J. Cent. South Univ. (2016) 23: 515-522

DOI: 10.1007/s11771-016-3097-x

Effect of optimal aging treatment on magnetic performance and mechanical properties of sintered Nd-Fe-B permanent magnets

DING Xia(丁霞)1, DING Kai-hong(丁开鸿)2, CUI Sheng-li(崔胜利)2, SUN Yong-cong(孙永聪)2, LI Mu-sen(李木森)1

1. Key Laboratory for Liquid-Solid Structural Evolution and Processing of Materials of

Ministry of Education (Shandong University), Ji′nan 250061, China;

2. Yantai Shougang Magnetic Materials Inc., Yantai 265500, China

Central South University Press and Springer-Verlag Berlin Heidelberg 2016

Central South University Press and Springer-Verlag Berlin Heidelberg 2016

Abstract: The magnetic performance and mechanical properties including hardness, brittleness, fracture toughness and strength characteristics of the as-sintered and the optimal aged Nd-Fe-B magnets were examined in this work. A new method of Vickers hardness indentation combined with acoustic emission was used to test the brittleness of the magnets.The results show that the magnetic properties of the magnets could be improved through aging treatment, especially the intrinsic coercive force. But it is accompanied by a decrease of strength and fracture toughness. Theoretical calculation confirms that acoustic emission energy accumulated count value could be used to characterize the material brittleness. The bending fracture morphologies of the as-sintered and the optimal aged NdFeB magnets were investigated with the emphasis on the relationship between mechanical properties and microstructure using a field emission scanning electron microscopy (FE-SEM). The research results indicate that the intergranular fracture is the primary fracture mechanism for both as-sintered and optimal aged NdFeB magnets. Aging treatment changes the morphology and distribution of the Nd-rich phases, reducing the sliding resistance between Nd2Fe14B main crystal grains and lowers the grain boundary strength, which is the main reason for the strength and fracture toughness decrease of the aged Nd-Fe-B magnets.

Key words: Nd-Fe-B permanent magnets; aging treatment; mechanical property; acoustic emission; fracture analysis; Nd-rich phase

1 Introduction

As the third generation of rare earth permanent magnet materials, Nd-Fe-B permanent magnets possess excellent magnetic properties such as high remanence (1.1 T), coercivity (1035 kA/m) [1] and maximum energy product (between 286 and 398 kJ/m3) [2-3]. Since their first invention in 1983, a lot of attention has been paid to improve the properties of the magnets. It has been found that the aging treatment after the sintering process can strongly increase the magnetic performance of the magnets, especially the intrinsic coercive force [4-5]. However, the magnets recently are used under more complicated operating conditions such as high loaded products with large load-carrying capacities. It is necessary to consider not only its magnetic parameters but also the mechanical properties.

RABINOVICH et al [6] checked the strength, fracture toughness, elastic modulus, hardness as well as the other physical properties of sintered Nd-Fe-B magnets with different compositions. The results show that the magnets have a poor ductility and low strength, which is disadvantageous to their applications. Studies have been done to raise the mechanical properties of the sintered Nd-Fe-B magnets. JIANG et al [7-8] found the Co addition with proper content could increase the bending strength of sintered Nd-Fe-B magnets by about 80%. LI et al [9] reported the effect of minor addition of grain boundary phase alloys and its boron variation on the mechanical properties of the magnets and suggested that slightly adding grain-boundary alloys and properly adjusting its composition can substantially increase the bending strength. But few researches have been done on the effect of aging treatment on the mechanical properties of sintered Nd-Fe-B magnets in the present literatures.

In this work, the magnetic performance and mechanical properties including brittleness, Vickers hardness, fracture toughness and strength characteristics of the as-sintered and the optimal aged Nd-Fe-B magnets were examined. It is noteworthy that a new method of Vickers hardness indentation combined with acoustic emission is used to test the brittleness of the magnets. Fracture mechanism and the reason for the mechanical properties variation are discussed from the perspective of microstructure change through the observation field emission scanning electron microscope (FE-SEM).

