文章编号: 1004-0609(2006)03-0428-08

炉料微观组织对AZ91D镁合金重熔行为的影响

张 军, 何良菊, 李培杰, E.G.Kandalova

(清华大学 机械工程系, 北京 100084)

摘 要: 通过重熔化学成分相同的AZ91D压铸件和铸锭, 研究了炉料组织对镁合金AZ91D金相形貌、 晶粒组织及力学性能的影响。 结果表明: 与铸锭重熔后相比, 压铸件重熔后共晶体的离异程度较大, 平均晶粒尺寸较小; 经过相同保温时间, 压铸件重熔后的抗拉强度、 屈服强度及断裂延伸率均较高; 随保温时间的延长, 两种炉料重熔后的力学性能均得到了提高。 采用DTA分析了炉料重熔后的凝固过程, 凝固过程中过冷度较小是压铸件重熔后晶粒尺寸小于铸锭重熔后晶粒尺寸的热力学原因。

关键词: 炉料组织; AZ91D; 晶粒组织; 力学性能; DTA 中图分类号: TG146.2

文献标识码: A

Effect of primary microstructure on

re-melting behavior of AZ91D magnesium alloy

ZHANG Jun, HE Liang-ju, LI Pei-jie, E.G.Kandalova

(Department of Mechanical Engineering, Tsinghua University, Beijing 100084, China)

Abstract: The effect of heredity on structure and properties of AZ91D alloy was investigated using ingots and rejected die-casting parts with the same composition as a furnace charge. After melting the charge, the melts were held for 15, 35 and 65min at 720℃ and poured into a preheated metal mould. Solidification of re-melted furnace charge was analyzed by DTA. The results show that the different furnace charges show the noticeable difference in the grain size of the alloys and tensile properties; the mean grain size of the samples produced from the die-casting parts is smaller than those produced from the ingots for all holding times. The ultimate tensile strength, yield strength and elongation are correspondingly better for the samples made of the die-casting parts. As the holding time increases, the tensile properties of the samples, made of both kinds of the furnace charge, slightly improve. The grain size also does not noticeably vary with the increase in the holding time.

Key words: heredity; AZ91D; grain structure; tensile properties

现代研究和生产实践表明, 铸造合金生产过程中炉料原始组织对重熔后铸件的性能和组织有很大影响。 早在20世纪20年代, 关于炉料组织对铸铁重熔行为的影响的研究就已经展开[1]。 从20世纪60年代, 许多前苏联学者开始研究炉料组织对有色合金重熔后组织和性能的影响[2]。 近些年国内很多学者也进行了很多这方面的研究[3-7], 并对炉料组织影响金属重熔行为的机制及金属熔体结构进行了研究探讨[8-10]。 利用炉料组织对金属重熔后组织和性能的影响, 可以有效地提高铸件的力学性能并降低金属液的耗用量[11]。

镁合金是目前最轻的工程结构材料, 具有密度小、 比强度和比刚度高、 导热导电性好、 高阻尼减震和电磁屏蔽性能良好和废料易于回收等特点[12]。 本文作者针对目前最为广泛应用的镁合金AZ91D, 通过重熔化学成分相同的铸锭和压铸件, 研究了炉料组织对AZ91D镁合金重熔后铸件金相形貌、 晶粒组织及力学性能的影响。

1 实验

实验采用自行开发的镁合金熔炼炉, 设备采用PID调节精确控温, 一次装炉量为12kg。 国内某镁合金压铸厂提供实验所用镁合金铸锭及由原生铸锭压铸生产的压铸件, 铸锭化学成分见表1。 实验中采用RJ-1熔剂覆盖保护镁合金熔体。

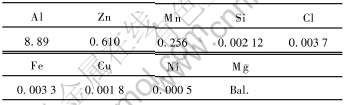

表1 AZ91D合金锭成分

Table 1 Compositions of ingots and die casting parts of AZ91D(mass fraction, %)

