文章编号:1004-0609(2012)09-2529-10

轴向取向组织BFe10-1-1管材冷轧加工过程中

组织、织构与力学性能的变化

梅 俊,刘新华,姜雁斌,谢建新

(1. 北京科技大学 材料先进制备技术教育部重点实验室,北京 100083;

2. 北京科技大学 新材料技术研究院,北京 100083)

摘 要:采用热冷组合铸型(HCCM)水平连铸技术制备具有轴向取向组织的BFe10-1-1管材,对管材进行冷轧加工,研究管材的组织、织构与性能的变化。结果表明:HCCM水平连铸管材不需铣面便可直接冷轧加工;无中间退火的累积冷轧变形量可达80%以上;冷轧管表面质量好,轧制过程中无裂纹、裂口和飞边等缺陷;随着变形量的增加,取向组织晶粒内一次枝晶主干间距逐渐减小,由铸态的100~200 μm减小到变形量60%时的10~20 μm;当冷变形量为60%时,组织中可观察到剪切带,当冷变形量为80%时,组织呈波浪状,枝晶、晶界很难辨认;冷轧过程中管材由铸造织构(主要取向{012}á ?)、经过渡型织构{012}á100?(变形量为20%)和{057}á

?)、经过渡型织构{012}á100?(变形量为20%)和{057}á ?(变形量为40%),转变为变形量为60%时的Cube织构,当变形量为80%时转变为G织构;随着变形量的增加,冷轧管的抗拉强度和硬度分别由铸态的234 MPa和70HV增加至变形量80%时的372 MPa和152HV,伸长率由铸态的46.5%降低至80%变形量时的13%。

?(变形量为40%),转变为变形量为60%时的Cube织构,当变形量为80%时转变为G织构;随着变形量的增加,冷轧管的抗拉强度和硬度分别由铸态的234 MPa和70HV增加至变形量80%时的372 MPa和152HV,伸长率由铸态的46.5%降低至80%变形量时的13%。

关键词:BFe10合金;水平连铸;热冷组合铸型;冷轧管;轧制织构

中图分类号:TG146.1;TG335.1 文献标志码:A

Evolution of microstructure,

texture and mechanical properties of BFe10-1-1 tube with

microstructure along axial orientation during cold-rolling

MEI Jun, LIU Xin-hua, JIANG Yan-bin, XIE Jian-xin

(1. Key Laboratory for Advanced Materials Processing, Ministry of Education,

University of Science and Technology Beijing, Beijing 100083, China;

2. Institute for Advanced Materials and Technologies, University of Science and Technology Beijing,

Beijing 100083, China)

Abstract: BFe10-1-1 cupronickel tubes with the microstructure along axial orientation were fabricated by a heating-cooling combined mold (HCCM) technology. The tubes were cold-rolled to study the evolution of microstructure, texture and mechanical properties during cold rolling. The results show that the tubes produced by the HCCM can be directly used for subsequent cold rolling without surface milling and the accumulated cold-rolling deformation approaches to 80% without intermediate annealing. The cold-rolled tubes have good surface quality without defects of crack, breach and flash. The primary dendrite arm space in the oriented grains decreases gradually with an increase in the deformation, i.e. 100-200 μm of the casting tube is decreased to 10-20 μm of the tube with 80% deformation. When the deformation reaches 60%, the shear band can be observed, and when the deformation reaches 80%, the grain is of a wavy-structure, and the dendrite and grain boundary are difficult to be identified. During cold rolling, the cast texture of the casting tube (main orientation{012}á ?) transforms into Cube texture after 60% deformation and into G texture after 80% deformation, through the transition type textures of {012}á100? (20% deformation) and {057}á

?) transforms into Cube texture after 60% deformation and into G texture after 80% deformation, through the transition type textures of {012}á100? (20% deformation) and {057}á ? (40% deformation). With increasing the deformation, the tensile strength (243 MPa) and hardness (70HV) of the casting tube are increased to 372 MPa and 152HV of the tube with 80% deformation, respectively, while the elongation (46.5%) of the casting tube is reduced to 13% of the tube with 80% deformation.

? (40% deformation). With increasing the deformation, the tensile strength (243 MPa) and hardness (70HV) of the casting tube are increased to 372 MPa and 152HV of the tube with 80% deformation, respectively, while the elongation (46.5%) of the casting tube is reduced to 13% of the tube with 80% deformation.