2 Experimental procedure

2.1 Material preparation and magnetism measurement

The Nd-Fe-B magnets used in this work were prepared by powder sintering process. Firstly, the alloy was produced by the strip casting process from standard industrial grade raw materials. Then they were broken into powders with size of nearly 5 μm through hydrogen explosion and jet mill. The powders were filled in a metal mold and pressed in a magnetic field to align the easy axis along the magnetic field and then sintered at around 1050 °C for 1 h. The Nd-Fe-B magnets of sintered state were obtained. Afterwards, the optimized two-stage aging treatment of 800-900 °C for 2 h in the first stage and 500-600 °C for 2 h in the second stage that we found in the earlier study were conducted on half of the sintered state magnets [10]. The standard magnetic and mechanical testing specimens were cut from the as-sintered and optimal aged blocks by spark erosion.

The magnetic properties including remanence (Br), intrinsic coercive force (Hcj), maximum energy product (BHmax) and the squareness (Hk/Hcj) of the two state Nd-Fe-B magnets were measured at room temperature by NIM-2000 magnetic measuring instrument made by National Institute of Metrology of China.

2.2 Mechanical properties test

2.2.1 Strength characteristics

Strength characteristics includes bending strength (σb, MPa) and compressive strength (δs, MPa) testing. Bending strength was measured using three point bending method. The three point bending test was performed with a Instron 8502 servo-hydraulic fatigue testing system. The specimen was fixed on a specific designed jig with a span of 25.7 mm for the tests in the testing machine. The final dimensions of the specimen were 5 mm×5 mm×35 mm. The loading rate was 0.1 mm/min and the loading direction was parallel to the easy axis. A minimum number of five specimens were examined for each condition. The load required to fracture the test specimen was recorded. The bending strength was calculated according to the international standard BS EN ISO 3327: 2009 [11] as

(1)

(1)

where P is the load required to fracture the test specimen (N); L is the distance between supports (25.7 mm); b is the width of test beam (5 mm); and h the height of test beam (5 mm). The surfaces of the samples were mechanically polished before testing because the bending strength of materials is sensitive to their surface defects.

Compressive strength (δs, MPa) tests were conducted on a material testing machine (SCHENCK TREBEL, made in Germany) in accordance with “Sintered metal friction materials-Determination of compressive strength” (GB/T 10424-2002). The size of the test samples was d10 mm×8 mm. The loading rate was 5 mm/min and the loading direction was parallel to the easy axis. Examinations of the sintered and optimal aged Nd-Fe-B magnets were repeated five times to characterize the dispersion of the experimental results. The load required to fragment the test specimen was recorded, and the compressive strength was calculated as

(2)

(2)

where F is the load required to fragment the test specimen (N), and d is the diameter of the samples.

2.2.2 Hardness and fracture toughness characteristics

A new method of Vickers hardness indentation combined with acoustic emission technique was used to test the brittleness of the magnets. The size of the test-pieces was 10 mm×10 mm×35 mm. In order to make the Vickers hardness indentation clear, the samples were burnished by abrasive papers and then polished after cleaning the surface. Indentation experiments were performed on a domestic Vickers hardness tester with different indentation loads of 10, 50, 100, 200 and 300 N, respectively, and the holding time was 10 s.

Acoustic emission experiment was conducted on domestic 4010 series acoustic emission instrument. The pre-amplifier gain was 40 dB, the main amplifier gain was 40 dB, the fixed threshold voltage was 1 V and the resonant frequency of the acoustic emission probe was 150 kHz. Energy accumulated counts (En) was choosen as the measuring parameter.

During the brittleness test, the acoustic emission probe was coupled with the side surface of the sample through Vaseline and clamped, in order to prevent friction interference noise caused by loosening. When the Vickers hardness indentation experiment was carried on the surface of the samples, the acoustic emission signals generated from the corresponding indentation was measured from the acoustic emission instrument. All the experiments were repeated at least five times to get the mean value.

