动态再结晶对Al-Mg-Si铝合金分流模挤出型材焊合区组织和力学性能的影响

来源期刊:中国有色金属学报(英文版)2019年第9期

论文作者:李世康 李落星 何洪 刘志文 张龙

文章页码:1803 - 1815

关键词:6063铝合金;多孔分流模挤压;动态再结晶;显微组织;力学性能

Key words:6063 aluminum alloy; porthole die extrusion; dynamic recrystallization; microstructure; mechanical properties

摘 要:通过实验与数值模拟相结合的方法,研究动态再结晶对6063铝合金多孔分流模挤出型材焊合区显微组织和力学性能的影响,并采用EBSD技术观察晶粒形貌。结果显示,在初始低速挤压时,随着挤压速度的增大,挤出型材温度升高和应变速率增大,挤出型材动态再结晶分数增大;而在高速挤压时,挤出型材温度随挤压速度的增大增幅较小,型材动态再结晶分数因应变速率的增大而减小。焊合区硬度和小角度晶界分数低于基体区的,较小的再结晶分数使得焊合区晶粒尺寸大于基体区的。减小晶粒尺寸和提高挤出温度有利于提高焊合区型材的硬度。

Abstract: The effect of dynamic recrystallization (DRX) on the microstructure and mechanical properties of 6063 aluminum alloy profile during porthole die extrusion was studied through experiment and simulation. The grain morphology was observed by means of electron backscatter diffraction (EBSD) technology. The results show that, at low ram speeds, increasing the ram speed caused an increase in DRX fraction due to the increase of temperature and strain rate. In contrast, at high ram speeds, further increasing ram speed had much less effect on the temperature, and the DRX faction decreased due to high stain rates. The microhardness and fraction of low angle boundaries in the welding zones were lower than those in the matrix zones. The grain size in the welding zone was smaller than that in the matrix zone due to lower DRX fraction. The decrease of grain size and increase of extrudate temperature were beneficial to the improvement of microhardness.

Trans. Nonferrous Met. Soc. China 29(2019) 1803-1815

Shi-kang LI1,2, Luo-xing LI1,2, Hong HE2, Zhi-wen LIU1, Long ZHANG1,2

1. State Key Laboratory of Advanced Design and Manufacturing for Vehicle Body, Hunan University, Changsha 410082, China;

2. College of Mechanical and Vehicle Engineering, Hunan University, Changsha 410082, China

Received 25 December 2018; accepted 17 May 2019

Abstract: The effect of dynamic recrystallization (DRX) on the microstructure and mechanical properties of 6063 aluminum alloy profile during porthole die extrusion was studied through experiment and simulation. The grain morphology was observed by means of electron backscatter diffraction (EBSD) technology. The results show that, at low ram speeds, increasing the ram speed caused an increase in DRX fraction due to the increase of temperature and strain rate. In contrast, at high ram speeds, further increasing ram speed had much less effect on the temperature, and the DRX faction decreased due to high stain rates. The microhardness and fraction of low angle boundaries in the welding zones were lower than those in the matrix zones. The grain size in the welding zone was smaller than that in the matrix zone due to lower DRX fraction. The decrease of grain size and increase of extrudate temperature were beneficial to the improvement of microhardness.

Key words: 6063 aluminum alloy; porthole die extrusion; dynamic recrystallization; microstructure; mechanical properties

1 Introduction

Al-Mg-Si alloy hollow profiles play an important role in the fields of automotive industries and civil construction due to their low density and high performance. As an effective deformation technique, hot porthole die extrusion has been widely used to fabricate Al alloy hollow profiles. Longitudinal weld seam is a typical feature of porthole die extrusion [1,2]. The weld quality is of critical importance and affected by the welding pressure, welding time, yielding strength of the material on the welding surface and microstructures in the welding zone and the surrounding region [3-5].

The microstructures of extruded profile are largely determined by the initial billet temperature, die structure, extrusion ratio, etc. Under a specific condition, such as a given alloy, extrusion press and porthole die, the only variable process parameter dictating the microstructure is the ram speed. The extrusion pressure and extrudate temperature increase with the increase of ram speed, which has a beneficial effect on welding quality during porthole die extrusion [6,7]. In addition, in actual production, the porthole die extrusion is usually expected to operate at a high productivity and a low scrap. However, a high ram speed leads to a high temperature rise, which will influence the surface quality of final products [8]. And too high ram speeds would also cause local melting and high extrusion pressure. Surface defects would occur when the extrudate temperature is higher than the incipient melting temperature, leading to scrap. The extrudate temperature can be fluctuated within a certain range by decreasing ram speed to improve the surface quality [9]. However, extrusion with a low ram speed will lead to a relatively low throughput, which is not in line with industrial production requirement. Accordingly, the ram speed is an important parameter affecting the welding quality and extrusion productivity, and should be well controlled in a reasonable range [10].

