the number of secondary α increases. To control aging temperature and aging time can control the shape and size secondary α, to obtain the optimum combination of strength with plasticity. Solution treating at 850 ℃, cooling to room temperature by water, and then aging at 510 ℃ or 550 ℃ will help the alloy to obtain the optimum combination of strength with plasticity.

Key words: SP-700 titanium alloy; solution treatment; aging treatment; secondary α phase

钛合金具有密度小、强度高、耐高温和抗腐蚀性强等优点,在航空航天领域中得到了广泛应用[1]。航空航天领域常用的Ti-6Al-4V具有较强的疲劳抗力和较好的断裂韧性,但是,由于其加工性能和可热处理性能较差使它在非航空与航天领域的应用受到限 制[2]。SP-700钛合金是日本在Ti-6Al-4V合金基础上研制开发的一种富含β相的(α+β)型钛合金[3],该钛合金进一步改善了Ti-6Al-4V的综合力学性能,并提高了其超塑成型性能,SP-700钛合金应用范围不断扩 大[4-5]。国产的SP-700钛合金材料与国外的相比,在相同的热处理工艺条件下,部分性能比国外产品的性能差,研究合适的热处理工艺可以提高国产的SP-700钛合金的性能,并可以为SP-700钛合金的生产和加工工艺的制定提供一定的参照依据。本文作者主要分析热处理参数在不同的条件下对合金显微组织的影响,讨论淬火温度、时效温度、时效时间对合金抗拉强度和伸长率的影响,并探索SP-700钛合金强度-塑性最佳匹配的热处理方案。

1 实验

1.1 试验材料

试验材料采用的是西部超导公司生产的锻造退火态SP-700钛合金棒材,其化学成分见表1。

表1 SP-700钛合金的化学成分

Table 1 Chemical composition of SP-700 titanium alloy (mass fraction, %)

1.2 试验方案与结果

1.2.1 固溶温度对合金组织和性能的影响

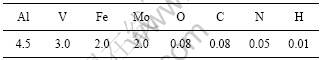

将试样分别在810,830,850和870 ℃保温1 h后水淬,在530 ℃时效6 h,然后进行性能检测,并观察其组织的变化,结果如图1所示。

图1 固溶温度合金对性能的影响

Fig. 1 Effects of solution temperature on properties of alloys

1.2.2 时效温度对合金组织和性能的影响

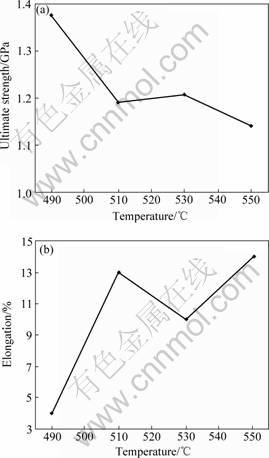

将试样在850 ℃固溶,分别在490,510,530和550 ℃时效6 h后空冷,然后进行性能检测,并观察其组织的变化,结果如图2所示。

图2 时效温度对合金性能的影响

Fig.2 Effects of aging temperature on properties of alloys

1.2.3 时效时间对合金组织和性能的影响

将试样在810 ℃固溶,在510 ℃分别时效6,8,10和12 h后空冷,然后进行性能检测,并观察其组织的变化,结果如图3所示。

2 结果与讨论

2.1 固溶温度对组织和性能的影响

从图1所示的固溶温度对性能的影响可以看到:在固溶温度为810~850 ℃时,强度随着固溶温度的升高而逐渐提高,而伸长率随着固溶温度的升高变化不大;当固溶温度超过850 ℃后,强度急剧提高,而伸长率急剧降低。