After Vickers hardness indentation test, the images of each indentation were taken through Nikon EPIPHOT 300 metallographic microscope immediately. The crack length of each indentation was measured to describe its relationship with the load. The diagonal length of the indentation was also measured to obtain the Vickers hardness values according to Refs. [12-13]. The fracture toughness was calculated as

(3)

(3)

where E is the elastic modulus; Hv is the Vickers hardness under 100 N; P is the applied indentation load (N); and L is the total length of the crack (mm).

2.3 Fracture microstructure analysis

A field emission scanning electron microscopy (FE-SEM, SU-70 model made in Japan) was applied to study the fracture surface morphology of the sintered and the optimal aged Nd-Fe-B magnets after the bending strength test. And the fracture surfaces were fresh without contamination.

3 Results and discussion

3.1 Magnetic properties

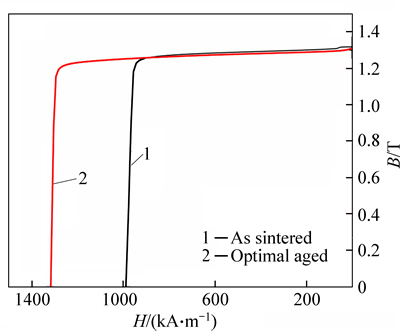

The main magnetic properties such as intrinsic coercive force (Hcj), magnetic induction coercive force (Hcb) and bending point (Hk) of the experimental magnets are compared in this work. Figure 1 shows the demagnetization curves of the as-sintered and the optimal aged Nd-Fe-B magnets and Table 1 shows the corresponding values of each magnetic parameter. The intrinsic coercive force of the optimal aged magnets is 1324.96 kA/m, compared to the as-sintered ones of only 982.78 kA/m, which has been improved by 34.8%.Magnetic induction coercive force (Hcb) and bending point (Hk) are also raised obviously.

Fig. 1 Demagnetization curves of as sintered and optimal aged Nd-Fe-B magnets

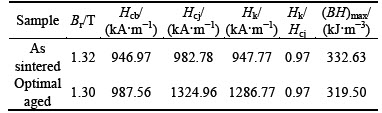

Table 1 Comparison of magnetic properties between as sintered and optimal aged Nd-Fe-B magnets

3.2 Mechanical properties

3.2.1 Bending and compressive strength

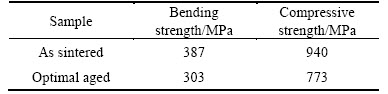

Strength including bending and compression of the Nd-Fe-B magnets are listed in Table 2. The bending and compressive strength of the as-sintered magnets are 387 MPa and 940 MPa, respectively, while the corresponding values of the optimal aged ones are 303 MPa and 773 MPa only. From the test results of the mechanical properties, it is found that the bending strength falls by 21.7%, and the compressive strength falls by 17.8% after the aging treatment.

Table 2 Comparison of strength characteristics between as sintered and optimal aged Nd-Fe-B magnets