The microstructure in the welding zone was affected by temperature, strain and strain rate through the dynamic recovery (DRV) and dynamic recrystallization (DRX) [11-13]. Dynamic recrystallization (DRX) would influence the grain size and its distribution. Compared with the conical die extrusion, porthole die extrusion is more helpful for grain refinement [14]. BINGOL et al [7] found that recrystallization had a significant influence on the microstructure in the welding zone with the increases of ram speed and temperature. CHEN et al [15] studied the microstructure and properties of Al/Mg/Al laminate extruded by a porthole die. Coarse elongated and fine equiaxed grains were observed in the Al layer owning to partial DRX. The microstructure of Mg layer was uniform due to complete DRX. There were no intermetallics at the welding interface, resulting in a lower hardness. Different DRX behaviors were found between the welding zone and matrix zone in Al-Zn-Mg alloy during porthole die extrusion [16]. The volume fractions of DRX in the zones close to bridge and porthole wall were the highest. DRX in the welding zone, volume reduction of micro-voids and migration of grain boundaries at the bonding interfaces were found to be beneficial to the improvement of welding quality [5,17].

As discussed above, much work has been done and a lot of achievements have been obtained. However, there are still some problems needed to be further investigated and clarified, such as the effect of DRX behavior on the weld quality. In this work, in order to study the DRX behavior and its influence on the microstructure and mechanical properties of welding zone, 6063 aluminum square hollow tubes were fabricated by porthole die extrusion under different ram speeds. The grain morphology was observed and characterized by means of electron backscatter diffraction technology (EBSD). The mechanical properties of extruded tubes were analyzed through microhardness. In addition, the numerical simulation of the square 6063 aluminum hollow tube under porthole die extrusion was conducted to further study the DRX behavior. And the microstructure and mechanical properties in matrix zone were also studied for comparison. The influence of DRX on the microstructure and mechanical properties was then discussed.

2 Experiment and simulation details

2.1 Materials

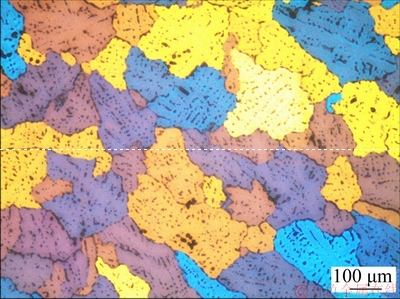

The studied alloy is a commercial 6063 aluminum alloy. The chemical composition and homogenization processing could be referred to Ref. [18]. The microstructure of the homogenized material is shown in Fig. 1. The coarse grains with uniform distribution are observed and the size is about 198 mm.

2.2 Hot porthole die extrusion

The porthole die extrusion was performed on an 800 t extruder. The cylindrical 6063 aluminum billet with dimensions of d86 mm × 300 mm was machined from homogenized billet for porthole die extrusion. Before porthole die extrusion, the billet was heated to 480 °C in an electrical resistance type muffle furnace and soaked for 3 h. The temperatures of the container and porthole die were both set up to be 450 °C. The ram speeds of 3, 7, 9 and 11 mm/s were attempted while the porthole die extrusions were started. A square hollow profile was extruded out. The cross-section shape and main dimensions of the square hollow profile are shown in Fig. 2. The extrusion ratio was 16.9. An AE-3000 type high temperature sensor was used to record the temperature of the extruded profile at 400 mm distance from the exit. After extrusion, the profiles were quenched into water.

Fig. 1 Optical micrograph of as-homogenized 6063 aluminum alloy

Fig. 2 Cross-section shape and main dimensions of profile (unit: mm)

2.3 Microstructure observation

The microstructure of the homogenized billet was observed by OM. The DRX behaviors of the welding zone and matrix zone on the cross-section were analyzed by EBSD. For the OM observation, the sample surfaces were ground with SiC paper up to 2000 grits and polished. Then, the sample surface was electropolished in the solution of 10 mL HCLO4 and 90 mL C2H6O at 25 V. Furthermore, anodic coating was performed on the surface with a mixed solution of 5 g HBF4 and 200 mL water at 20 V for 3 min. The OM observation was carried on an MM-6 type horizontal metallographic microscope. The grain structures were investigated by a ZEISS EVO MA10 scanning electron microscope (SEM) equipped with EBSD detector. The step size was 2 mm. The commercial software HKL Channel 5 was used for post-processing.

2.4 Microhardness test

The microhardness was tested on a Vickers microhardness tester at room temperature. The load and dwell time were 0.5 N and 15 s, respectively. The distance between the successive indentations was about 100 μm. Hardness testing was performed in the cross direction of the sample.

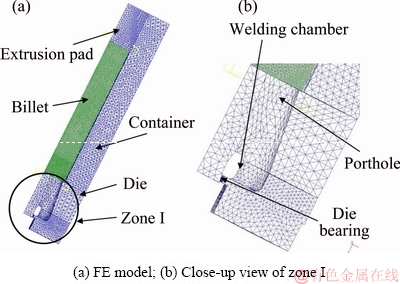

2.5 Simulation

The porthole die extrusion was modelled using the Deform-3D v.10.0 software package. A thermovisco- plastic material model and a thermo-rigid material model were applied for billet and tools, respectively. The heat exchange between the tools and billet was allowed. Hot compression was carried out to obtain the true stress-true strain curves of 6063 aluminum alloy. The detailed information about the hot compression could be referred to Ref. [18]. As needed by DEFORM software system for the aluminum extrusion process, a friction factor of 0.4 was assumed at the interfaces of the billet and tools. 1/8 of the numerical simulation model was set up for reducing the total computational time, owing to the symmetries of dies and deformation, as shown in Fig. 3. The welding chamber zone, die bearing area and extrudate profile were meshed into tetrahedral elements with the size of 0.3 mm, while container and porthole areas were meshed with sizes of 5 and 1 mm, respectively.

