DOI: 10.11817/j.issn.1672-7207.2019.07.005

镍钴基高温合金的氧化动力学与界面结合性能

宋正奇1,李志强2,郑绪东2,沈明明2,邹俭鹏1

(1. 中南大学 粉末冶金国家重点实验室, 湖南 长沙,410083;

2. 云南中烟工业有限责任公司技术中心, 云南 昆明,650231)

摘要:采用XRD,SEM和静态增重法等研究镍钴基GH783高温合金的氧化行为和氧化过程动力学,并通过纳米划痕试验对膜基结合性能进行表征。研究结果表明:合金在500~700 ℃没有生成氧化膜,在800 ℃时开始生成由Fe2O3和少量Fe3O4组成的氧化层,900 ℃时生成的氧化膜中Fe3O4含量增多;合金在800 ℃氧化100 h后,合金表面生成致密的Fe2O3-Fe3O4复合物氧化膜,膜厚约为15 μm;合金的氧化动力学曲线符合抛物线规律,抛物线速度常数为3.44×10-5 mg2/(cm4·h);随着氧化时间增长,氧化膜与基体的界面结合性能愈趋良好,于800 ℃氧化 100 h后膜基结合力达8.92 N。

关键词:高温合金;高温氧化;氧化动力学;界面结合性能

中图分类号:TG172.82 文献标志码:A 文章编号:1672-7207(2019)07-1537-07

Oxidation kinetics and interfacial bonding properties of Ni-Co based superalloys

SONG Zhengqi1, LI Zhiqiang2, ZHENG Xudong2, SHEN Mingming2, ZOU Jianpeng1

(1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. R&D Center, China Tobacco Yunnan Industrial Co. Ltd., Kunming 650231, China)

Abstract: The oxidation behavior and oxidation kinetics of Ni-Co based superalloy were studied by XRD, SEM and the thermogravimetric analysis method. The adhesion strength of the films was characterized by nanoscratch test. The results show that the oxide film is not formed at 500-700 ℃, and an oxide layer is composed of Fe2O3 and a small amount of Fe3O4 forms at 800 ℃. Moreover, the content of Fe3O4 increases rapidly in the oxide film formed at 900 ℃. After oxidized at 800 ℃ for 100 h, a dense oxide film of Fe2O3-Fe3O4 with the film thickness of about 15 μm is formed on the surface of the alloy. The oxidation kinetics curve of the alloy obeys the parabolic law and the speed constant is 3.44×10-5 mg2/(cm4·h). With the increase of oxidation time, the interface bonding performance between the oxide film and the matrix gets better and better. The film/substrate bonding force reaches 8.92 N after oxidation at 800 ℃ for 100 h.

Key words: superalloy; high temperature oxidation; oxidation kinetics; interfacial bonding properties