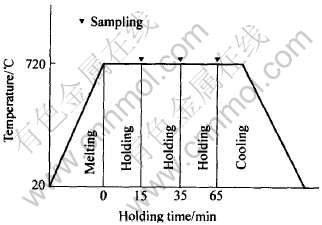

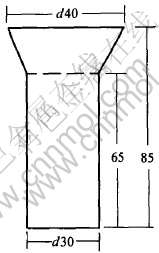

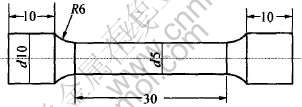

实验前, 在150℃预热炉料1h以脱去表面水气、 油脂; 预热熔剂1h。 实验过程中, 先向坩埚壁及底部撒一定量熔剂, 然后加入炉料, 并在炉料表面撒熔剂, 升温开始熔化炉料。 在熔炼过程中需不断添加熔剂以免熔体氧化燃烧, 实验工艺如图1所示。 炉料完全熔化后, 在720℃对熔体进行保温静置处理, 分别在保温15、 35和65min时将镁合金液舀出浇铸于金属型中, 试样尺寸如图2所示。 切去试样浇冒口部分, 按照国家标准GB/T 228—2002通过机械加工将其余部分加工成拉伸实验试样, 拉伸试样尺寸如图3所示。 将拉伸试样拉断后, 截取其夹头部分, 用来进行金相组织、 晶粒尺寸的观察分析, 以达到试样组织与性能统一对应的目的。 实验中采用了一种新的晶粒腐蚀观察方法[13]。 该方法不再需要对合金进行固溶处理, 试样机械抛光后经特殊腐蚀剂腐蚀, 会在基体上形成细密的条纹状裂纹。 在偏振光照射下, 晶粒之间会呈现不同的光学对比度, 从而得到试样的晶粒组织。

图1 合金熔炼工艺示意图

Fig.1 Chart of alloy melting process chart

图2 镁合金浇铸试样示意图

Fig.2 Dimensions of Mg alloy casting sample (unit: mm)

图3 拉伸试样示意图

Fig.3 Dimensions of tensile experiment sample (unit: mm)

2 结果与讨论

炉料组织对铸件的组织和力学性能都有较大的影响, 这是铸造过程中普遍存在的现象。 由于炉料组织的不同, 合金重熔后的晶粒尺寸和拉伸性能不同。 在实验过程中, 保温时间等工艺参数对AZ91D镁合金重熔后的组织和性能也有一定影响。

2.1 炉料组织对AZ91D重熔后金相形貌的影响

根据Mg-Al相图[14], 当合金中Al含量为9%且在平衡结晶条件下, 凝固组织中将不会出现共晶组织, 只存在从α固溶体中析出的第二相Mg17Al12即β相。 但在非平衡结晶条件下, 即使冷至与固相线相交的温度时, 枝晶间也尚残留有溶质量很高的少量液相, 这样液相将在更低的温度下发生共晶转变, 而且共晶体中的α相将与初晶结合在一起, 共晶体中的β相被推至晶界, 从而形成完全离异或部分离异的共晶组织。 由于枝晶偏析的缘故, 这种共晶组织通常存在于晶界和枝晶臂间。

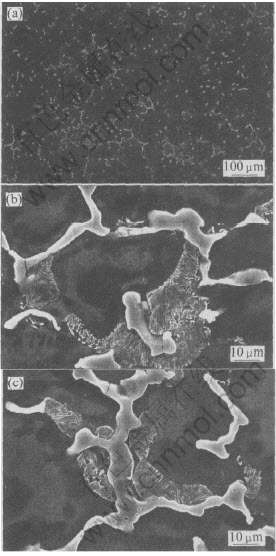

实验中作为炉料的AZ91D压铸件和铸锭的金相组织如图4所示。 由于冷却速度快且在压力下成型, 压铸件的组织由呈树枝状的基体和完全离异共晶组成, 没有层状β相的存在; 而在冷速较慢的铸锭的组织中, 在离异共晶体的周围析出了大量的层状β相, 与压铸件相比铸锭中共晶体的体积分数大大减小。