Fig. 3 Initial meshes of billet, container, die and extrusion pad (1/8 model)

3 Results

3.1 Microstructure evolution

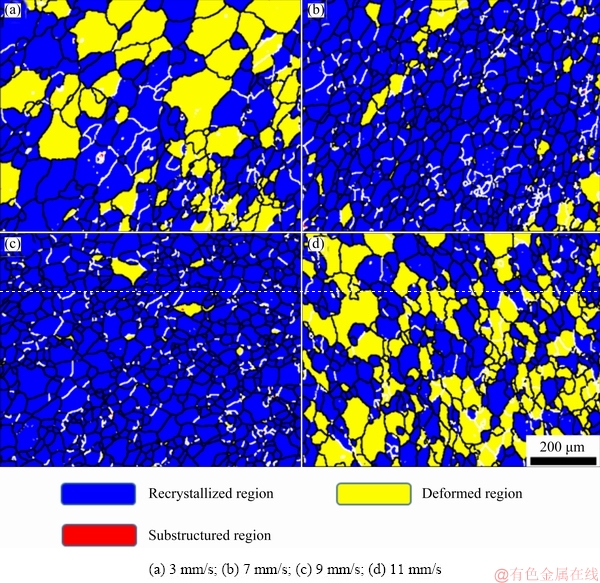

Figure 4 shows the EBSD DRX fraction maps in the welding zone at different ram speeds, where blue represents recrystallized grains, while yellow and red indicate substructured grains and deformed grains, respectively. The high-angle grain boundaries with a misorientation larger than 15° and the low-angle grain boundaries with a misorientation larger than 2° were set as black lines and white lines, respectively. It can be found that the majority of microstructures in the welding zones were recrystallized and substructured grains. The fraction of recrystallized grains firstly increased with the ram speed increasing from 3 to 9 mm/s, and then decreased with further increasing the ram speed. At a ram speed of 3 mm/s, a relative low recrystallized grain fraction was observed. When the ram speed increased up to 9 mm/s, almost all of them were recrystallized grains. Further increasing ram speed to 11 mm/s, recrystallized and substructured grains coexisted. Compared with the fraction of the recrystallized grains, the fraction of substructured grains in the welding zone showed an opposite trend with ram speed (Fig. 4).

Figure 5 shows the EBSD DRX fraction maps in the matrix zone at different ram speeds, where blue represents recrystallized grains, while yellow and red indicate substructured grains and deformed grains, respectively. The high-angle grain boundaries with a misorientation larger than 15° and the low-angle grain boundaries with a misorientation larger than 2° were set as black lines and white lines, respectively. The majority of grains in the matrix zones were recrystallized grains and some substructured grains. The trend of the microstructure fraction with the ram speed in the matrix zones was the same as that in the welding zones. Compared with the microstructure in the welding zones, the recrystallized grain fractions were higher and the substructured grain fractions were lower in the matrix zones.

Figure 6 shows the relative frequency of mis- orientation angle in welding zone at different ram speeds. The f represents the fraction of the grain boundaries with misorientation angles of 2°-15°. It is obvious that f gradually decreased with the increase of ram speed from 3 to 9 mm/s, and then increased with further increasing the ram speed. The values of f at ram speeds of 3, 7, 9 and 11 mm/s were 34.11%, 18.23%, 14.33% and 20.08%, respectively.

Figure 7 gives the relative frequency of mis- orientation angle in matrix zone at different ram speeds. As a whole, the values of f firstly decreased and then increased with the increase of ram speed. At the ram speeds of 3, 7, 9 and 11 mm/s, the values of f in the matrix zone were 21.61%, 20.49%, 14.51% and 17.52%, respectively. It can be seen that the fraction of the low-angle grain boundaries in the matrix showed a similar tendency with that in the welding zone. However, the values of f in the matrix zone were smaller than those in the welding zones.

Fig. 4 EBSD DRX fraction maps in welding zone at different ram speeds

Fig. 5 EBSD DRX fraction maps in matrix zone at different ram speeds

Fig. 6 Relative frequency of misorientation angle in welding zone at different ram speeds

Fig. 7 Relative frequency of misorientation angle in matrix zone at different ram speeds

3.2 DRX fraction and grain size

Figure 8 displays the DRX fraction and grain size as a function of the ram speed. With the increase of ram speed, the DRX fraction firstly increased and then decreased, whereas the grain size firstly decreased and then slowly increased. At ram speed 3 mm/s, the DRX fraction and the average recrystallized grain size in the welding zone were 30.5% and 85.7 μm, respectively. When the ram speed increased from 3 to 7 mm/s, grain size decreased significantly due to the increase of DRX fraction. When the ram speed reached up to 9 mm/s, the DRX fraction and average grain size both increased. Further increasing ram speed, the DRX fraction in the welding zone decreased from 97.5% at the ram speed of 9 mm/s to 52.1% at the ram speed of 11 mm/s. Meanwhile, the grain size slowly increased. At the ram speeds of 7, 9 and 11 mm/s, the grain sizes in the welding zone were 49.8, 52.1 and 54.5 μm, respectively.