图3 时效时间对合金性能的影响

Fig.3 Effects of aging time on properties of alloys

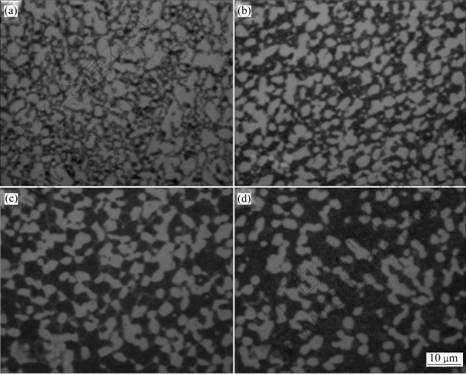

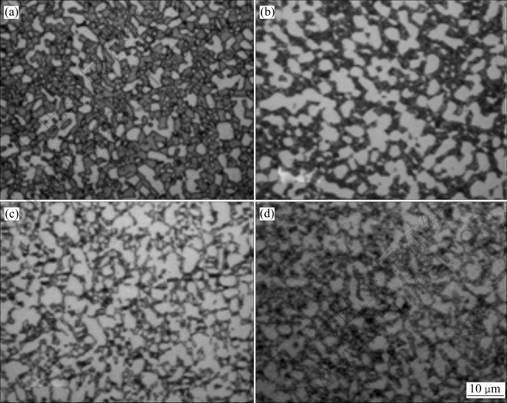

观察其金相组织可以看到:在810 ℃固溶初生α相的数量比较多,差异大且形状不规则(见图4(a)),此时塑性较好。其原因是:等轴α相颗粒粗大,可以开动的滑移系较多[6],当塑性变形时,不致于在个别晶粒中引起应力集中,所以表现为较好的塑性;随着固溶温度的升高,初生α相含量明显减少,α相的等轴性变得比较好且分布更加均匀,时效后次生α相的数量增加(见图4(b)和(c))。850 ℃后,初生α相含量急剧减少,经530 ℃时效后,析出比较细小的次生α相随着固溶温度的升高而明显增加(见图4(d)),从而导致强度增大而塑性降低。由此可见,强度随着固溶温度的升高而提高是次生α相析出量增加所致[7]。

2.2 时效温度对合金组织和性能的影响

钛合金的时效主要是依靠固溶时产生的亚稳β相或马氏体组织在时效过程中析出弥散的α固溶体,使合金得到强化。

从试验结果(见图2)可以看到:490 ℃时效时合金强度很高,此时伸长率很低;到510 ℃时强度急剧下降,伸长率大幅度提高;510~550 ℃时强度继续降低,伸长率持续提高,但其变化比较平缓。因此,在510~550 ℃时效能获得强度和伸长率的良好匹配。

图4 固溶温度对合金组织的影响

Fig.4 Effects of solution temperature on microstructure of alloys (solution treating for 1 h, aging treating at 530 ℃ for 6 h ): (a) 810 ℃; (b) 830 ℃; (c) 850 ℃; (d) 870 ℃

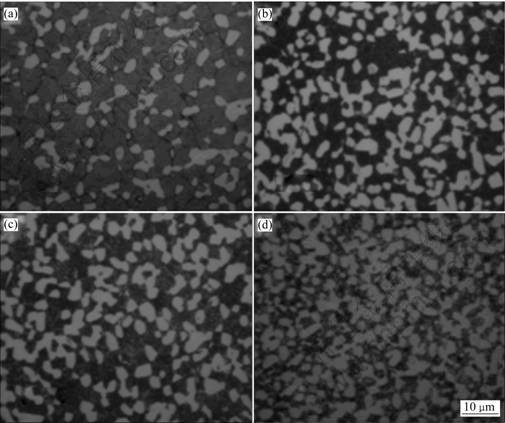

观察金相组织可以看到:合金在490 ℃时效时,温度较低,金相组织基本上由等轴α组织和β相组成(见图5(a)),从基体中析出弥散、细小的次生α相,因此,强度较高;随着时效温度的升高,510~550 ℃时次生α相开始长大,呈现比较细小的针状或板条状(见图5(b)和(c)),组织向双态组织变化,从而导致室温力学性能降低和塑性提高。当时效温度达到550 ℃时,次生α相进一步长大为等轴α组织(见图5(d)),细小的次生α相几乎消失,从而使塑性进一步提高。由此可见:适当的时效温度能控制次生α相的尺寸,从而能获得强度和塑性的最佳匹配。

2.3 时效时间对合金组织和性能的影响

从试样的性能来看(见图3),在时效时间为6~8 h时,抗拉强度降低,随后有所升高,但是变化不大;6~8 h时伸长率升高幅度较大。

固溶后的组织是由等轴α和亚稳β相组成的,其中有较大的晶格畸变。经过时效后,虽然时效的温度较低,但储存的畸变能使等轴α相颗粒长大,并使其间的亚稳β相开始分解,其弥散强化可能在几分钟内就可完成[8]。从金相组织可看出:当时效时间短时,析出的次生α相比较细小且沿晶界分布,晶界比较清晰(见图6(a));当时效时间延长时,次生α相逐渐长大,晶界变得不清晰(见图6(b)和(c))。次生α相通过相界的迁移发生合并长大,变为短片状或等轴化,使得β转变组织呈灰白色,同时等轴颗粒边界也变得模糊(见图6(d))。强度的变化主要是时效对次生α析出相的形态影响不同造成的,强度增高是次生α相的数量和尺寸增加引起的,而强度下降主要是由次生α相等轴化和β相减少引起的。