图4 AZ91D压铸件和铸锭的微观组织

Fig.4 Microstructures of die casting parts and ingots

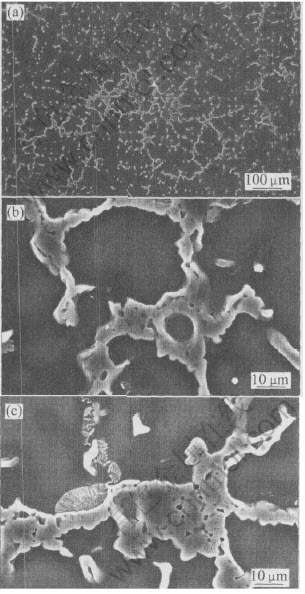

AZ91D压铸件及铸锭重熔后的金相组织如图5和图6所示。 由图可见, 与重熔前的炉料组织相比, 合金重熔后的金相组织发生了较大变化。 在压铸件重熔后的金相组织中, 由于试样的凝固速度较压铸条件下慢很多, 在共晶体周围析出了层状的β相; 共晶体绝大部分仍然为完全离异共晶, 但数量有所减少, 体积分数约占11%, 尺寸也有所增加。 铸锭重熔后的金相组织中, 析出β相的数量有所减少, 共晶体全部为部分离异共晶, 几乎观察不到完全离异共晶, 共晶体的数量增加很多, 体积分数约为16%, 超过了压铸件重熔后的共晶体数量, 尺寸相比于重熔前也有所增加, 呈岛状的共晶体增多。

图5 AZ91D压铸件重熔后的金相组织

Fig.5 Microstructures of re-melted die casting parts of AZ91D

2.2 炉料组织对AZ91D重熔后晶粒组织的影响

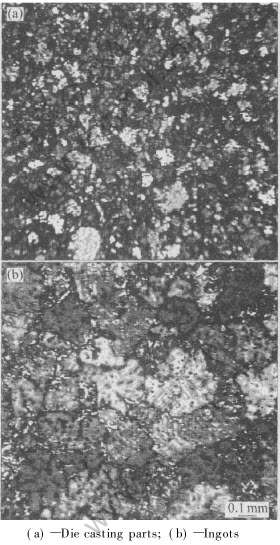

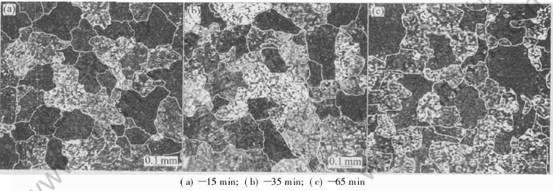

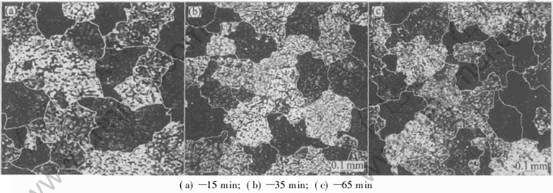

AZ91D压铸件和铸锭的晶粒组织如图7所示。 两种炉料的晶粒均为等轴晶粒, 但由于压铸件的凝固速度快, 所以晶粒比铸锭的晶粒细小很多。 两种炉料经过重熔后各个保温时间下的试样的晶粒组织如图8和9所示。 由于晶粒组织相片是彩色的, 但在文中只能使用灰度照片, 这样使得晶粒之间的对比度减小, 一些晶粒将较难分辨, 所以使用图像处理软件将晶界突出表示, 以方便不同晶粒的辨别。

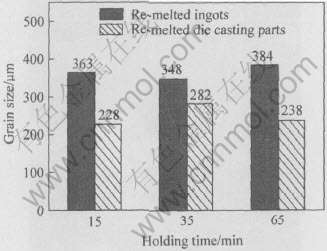

使用直线截距法测量两种炉料重熔后的平均晶粒尺寸, 平均晶粒尺寸与保温时间的关系如图10所示。 由图可见, 受炉料组织的影响, 压铸件重熔后的平均晶粒尺寸明显小于铸锭重熔后的平均晶粒尺寸。

图6 AZ91D铸锭重熔后的金相组织

Fig.6 Microstructures of re-melted ingots of AZ91D

使用数值统计分析方法, 分别对压铸件和铸锭重熔后试样的晶粒尺寸两组样本进行F等方差检验和t等方差均值检验(或t异方差均值检验), 取置信水平α=0.05。 结果表明, “同种炉料重熔, 经不同保温时间得到试样的晶粒尺寸的平均值相同”这一假设是可以接受的, 即熔体保温时间对AZ91D压铸件或铸锭重熔后试样的晶粒尺寸基本没有影响。