Fig. 8 Effect of ram speed on DRX fraction (a) and grain size (b) during porthole die extrusion

Compared with those in the welding zone, the DRX fraction and grain size in the matrix zone were higher and smaller, respectively.

4 Discussion

Compared with the conventional extrusion, in the case of porthole extrusion, the billet is firstly separated into several streams by bridges and then welded in the welding chamber. After that, profile is extruded out of the die bearing for forming. Therefore, higher pressure is required and higher temperature rise is likely to occur. Moreover, according to the study of DONATI et al [19], the distribution of strain rate, strain and temperature inside the porthole die varied greatly, which would influence the microstructure and homogeneity of the profile.

4.1 Effect of ram speed on welding surface parameters

The distribution of temperature, strain rate and strain on the welding surface was discussed in this part, which corresponded to microstructure observation in Fig. 4. Figure 9 shows the temperature distribution on the welding surface at different ram speeds. It can be seen that the highest and lowest temperatures were in the die outlet and dead zones, respectively. Thus, when the stream flowed through the welding surface to the die outlet, its temperature increased. This was due to the large plastic deformation of the billet flowing from the welding chamber into the die bearing zone and strong shear friction between the billet and die in the bearing zone [20,21]. In addition, with the increase of the ram speed, the maximum value of temperature increased. And at ram speeds of 3, 7, 9 and 11 mm/s, the maximum temperatures on the welding surface were 476, 485, 490 and 495 °C, respectively. The exit temperatures are shown in Table 1. Obviously, the measured exit temperature was higher than the temperature on the welding surface. This indicated that the main temperature rise during porthole die extrusion occurred in the die bearing zone. This result was in confirmation with the experimental result of JO et al [21].

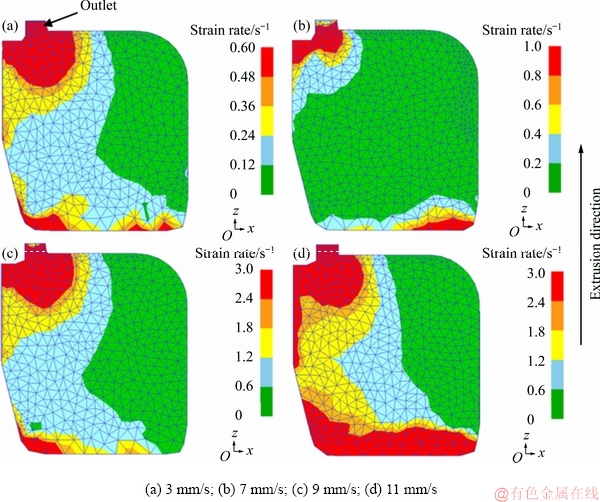

Figure 10 gives the strain rate distribution on the welding surface at different ram speeds. Obviously, the strain rate distribution on the welding surface varied significantly. The dead zone had the smallest value of strain rate, while the strain rates in the zones near the die outlet and under the divergent bridges were larger than those in other zones. The strain rate in the dead zone reduced to be close to zero, which existed in all conditions due to strong friction between the stream and welding chamber. With the increase of ram speed, the zones with the strain rate exceeding 0.2 s-1 were enlarged obviously. The maximum effective strain rate increased from 0.6 s-1 at the ram speed of 3 mm/s to 3 s-1 at the ram speed of 11 mm/s.

Fig. 9 Simulated temperature distribution on welding surface at different ram speeds

Table 1 Measured exit temperatures at different ram speeds

Figure 11 shows the effective strain distribution on the welding surface at different ram speeds. The difference of the strain values along the welding surface was significant. The values of effective strain near the die outlet and under the divergent bridges were larger than those in other zones, while the value of effective strain in the middle of welding surface was the smallest. CHEN et al [16] investigated the DRX behavior of an Al-Zn-Mg alloy during porthole die extrusion process and found that DRX volume fractions in the zones close to bridge and porthole wall were much higher than those in other zones due to large strains. In addition, the ram speed had little effect on the maximum and minimum effective strain values, but had a significant effect on the strain distribution.

4.2 Effect of ram speed on DRX behavior

The process parameters, such as temperature, strain rate and strain, have a significant effect on the DRX process [22,23]. In this work, ram speed had a significant influence on temperature and strain rate, as shown in Figs. 9 and 10, respectively. But it had little influence on strain, as seen in Fig. 11. At a ram speed of 3 mm/s, the main microstructures of square tube were recrystallized and substructured grains, as shown in Figs. 4(a) and 5(a), respectively. This phenomenon was mainly due to the lowest DRX fraction, as shown in Fig. 8(a). Owning to the high stacking fault energy, DRV is likely to appear in aluminum alloy during hot deformation [24,25]. At a ram speed of 3 mm/s, the adiabatic temperature and the stored energy during porthole die extrusion were low. Meanwhile, there was enough time for the migration of grain boundary. Thus, DRV was enhanced and more substructures were formed.

