Magnetic anisotropy in Fe-25Cr-12Co-1Si alloy induced by external magnetic field

ZHEN Liang(甄 良)1, SUN Xue-yin(孙学银)1, XU Cheng-yan(徐成彦)1, 2,

GAO Run-sheng(高润生)1, XU Ren-gen(徐仁根)1, QIN Lu-chang(秦禄昌)2, 3

1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. Department of Physics and Astronomy, University of North Carolina at Chapel Hill, Chapel Hill,

NC 27599-3255, USA;

3. Curriculum in Applied and Materials Sciences, University of North Carolina at Chapel Hill, Chapel Hill,

NC 27599-3255, USA

Received 29 June 2006; accepted 15 January 2007

Abstract: Structural and magnetic properties of Fe-25Cr-12Co-1Si alloy thermo-magnetically treated under different external magnetic field conditions were investigated. Orientation and morphology of the ferromagnetic α1 phase embedded in α2 phase matrix before and after step ageing are characterized by transmission electron microscope(TEM). The results show that the ellipsoidal particles of ferromagnetic α1 phase are aligned along the direction of external magnetic field during isothermal magnetic ageing. Approximately 28% of the total coercivity can be attributed to the shape anisotropy of α1 phase particles induced by external magnetic field for Fe-25Cr-12Co-1Si alloy thermo-magnetically treated with a parallel magnetic field.

Key words: Fe-Cr-Co alloy; magnetic anisotropy; microstructure; magnetic properties

1 Introduction

The ductile permanent magnets based on Fe-Cr-Co system have found applications in magnetic sensors, telephone receivers, hysteresis motors and aircraft magnetos etc, due to the combination of excellent ductility and good magnetic properties[1-6]. The Fe-Cr-Co alloy undergoes a spinodal decomposition to form (Fe, Co)-rich α1 phase and Cr-rich α2 phase within the miscibility gap, similar to the binary Fe-Cr systems[7]. The origin of permanent magnetic properties for this kind of alloy is attributed to the two-phase structure formed by spinodal decomposition. Orientation, size, volume fraction and chemical composition of the ferromagnetic α1 phase will determine the magnetic properties of this alloy.

Magnetic properties of Fe-Cr-Co alloys can be enhanced by imparting shape anisotropy to the two-phase structure. Thermo-magnetic treatment(TMT) is usually adopted to elongate the ferromagnetic α1 phase and thus imparts magnetic anisotropy to this kind of alloy[8-10]. Deformation-ageing process was also developed to introduce magnetic anisotropy by mechanically elongating particles of the ferromagnetic α1 phase [11-12]. Attempts have been made to separate the contribution of shape anisotropy to the total coercivity in Fe-Cr-Co alloy. The contribution of shape anisotropy induced by wire drawing to the total coercivity was determined as 75% in the case of deformation-aged anisotropy Fe-33.7Cr- 11.6Co alloy, and 55% in the case of isotropy alloy with elongated and randomly distributed α1 particles[13]. In the present work, we attempt to separate the contribution of shape anisotropy of α1 phase particles induced by external magnetic field to the total coercivity for Fe-25Cr-12Co-1Si alloy. Structural and magnetic properties of the alloy with different orientations to the direction of external magnetic field during isothermal ageing were also studied.

2 Experimental

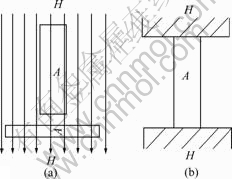

The Fe-25Cr-12Co-1Si alloy (mass fraction, %) was melted in a vacuum induction furnace. The ingot was homogenized at 1 200 ℃ and then hot forged to d60 mm bars. Flake-like samples of 18 mm×10 mm×2.8 mm cut from the bar were solid solution treated at 1 050 ℃ for 1 h, and then quenched into iced brine. The same optimal parameters of isothermal ageing at 647 ℃ for 1 h were adopted for the alloy, without external magnetic field (Hext), with a parallel and a perpendicular external magnetic field of 636.6 kA/m (8 kOe), respectively, as shown in Fig.1(a). A complex step ageing process was subsequently conducted following the isothermal treatment. The detail of heat treatment process was described in Ref.[14].

TEM foils were jet-polished and then observed on Philips CM-12 transmission electron microscope at 120 kV and JEM-100CX at 100 kV. Magnetic properties were measured with a DC automatic hysteresisograph (Model NIM-200) at room temperature. The sample orientation relative to the magnetization field is shown in Fig.1(b).