高温合金是指以铁、钴、镍为基,能长期在600 ℃以上的高温环境中工作的金属材料,具有良好的高温抗氧化性能和抗腐蚀性能以及优异的高温强度、疲劳性能等综合性能,主要用于制造航空航天领域中高温环境下工作的部件如发动机中的叶片、燃烧室、涡轮盘等零部件。高温合金的抗氧化性是评价其性能的重要指标之一,该合金的氧化行为很复杂,含有不同种类和含量合金元素的高温合金氧化行为差别很大,但通常将氧化动力学和氧化膜的成分组成作为评价高温合金抗氧化性的指标[1-2]。国内外对高温合金的氧化行为进行了大量研究,如SHENG等[3]研究了镍基高温合金C263表面再结晶对其氧化行为的影响,发现试样经机械加工后会产生残余应力,导致合金在高温氧化时表面会产生再结晶,再结晶的细晶粒层为氧化层下的Ti和Cr元素以及外界的O和N元素提供了快速扩散的途径,降低了合金的抗氧化性能,抛光后的试样没有产生再结晶现象,抗氧化性能与未经抛光的试样相比有所改善;WANG等[4]研究了多孔 Haynes 214合金在800~1 000 ℃时的氧化行为,发现合金的氧化动力学近似遵循抛物线规律,氧化膜主要由Cr2O3,NiCr2O4和Al2O3组成,合金的微孔为氧提供了快速通道,对氧化层的组成产生了影响;SABER等[5]研究了Inconel 617 高温合金在750~1 000 ℃时的循环氧化行为,发现在850,950和1 000 ℃时合金的氧化动力学遵循抛物线规律,产生的氧化膜由Cr2O3,NiO和NiCr2O4组成,产生的氧化层致密且均匀地附在合金表面;HAMIDI等[6]研究了高温合金In-738LC的氧化动力学和氧化层的成分组成,在高温950 ℃下,氧化动力学遵循抛物线规律,氧化膜由外层的TiO2、中间层的Cr2O3和NiCr2O4以及最内层的Al2O3组成。GH783合金是一种Ni-Co基沉淀硬化型铁磁性抗氧化低膨胀变形高温合金,常用温度低于750 ℃,但在苛刻环境下服役时,有可能超过750 ℃,甚至超过800 ℃。该合金在热变形过程中通过析出β-NiAl相可控制粒径小的晶粒。GH783合金具有优良的室温及高温力学性能、较低的热膨胀系数、易于加工等特点。GH783合金主要用于航空发动机的间隙控制零件,例如压气机机匣、涡轮外环等发动机零件。人们对于GH783合金的研究主要集中于热处理以及长期时效对合金内部组织性能的影响[7-10],而对GH783合金的氧化行为以及界面结合性能的研究较少。为此,本文作者以典型Ni-Co基合金GH783合金为研究对象,研究其在不同温度下的高温氧化行为,利用XRD,SEM和静态增重法分析该合金的氧化膜组成、形貌和氧化动力学规律,通过纳米划痕试验测试氧化膜与基体的结合强度,并探讨GH783合金的高温氧化机理,以便为GH783合金的应用提供参考。

1 实验材料与过程

1.1 实验材料

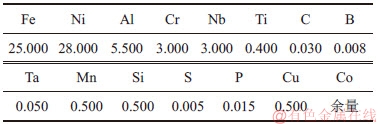

实验所用的GH783高温合金购自上海龙彰实业有限公司。合金的具体化学成分和力学性能分别如表1和表2所示。将GH783合金线切割成长×宽×高为20.0 mm×5.0 mm×0.5 mm标准薄片试样,用320号、500号、800号、1000号和1200号金相砂纸逐级打磨,并采用粒度为0.5 μm的氧化铝抛光粉进行抛光。试样经丙酮、无水乙醇清洗干净,干燥后备用。

表1 合金的化学成分(质量分数)

Table 1 Chemical composition of alloy%

表2 合金的力学性能

Table 2 Mechanical property of alloy

1.2 实验过程

恒温氧化实验在马弗炉里进行。试样置于石英坩埚中,使之与坩埚壁保持线接触,以保证试样能与空气充分接触,在石英坩埚上倒扣另一个石英坩埚以防止灰尘落入。首先选择合适的氧化温度,试样分别在500,600,700,800和900 ℃氧化50 h。然后,对试样进行XRD分析,分析试样表面氧化膜的组成。优选合适的温度后,在该温度下测定合金的氧化动力学曲线,以炉温达到预定温度时开始计时。累计氧化 100 h,其中,分别在1,3,6,12,25,50和100 h后取出试样,冷却10 min后在ME155DU电子分析天平(精度为0.01 mg)上称质量,实验值取3个试样的平均值。在氧化膜的划痕试验中,选用的是锥角为120°、尖端半径为100 μm的金刚石压头,加载范围为0~20 N,划痕速度为2 mm/min,划痕长度为2 mm。在划痕测试过程中,氧化膜在压头连续增加的垂直载荷下会产生剥落,将氧化膜剥落的位置所对应的垂直载荷定义为临界载荷,临界载荷是衡量膜基结合强度的主要依据[11]。