Key words: BFe10 alloy; horizontal continuous casting; heating-cooling combined mold; cold-rolled tube; rolling texture

基金项目:国家“十二五”科技支撑计划资助项目(2011BAE23B00)

收稿日期:2011-07-04;修订日期:2012-04-28

通信作者:谢建新,教授,博士;电话:010-62332254;E-mail: jxxie@mater.ustb.edu.cn

铁白铜具有较高的强度、良好的导热性能和优良的耐蚀性能。铁白铜管材作为冷凝管、热交换器管等广泛应用于火电、船舶、海水淡化等领域[1]。

作为铁白铜典型代表的BFe10-1-1(简称BFe10)管材,传统生产方法采用“半连铸实心铸锭—热挤压管材—冷轧—拉拔”的工艺(简称挤轧拉拔法),由于冷轧/拉拔道次多,加上酸洗、中间退火等工艺,总加工工序多达20多个道次,导致工艺流程长、能耗高、成材率低、成本高等一系列问题[2]。

“水平连铸白铜管坯-内外表面加工处理-行星轧制开坯-直拉或盘拉”(简称冷型连铸轧拉法)是近年来开发的一种短流程新工艺,采用该工艺可高效生产大直径、厚壁白铜管坯,成材率较传统的挤轧拉拔法明显提高,但白铜管普通水平连铸(冷型连铸)时存在两个主要问题:一是管材内外表面质量较差,存在橘皮、褶皱、裂纹等表面缺陷,在后续加工前,须进行外表面铣面、内表面采用钢丝刷进行刷铣(抛光)处理,一方面增加了工序,降低了成材率,另一方面管坯内表面缺陷往往难以有效消除,被带入后续加工工序,影响产品的质量;二是冷型连铸管材组织具有发达的径向柱状晶组织,致密度较低,不利于后续的壁厚减薄、轴向延伸的冷加工成形(如轧制、拉拔)。

采用连续定向凝固方法(热型连铸)制备小尺寸薄壁纯铜或铜合金管材[3-4],然后根据需要进一步加工成精密细小管材,是一种有发展前景的短流程新工艺[5]。采用热型连铸制备的小尺寸薄壁白铜管材具有接近镜面级的表面质量和沿轴向取向的连续柱状晶组织,室温拉伸伸长率达到49%[3],特别适合于采用盘拉、连拉等方法直接进行后续冷加工成形。热型连铸时,金属的固液界面被控制在加热铸型(热型)的出口附近,以建立沿拉坯方向的高温度梯度,获得沿轴向生长的单晶或连续柱状晶组织。这一凝固特点导致热型连铸也存在两个方面的问题:一是在连铸速度较大或工艺参数波动时,铸型出口处容易出现拉漏问题[3],因而工艺控制难度较大;二是由于受拉坯方向高温度梯度要求的限制,连续定向凝固所制备的管材直径较小(一般直径小于40 mm),壁厚较薄(小于2 mm),连铸速度较慢(小于30 mm/min)。

热冷组合铸型(Heating-cooling combined mold,简称HCCM)水平连铸技术[6]是一种管材连铸新工艺,其特点如下:通过将加热铸型和冷却铸型组合在一起,构成一个由加热段(热型段)和冷却段(冷型段)组合而成的热冷组合铸型,可在热型段和冷型段过渡区域内建立沿拉坯方向的高温度梯度,实现组织沿拉坯方向结晶生长,获得沿轴向取向的柱状晶组织[7]。同时,由于金属的固液界面位置可以在组合铸型中一定范围内变化,不仅解决了热型连铸法易拉漏的问题,而且有利于增大连铸管材的直径、壁厚和连铸速度,使其接近冷型连铸的水平[8]。研究结果表明,HCCM水平连铸法可有效消除冷型连铸管材中沿径向发达的柱状晶组织,获得高轴向取向、高致密的柱状晶组织;可完全消除橘皮、褶皱、裂纹等表面缺陷。采用HCCM水平连铸制备管坯,然后直接进行冷加工成形,可大大缩短白铜管材传统生产工艺流程,有利于提高成材率和降低生产成本,是一种具有重要发展前景的高效短流程工艺。