3.2.2 Hardness

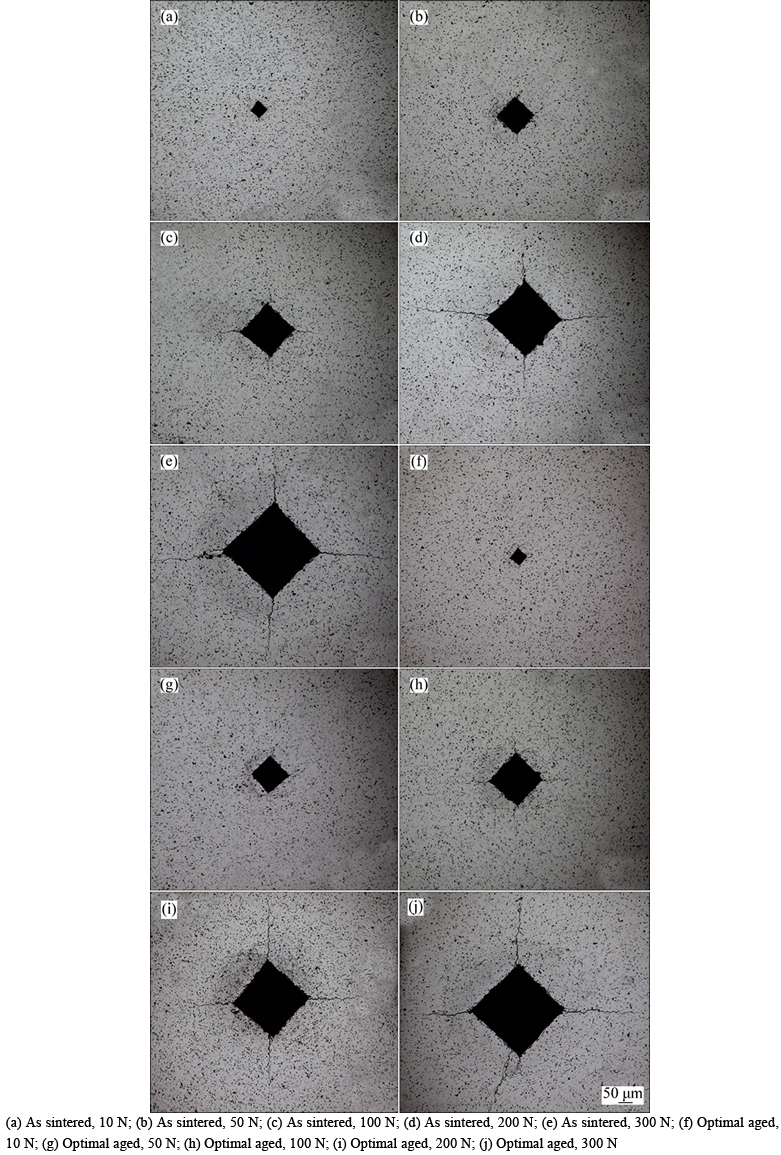

The Vickers hardness indentations of the as-sintered and the optimal aged Nd-Fe-B magnets under different loads are shown in Fig. 2. It can be seen that the indentations at the surface of the sample become bigger and bigger with the increasing load. Both the as-sintered and the optimal aged samples exhibit the same rule.

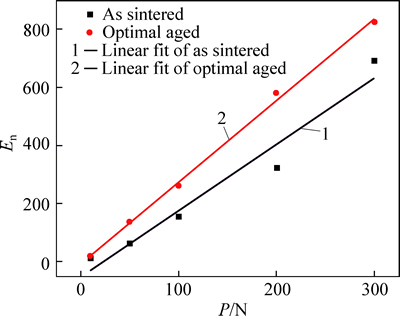

Table 3 exhibits the Vickers hardness calculated according to the indentation diagonal length. It is noted that the Vickers hardness of the two-state Nd-Fe-B magnets are both nearly 510. The comparison indicates that the hardness of the as-sintered magnet is a bit higher than the aged ones, but the difference is small.

3.2.3 Brittleness and facture toughness

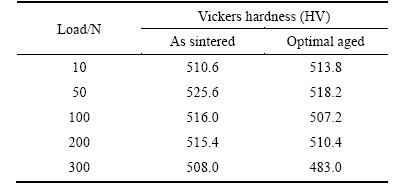

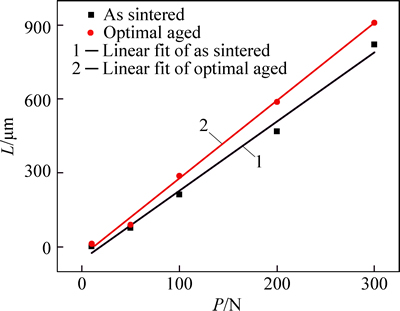

The Vickers hardness test was conducted on the as sintered and the optimally aged Nd-Fe-B magnets with different loads, while the corresponding acoustic emission energy accumulated count value En was recorded. The measurement results of En are shown in Table 4. Figure 3 shows the En-P curves of the two-state Nd-Fe-B magnets. The results show that the En values increase with load P under a linear relationship approximately. The experimental data are fitted according to linear rule and k is used to represent the slope of the En-P curves. Obviously, the k value reflects the rate of change of acoustic emission energy accumulated count value En with the increase of load. The k value of the as sintered magnets is 2.28, while that of the optimal aged is 2.82. Thus, the k value of the optimal aged Nd-Fe-B magnets is 1.24 times the as- sintered ones.