氧化结束后,用SEM和EDS分析试样氧化膜的组成和形貌,并对氧化膜横截面进行观察和分析。通过纳米划痕试验测定氧化膜与基体的结合强度。在上述实验中,采用的设备为X线衍射仪(日本理学(PIGAKV)电机珠式会社,D/max2550)、扫描电子显微镜(FEI公司,Quanta 250 FEG,可进行EDS成分分析)和微纳米划痕仪(瑞士CSM仪器股份有限公司,Micro-Combi Tester型)。

2 结果与讨论

2.1 不同氧化温度下氧化膜的物相组成

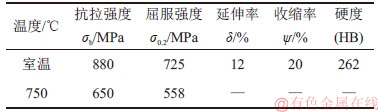

采用X线衍射仪对在不同温度下氧化后的合金表面进行物相分析,结果如图1所示。从图1可知:GH783合金在经过500,600,700,800和900 ℃氧化50 h后,各温度下都有3条较强的特征峰,3条特征峰的晶面指数分别为(111),(200)和(220),这是基体中所含元素Fe和Ni元素形成的固溶体Fe0.64Ni0.36相(PDF 47-1405)的特征峰。此外,各氧化温度下都有CoFe相(PDF 49-1567)的衍射峰,晶面指数为(110)。从图1可以看出:在500,600和700 ℃氧化50 h后其表面并没有生成氧化物;在800 ℃时,出现了Fe2O3相(PDF 84-0309)和Fe3O4相(PDF 89-0951)的特征峰,但Fe3O4相衍射峰强度很小,说明生成的Fe3O4相较少,这时,合金表面的氧化膜主要由Fe2O3和少量Fe3O4组成;当氧化温度上升到900 ℃时,与800 ℃时相比,Fe2O3相和Fe3O4相的衍射峰强度增大,说明温度升高会加快合金的氧化速率。REBAK等[12-13]也在高温合金的氧化实验中观察到类似的氧化膜成分。

图1 合金GH783经不同温度氧化50 h后表面的XRD像

Fig. 1 XRD patterns of surfaces of GH783 superalloy after 50 h oxidation at different temperatures