Fig. 10 Simulated strain rate distribution on welding surface at different ram speeds

Fig. 11 Simulated effective strain distribution on welding surface at different ram speeds

With the increase of ram speed, the volume fraction of recrystallized grains increased. This phenomenon indicated the increase of nucleation for DRX. It is generally known that dislocation density decreased with the process of DRV [26-28]. Then, the dislocation further annihilated and became the energy of DRX with the increase of ram speed. In addition, the adiabatic heating and stored energy of the billet increased with the increase of ram speed. This was beneficial to the nucleation of new grain, resulting in a small grain size, as seen in Fig. 8(b). Thus, a higher DRX fraction was obtained, as shown in Fig. 8(a). It is also seen that the DRX process at a ram speed of 9 mm/s was nearly completed. When the ram speed increased up to 11 mm/s, the volume fraction of recrystallized grains in the welding zone decreased to 52.1%. This was because there was no enough time for the migration of grain boundary at high strain rates.

Overall, at an initially low speed, increasing the ram speed caused a large increase of temperature and strain rate, and provided a sufficient number of sites for the nucleation of DRX. At high ram speeds, the increase of ram speed had much less effect on the temperature; thus DRX was suppressed due to high stain rates. The influence of the combination of strain rate and temperature on DRX could be described by Z parameter ( ) [29]. DRX is generally more pronounced at lower Z values. With the decrease of Z value, the main softening mechanism of the alloy transformed from DRV to DRX. According to the study of WANG et al [30], the deformation activation energy (Q) of 6063 aluminum alloy was 173 kJ/mol; R is the universal gas constant (8.314 J/(mol·K));

) [29]. DRX is generally more pronounced at lower Z values. With the decrease of Z value, the main softening mechanism of the alloy transformed from DRV to DRX. According to the study of WANG et al [30], the deformation activation energy (Q) of 6063 aluminum alloy was 173 kJ/mol; R is the universal gas constant (8.314 J/(mol·K));  and T can be determined from the simulated results. Table 2 shows the average values of Z on the welding surfaces at various ram speeds. It is evident that Z value firstly decreased and then increased with the increase of ram speed. At an initially low speed, high temperature rise led to the decrease of Z value with the increase of ram speed, and provided great driving force for DRX. The maximum temperature on the welding surface increased from 476 °C at a ram speed of 3 mm/s to 490 °C at a ram speed of 9 mm/s, as shown in Fig. 9. When the ram speed increased to 11 mm/s, the value of Z slightly decreased as a result of a high strain rate, which was consistent with the trend of DRX fraction.

and T can be determined from the simulated results. Table 2 shows the average values of Z on the welding surfaces at various ram speeds. It is evident that Z value firstly decreased and then increased with the increase of ram speed. At an initially low speed, high temperature rise led to the decrease of Z value with the increase of ram speed, and provided great driving force for DRX. The maximum temperature on the welding surface increased from 476 °C at a ram speed of 3 mm/s to 490 °C at a ram speed of 9 mm/s, as shown in Fig. 9. When the ram speed increased to 11 mm/s, the value of Z slightly decreased as a result of a high strain rate, which was consistent with the trend of DRX fraction.

Table 2 Average Z values at different ram speeds

In the studies of CHEN et al [16] and FAN et al [31], it was found that the strain energy in the welding zone was higher than that in the matrix zone. The complete DRX and partial DRX occurred in the welding and matrix zones, respectively. However, in our study, DRX fraction in the matrix zone was higher than that in the welding zone. From Table 3, it can be seen that the temperature in welding zone was quite close to that in the matrix zone during the metal flowing through the bearing zone. Therefore, different DRX fractions in the profile may be due to the strain rate. Figure 12 shows the strain rate distribution during the metal flowing through the bearing zone at different ram speeds. It can be seen that the strain rate in the matrix zone was lower than that in the welding zone. Thus, there was enough time for the cross-sliding and climbing of dislocations in the matrix zone, leading to a lower value of Z and a higher DRX fraction.

Table 3 Simulated profile temperatures during flowing through die bearing zone

4.3 Effect of DRX on grain structure of welding zone

Under the influence of shearing and compressing stress, the homogenized coarse grains were elongated and grew into strip-shaped grains in the extrusion direction during hot porthole die extrusion [5,27]. Simultaneously, lots of low-angle grain boundaries were formed inside the elongated grains and strip-shaped grains. With the increase of ram speed, substructures with the low-angle grain boundaries were transformed into new grains due to the occurrence of DRX. SAKAI et al [32] found that the accumulation of dislocations at the low-angle grain boundaries led to the transformation from low-angle grain boundaries to high-angle grain boundaries, which resulted in the formation of new DRXed grains. DENG et al [33] found that DRX did not occur in the stretched samples of the 2024 aluminum alloy. However, the transformation from low-angle to high-angle boundaries in the compressed samples resulted in the occurrence of DRX. At a ram speed of 3 mm/s, there were 34.11% of low-angle grain boundaries in the welding zone because of insufficient energy and time for DRX. With the increase of ram speed, the amount of low-angle boundaries significantly decreased as subgrains were removed and the amount of high-angle grain boundaries increased, as shown in Figs. 6 and 7. When the extrusion ram speed increased to 11 mm/s, the fraction of the low-angle grain boundaries gradually increased owing to the inhibition of DRX behavior. Thus, the value of f in the welding zone increased from 14.33% at a ram speed of 9 mm/s to 20.08% at a ram speed of 11 mm/s. In all, the decline of f value was due to DRX, which was beneficial to the grain boundary migration. Before hot porthole die extrusion, the microstructure of the billet featured with equiaxed coarse grains. The average size was around 198 mm. According to the aforementioned experimental results, it can be seen that the coarse grain size of the homogenized billets was considerably refined by porthole extrusion (Figs. 4 and 5). This was primarily due to DRX. As a key factor to determine the final microstructure, DRX is well known to occur in the case of Al alloys.

