文章编号:1004-0609(2016)-01-0103-09

电子束蒸镀法制备CuIn0.7Ga0.3Se2薄膜太阳电池的性能

王星星1,张福勤1,周 俊1,郑吉祥1,黎炳前2,刘 怡2

(1. 中南大学 粉末冶金国家重点实验室,长沙 410083;2. 中南大学 材料科学与工程学院,长沙 410083)

摘 要:封装石英管真空熔炼合成CuIn0.7Ga0.3Se2(CIGS)块体,再采用电子束蒸镀此块体,制备用于太阳电池吸收层的CIGS薄膜,然后对薄膜进行不同温度的真空退火处理。分别采用XRD、EDS、SEM及光谱分析等方法,研究CIGS块体和退火薄膜的表面形貌、晶体结构、成分或者光电性能。结果表明:在1200 ℃、保温2 h后,采用真空熔炼获得结晶性能较好、单一黄铜矿结构的CuIn0.7Ga0.3Se2块体。随着退火温度的升高,薄膜中In-Se杂质相分解,从而获得单一相的CIGS薄膜;并且颗粒不断长大,达到1.0~3.5 μm;成分和光学禁带不断得到优化。600 ℃退火薄膜是比较符合理想太阳电池要求的吸收层材料。

关键词:太阳电池;CuIn0.7Ga0.3Se2;真空熔炼;电子束蒸镀;退火处理

中图分类号:TM914.4 文献标志码:A

Cu(In1-xGax)Se2(CIGS)薄膜太阳电池具有光吸收系数高(>1×105 cm-1[1])、光电转化效率高(目前实验室最高效率已经达到21.7%[2])、禁带宽度可调,没有光致衰退问题、抗辐射能力强[3]等优点,目前已成为最有希望获得大规模应用的薄膜太阳电池[4]。

CIGS薄膜太阳电池吸收层为CIGS薄膜,对光电转化效率有着决定性的影响[5]。目前,CIGS吸收层薄膜的制备方法主要包括:油墨印刷法[6]、电化学沉积法[7]、真空蒸镀法[8]和硒化法[3,9]等。油墨印刷法可以方便地控制薄膜的厚度和均匀性[10],但是由于前驱物的颗粒尺寸细小,所以在随后的硒化退火过程中较难形成致密的微米级晶粒[11]。电化学沉积法需要很精确地调节溶液的pH值、浓度、电位及络合剂的种类与含量才能获得高质量的薄膜,制备过程也相对复杂[12]。真空蒸发镀膜时工艺参数调整比较复杂,需要对每种元素的蒸发速率和沉积量进行精确控制,要求设备具有很高的控制精度,不利于生产大规模、均匀化的薄膜[3];REPINS等[8]和ZHANG等[13]利用3步共蒸发法制备CIGS薄膜吸收层,详细分析了4种元素的蒸发控制过程和对薄膜性能的影响,研究表明:制备了Ga元素浓度梯度的贫铜薄膜,也得到了相对高效率的太阳电池,但由于过程复杂而增加了成本。预制膜硒化时,H2Se是最好的硒源,但H2Se的最大缺点是有毒且易挥发。固态Se作为硒源,Se蒸气压难以控制,在热处理过程中会产生In2Se和Ga2Se等挥发性气体而导致In、Ga等元素损失和不必要的氧化扩散,而使得薄膜成分发生改变,也难以制备出高质量的薄膜[12];栾和新等[3]和LIU等[14]采用磁控溅射单一靶材方法制备CIGS吸收层薄膜,分析了不同退火工艺对薄膜性能的影响,结果表明:前者在400 ℃、保温2 h,后者在550 ℃、保温1 h条件下退火,制备得到了成分合理、颗粒均匀的单一相薄膜,但是由于是在Se气氛下退火才使薄膜形貌、成分得到改善,从而提高了大规模生产的难度。

耿魁伟等[15]和郝安林[16]研究了电子束蒸镀法制备Fe/Ru和Co/Ru多层膜的微观结构和磁学性能,结果表明:不同厚度的Fe或者Co层对于多层膜的结晶、磁阻效应及生长方式会产生很大影响。与其他镀膜方法对比可知,电子束蒸镀时到达基板的原子能量较低,可以得到较好的界面。不仅如此,电子束蒸镀法还结合了共蒸发镀膜和溅射硒化制膜工艺的优点,不仅简化了蒸发、沉积过程的速率控制,还提高了设备操作的灵活性[17]。另外,在电子束蒸镀过程中,高能热流集聚于蒸发源,可以确保材料完全蒸发,能够得到精准化学计量比的镀膜,同时避免了硒化过程[18]。所以,本文作者采用封装石英管直接熔炼合成CIGS块体,

然后以此块体为原料,采用电子束蒸镀法在玻璃衬底上蒸发镀膜形成CIGS预制薄膜,然后对预制薄膜进行真空退火处理。重点研究了不同热处理温度对CIGS薄膜的结构、成分、表面形貌和光电性能的影响,以此来判定高效率太阳电池的最优工艺条件。