Fig. 2 Vickers hardness indentations and indentation cracks of as-sintered and optimal aged Nd-Fe-B magnets under different loads:

Table 3 Comparison of Vickers hardness between as-sintered and optimally aged Nd-Fe-B magnets

Table 4 Acoustic emission energy accumulated count value En of as sintered and optimally aged Nd-Fe-B magnets under different loads

Fig. 3 En-P curves of as-sintered and optimal aged Nd-Fe-B magnets

After the Vickers hardness indentation test, the samples were placed directly under the metallographic microscope to observe the indentation cracks. Figure 2 also exhibits the indentation crack of the as-sintered and the optimal aged Nd-Fe-B magnets under different loads. The results indicate that when the loads are 10 N and 50 N, no obvious crack can be observed generally. But when the load is more than 100 N, obvious cracks begin to appear. Indentation cracks usually appear at the four corners of the indentations. The total length of the indentation crack raises significantly with the increase of the load. In Fig. 2(j), the indentation crack of the optimal aged magnets even appears bifurcation when the load is 300 N. The bifurcation phenomenon implies that the crack driving force exceeds the propagation resistance greatly. The indentation crack extends extremely fast when the magnet is under a high load.

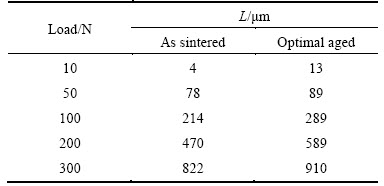

The total length L of the indentation crack under different loads was measured, and the results are shown in Table 5. Figure 4 shows the L—P curves according to the results in Table 5. It can be found that the indentation crack length L increases with the increase of the applied indentation load P. L has a linear relationship with P on the whole. The experimental data are fitted according to linear rule and k is used to represent the slope of the L—P curves. Similarly to the En-P curves, the k value reflects the rate of change of the total crack length with the increasing load. The k value of the as sintered magnets is 2.81, while the optimal aged is 3.15. Thus, the k value of the optimal aged Nd-Fe-B magnets is 1.12 times the as sintered, which indicates that both the indentation crack nucleation rate and the crack growth rate of the optimal aged magnets are higher than the as sintered, resulting in a greater brittleness.

Table 5 Total length of indentation crack under different loads of as sintered and optimal aged Nd-Fe-B magnets

Fig. 4 L-P curves of as-sintered and optimally aged Nd-Fe-B magnets

Acoustic emission refers to the strain energy released by the material in the form of elastic stress wave during deformation or fracture, when the material is subjected to external force or internal stress [14-16]. In the process of brittle crack formation and propagation, elastic strain energy is always released. Consequently, the acoustic emission signals are related to the kinetics process of crack formation. According to Griffith’s theory, the relationship between elastic strain energy and crack length can be expressed as

(4)

(4)

where U is the elastic strain energy; L is the crack length; σ is the stress; and E is the elastic modulus.

The elastic strain energy released from crack propagation per unit area is presented as

(5)

(5)

where G is the elastic strain energy. In other words, G is the driving force of the crack propagation.

The increased surface energy of the system during the crack formation and propagation is given as

(6)

(6)

where W is the increased surface energy and γ is the surface energy of per unit area.

The energy required for the crack to extend per unit area can be expressed as

(7)

(7)

where R is the energy required for the crack to extend per unit area. In other words, R is the crack propagation resistance .