图7 两种炉料的晶粒尺寸

Fig.7 Grain sizes of two kinds of furnace charges

图8 压铸件重熔后不同保温时间下的晶粒尺寸

Fig.8 Grain sizes of samples from die casting parts at different holding times

图9 铸锭重熔后不同保温时间下的晶粒尺寸

Fig.9 Grain sizes of samples from ingots at different holding times

图10 重熔后不同保温时间的晶粒尺寸

Fig.10 Grain sizes of samples at different holding times

2.3 炉料组织对AZ91D重熔后力学性能的影响

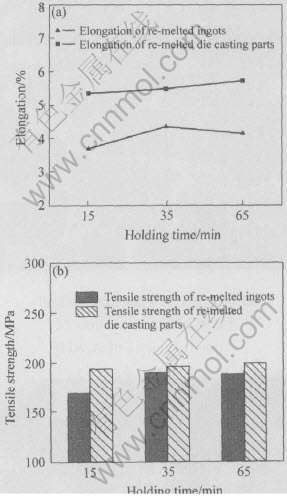

AZ91D压铸件和铸锭重熔后所得试样的抗拉强度和断裂延伸率随保温时间的变化如图11所示。 由图可见, 受炉料组织的影响, 在任何保温时间下, 与由铸锭重熔得到试样相比, 由压铸件重熔得到试样的抗拉强度和断裂延伸率都较高。 随着保温时间的延长, 由压铸件重熔得到试样的抗拉强度和断裂延伸率都增加, 但提升程度不大; 由铸锭重熔得到试样的抗拉强度和断裂延伸率先增加后降低, 在保温时间35min左右达到最大值。

图11 不同保温时间试样的抗拉强度和断裂延伸率

Fig.11 Ultimate tensile strength and

elongation of samples at different holding times

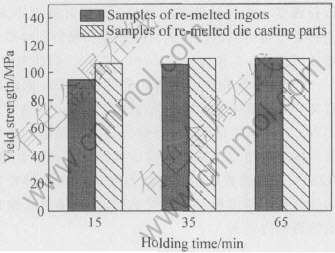

炉料重熔后试样的屈服强度σ0.2随保温时间的变化如图12所示。 在保温15min时, 压铸件重熔后试样的屈服强度明显高于铸定重熔后试样的屈服强度。 随着保温时间的延长, 压铸件和铸锭重熔后试样的屈服强度都有不同程度的增加, 但由于铸锭重熔后试样的屈服强度提升更快, 保温65min时已略微超过由压铸件重熔后试样的屈服强度。 由此可见, 通过延长熔体的保温时间, 可以有效地提高铸件的屈服强度。

图12 不同保温时间试样的屈服强度

Fig.12 Yield strength of samples at different holding times

2.4 炉料组织对AZ91D重熔行为的影响机制

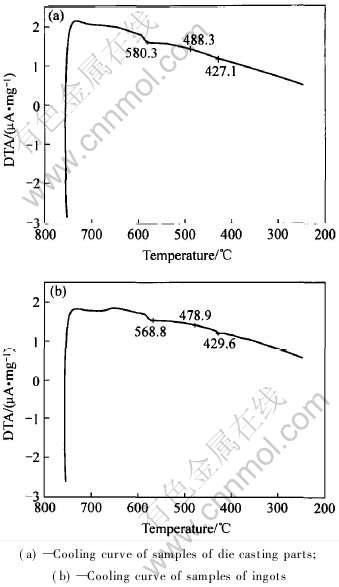

采用DTA方法分析了炉料重熔后的凝固过程, DTA分析结果如图13所示。 AZ91D压铸件重熔后的开始凝固温度为580.3℃, 比铸锭重熔后的开始凝固温度568.8℃高出11.5℃。 这说明, 压铸件重熔后的液相比铸锭重熔后的液相更容易形核、 结晶, 即形核率较高, 从而导致凝固后的晶粒组织更细小。

图13 不同炉料的冷却DTA曲线

Fig.13 DTA curves of cooling stage of two kinds of furnace charges

AZ91D压铸件重熔后的共晶凝固温度为427.1℃, 比铸锭重熔后的共晶凝固温度429.6℃低2.5℃。 由AZ91D合金液相的凝固顺序可知, 实际共晶凝固温度越低, 在该温度时枝晶间剩余的液相就越少, 从而导致形成的离异共晶的数量就越少。 因此, AZ91D压铸件重熔后的共晶凝固温度较低, 会导致压铸件重熔后金相组织中的离异共晶体的数量少于铸锭重熔后金相组织中的离异共晶体的数量, 这与实验结果是一致的。