Fig.1 Orientation of flake-like samples: (a) External magnetic field; (b) Magnetization field during measurement

3 Results and discussion

3.1 Orientation and morphology of ferromagnetic α1 phase

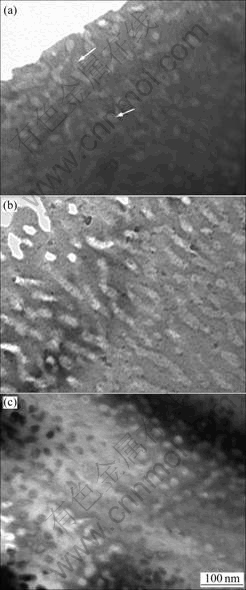

Fig.2(a) shows a typical isotropic modulated structure in Fe-25Cr-12Co-1Si alloy isothermally aged without external magnetic field. The rod-like particles of ferromagnetic α1 phase (marked by white arrows in Fig.2(a)) interconnect with each other to some extend. The isolated circular cross sections of rod-like particles indicate the isotropic nature in three-dimension space. When isothermal ageing is conducted in an external magnetic field, the ferromagnetic α1 phase particles are elongated and aligned along the direction of the external magnetic field, as shown in Fig.2(b). The aspect ratio of the ferromagnetic α1 phase particles is about 5. The energy of external magnetic field is large enough to rotate the magnetic moment direction of α1 phase particles to the nearest direction of external magnetic field, because the demagnetization energy along the direction of external magnetic field is the smallest. The remanence of the alloy can reach 0.94Ms (Ms is the saturation magnetization) after magnetic ageing and 28 h of step ageing. The high remanence indicates that the elongated particles of α1 phase are aligned along the direction of the external magnetic field, independent of crystal orientation[15]. This is further proved in Fig.3, where the particles of α1 phase in three adjacent grains are almost aligned in the same direction. When TEM micrograph was taken perpendicular to external magnetic field, cross sections of the elongated α1 phase were presented, as shown in Fig.2(c). The average diameter of the cross section was measured as 17.5 nm, which is the same as that of elongated rods in Fig.2(b).

Fig.2 TEM images of as-TMT alloy treated under different TMT conditions: (a) Without Hext; (b) With parallel Hext; (c) With perpendicular Hext

Fig.3 TEM images showing orientation of ferromagnetic α1 phase in adjacent grains of as-TMT alloy

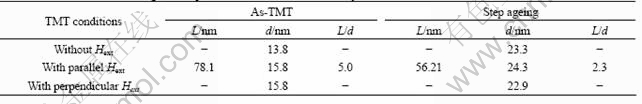

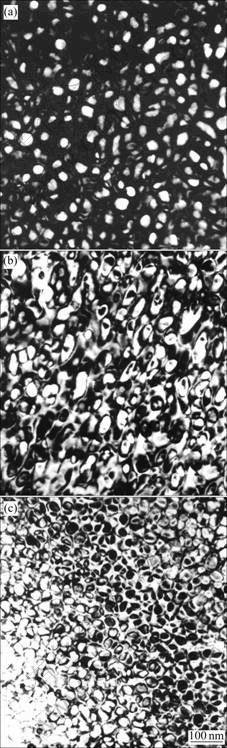

Phase separation further processes at lower temperatures during step ageing, in which the difference of composition between the two phases increases and thus leads to morphology change of the ferromagnetic α1 phase. Fig.4 shows the two-phase structure of the alloy after long time ageing at lower temperatures. For the alloy treated without external magnetic field, the interconnected particles of α1 phase turn to be spherical and are randomly distributed in the matrix, as shown in Fig.4(a). Compared with those shown in Fig.2(a), the isolated particles are responsible for larger diameter than that of as-TMT alloy. Coarsening of α1 particles could also be found for the alloy treated in parallel and perpendicular magnetic field. The diameter of α1 phase particles increases to about 23 nm, and the α1 phase particles give aspect ratio of 2.3 for the alloy treated parallel to the external magnetic field, as depicted in Table 1. However, the alignment of α1 phase remains unchanged for the alloy treated in parallel magnetic field after step ageing.