To make the cracks formed from the Vickers hardness indentation exceed the critical size and result in unstable propagation, it must satisfy the condition of G>R, meaning that the elastic strain energy released should firstly compensate the increase of the surface energy, then the remainder consumed in the form of mechanical energy and heat energy. Some mechanical energy releases quickly through stress waves and produces acoustic emission signals.

The experimental results show that both the acoustic emission energy accumulated count value En and the total length L of the indentation crack have a linear relationship with the indentation load P, and it can be expressed as

(8)

(8)

(9)

(9)

where k and k′ are the slope of the En-P and L-P curves, respectively, b and b′ are constants.

When Eqs. (4), (8) and (9) are considered simultaneously, the following Formula (10) could be got.

and

and  (10)

(10)

Formula (10) indicates that En is proportional to L and  Therefore, En reflects the value of the elastic strain energy released from crack formation and unstable propagation. En also reflects the value of the total length L of the indentation crack. The slope value k of the En-P curves can be used to evaluate the brittleness of the sintered Nd-Fe-B magnets quantitatively. The larger the k value, the greater the brittleness.

Therefore, En reflects the value of the elastic strain energy released from crack formation and unstable propagation. En also reflects the value of the total length L of the indentation crack. The slope value k of the En-P curves can be used to evaluate the brittleness of the sintered Nd-Fe-B magnets quantitatively. The larger the k value, the greater the brittleness.

After the brittleness testing through acoustic emission technology, the fracture toughness KIC is calculated to verify the new characterization method. Early research shows that the elastic modulus of sintered Nd-Fe-B is typically 160 GPa. According to Eq. (3), the fracture toughness of the as sintered Nd-Fe-B magnet based on the experimental data is 2.44 while the value of the optimal aged one is 1.91. The KIC value of the as sintered Nd-Fe-B magnet is 1.28 times of the optimal aged one. It suggests that the ability of the as sintered magnets to prevent indentation crack from propagating is stronger. As a result, the as sintered ones exhibit a smaller brittleness than the optimal aged ones. This is consistent with the results of acoustic emission analysis.

3.3 Fracture morphology analysis

In order to learn the reason for the decrease of the mechanical properties, fracture morphology analysis is employed. The fracture surface morphology of the as-sintered (Figs. 5(a) and (c)) and the optimal aged (Figs. 5(b) and (d)) Nd-Fe-B magnets are exhibited. In Figs. 5 (a) and (b), three phases can be identified: the Nd2Fe14B matrix phase (marked as A), block-like Nd-rich phase at grain-junction region (marked as B) and the thin film Nd-rich phase at grain boundaries (marked as C). Some sintering pores (marked as D) are also visible in the images.

Figure 5 indicates that the fracture mode of Nd-Fe-B permanent magnets is mainly brittle fracture characteristic in intergranular way, i. e. cracks propagate along the grain boundaries. The fundamental reason is the complicated crystal structure and the microstructure resulted from sintered process, which contributes to the magnetic properties of Nd-Fe-B alloy but are harmful for the mechanical properties [17]. Firstly, thin film Nd-rich phase distributed around the matrix grain shows a hardness of HV 262 [18], which is lower than that of the matrix. The presence of thin film Nd-rich phase weakens the strength of grain-boundary. When the magnets are loaded, the nucleation of cracks occur at the defect or the stress concentration region. And then the crack propagates along the grain boundary, which results in intergranular fracture. Secondly, the complicated anisotropic crystal structure of Nd2Fe14B matrix leads to rare slip system [19]. The fewer the slip systems are, the smaller the possibility of plastic deformation generation is, which leads to the brittle rupture. In addition, it is inevitable for the presence of pores (marked as D in Figs. 5(a) and (b), because the Nd-Fe-B magnets are prepared by powder sintering process. The emergence of pores not only decreases the density of the materials, but also destroys the continuity of the structure, which increases the severity of the stress concentration [20]. What is more, the sintering pore can also weaken the strength of grain boundaries simultaneously. Therefore, the intergranular fracture of the sintered Nd-Fe-B permanent magnets is caused by grain boundary thin film Nd-rich phase, crystal structure of Nd2Fe14B matrix phase and sintering pores.