2.2 氧化膜的形貌和组成

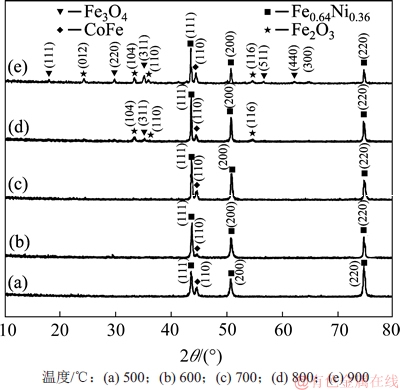

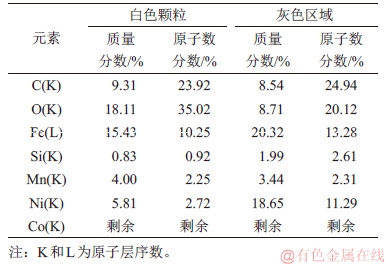

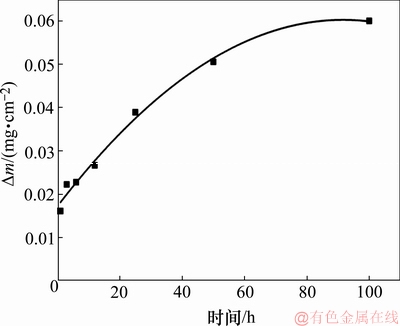

根据上述合金在不同温度氧化50 h后表面的XRD分析结果可知,在500,600和700 ℃时均没有生成氧化物,在800 ℃开始生成氧化物,为此,选择800 ℃为合金不同氧化时间的恒温氧化温度。图2所示为合金在800 ℃的空气中分别氧化1,3,6,12,25,50和100 h后的表面形貌。通过EDS能谱分析,可知合金氧化过程中表面产生的白色颗粒氧质量分数和原子数分数均比灰色区域的高很多(见表3)。结合合金在800 ℃时氧化50 h的XRD图谱发现,银白色颗粒为Fe2O3-Fe3O4复合物。图2(a)表明:氧化1 h后,合金表面出现了很少的Fe2O3-Fe3O4复合物颗粒。从图2(b)~(d)可以看出:氧化1~12 h期间,合金表面的Fe2O3-Fe3O4复合物颗粒逐渐增多;氧化12 h后,合金表面均匀分布着大量的Fe2O3-Fe3O4复合物颗粒,但此时Fe2O3-Fe3O4复合物颗粒粒度较小。图2(e)表明:氧化25 h后,合金表面Fe2O3-Fe3O4复合物颗粒明显团聚长大。图2(f)表明:合金在800 ℃氧化50 h后,样品表面仍能分辨出砂纸打磨的痕迹,说明此时氧化层比较薄,而且此时氧化膜表面出现了“胶状物”,相较于非“胶状”物区域的Fe元素含量,“胶状”物区域Fe元素含量较高,其他元素含量无较大差异(见表4)[14],这些应该是没有发育完全的Fe2O3- Fe3O4复合物颗粒,作为连接物存在于Fe2O3-Fe3O4复合物颗粒之间起黏结剂作用,促使Fe2O3-Fe3O4复合物颗粒的团 聚[15]。从图2(g)可以看出:合金在800 ℃氧化100 h后,合金表面的打磨痕迹消失,析出了大量块状Fe2O3- Fe3O4复合物颗粒并形成了覆盖层,氧化膜表面致密且平整,表面氧化物无脱落。这说明合金在氧化100 h后生成了较厚的氧化膜,氧化膜和GH783合金基体形成了很好的界面结合。