Table 1 Particle size of ferromagnetic α1 phase for Fe-25Cr-12Co-1Si alloy under different TMT conditions

3.2 Magnetic properties and shape anisotropy

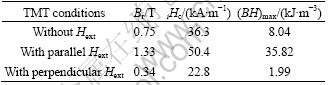

Table 2 gives the magnetic properties of the Fe-25Cr-12Co-1Si alloy thermo-magnetically treated at 647 ℃ for 1 h, without Hext and with a parallel and a perpendicular Hext of 636.6 kA/m, respectively, followed by the same step ageing process. The parameters for the thermo-magnetic treatment here are the optimized ones for this alloy[14]. The isotropic alloy treated without applied magnetic field gives medium remanence of Br=0.75 T and coercivity of iHc=36.3 kA/m, but poor maximum energy product (BH)max. It is interesting to note that Mr/Ms is 0.53, which is a little larger than the limitation of 0.5 for isotropy uniaxial magnets according to Stoner-Wohlfarth model[16]. This may also infer the isotropic nature of the alloy if no external magnetic field was applied during isothermal ageing. Magnetic anisotropy was introduced to the alloy by applying an external magnetic field during isothermal ageing and larger coercivity was obtained for the alloy treated in a parallel magnetic field. While the alloy treated perpendicular to the external magnetic field gives even worse magnetic properties than that of the isotropic alloy. (Fe, Co)-rich particles of ferromagnetic α1 phase for the isotropic alloy are spherical with no significant shape anisotropy after step ageing, as shown in Fig.4(a), so it is possible to determine the contribution of shape anisotropy of α1 phase particles to the total coercivity in the Fe-Cr-Co alloy. Compositions of the two phases are here assumed to reach the near-equilibrium compositions already and to be the same for the three structures in Fig.4. Approximately 28% of the total coercivity can be attributed to the shape anisotropy of a1 phase particles for the alloy treated in a parallel magnetic field, compared with that treated without magnetic field, which corresponds to an isotropic structure.

Fig.4 Final state microstructures of alloy treated with different TMT conditions: (a) Without Hext; (b) With parallel Hext; (c) With perpendicular Hext

Table 2 Magnetic properties of Fe-25Cr-12Co-1Si alloy treated under different TMT conditions

The orientation of the ferromagnetic a1 phase in the magnetization field is shown in Fig.5 for both anisotropy and isotropy alloy, depending on external magnetic field applied or not. For the alloy treated with a parallel magnetic field (Fig.1(a)), the ferromagnetic α1 phase is aligned along the direction of applied magnetic field. In this condition, the alloy gets the best magnetic properties since the orientation of ferromagnetic phase is consistent with the direction of saturation field, as shown in Fig.5(a). While particles of the ferromagnetic α1 phase in the alloy treated in a perpendicular magnetic field are perpendicular to the saturation magnetic field, as shown in Fig.5(b), the alloy exhibits even worse properties than the isotropy alloy. So it is very important for a bulk alloy that the direction of applied magnetic field both in TMT and magnetization should be the same. If there is a small angle difference between these directions, magnetic properties of the alloy will have some difference. Increasing the long axis b or reducing the short axis a of the ellipsoid, that is, a larger aspect ratio, will lead to larger shape anisotropy of α1 phase particles and thus give higher coercivity. However, the as-TMT alloy with larger aspect ratio of α1 phase gives hardly any permanent magnetic properties. From the discussion above, it is known that the coercivity of the alloy mainly comes from the difference between the magnetization of the two phases, which increases with increasing the difference of chemical composition between the two phases. Step ageing till low temperature under 550 ℃ is essentially necessary to turn the α2 phase to be paramagnetic[17] and thus to give larger difference of magnetization between α1 phase and α2 phase. So it is important to maintain high aspect ratio for α1 phase particles during step ageing, which can be realized by applying external magnetic field during step ageing or by optimizing the parameters of step ageing.

Fig.5 Orientation of magnetization field for α1 phase particles during magnetization: (a) Parallel to long axis; (b) Parallel to short axis

4 Conclusions

1) The particles of ferromagnetic a1 phase are aligned along the direction of external magnetic field, while the elongated and randomly distributed α1 phase particles turn to be spherical for the alloy treated without applied magnetic field.

2) The contribution of shape anisotropy induced by applied magnetic field of 636.624 kA/m to the total coercivity of the Fe-25Cr-12Co-1Si alloy is approximately 28%.

References

[1] KUBOTA T, WAKUI G, ITAGAKI M. Hysteresis motor using magnetically anisotropic Fe-Cr-Co magnet [J]. IEEE Transactions on Magnetics, 1998, 34(6): 3888-3896.