Fig. 5 Fracture morphology of sintered and optimally aged Nd-Fe-B magnets:

The experimental data of the mechanical properties tests show that the strength and the fracture toughness of the optimal aged magnets fall by 20% than the as-sintered ones. This is mainly caused by the morphology and distribution variation of the Nd-rich phase. In Figs. 8(c) and (d), it can be seen that the Nd-rich phase in as-sintered magnets is generally block-like at grain-junction region, while it is mainly lamellate around the main phase in the optimal aged magnets. The thin film Nd-rich phase not only weakens the grain boundary strength, but also reduces the sliding resistance between Nd2Fe14B main crystal grains, resulting in the decrease of the mechanical properties. On the other hand, block-like Nd-rich phase at grain-junction region in the sintered Nd-Fe-B magnets can prevent the crack propagation [21]. Because the Nd-rich phase changes from block-like into lamellate through the optimal aging treatment, the resistance of the crack propagation is decreased. Thus, the mechanical properties of the optimal aged magnets are lower than the as-sintered ones.

Considering the fracture mechanism of the Nd-Fe-B magnets, the following two methods can be employed to improve its mechanical properties. The first one is to strengthen the grain boundary phase by proper alloy addition, so the crack-propagating resistance of grain boundary phase can be improved. The second one is to reduce the local stress concentration via controlling sintering defects such as pores through proper manufacturing techniques [17].

4 Conclusions

The magnetic properties especially the intrinsic coercive force of the Nd-Fe-B magnets are obviously improved by the optimal aging treatment. But the strength and the fracture toughness of the optimal aged magnets fall by 20% than the as-sintered ones. Theoretical calculation confirms that the new method of Vickers hardness indentation combined with acoustic emission technique could be used to characterize the material brittleness. The decrease of the mechanical properties is mainly caused by the morphology and distribution variation of the Nd-rich phase. Thin film Nd- rich phase forming in the aging treatment weakens the grain boundary strength and decreases the resistance of the crack propagation. The main fracture mode of the sintered magnets is intergranular cracking, which is caused by grain boundary thin film Nd-rich phase, crystal structure of Nd2Fe14B matrix phase and sintering pores.

References

[1] FABIANO F, CELEGATO F, GIORDANO A, BORSELLINO C, BONACCORSI L, CALABRESE L, TIBERTO P, CORDASCO G, MATARESE G, FABIANO V, AZZERBONI B. Assessment of corrosion resistance of Nd–Fe–B magnets by silanization for orthodontic applications [J]. Physica B: Condensed Matter, 2014, 435: 92-95.

[2] SHENG Hong-chao, ZENG Xie-rong, JIN Chao-xiang, QIAN Hai-xia. Microstructure and magnetic properties of directly quenched Nd2Fe14B/α-Fe nanocomposite materials at different temperatures [J]. Journal of Central South University, 2014, 21: 1275-1278.

[3] SALIBASILVA A, FARIA R N, BAKER M A, COSTA I. Improving the corrosion resistance of NdFeB magnets: An electrochemical and surface analytical study [J]. Surface and Coating Technology, 2004, 185: 321-328.

[4] LI W F, OHKUBO T, HONO K. Effect of post-sinter annealing on the coercivity and microstructure of Nd–Fe–B permanent magnets [J]. Acta Materialia, 2009, 57: 1337-1346.

[5] VIAL F, JOLY F, NEVALAINEN E, SAGAWA M, HIRAGA K, PARK K T. Improvement of coercivity of sintered NdFeB permanent magnets by heat treatment [J]. Journal of Magnetism and Magnetic Materials, 2002, 242-245: 1329-1334.

[6] RABINOVICH Y M, SERGEEV V V, MAYSTRENKO A D, KULAKOVSKY V, SZYMURA S, BALA H. Physical and mechanical properties of sintered Nd-Fe-B type permanent magnets [J]. Intermetallics, 1996, 4: 641-645.