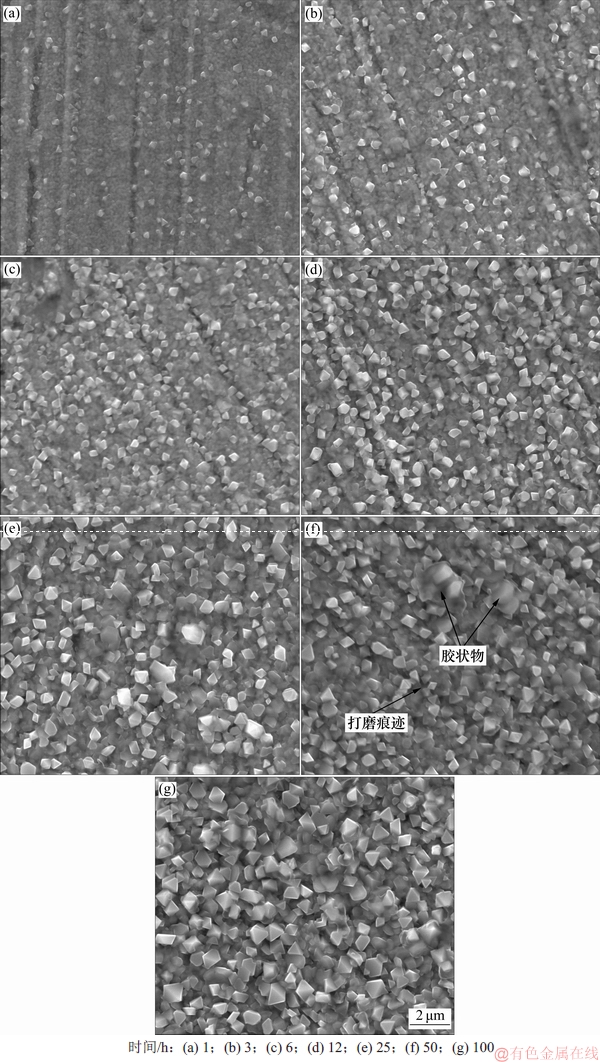

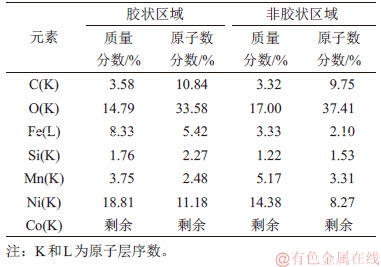

图3所示为合金在800 ℃的空气中氧化1,3,6,12,25,50和100 h后的截面形貌,其中的A区域是基体,B区域是氧化层。图3(a)表明:合金氧化1 h后,此时的氧化层很薄,甚至部分区域还没形成氧化层。从图3(b)~(f)可以看出:合金在氧化3~50 h时,氧化膜都呈现“叠层”状,且存在较多孔洞,空气中的氧通过外层氧化膜的空隙侵入基体,与基体中的Fe元素发生氧化,氧化膜呈堆叠型生长。此外,还可以观察到合金表面的氧化膜厚度并不均匀。但总的来说,随着氧化时间增加,氧化膜的厚度逐渐增加。从图3(g)可以看出:合金氧化100 h后,此时的氧化膜截面形貌与氧化50 h之前相比氧化膜密实平整,氧化膜的“叠层”状结构消失,孔洞也逐渐消失,其氧化膜的平均厚度约为15 μm,氧化膜无脱落现象。这表明合金在800 ℃氧化100 h后得到了致密的氧化膜,且与基体结合良好。

图2 合金GH783在800 ℃氧化不同时间后的表面SEM图

Fig. 2 Surface morphologies of superalloy GH783 oxidized at 800 ℃ for different time

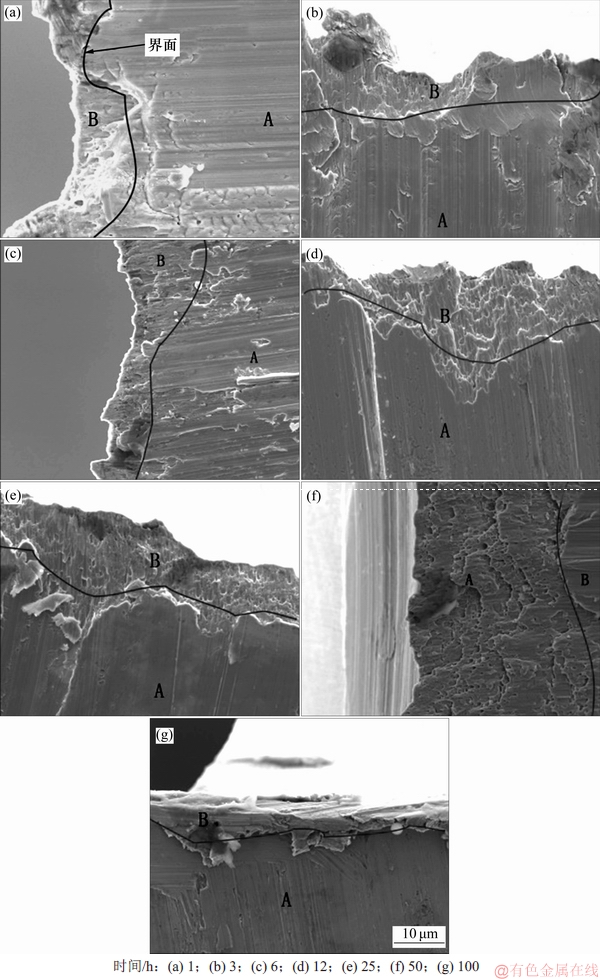

2.3 氧化动力学

图4所示为GH783合金在800 ℃及静态空气中的氧化动力学曲线。从图4可以看出:氧化初期,试样的氧化速度比较快。这是因为合金在氧化初期,合金表面上含有大量的空位、晶界等缺陷,可以作为氧化物成核位点,氧化速度很快,属于氧化膜成型期;随着氧化时间增多,合金表面的晶体缺陷已大部分转化为氧化膜,未成膜晶体缺陷大大减少,氧化膜形核位点减少,氧化速率变化逐渐变缓[16]。