本文作者以HCCM水平连铸制备的轴向取向柱状晶组织BFe10管为原料,研究合金管在冷轧加工过程中的组织、织构和力学性能的变化。

1 实验

1.1 管材制备与轧制成形

实验材料为BFe10铁白铜合金,合金成分按标准成分中间值配比,熔炼后取样进行化学成分分析,其结果如表1所列。

表1 BFe10-1-1铁白铜的化学成分(参照GB/T 5234—2001)

Table 1 Chemical compositions of BFe10-1-1 according to GB/T 5234—2001

.jpg)

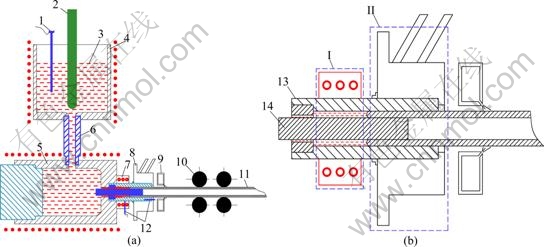

HCCM水平连铸的基本原理如图1[6]所示。合金在熔炼坩埚4中熔化后,经导流管6进入保温坩埚5中保温;当保温坩埚温度与热型段Ⅰ的温度达到设定值后,开启牵引机构10进行管材连铸成形。实验时,可通过调整熔体温度、热型段加热温度、冷型段冷却水流量和连铸拉坯速度等参数控制管材的质量。

图1 热冷组合铸型水平连铸工艺原理示意图[6]

Fig. 1 Process principle schematic diagram for heating-cooling combined mold (HCCM) casting[6]: (a) Schematic diagram of process principle; (b) Structure schematic diagram of HCCM; 1—Temperature measuring device; 2—Stopper; 3—Alloy melt; 4—Melting crucible; 5—Holding crucible; 6—Diversion pipe; 7—Mold heating device; 8—Water-cooled copper sleeve; 9—Secondary cooling water; 10—Traction device; 11—Tube; 12—Temperature measuring device; 13—Mold; 14—Core rod;Ⅰ—Section of heating mold;Ⅱ—Section of cooling mold

HCCM水平连铸制备参数如下:熔化温度1 250 ℃,保温温度1 250 ℃,热型段采用感应加热方式,热型段加热温度(热型温度)1 200 ℃,冷型段冷却水流量700 L/h,连铸拉坯速度80 mm/min,连铸管材尺寸d 50 mm×5 mm。

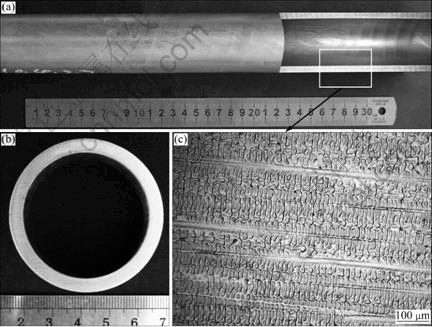

图2所示为连铸管材的宏观形貌[8]。由图2(a)可知,连铸管材的内外表面光亮,无橘皮、微裂纹等表面缺陷,因而无需铣面可直接进行后续轧制;由图 2(b)可知,管材横截面壁厚尺寸均匀;由图2(c)可知,连铸管材组织为明显沿轴向取向生长的柱状晶组织,枝晶主干方向与管材轴向存在一个小的角度,沿生长方向不完全连续,一次枝晶主干间距为100~150 μm。

图2 连铸管材的形貌及金相组织[8]

Fig. 2 Morphology and metallograph of cast tube[8]: (a) External and internal surface of tube; (b) Transverse section of tube; (c) Metallograph of tube