Fig. 12 Simulated strain rate distribution during metal flowing through bearing zone at different ram speeds

With the increase of ram speed, the fraction of DRX increased. Correspondingly, the subgrain size decreased. In this work, it was generally observed that deformation speed did not have an effect on the grain size. The effect of ram speed on the microstructure was actually exerted through its effects on temperature and strain rate. When the extrusion ram speed varied from 3 to 7 mm/s, the maximum strain rate increased more than two times. FATEMI-VARZANEH et al [34] found that high strain rate was beneficial to the motivation of DRX and the inhibition of grain growth. Therefore, the grain size in the welding zone decreased from 85.7 to 49.8 μm. In the current trials, when the extrusion ram speed varied from 3 to 11 mm/s, the extrusion temperature increased linearly with deformation speed, as shown in Table 1. However, the maximum strain rate only increased by 17.6% when the ram speed increased from 9 to 11 mm/s. According to ZHAO et al [35], the temperature rise increased with the increase of ram speed, which would lead to the grain growth. Thus, the grain size in the welding zone slowly increased from 49.8 μm at a ram speed of 7 mm/s to 54.5 μm at a ram speed of 11 mm/s due to high temperature rise. The grain sizes in the matrix zone were finer and more uniform compared with those in the welding zone. That was due to the higher DRX fraction in the matrix zone (as seen in Fig. 8), which was beneficial to grain refinement.

Therefore, at a low ram speed, increasing the ram speed led to an increase of temperature and a sufficient number of sites for the nucleation, which was beneficial to DRX. This resulted in a significant grain refinement. At a high ram speed, increasing the ram speed caused the inhibition of DRX due to the high strain rate and the slow increase of grain size because of high temperature rise.

4.4 Microhardness variation

Figure 13 shows the microhardness of samples measured at different locations and ram speeds in the extruded tubes. The average microhardness of the homogenized billet was HV0.5 (38±3). It can be seen that the tube extruded at ram speeds of 3 and 9 mm/s had the lowest and the highest hardness, respectively. Overall, the microhardness in the welding zone was lower than that in other zones. The increase of microhardness with the increase of ram speed was mainly caused by two factors. One is that the grain size decreased with the increase DRX fraction, which was helpful for the improvement of microhardness. NAKATA et al [36] claimed that DRX was a process of grain refinement and contributed to the improvement of mechanical properties. BAI et al [37] found that DRX could reduce the grain size and was beneficial to the improvement of strength during porthole die extrusion process. The other is that the dissolution of Mg and Si atoms was enhanced at a high extrudate temperature. The extrudate temperature increased with the increase of ram speed, which was beneficial to the dissolution of Mg and Si atoms in Al matrix. The microhardness increased with the increase of the degree of supersaturation. According to the ZUO et al [38], the average microhardness increased from HV0.1 64.2 to HV0.1 75.3 with the increase of solution temperature. However, at a ram speed of 11 mm/s, the ram speed has much less effect on the temperature rise, as shown in Tables 1 and 3, resulting in a decrease in microhardness due to grain growth.

Fig. 13 Microhardness distribution at different ram speeds

5 Conclusions

(1) Ram speed had a significant impact on the temperature and strain rate, resulting in different DRX fractions in welding zone of 6063 aluminum alloy profile extruded by a porthole die. With the increase of ram speed, the DRX fraction firstly increased due to the increase of strain rate and temperature, and then decreased at high strain rates because there was not enough time for the migration of grain boundary. The DRX fraction in the welding zone was lower than that in the matrix zone due to the higher strain rate.

(2) With the increase of ram speed, the grain size firstly decreased due to the increase of DRX fraction and then slightly increased because of the increase of extrudate temperature. The fraction of low-angle boundaries firstly decreased and then increased with the increase of ram speed. The grain size in the welding zone was larger than that in the matrix zone due to lower DRX fraction.

(3) The decrease of grain size and increase of extrudate temperature were helpful for the improvement of microhardness in the welding zone.

References

[1] LIU G, ZHOU J, DUSZCZYK J. FE analysis of metal flow and weld seam formation in a porthole die during the extrusion of a magnesium alloy into a square tube and the effect of ram speed on weld strength [J]. Journal of Materials Processing Technology, 2008, 200(1): 185-198.

[2] ZHANG X M, FENG D, SHI X K, LIU S D. Oxide distribution and microstructure in welding zones from porthole die extrusion [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(3): 765-772.