表3 合金在800 ℃氧化6 h后表面氧化膜的能谱分析

Table 3 Apparent EDS results of surface film of superalloy GH783 oxidized at 800 ℃ for 6 h

表4 合金在800 ℃氧化50 h后表面氧化膜的能谱分析

Table 4 Apparent EDS results of surface film of superalloy GH783 oxidized at 800 ℃ for 50 h

图3 合金GH783在800 ℃氧化不同时间后的截面SEM图

Fig. 3 Section morphologies of superalloy GH783 oxidized at 800 ℃ for different time

图4 合金GH783在800 ℃的氧化动力学曲线

Fig. 4 Oxidation kinetics curve of superalloy GH783 at 800 ℃

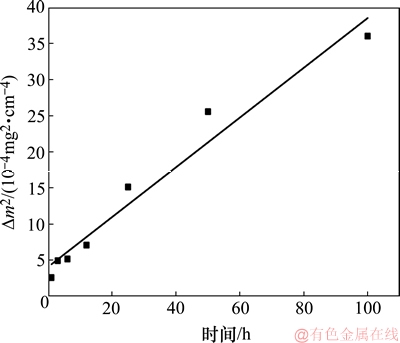

合金在800 ℃下氧化100 h后,氧化增量的平方△m2与氧化时间t的关系如图5所示,其符合曲线方程(△m)2=atb(其中a和b为常数,△m为氧化增量,t为氧化时间),即(△m)2/b=a1/bt,可写成一般形式:Xn=kt,则X为氧化增量,n=2/b, k=a1/b[17]。根据Wagner理 论[18],当n=2时,氧化遵循抛物线规律,此时的氧化速率会随氧化膜厚度增加而降低,说明金属基体的氧化是具有保护效果的氧化,氧化过程通过反应元素在氧化膜中扩散传质来实现;当n>2时,反应元素扩散的阻滞作用比膜增厚产生的阻滞作用更大,氧化膜在增厚的同时会使氧化膜致密化,不利于元素的扩散和氧化。通过对比可知:在n>2时,氧化速率比呈抛物线规律变化的氧化速率小;当n<2时,生成的氧化膜较疏松,不能有效阻止反应元素的扩散和氧化,所以,此时的氧化速率比抛物线规律的氧化速率大。图5中,拟合的动力学曲线方程为(△m)2=3.440 64×10-5t,可知n=2,结合Wagner理论,合金的氧化遵循典型的抛物线规律,是具有保护效果的氧化。用回归分析求出其抛物线速度常数为3.44×10-5 mg2/(cm4·h)。

2.4 氧化膜与合金基底的结合强度

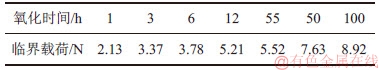

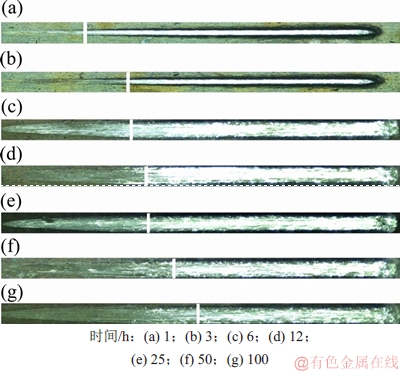

表5和图6所示为合金在800 ℃氧化不同时间后氧化膜的划痕临界载荷以及对应于各样品的划痕形貌。将临界载荷和样品微观的划痕形貌结合起来进行分析可以得出:当氧化时间为1 h时,临界载荷只有2.13 N;随着氧化时间增长,临界载荷越来越大,氧化100 h后的临界载荷达8.92 N,这说明随着氧化时间增长,氧化膜与基体的结合力越来越大(图6中的白色竖线处为膜基界面完全失效时的位置)。