采用LD60型皮尔格三辊周期式冷轧机对管材进行轧制,轧制送进量4~15 mm/次,双行程次数75~85 次/min,轧制过程中不进行中间退火。

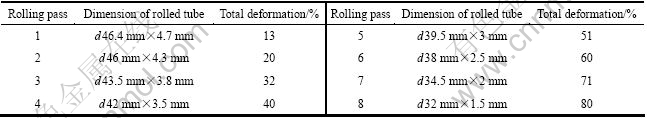

轧制管材的初始尺寸为d 50 mm×5 mm,轧制制度如表2所列。

表2 BFe10-1-1白铜管材三辊周期式冷轧轧制制度表

Table 2 Rolling schedule table of Bfe10-1-1 tube in 3-roller cold pilger mill

1.2 测试分析方法

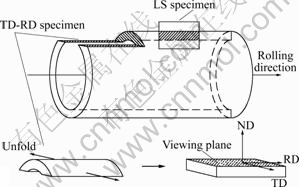

分别从表2所示总变形量为20%、40%、60%和80%的冷轧管材上截取长约150 mm的管材试样,采用线切割从所截取的管材试样上取近轧制平面(TD-RD)试样和纵截面(LS)试样,取样方法如图3所示。试样经粗磨、细磨和抛光后,采用HNO3 40 mL + CH3COOH 40 mL + H2O 20 mL混合溶液侵蚀以获得微观组织。采用LV150型光学金相显微镜进行金相分析;采用西门子D5000型X射线衍射仪进行冷轧管 近轧制平面试样的织构分析,织构测定时采用Cu Kα辐射,管电压为35 kV,管电流为28 mA,测量{111}、{200}和{220} 3张不完整极图,扫测按同心圆步进方式进行,α为0°~70°,β为0°~360°,测量步长为5°,采用二步法计算ODF极图,结果用恒φ2 ODF截面图表示。在HXD-1000T型维氏显微硬度计上测量不同变形量冷轧管8点硬度,然后取平均值,载荷大小为49 N,加载时间为15 s;采用MTS万能材料实验机分析不同变形量冷轧管的力学性能,拉伸试样加工及拉伸实验参照GB/T 228—2002《金属材料室温拉伸实验》。

图3 冷轧管试样取样位置与方法示意图

Fig. 3 Schematic diagram of sampling position and method for specimens of cold-rolled tube

2 结果与分析

2.1 冷轧管形貌及宏观组织演变

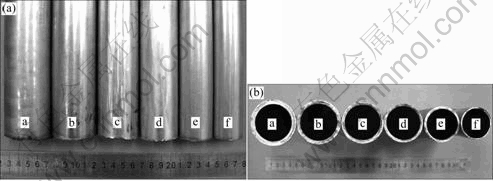

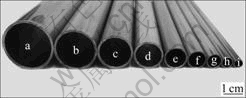

白铜管材传统生产的冷轧和冷拉拔工序中,当变形量达到60%左右时,为保证后续加工的顺利进行,管材需进行中间退火,并且退火温度较高(700~750 ℃)。图4所示为未经中间退火处理的不同变形量冷轧管照片。由图4可知,连铸管材不经铣面可直接进行多道次冷轧,各道次轧后管材表面光亮,未产生裂纹、裂口、飞边等缺陷,表明采用HCCM水平连铸工艺制备的管材,无需中间退火,可实现多道次大变形量的冷轧变形,具有良好的冷加工性能。

图4 不同变形量冷轧后的管材形貌

Fig. 4 Morphologies of tubes under different cold-rolling deformations: (a) Surface morphology of rolled tubes; (b) Morphology of transverse section of rolled tubes; a—20%; b—40%; c—51%; d—60%; e—71%; f—80%

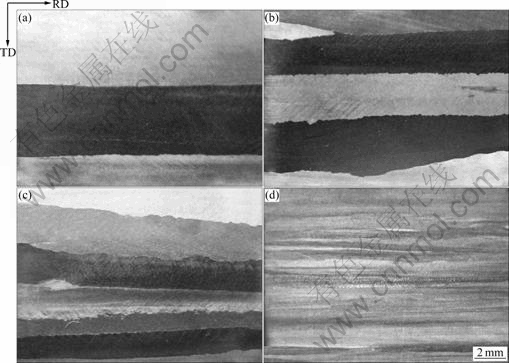

图5所示为不同变形量冷轧后管材的宏观组织。由图5可知,随着变形量的增加,晶粒直径逐渐变小,当变形量达到80%时,晶粒变得细长且晶界难以辨认。

图5 不同变形量冷轧后管材TD-RD平面宏观组织

Fig. 5 Macrostructures of tubes (TD-RD plane) under different cold-rolling deformations: (a) 20%; (b) 40%; (c) 60%; (d) 80%