[7] JIANG Jian-hua, ZENG Zhen-peng, YU Jian, WU Jian-sheng, TOKUNAGA M. The effect of Co addition on the fracture strength of NdFeB sintered magnets [J]. Intermetallics, 2001, 9: 269-272.

[8] JIANG Jian-hua, ZENG Zhen-peng, WU Jian-sheng, TOKUNAGA M. Influence of alloying elements on mechanical properties and microstructures of sintered Nd–Fe–Co–B magnet [J]. Journal of Magnetism and Magnetic Materials, 2000, 214: 61-68.

[9] LI An-hai, LI Wei, DONG Sheng-zhi, LI Xiu-mei. Sintered Nd–Fe–B magnets with high strength [J]. Journal of Magnetism and Magnetic Materials, 2003, 265: 331-336.

[10] DING Xia, WANG Xiao-li, SI Cong-hui, ZHAO Li-na, DING Kai-hong, CUI Sheng-li, SUN Yong-cong, LI Mu-sen. Study on the relativity between intrinsic coercivity and microstructure of the Nd-Fe-B magnet treated by the optimized aging treatment [J]. Advanced Materials Research, 2014, 1002: 73-76.

[11] BS EN ISO 3327. Hardmetals-determination of transverse rupture strength [S]. European Committee for Standardization. Brussels: 2009.

[12] FERREIRA J A M, AMARAL M A P, ANTUNES F V, COSTA J D M. A study on the mechanical behaviour of WC/Co hardmetals [J]. International Journal of Refractory Metals and Hard Materials, 2009, 27: 1-8.

[13] PETERS C T. The relationship between Palmqvist indentation toughness and bulk fracture toughness for some WC/Co cemented carbides [J]. Journal of Materials Science, 1979, 14: 1619-1623.

[14] CHEN Bing, LIU Juan-yu. Experimental study on AE characteristics of three-point-bending concrete beams [J]. Cement and Concrete Research, 2004, 34: 391-397.

[15] ALAM S Y, SALIBA J, LOUKILI A. Fracture examination in concrete through combined digital image correlation and acoustic emission techniques [J]. Construction and Building Materials, 2014, 69: 232-242.

[16] BOURAS S, ZERIZER I, GHELDANE F, BOUAZZAO M T, BOUZABATA B. Study of the resistance to crack propagation in alumina by acoustic emission [J]. Ceramics International, 2008, 34: 1857-1865.

[17] LIU Wei, WU Jian-sheng. Mechanical properties and fracture mechanism study of sintered Nd–Fe–B alloy [J]. Journal of Alloys and Compounds, 2008, 458: 292-296.

[18] ZENG Zhen-peng. A study of alloy elements affecting the fracture strength of sintered Nd-Fe-B magnets [J]. Physical Testing and Chemical Analysis Part A: Physical Testing, 1999, 33(9): 19-21. (in Chinese)

[19] LIU Zhi-en. Material science [M]. Xian: Northwestern Polytechnical University Press, 2007: 214-222. (in Chinese)

[20] ZENG Zhen-peng. A study of the fracture in sintered Nd-Fe-B permanent magnetic materials [J]. Rare Metal Materials and Engineering, 1996, 25(3): 18-21. (in Chinese)

[21] JIANG Jian-hua, ZENG Zhen-peng. Study of alloy elements affecting the fracture strength of sintered Nd-Fe-B magnets [J]. Rare Metal Materials and Engineering, 1999, 28(3): 144-147. (in Chinese)

(Edited by FANG Jing-hua)

Foundation item: Project((2012) 1743) supported by the China National Major Special Program for the Rare Earth and Rare Metallic Materials

Received date: 2015-01-10; Accepted date: 2015-04-10

Corresponding author: LI Mu-sen, Professor; Tel: +86-531-88395693; E-mail: msli@sdu.edu.cn