[2] AHMAD Z, UL HAQ A, HUSAIN SW, ABBAS T. Magnetic properties of isotropic Fe-28Cr-15Co-3.5Mo permanent magnets with additives [J]. Physica B, 2002, 321(1/4): 54-59.

[3] AHMAD Z, ULHAQ A, HUSAIN S W, ALI A, ABBAS T. Influence of Ti content on magnetic and microstructural properties of Fe-28Cr-15Co-3.5Mo permanent magnets [J]. Journal of Magnetism and Magnetic Materials, 2003, 257(2/3): 397-402.

[4] LI T, LI W, PAN W, LI X M. Effect of microstructure on the coercivity of Fe40-45Cr30-35Co20-25Mo0-4Zr0-2 alloy [J]. Acta Physica Sinica, 2005, 54(9): 4389-4395.

[5] LI L Y, YI J H, PENG Y D, TANG X W, ZENG Q L, FU Y S, LUO S D. Structure and magnetic properties of high-performanced Sm2(Co, Fe, Cu, Zr)17 alloys [J]. Trans Nonferrous Met Soc China, 2002, 12(2): 294-296.

[6] LIAN L X, LIU Y, LI J, GAO S J, TU M J. Effect of magnetic-field heat treatment on magnetic properties of Nd2Fe14B/α-Fe nanocrystalline peranent magnets [J]. The Chinese Journal of Nonferrous Metals, 2004, 14(2): 2085-2089. (in Chinese)

[7] ALLEG S, BOUZABATA B, GRENECHE J M. Study of the local environment during the phase decomposition of Fe-30.8Cr-12.2Co alloy by M?ssbauer spectrometry [J]. Journal of Alloys and Compounds, 2000, 312(1/2): 265-272.

[8] OKANA M, THOMAS G, HOMMA M. Microstructure and magnetic properties of Fe-Cr-Co alloys [J]. IEEE Transactions on Magnetics, 1978, 14(4): 245-252.

[9] KANEKO H, HOMMA M, FUKUNAGE T, OKADA M. Fe-Cr-Co permanent magnet alloys containing Nb and Al [J]. IEEE Transactions on Magnetics, 1975, 11(5): 1440-1402.

[10] SUGIMOTO S, HONDA J, OHTANI Y, OKADA M, HOMMA M. Improvements of the magnetic properties of equiaxed Fe-Cr-Co-Mo hard magnets by two-step thermomagnetic treatment [J]. IEEE Transactions on Magnetics, 1987, 23(5): 3193-3195.

[11] JIN S. Deformation-induced anisotropic Cr-Co-Fe permanent magnet alloys [J]. IEEE Transactions on Magnetics, 1979, 15(6): 1748-1750.

[12] JIN S, GAYLE N V, BERNARDINI J E. Deformation-aged Cr-Co-Cu-Fe permanent magnet alloys [J]. IEEE Transactions on Magnetics, 1980, 16(5): 1050-1052.

[13] JIN S, BRASEN D, MAHAJAN S. Coercivity mechanisms in Fe-Cr-Co magnet alloys [J]. Journal of Applied Physics, 1982, 53(6): 4300-4303.

[14] SUN X Y, XU C Y, ZHEN L, GAO R S, XU R G. Microstructure and magnetic properties of Fe-25Cr-12Co-1Si alloy thermo-magnetically treated in intense magnetic field [J]. Journal of Magnetism and Magnetic Materials, 2004, 283(2/3): 231-237.

[15] CHIN T S, WU T S, CHANG C Y. Spinodal decomposition and magnetic properties of Fe-Cr-12Co permanent magnet alloys [J]. Journal of Applied Physics, 1983, 54(8): 4502-4511.

[16] STONER E C, WOHLFARTH E P. A mechanism of magnetic hysteresis in heterogeneous alloys [J]. IEEE Transactions on Magnetics, 1991, 27(4): 3475-3518.

[17] XU C Y, ZHEN L, SUN X Y, XU R G, GAO R S, ZHANG X M. M?ssbauer spectrometry study of spinodal decomposition in Fe-25Cr-12Co-1Si alloy during step ageing [J]. Materials Science Forum, 2005, 475: 2139-2142.

Corresponding author: ZHEN Liang; Tel: +86-451-86412133; E-mail: zhenl@hit.edu.cn

(Edited by YANG Hua)