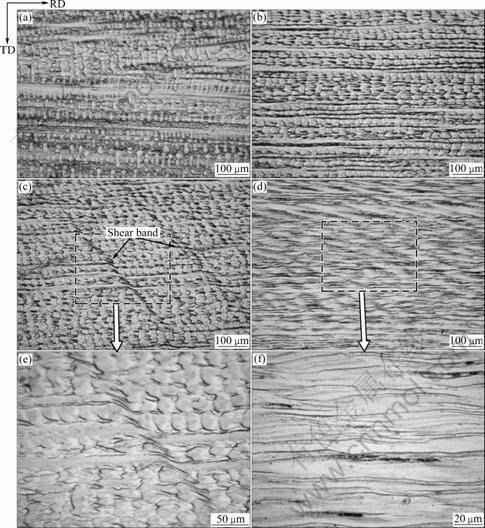

图6所示为不同变形量冷轧后管材的高倍金相组织。由图6可知,随着变形量的增加,晶粒内一次枝晶主干间距逐渐减小,由图2(c)铸态的100~150 μm减小到图6(c)所示变形量为60%时的10~20 μm,并且由于轧辊的碾压,枝晶主干以及枝晶臂从尖锐到扁平直至模糊不清;在60%变形量下,由于位错之间的相互作用,出现局部剪切变形,形成剪切带(Shear band),枝晶主干发生弯曲,如图6(e)所示。

由图6(d)可知,当变形量为80%时,冷轧管中呈现明显的“波浪”型层状形变组织,晶界和枝晶难以分辨。由图6(f)可以观察到层状组织宽度为5~10 μm。

图6 不同变形量冷轧后管材的纵截面金相

Fig. 6 Metallographs of tubes(LS) under different cold-rolling deformations: (a) 20%; (b) 40%; (c) 60%; (d) 80%; (e) Local enlarged view of Fig. (c); (f) Local enlarged view of Fig. (d)

随变形量的增加,管材晶粒“碎化”成胞块,碎化的各区域主要由稠密位错墙分隔开,随着形变的进行,稠密位错墙分裂成平行的位错墙,称为显微带[9-10];在中等应变量时,局部切变使冷轧管纵截面存在的显微带受干扰形成S形,这些局部切变区域称为剪切带;在较大应变量时,变形组织内现有剪切带之间有更多的剪切带形成,而被剪切带切动形成的台阶在能量上是不稳定的,为了降低能量,这些台阶会逐渐变直,最后形成冷轧管的层状组织[11]。

2.2 冷轧管材组织取向演变

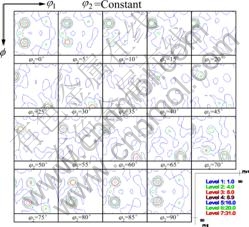

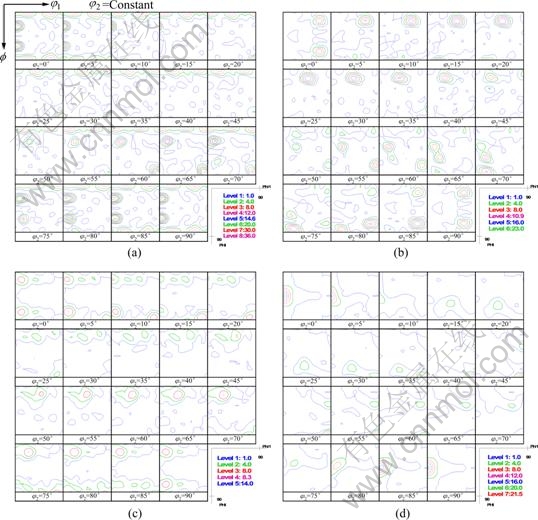

图7所示为连铸态管材的晶粒取向分布函数(ODF)恒φ2截面图。通过ODF图计算可得,其织构 中的主要取向为{012}á ?,取向密度水平为7级,表明HCCM水平连铸制备的管材具有很强的铸造织构。图8所示为不同变形量冷轧管的晶粒取向分布函数(ODF)图。