表5 合金GH783在800 ℃氧化不同时间后的膜基结合力

Table 5 Cohesion of between film and substrate of superalloy GH783 oxidized at 800 ℃ for different time

图5 合金在800 ℃氧化增量的平方与时间的关系

Fig. 5 Dependence of square of mass gain of superalloy on oxidation time at 800 ℃

图6 合金GH783在800 ℃氧化不同时间后氧化膜的划痕形貌

Fig. 6 Scratch morphology of superalloy GH783 oxidized at 800 ℃ for different time

划痕具有3种典型的形貌:膜层与基体界面处的整体楔形剥落,划痕轨迹边缘的界面剥落以及膜层的韧性穿透。从图6可以看出:氧化不同时间后,氧化膜的划痕形貌皆为韧性穿透所致。这是因为基体硬度相对于氧化膜的硬度低,当压头压入样品表面后,基体产生塑性变形,不能提供足够的支撑,从而产生较大的压入深度,这时,氧化膜与基体的界面处产生较大的变形量,随之产生韧性穿透的划痕形貌。氧化膜没有产生楔形剥落,说明氧化膜的残余内应力较小,氧化膜与基体结合良好[19]。

3 结论

1) GH783合金在500,600和700 ℃时没有发生氧化;在800 ℃时,氧化产生了Fe2O3和少量Fe3O4;在900 ℃时,氧化产生的Fe2O3和Fe3O4含量增加,说明温度升高加速了GH783合金的氧化。

2) 合金在800 ℃氧化100 h后,表面生成了致密的Fe2O3-Fe3O4复合物氧化膜,氧化膜与基体结合良好,无脱落现象。氧化初期,氧化膜的孔洞较多,氧化膜呈堆叠型生长,氧化100 h后,氧化膜孔洞消失,氧化膜的厚度大约为15 μm。

3) 合金在800 ℃氧化时,氧化动力学行为遵循抛物线规律变化,其抛物线的速度常数为3.44×10-5 mg2/(cm·h)。

4) 在划痕测试中,氧化膜发生了韧性穿透。随着氧化时间增长,氧化膜与基体的结合力越来越大,氧化100 h后,膜基结合力达8.92 N。

参考文献:

[1] SHAW S W K, FLEETWOOD M J. New nickel base investment casting alloys IN 6201 and IN 6203[J]. Materials Science and Technology, 1989, 5(9): 925-933.

[2] PANDEY M C. Decarburization and internal oxidation in a commercial-grade nickel[J]. Oxidation of Metals, 1997, 48(1/2): 129-141.

[3] SHENG Naicheng, HORKE K, MEYER A, et al. Surface recrystallization and its effect on oxidation of superalloy C263[J]. Corrosion Science, 2017, 128: 186-197.

[4] WANG Yan, LIU Yong, TANG Huiping, et al. Oxidation behaviors of porous Haynes 214 alloy at high temperatures[J]. Materials Characterization, 2015, 107: 283-292.

[5] SABER D, EMAM I S, ABDEL-KARIM R. High temperature cyclic oxidation of Ni based superalloys at different temperatures in air[J]. Journal of Alloys and Compounds, 2017, 719: 133- 141.

[6] HAMIDI S, RAHIMIPOUR M R, ESHRAGHI M J, et al. Kinetics and Microstructural Investigation of high-temperature oxidation of in-738LC super alloy[J]. Journal of Materials Engineering and Performance, 2017, 26(2): 563-570.

[7] JIANG Tao, CHEN Liangbin, JIANG Feng, et al. Microstructural evolution and mechanical properties of a nickel-based superalloy through long-term service[J]. Materials Science and Engineering: A, 2016, 656: 184-189.

[8] HAN Guangwei, ZHANG Yiyong. Segregation of niobium and aluminum in GH783 alloy ingots[J]. Materials Science and Engineering: A, 2005, 412(1/2): 198-203.