2.4 强度-塑性最佳匹配的热处理方案

由于SP-700钛合金主要应用的是其超塑性能,因而对于塑性的要求就比较高,应在较好塑性的前提下尽可能地提高强度。

从图1所示的固溶温度对性能的影响可以看 到:810 ℃时虽然塑性较高但是强度太低,870 ℃时则伸长率太低;830 ℃和850 ℃时伸长率相差不大,但

图5 时效温度对合金组织的影响

Fig.5 Effects of aging temperature on microstructure of alloys (solution treating at 850 ℃, aging treating for 6 h): (a) 490 ℃; (b) 510 ℃; (c) 530 ℃; (d) 550 ℃

图6 时效时间对合金组织的影响

Fig.6 Effects of aging time on microstructures of alloys (solution treating at 810 ℃, aging treating at 510 ℃): (a) 6 h; (b) 8 h; (c) 10 h; (d) 12 h

是850 ℃时强度更高,所以,固溶温度选为850 ℃。

从图2所示的时效温度对性能的影响可以看到:时效温度选择在510 ℃或550 ℃。因为在此温度时效时,其强度和塑性差异不大。

时效时间的选择定在8 h,因为从图3所示的时效时间对性能的影响中可以看到8 h或12 h的伸长率较好,但是12 h的强度略低。

3 结论

1) SP-700钛合金在810~870 ℃温度范围内固溶处理时,强度随着固溶温度的升高而逐渐提高,而塑性随着固溶温度的升高基本不变。当固溶温度超过850 ℃时,强度急剧提高,而塑性急剧降低。这是初生α相含量急剧减少、次生α相急剧增加所致。

2) SP-700钛合金在较低温度时效,可获得弥散、细小的次生α相,使合金抗拉强度较高;随着时效温度的升高,次生α相逐渐长大成片状或等轴化,使合金塑性提高。控制时效温度和时效时间,可以控制次生α相的形状和尺寸,从而能获得强度和塑性的最佳匹配。

3) 通过分析得出SP-700钛合金的强度-塑性最佳匹配热处理工艺为:于850 ℃固溶,于510 ℃或550 ℃时效,时效时间为8 h。

REFERENCES

[1] 钱九红. 航空航天用新型钛合金的研究发展及应用[J]. 稀有金属, 2000, 24(3): 218-223.

QIAN Jiu-hong. Application and development of new titanium alloys for aerospace[J]. Chinese Journal of Rare Metals, 2000, 24(3): 218-223.

[2] 张治民, 张 星, 王 强, 等. ZTC4的变形组织及力学性能研究[J]. 塑性工程学报, 2004, 11(1): 6-8.

ZHANG Zhi-min, ZHANG Xing, WANG Qiang, et al. Research on formed tissue and mechanical behaviors of ZTC4 [J]. Journal of Plasticity Engineering, 2004, 11(1): 6-8.

[3] 黄金昌. SP-700钛合金的开发和应用[J]. 稀有金属与硬质合金, 1998(134): 58.

HUANG Jin-chang. Development and application of SP-700 Ti alloy[J]. Rare Metals & Cemented Carbides, 1998, 134: 58-62.

[4] OUCHI C. Development and application of new titanium alloy SP-700 [J]. The Minerals, Metals & Materials Society, 1994: 37-44.

[5] OUCHI C, FUKAI H, HASEGAWA K. Microstructural characteristics and unique properties obtained by solution treating or aging in β-rich α+β titanium alloy[J]. Materials Science and Engineering A, 1999, 263(2): 132-136.

[6] 张 民. 热处理对TC21钛合金组织和性能的影响[D]. 西安: 西北工业大学材料学院, 2004.

ZHANG Min. Effect of heat treatment on microstructure and properties of TC21 alloy[D]. Xi’an: Materials College, Northwestern Polytechnical University, 2004.

[7] NIINOMI G M, EYLON D, et al. Effect of β phase stability at room temperature on mechanical properties in β-rich α+β type Ti-4.5Al-3V-2Mo-2Fe alloy[J]. ISIJ International, 2002, 42(2): 191-199.

[8] 黎俊初, 王 晗, 张国光, 等. 固溶时效对热等静压制得的TC4钛合金组织与性能的影响[J]. 热加工工艺, 2007, 36(10): 65-67.

LI Jun-chu, WANG Han, ZHANG Guo-guang, et al. Effect of solution aging on microstructure and property of TC4 titanium alloy prepared by hot isosmtatic pressing[J]. Metal Hot Working Technology, 2007, 36(10): 65-67.

(编辑 陈灿华)

通信作者:张 钢;电话:029-86527358;E-mail: zhgchsy@163.com