?,取向密度水平为7级,表明HCCM水平连铸制备的管材具有很强的铸造织构。图8所示为不同变形量冷轧管的晶粒取向分布函数(ODF)图。

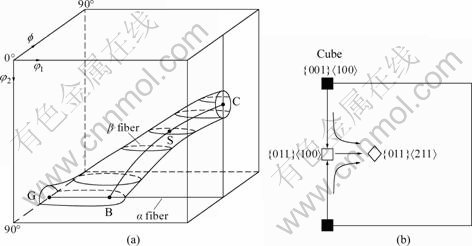

随着变形量的增加,冷轧管的初始织构经过渡型织构先转向不稳定取向区(离散区),而后转向稳定取向区(聚集区)。通过计算图8中所示不同变形量冷轧轧管的取向分布函数图中φ2=0o或45o取向密度极大值时晶粒的取向可知,过渡型织构分别是20%变形量对应的主要取向{012}á100?和40%时的{057}á ?,由于管材初始组织虽具有较强的织构,但存在不均匀 性,因此,在0~40%变形量内,晶粒转动较为复杂;当变形量为60%时,冷轧管大部分晶粒已转向不稳定取向区内的立方取向Cube {001}á100?上,而高斯取向G{011}á100?相对于立方取向位于聚集区内,因此,当变形量达到80%时晶粒大部分转到高斯取向上,取向变化轨迹如图9所示。

?,由于管材初始组织虽具有较强的织构,但存在不均匀 性,因此,在0~40%变形量内,晶粒转动较为复杂;当变形量为60%时,冷轧管大部分晶粒已转向不稳定取向区内的立方取向Cube {001}á100?上,而高斯取向G{011}á100?相对于立方取向位于聚集区内,因此,当变形量达到80%时晶粒大部分转到高斯取向上,取向变化轨迹如图9所示。

图7 恒φ2铸态管材的晶粒取向分布函数(ODF)截面图

Fig. 7 Orientation distribution function sections of cast tube grains at constant φ2

由于BFe10合金中的Cu和Ni无限互溶,形成单一的固溶体,其晶体点阵结构属于面心立方(FCC),因此,符合FCC多晶体冷轧取向变化的一般规 律[12-13]:面心立方金属的最终稳定取向为β取向线或

图8 恒φ2不同变形量冷轧管材的晶粒取向分布函数(ODF)截面图

Fig. 8 Orientation distribution functions sections of tube grains under different cold-rolling deformations at constant φ2: (a) 20%; (b) 40%; (c) 60%; (d) 80%

β线上的B取向点,高层错能面心立方金属轧制变形时的稳定取向是一条线(β线),而低层错能面心立方金属轧制变形基本的稳定取向只是一个取向点(B(黄铜)取向{011}á211?)。BFe10合金的层错能随着Ni含量的增加而增高(Cu层错能为40 mJ/m2、Ni层错能为250 mJ/m2),并且轧后管材组织中未见明显孪生现象,表明BFe10合金的变形机制以位错滑移为主。具有相同变形机制的合金[14-15]在冷变形中表现出相同的规律,即管材初始织构对最终轧制织构有一定影响。

具有初始织构的BFe10管材在冷轧变形量达到80%时,主要取向仍为α线上的G取向,这表明初始织构对轧制织构的演变具有很大的影响。由图9可知,B取向相对于G取向位于聚集区内,因此G取向是一个亚稳取向,而有B取向的晶粒都有稳定性,许多晶粒取向尽管在小变形量时流向G取向,但随变形量的增大又逐渐沿α线流向B取向[16],因此可以预见,具有初始织构的BFe10管材在变形量大于80%下变形时,管材织构将由G取向沿α线转到β取向线的B织构上。

图9 取向空间和冷轧取向变化轨迹

Fig. 9 Orientation space(a) and changing track of orientation during cold rolling (b)

2.3 冷轧管材的力学性能及硬度

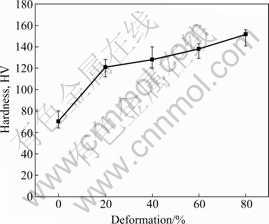

图10所示为不同变形量冷轧后管材的力学性能。由图10可知,随着变形量的增加,冷轧管材的抗拉强度呈直线上升趋势,由铸态时的234 MPa增加至80%变形量时的372 MPa;伸长率在变形量0~20%范围内下降较快,当变形量大于20%后变化较慢。铸态管材的伸长率为46.5%,20%变形量时降至19.8%,当变形量超过60%,伸长率变化较小,维持在13%左右。