[3] LIU Z W, LI L X, YI J, LI S K, WANG G. Influence of extrusion speed on the seam weld quality in the porthole die extrusion of AZ31 magnesium alloy tube [J]. The International Journal of Advanced Manufacturing Technology, 2017, 92(1): 1039-1052.

[4] LOUKUS A, SUBHASH G, IMANINEJAD M. Mechanical properties and microstructural characterization of extrusion welds in AA6082-T4 [J]. Journal of Materials Science, 2004, 39(21): 6561-6569.

[5] YU J, ZHAO G Q, ZHANG C S, CHEN L. Dynamic evolution of grain structure and micro-texture along a welding path of aluminum alloy profiles extruded by porthole dies [J]. Materials Science and Engineering A, 2017, 682: 679-690.

[6] ZHANG C S, ZHAO G Q, CHEN Z R, CHEN H, KOU F J. Effect of extrusion stem speed on extrusion process for a hollow aluminum profile [J]. Materials Science and Engineering B, 2012, 177(19): 1691-1697.

[7] BINGOL S, KESKIN M S. Effect of different extrusion temperature and speed on extrusion welds [J]. Journal of Achievements in Materials and Manufacturing Engineering, 2007, 23(2): 39-42.

[8] SHI L, YANG H, GUO L G, DANG L, ZHANG J. Large-scale manufacturing of aluminum alloy plate extruded from subsize billet by new porthole-equal channel angular processing technique [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(5): 1521-1530.

[9] ZHOU J, LI L, DUSZCZYK J. Computer simulated and experimentally verified isothermal extrusion of 7075 aluminium through continuous ram speed variation [J]. Journal of Materials Processing Technology, 2004, 146(2): 203-212.

[10] GAGLIARDI F, CITREA T, AMBROGIO G, FILICE L. Influence of the process setup on the microstructure and mechanical properties evolution in porthole die extrusion [J]. Materials and Design, 2014, 60: 274-281.

[11] YANG Y, WANG J L, CHEN Y D, HU H B. Effect of strain rate on microstructural evolution and thermal stability of 1050 commercial pure aluminum [J]. Transactions of Nonferrous Metals Society of China, 2018, 28(1): 1-8.

[12] ZHAO Y, SONG B Y, PEI J Y, JIA C B, LI B, GUO L L. Effect of deformation speed on the microstructure and mechanical properties of AA6063 during continuous extrusion process [J]. Journal of Materials Processing Technology, 2013, 213(11): 1855-1863.

[13] ZHU R H, LIU Q, LI J F, CHEN Y L, ZHANG X H, ZHENG Z Q. Flow cure correction and processing map of 2050 Al-Li alloy [J]. Transactions of Nonferrous Metals Society of China, 2018, 28(3): 404-414.

[14] SIKANG R S, KUMAR A M, SACHDEV A K, LUO A A, JAIN V, GUPTA A K. AM30 porthole die extrusions—A comparison with circular seamless extruded tubes [J]. Journal of Materials Processing Technology, 2009, 209(18): 6010-6020.

[15] CHEN L, TANG J W, ZHAO G Q, ZHANG C S, CHU X R. Fabrication of Al/Mg/Al laminate by a porthole die co-extrusion process [J]. Journal of Materials Processing Technology, 2018, 258: 165-173.

[16] CHEN G J, CHEN L, ZHAO G Q, ZHANG C S, CUI W C. Microstructure analysis of an Al-Zn-Mg alloy during porthole die extrusion based on modeling of constitutive equation and dynamic recrystallization [J]. Journal of Alloys and Compounds, 2017, 710: 80-91.

[17] YU J Q, ZHAO G Q, CHEN L. Investigation of interface evolution, microstructure and mechanical properties of solid-state bonding seams in hot extrusion process of aluminum alloy profiles [J]. Journal of Materials Processing Technology, 2016, 230: 153-166.

[18] LI S K, LI L X, HE H, WANG G. Influence of the deformation heating on the flow behavior of 6063 alloy during compression at medium strain rates [J]. Journal of Materials Research, 2019, 34(2): 309-320.

[19] DONATI L, TOMESANI L, MINAK G. Characterization of seam weld quality in AA6082 extruded profiles [J]. Journal of Materials Processing Technology, 2007, 191(1-3): 127-131.

[20] LI L, ZHOU J, DUSZCZYK J. Prediction of temperature evolution during the extrusion of 7075 aluminium alloy at various ram speeds by means of 3D FEM simulation [J]. Journal of Materials Processing Technology, 2004, 145(3): 360-370.

[21] JO H H, LEE S K, JUNG C S, KIM B M. A non-steady state FE analysis of Al tubes hot extrusion by a porthole die [J]. Journal of Materials Processing Technology, 2006, 173(2): 223-231.

[22] ZHU F J, WU H Y, LEE S, LIN M C, CHEN D. Dynamic behavior of a 6069 Al alloy under hot compression [J]. Materials Science and Engineering A, 2015, 640: 385-393.

[23] CAO Z H, SUN Y, ZHOU C, WAN Z P, YANG W H, REN L L, HU L X. Cellular automation of dynamic recrystallization behavior in V-10Cr-5Ti alloy under hot deformation conditions [J]. Transactions of Nonferrous Metals Society of China, 2019, 29(1): 98-111.