[9] HAN Guangwei, ZHANG Yiyong. Variations in microstructure and properties of GH783 alloy after long term thermal exposure[J]. Materials Science and Engineering: A, 2006, 441(1/2): 253-258.

[10] YU Lianxu, ZHAO Yating, YANG Shulin, et al. As-cast microstructure and solidification behavior of a high Al- and Nb-containing superalloy[J]. Journal of Materials Science, 2010, 45(13): 3448-3456.

[11] PALESCH E, CECH V. Characterization of interlayer adhesion on single glass fibers and planar glass using the nanoscratch test technique[J]. Thin Solid Films, 2017, 636: 353-358.

[12] REBAK R B, GUPTA V K, LARSEN M. Oxidation characteristics of two FeCrAl alloys in air and steam from 800 °C to 1 300 °C[J]. JOM, 2018, 70(8): 1484-1492.

[13] 邓波, 陈淦生, 龙正东, 等. 微量元素对低膨胀Fe-Ni基高温合金抗氧化性能的影响[J]. 金属学报, 2000, 36(2): 155-158.

DENG Bo, CHEN Gansheng, LONG Zhengdong, et al. The oxidation-resistance properties of low-expansion superalloys[J]. Acta Metallurgica Sinica, 2000, 36(2): 155-158.

[14] WENG Fei, YU Huijun, CHEN Chuanzhong, et al. High- temperature oxidation behavior of Ni-based superalloys with Nb and Y and the interface characteristics of oxidation scales[J]. Surface and Interface Analysis, 2015, 47(3): 362-370.

[15] 肖旋, 徐乐, 秦学智, 等. 稀土元素Y和Ce对定向凝固镍基高温合金高温氧化行为的影响[J]. 中国有色金属学报, 2014, 24(11): 2769-2776.

XIAO Xuan, XU Le, QIN Xuezhi, et al. Effect of elements Y and Ce on high temperature oxidation behavior of directionally-solidified Ni-based superalloy[J]. Chinese Journal of Nonferrous Metals, 2014, 24(11): 2769-2776.

[16] 党理. 镍基单晶高温合金DD5的初始氧化研究[D]. 杭州: 浙江大学材料科学与工程学院, 2017: 19-25.

DANG Li. Study of initial oxidation of Ni-based single crystal superalloy DD5[D]. Hangzhou: Zhejiang University. School of Materials Science and Engineering, 2017: 19- 25.

[17] 潘娜. 镁铝合金高温氧化动力学及氧化过程研究[D].太原: 太原理工大学材料科学与工程学院, 2012: 21-38.

PAN Na. Investigation on oxidation dynamic and process of magnesium-aluminium alloys[D]. Taiyuan: Taiyuan University of Technology. School of Materials Science and Engineering, 2012: 21-38.

[18] 李铁蕃. 金属高温氧化和热腐蚀[M]. 北京: 化学工业出版社, 2003: 139-164.

LI Tiefan. High temperature oxidation and hot corrosion of metals[M]. Beijing: Chemical Industry Press, 2003: 139-164.

[19] BEAKE B D, ENDRINO J L, KIMPTON C, et al. Elevated temperature repetitive micro-scratch testing of AlCrN, TiAlN and AlTiN PVD coatings[J]. International Journal of Refractory Metals and Hard Materials, 2017, 69: 215-226.

(编辑 陈灿华)

收稿日期: 2018 -09 -10; 修回日期: 2018 -11 -21

基金项目(Foundation item):国家自然科学基金资助项目(51274248);湖南省自然科学基金资助项目(2018JJ2524) (Project(51274248) supported by the National Natural Science Foundation of China; Project(2108JJ2524) supported by the Natural Science Foundation of Hunan Province)

通信作者:邹俭鹏,博士,教授,从事粉末冶金新材料和涂层、厚膜与薄膜材料研究;E-mail: zoujp@csu.edu.cn