图10 不同变形量冷轧管材的力学性能

Fig. 10 Mechanical properties of tube under different cold- rolling deformations

图11所示为不同变形量冷轧管材的硬度。由图11可知,铸态管坯的维氏硬度为70HV,在变形量0~20%范围内硬度上升较快,当变形量达到20%时,硬度迅速增加到121HV,其后,随着变形量的增加,硬度增加较慢;当变形量从20%增加到80%时,硬度从121 HV增加至152HV。

图11 不同变形量冷轧管材的硬度

Fig. 11 Hardness of tube under different cold-rolling deformations

从变形量对冷轧管材的力学性能以及硬度影响的结果分析可知,BFe10铸态管材在冷加工过程同样表现出明显的加工硬化特征,在0~20%变形量内,伸长率下降和硬度上升都较快,因此,在制定轧制制度时,第一道次的加工量应小于20%,以避免加工硬化速率过快对管材冷加工造成的不利影响。由变形量80%冷轧后管材伸长率仍大于10%,且管材的织构仍未达到稳定状态可知,BFe10管材经80%变形量冷轧加工 后,仍具有后续冷加工的能力。

因此,将80%变形量冷轧管进行了后续冷拉拔,不同变形量冷拉管材形貌如图12所示。尺寸为d32 mm×1.5 mm的冷轧管材无需退火处理,经9道次拉拔(平均延伸系数1.43)至d5 mm×0.4 mm,冷拉管表面质量良好,表明轴向取向的BFe10白铜管材具有优良的冷加工性能。

图12 不同变形量冷拉管材形貌

Fig. 12 Morphologies of tube under different cold-drawing deformations: a—27%; b—48%; c—60%; d—70%; e—80%; f—88%; g—92%; h—94%; i—96%

3 结论

1) 采用HCCM水平连铸制备的BFe10管材冷加工性能优良,无需铣面等处理,可直接用于冷轧加工,经累积变形量80%冷轧后,管材表面质量良好,轧制过程中未产生裂纹、裂口和飞边等缺陷。

2) 在冷轧加工过程中,随着变形量的不断增加,晶粒沿轧向逐渐变得细长,晶粒内一次枝晶主干间距逐渐减小,从铸态的100~200 μm变化到变形量60%时的10~20 μm。当变形量达到60%时,组织中可观察到明显的剪切带;当变形量达到80%时,组织呈波浪状,枝晶和晶界难以辨认。

3) 在冷轧加工过程中,管材的主要织构发生明显变化,铸态管材组织具有较强的铸造织构,主要取向为{012}á ?,当变形量为20%时转变为{012}á100?,变形量40%时为{057}á

?,当变形量为20%时转变为{012}á100?,变形量40%时为{057}á ?,变形量60%时为{001} á100?,变形量80%时为α线的G(高斯取向) {011}á100?织构。

?,变形量60%时为{001} á100?,变形量80%时为α线的G(高斯取向) {011}á100?织构。

4) 管材冷轧过程中随着变形量的增加,抗拉强度由铸态的234 MPa增加至80%变形量时的372 MPa;伸长率和硬度变化呈现相似的变化特点,变形量在0~20%范围内均变化显著,分别由铸态的46.5%和70HV变化为20%时的19.8%和121HV,但变形量大于20%后变化趋缓,当变形量为80%时,冷轧管的伸长率为13%,硬度增加到152HV。

REFERENCES

[1] GLOVER T J. Copper-nickel alloy for the construction of ship and boat hulls [J]. British Corrosion Journal, 1982, 17(4): 155-157.

[2] YAN Zhi-ming, LI Xin-tao, QI Kai. Study on horizontal electromagnetic continuous casting of CuNi10Fe1Mn alloy hollow billets [J]. Materials and Design, 2009, 30(6): 2072- 2076.

[3] 甘春雷, 刘雪峰, 黄海友, 谢建新. BFe10-1-1合金管材连续定向凝固制备工艺及组织力学性能[J]. 金属学报, 2010, 46(12): 1549-1556.

GAN Chun-lei, LIU Xue-feng, HUANG Hai-you, XIE Jian-xin. Fabrication process, microstructure and mechanical properties of BFe10-1-1 alloy tubes by continuous unidirectional solidification [J]. Acta Metallurgica Sinica, 2010, 46(12): 1549- 1556.

[4] 余业球, 赵 锋, 黎沃光. 热型连铸BFe30-1-1白铜管的组织与性能[J]. 热加工工艺, 2005, 11: 8-11.