[24] ZHANG F, SUN J L, SHEN J, YAN X D, CHEN J. Flow behavior and processing maps of 2099 alloy [J]. Materials Science and Engineering A, 2014, 613: 141-147.

[25] HU H E, ZHEN L, ZHANG B Y, YANG L, CHEN J Z. Microstructure characterization of 7050 aluminum alloy during dynamic recrystallization and dynamic recovery [J]. Materials Characterization, 2008, 59(9): 1185-1189.

[26] XIE J F, ZHU Y L, BIAN F L, LIU C. Dynamic recovery and recrystallization mechanisms during ultrasonic spot welding of Al-Cu-Mg alloy [J]. Materials Characterization, 2017, 132: 145-155.

[27] TANG J W, CHEN L, FAN X K, ZHAO G Q, ZHANG C S. Co-extrusion of dissimilar AA6063/AA7075 by porthole die at various temperatures [J]. Journal of Alloys and Compounds, 2018, 764: 162-169.

[28] LI P W, LI H Z, HUANG L, LIANG X P, ZHU Z X. Characterization of hot deformation behavior of AA2014 forging aluminum alloy using processing map [J]. Transactions of Nonferrous Metals Society of China, 2017, 27(8): 1677-1688.

[29] RAJPUT S K, CHAUDHARI G P, NATH S K. Characterization of hot deformation behavior of a low carbon steel using processing maps, constitutive equations and Zener-Hollomon parameter [J]. Journal of Materials Processing Technology, 2016, 237: 113-125.

[30] WANG M J, YANG L B, GAN C L, PENG D S. Constitutive equation of the flow for 6063 aluminum alloy at elevated temperature [J]. Journal of Huazhong University of Science and Technology (Natural Science Edition), 2003, 31(6): 20-22. (in Chinese)

[31] FAN X H, TANG D, FANG W L, LI D Y, PENG Y H. Microstructure development and texture evolution of aluminum multi-port extrusion tube during the porthole die extrusion [J]. Materials Characterization, 2016, 118: 468-480.

[32] SAKAI T, MIURA H, GOLOBORODKO A, SITDIKOV O. Continuous dynamic recrystallization during the transient severe deformation of aluminum alloy 7475 [J]. Acta Materialia, 2009, 57(1): 153-162.

[33] DENG L, ZHOU P, WANG X Y, JIN J S, ZHAO T. Microstructure evolution and modeling of 2024 aluminum alloy sheets during hot deformation under different stress states [J]. Metals and Materials International, 2018, 24(1): 112-120.

[34] FATEMI-VARZANEH S M, ZAREI-HANZAKI A, BELADI H. Dynamic recrystallization in AZ31 magnesium alloy [J]. Materials Science and Engineering A, 2007, 456(1): 52-57.

[35] ZHAO Z, CHEN Q, WANG Y B, SHU A Y. Microstructures and mechanical properties of AZ91D alloys with Y addition [J]. Materials Science and Engineering A, 2009, 515: 152-161.

[36] NAKATA T, MEZAKI T, XU C, OH-ISHI K, SHIMIZU K, HANAKI S, KAMADO S. Improving tensile properties of dilute Mg-0.27Al-0.13Ca-0.21Mn (at.%) alloy by low temperature high speed extrusion [J]. Journal of Alloys and Compounds, 2015, 648: 428-437.

[37] BAI S W, FANG G, ZHOU J. Analysis of the bonding strength and microstructure of AA6082 extrusion weld seams formed during physical simulation [J]. Journal of Materials Processing Technology, 2017, 250: 109-120.

[38] ZUO W, MA L, LU Y, LI S Y, JI Z Q, DING M. Effects of solution treatment temperatures on microstructure and mechanical properties of TIG–MIG hybrid arc additive manufactured 5356 aluminum alloy [J]. Metals and Materials International, 2018, 24(6): 1346-1358.

李世康1,2,李落星1,2,何 洪2,刘志文1,张 龙1,2

1. 湖南大学 汽车车身先进设计制造国家重点实验室,长沙 410082;

2. 湖南大学 机械与运载工程学院,长沙 410082

摘 要:通过实验与数值模拟相结合的方法,研究动态再结晶对6063铝合金多孔分流模挤出型材焊合区显微组织和力学性能的影响,并采用EBSD技术观察晶粒形貌。结果显示,在初始低速挤压时,随着挤压速度的增大,挤出型材温度升高和应变速率增大,挤出型材动态再结晶分数增大;而在高速挤压时,挤出型材温度随挤压速度的增大增幅较小,型材动态再结晶分数因应变速率的增大而减小。焊合区硬度和小角度晶界分数低于基体区的,较小的再结晶分数使得焊合区晶粒尺寸大于基体区的。减小晶粒尺寸和提高挤出温度有利于提高焊合区型材的硬度。

关键词:6063铝合金;多孔分流模挤压;动态再结晶;显微组织;力学性能

(Edited by Wei-ping CHEN)

Foundation item: Project (U1664252) supported by the National Natural Science Foundation of China

Corresponding author: Luo-xing LI; Tel:+86-731-88821571; E-mail: luoxing_li@yahoo.com

DOI: 10.1016/S1003-6326(19)65088-0