合金的热裂倾向受合金凝固温度区间的影响, 合金凝固过程中开始形成完整的枝晶骨架的温度与凝固终了的温度之差越大, 合金的热裂倾向就越大。 由DTA分析结果可知, AZ91D压铸件重熔后的凝固温度区间为153.2℃, 大于铸锭重熔后的凝固温度区间139.2℃。 这说明, AZ91D压铸件重熔后合金的热裂倾向较大。

晶体的主要熔化机制是以原子集团为单位, 采取逐渐分裂的方式进行的, 可表示为[8]

式中 an为含有n个原子的集团; ain为聚集了i个原子集团的集合体。

AZ91D炉料组织是不均匀的, 如存在共晶体、 α初晶体、 金属间化合物Mg17Al12或各种偏析物质等。 根据上述熔化机制, 炉料熔化时会形成宏观不均匀的熔体, 熔体中存在悬浮于均匀液相中的有序原子集团。 根据对铝镁合金熔体的研究[17], 这种有序原子集团可能具有由Mg-Al相和纯Mg组成的准共晶结构, 与周围的熔体没有明确的分界面。 在原子集团内部, 与原子集团中心的距离不同, 化学成分和结构不同。 熔体中还会存在一些富含Mg或Al元素的较大原子集团, 这些原子集团与熔体具有明确的界面, 一些文献把它们称为弥散相。 这些弥散相导致了AZ91D熔体纳米尺度的非均匀性[15]。

AZ91D镁合金凝固时, 熔体中的有序原子集团和弥散相将发挥晶核作用, 它们的结构、 尺寸和化学成分都会对凝固后的铸件产生影响。 AZ91D压铸件晶粒组织细小, 组织中的晶核数目和晶界较多, 重熔后在熔体中存在的有序原子集团就较多, 能长大成为晶核的晶胚数目较多, 从而使重熔后的晶粒组织仍然保持较为细小的尺寸。 反之, 如果铸锭的晶粒组织粗大, 重熔后镁合金熔体中有序原子集团就较少, 能长大成为晶核的晶胚就少, 从而使重熔后的晶粒组织仍然较粗大。 炉料组织影响AZ91D重熔晶粒组织的演变过程如图14所示。

图14 炉料组织影响晶粒尺寸的演变过程

Fig.14 Effect of microstructure of

furnace charge on solidification of re-melted alloys

3 结论

1) 炉料组织对AZ91D炉料重熔后试样的金相形貌影响较小, 试样的金相组织均是由呈树枝状的基体相和晶间存在的离异共晶体及二次β相组成的, 但压铸件重熔后金相组织中共晶体的离异程度要大于铸锭重熔后共晶体的离异程度。

2) 压铸件重熔后试样的晶粒尺寸明显小于铸锭重熔后的试样的晶粒尺寸, 保温时间对炉料重熔后试样的晶粒尺寸影响较小。

3) 与铸锭重熔后得到的试样相比, 由压铸件重熔得到的试样的抗拉强度和断裂延伸率都较高。 随着保温时间的延长, 由压铸件重熔得到的试样的抗拉强度和断裂延伸率都增加, 但提升程度不大; 由铸锭重熔得到的试样的抗拉强度和断裂延伸率先增加后降低, 在保温时间35min左右达到最大值。

4) 与铸锭相比, 压铸件重熔后开始凝固温度较高, 这是压铸件重熔后晶粒组织更细小的热力学原因; 共晶温度较低, 会导致压铸件重熔后的离异共晶体的数量少于铸锭重熔后的离异共晶体数量; AZ91D压铸件重熔后的凝固温度区间大于铸锭重熔后的凝固温度区间, 表明AZ91D压铸件重熔后的热裂倾向较大。

REFERENCES

[1]Levi A. Heredity in Cast Iron[J]. The Iron Age, 1927(6): 960.

[2]Noviko I I, Nikiforov I A. Study on the microstructure of ingots of aluminum alloys[J]. Foundry Product, 1965(7): 6-7.

[3]耿浩然, 叶以富, 马家骥, 等. 铸铁合金的遗传效应及其利用[J]. 钢铁研究学报, 1996, 8(4): 37-41.

GENG Hao-ran, YE Yi-fu, MA Jia-ji, et al. Effects and application of inheritance to cast iron[J]. Journal of Iron and Steel Research, 1996, 8(4): 37-41.