YU Ye-qiu, ZHAO Feng, LI Wo-guang. Microstructure and performance of BFe30-1-1 cupronickel tubes [J]. Hot Work Technology, 2005, 11: 8-11.

[5] 谢建新, 娄花芬, 王自东, 胡萍霞, 张 鸿, 董亚正, 康敬乐, 苗国伟, 符学智, 闫 敏, 关保红, 蒋小亮. 铜及铜合金精密管材短流程制备工艺: 中国, ZL200710065281.9 [P]. 2009- 06-10.

XIE Jian-xin, LOU Hua-fen, WANG Zi-dong, HU Ping-xia, ZHANG Hong, DONG Ya-zheng, KANG Jing-le, MIAO Guo-wei, FU Xue-zhi, YAN Min, GUAN Bo-hong, JIANG Xiao-liang. Compact process for fabrication of copper and copper alloy precision tube: China, ZL200710065281.9 [P]. 2009-06-10.

[6] 谢建新, 梅 俊, 刘新华, 刘雪峰.一种白铜管材热冷组合铸型水平连铸工艺与设备: 中国, ZL 201010501407.4 [P]. 2012- 06-27.

XIE Jian-xin, MEI Jun, LIU Xin-hua, LIU Xue-feng. A kind of process and equipment for fabricating cupronickel pipes with heating-cooling combined mold casting: China, ZL 201010501407.4 [P]. 2012-06-27.

[7] MEI Jun, LIU Xin-hua, XIE Jian-xin. Microstructure and mechanical properties of BFe10 cupronickel alloy tubes fabricated by a horizontal continuous casting with heating- cooling combined mold technology [J]. International Journal of Minerals Metallurgy and Materials, 2012, 19(4): 339-347.

[8] 梅 俊, 刘新华, 谢建新. BFe10白铜管材热冷组合铸型水平连铸凝固温度场模拟[J]. 中国有色金属学报, 2012, 22 (5): 1430-1439.

MEI Jun, LIU Xin-hua, XIE Jian-xin. Solidification temperature field simulation of BFe10 cupronickel tube during heating- cooling combined mold continuous casting [J]. The Chinese Journal of Nonferrous Metals, 2012, 22(5): 1430-1439.

[9] KANENO Y, TAKAHASHI A, TAKASUGI T. Microstructure and texture evolution during cold rolling and annealing of Ni3Fe alloy [J]. Materials Science and Engineering A, 2006, 431(1/2): 328-338.

[10] CHEN H S, GODFREY A, HANSEN N, XIE J X, LIU Q. Microstructure-grain orientation relationship in coarse grain nickel cold-rolled to large strain [J]. Materials Science and Engineering A, 2008, 483/484: 157-160.

[11] PAUL H, DRIVER J H, MAURICE C, PIATKOWSKI A. The role of shear banding on deformation texture in low stacking fault energy metals as characterized on model Ag crystals [J]. Acta Materialia, 2007, 55(2): 575-588.

[12] ZHEN Liang, CHEN Jun-zhou, YANG Shou-jie, SHAO Wen-zhou, DAI Sheng-long. Development of microstructures and texture during cold rolling in AA 7055 aluminum alloy [J]. Materials Science and Engineering A, 2009, 504(1/2): 55-63.

[13] KUMAR M, SCHWARTZ A J, KING W E. Microstructural evolution during grain boundary engineering of low to medium stacking fault energy fcc materials [J]. Acta Materialia, 2002, 50(10): 2599-2612.

[14] LIU W C, MORRIS J G. Texture evolution of polycrystalline AA 5182 aluminum alloy with an initial {001}á110? texture during rolling [J]. Scripta Materialia, 2002, 47(7): 487-492.

[15] STOLYAROV V V, ZHU Y T, RAAB G I, ZHARIKOV A I, VALIEV R Z. Effect of initial microstructure on the microstructural evolution and mechanical properties of Ti during cold rolling [J]. Materials Science and Engineering A, 2004, 385(1/2): 309-313.

[16] 毛卫民, 张新明. 晶粒材料织构定量分析[M]. 北京: 冶金工业出版社, 1995: 96-101.

MAO Wei-min, ZHANG Xin-min. Texture quantitative analysis of grain material [M]. Beijing: Metallurgical Industry Press, 1995: 96-101.

(编辑 陈卫萍)