[4]LI Pei-jie, ZHANG Yan-fei, Nikitin V I, et al. Hereditary effect of Al-based modifier and grain refiners on structure and properties of A365.2 alloy[J]. Trans Nonferrous Met Soc China, 2002, 12(2): 233-237.

[5]LIU Xiang-fa, BIAN Xiu-fang, QI Xiao-gang, et al. Structural heredity between Al5Ti1B and AlTi, AlB master alloys[J]. Trans Nonferrous Met Soc China, 1999, 9(4): 806-809.

[6]张作贵, 刘相法, 边秀房, 等. Al-Ti-B中间合金的遗传性研究与推广应用[J]. 铸造, 2000, 49(10): 758-763.

ZHANG Zuo-gui, LIU Xiang-fa, BIAN Xiu-fang, et al. Heredity study and application of Al-Ti-B master alloy[J]. Foundry, 2000, 49(10): 758-763.

[7]李培杰, 曾大本, 贾均, 等. 铝硅合金中的结构遗传及其控制[J]. 铸造, 1996( 6): 10-14.

LI Pei-jie, ZENG Da-ben, JIA Jun, et al. Structure heredity and control of Al-Si alloys[J]. Foundry, 1996(6): 10-14.

[8]李培杰, 曾大本, 贾均, 等. 合金熔体遗传现象的热力学分析[J]. 铸造, 1999(10): 12-15.

LI Pei-jie, ZENG Da-ben, JIA Jun, et al. Thermodynamics analysis of heredity phenomena in alloy melt[J]. Foundry, 1999(10):12-15.

[9]边秀房, 潘学民, 秦绪波. 金属熔体中程有序结构[J]. 中国科学(E辑), 2002, 32(2): 145-151.

BIAN Xiu-fang, PAN Xue-min, QIN Xu-bo. Medium-range structure of alloy melts[J]. Science in China (Series E), 2002, 32(2): 145-151.

[10]BIAN Xiu-fang, WANG Wei-ming, YUAN Shu-juan, et al. Structure factors of modified liquid Al-Si alloys[J]. Science and Technology of Advanced Materials, 2001(2): 19-23.

[11]边秀房, 刘相法, 马家骥. 铸造金属遗传学[M]. 济南: 山东科学技术出版社, 1999.

BIAN Xiu-fang, LIU Xiang-fa, MA Jia-ji. Heredity of Casting Metal[M]. Jinan: Shandong Science and Technology Press, 1999.

[12]师昌绪, 李恒德, 王淀佐, 等. 加速我国金属镁工业发展的建议[J]. 材料导报, 2001, 15(4): 5-6.

SHI Chang-xu, LI Heng-de, Wang Dian-zuo, et al. Suggestions for accelerating magnesium industry development of China[J]. Materials Review, 2001, 15(4): 5-6.

[13]Maltais A, Dubé D, Fiset M, et al. Improvements in the metallography of as-cast AZ91 alloy[J]. Materials Characterization, 2004, 52: 103-119.

[14]虞觉奇, 易文质, 陈邦迪, 等. 二元合金状态图集[M]. 上海: 上海科学技术出版社, 1987.

YU Jue-qi, Yi Wen-zhi, CHEN Bang-di, et al. Collection of Binary Phase Diagram[M]. Shanghai: Shanghai Science and Technology Press, 1987.

[15]Brodova I G, Popel P S, Eskin G I. Liquid Metal Processing: Applications to Aluminium Alloy Production[M]. London and New York: Gordon & Breach, 2004. 269.

[16]WANG Q, LI Y X, LI X C. Grain refinement of Al-7Si alloys and the efficiency assessment by recognition of cooling curves[J]. Metallurgical and Materials Transactions A, 2003, A34: 1175-1182.

[17]边秀房, 王伟民, 李辉, 等. 金属熔体结构[M]. 上海: 上海交通大学出版社, 2003.

BIAN Xiu-fang, WANG Wei-min, LI Hui, et al. Metal Melt Structure[M]. Shanghai: Shanghai Jiao Tong University Press, 2003.

基金项目: “985”清华大学重点项目——镁合金绿色设计与制造(j22001001)

收稿日期: 2005-09-16; 修订日期: 2005-12-12

作者简介: 张 军(1981-), 男, 硕士研究生

通讯作者: 张 军; 电话: 62773639; E-mail: zhangjun99@mails.tsinghua.edu.cn

(编辑何学锋)