1 实验

1.1 合成CIGS块体

将高纯铜粉、铟粉、硒粉(国药集团公司生产)和高纯镓块(上海镓业公司生产)4种原料,以Cu、In、Ga和Se分别为19.69%、24.90%、6.48%和50%(质量分数)来制备CuIn0.7Ga0.3Se2四元化合物。适度过量的Se元素可以避免在接下来的退火过程中,Se元素的损失不会对薄膜成分有很大影响[17]。4种元素混合均匀后置于d 20 mm×150 mm的石英管中,抽真空至低真空状态(约10 Pa)后再使用自制的封装设备进行封装。将封装完好的石英管置于烧结炉中直接熔炼,控制5 ℃/min的升温速度至1200 ℃,保温2 h,再缓慢冷却至室温。

1.2 制备CIGS预制薄膜

采用电子束蒸镀法在玻璃衬底上制备CIGS薄膜。镀膜设备是由成都现代南光真空设备有限公司生产的ZZS-600型箱式真空镀膜机,其真空室尺寸为d600 mm×750 mm,极限真空度为3×10-4 Pa,烘烤温度最高为350 ℃,可控可调,利用晶振片来控制膜厚。在玻璃衬底上沉积CIGS预制薄膜,控制沉积电压为8 kV,沉积速率为10  /S,衬底温度为350 ℃,工作真空为1.5×10-3 Pa,沉积薄膜厚度控制在15 k

/S,衬底温度为350 ℃,工作真空为1.5×10-3 Pa,沉积薄膜厚度控制在15 k 。

。

1.3 退火处理CIGS预制薄膜

薄膜退火在真空退火炉中进行,抽真空至10 Pa后,设置升温速率为2 ℃/min,分别缓慢升温至300、400、500和600 ℃,各保温1 h,然后再控制降温速率也为2 ℃/min,使薄膜缓慢在真空环境中冷却至室温。之所以控制很低的变温速率,是因为预制薄膜与衬底的结合强度不高,膜层内部颗粒松散,结晶并不完全,太快的温度变化,会导致膜层内部热应力较大而产生胞状突起或者裂纹等缺陷。

1.4 薄膜性能检测

采用X射线衍射仪(XRD,D\max-2550型,日本理学公司生产)分析薄膜的晶体结构,扫描范围为10°~80°,步幅为0.02°;采用扫描电镜(SEM,Quanta FEG 250型,美国)和自带的能谱仪(EDS)分析薄膜的表面形貌以及薄膜成分;采用紫外可见分光光度计(UV1700 PC,上海奥析科学仪器有限公司生产)分析薄膜的光电性能。

2 结果与讨论

2.1 CIGS块体的性能表征

真空熔炼合成CIGS块体的XRD谱如图1所示。由图1可知,在1200 ℃熔炼获得了单一黄铜矿结构的CuIn0.7Ga0.3Se2相(PDF#35-1102)。图1中标记的晶面指数如(112)、(220)/(204)等表明该方法合成了多晶块体。LEI等[19]认为:晶界作为缺陷阱可以改善晶体质量,晶界的化学改性可使材料性能发生改变。所以晶界的存在对于CIGS材料的性能有重要影响,从而使得多晶材料比单晶材料表现出更好的性能。对于CIGS的择优生长问题。BAEK等[20]研究表明,在1200 ℃合成的CIGS具有(112)择优取向。但由图1可知,合成的CIGS块体的择优取向是(220)/(204)晶面结果与其并不一致。原因可能是:Se蒸气压对于CIGS块体合成具有重要影响,在很高的蒸气压下往往得到具有(220)/(204)择优取向的材料[21]。原料及CIGS块体的成分分析如表1所列。由表1可知,In和Se元素都有损失,而使得Cu的含量有所升高。纯物质的饱和蒸气压与温度的关系式如式(1)所示[22]:

图1 真空熔炼合成CIGS块体的XRD谱

Fig. 1 XRD pattern of CIGS bulk prepared by vacuum smelting

lgp=At-1+Blgt+Ct+D (1)

表1 原料及块体的成分分析

Table 1 Compositions of raw materials and CIGS bulk

式中:p为纯物质的饱和蒸气压;t为温度;A、B、C和D为相关系数。

根据式(1)可以计算:在1200 ℃时,Cu的蒸气压是0.4 Pa,Ga的是14 Pa,In的是89 Pa,Se的是6.7× 103 kPa。表1出现的结果可能是In和Se蒸气压较高,In-Se形成了挥发相或者过量的Se本身没有完全参加反应,造成这两种元素有较大的损失。文献[20]指出:保温10 h,对于成分、择优取向的控制可能更好。所以,本实验中熔炼合成时保温2 h,反应时间较短,不利于元素间充分反应,这也可能是元素成分有较大偏差的原因。

真空熔炼合成CIGS块体的断面形貌如图2所示。由图2可知,材料内部有很多不规则的孔洞,并没有典型晶粒形貌特征,呈连续蔓延生长,以孔洞为界,形成一种结晶完整的材料。孔洞的存在很可能是In-Se挥发相或者游离的Se以气体形式残留在块体之中,材料冷却至室温,气体逸散,基体中就留下了大量的孔洞。

图2 真空熔炼合成CIGS块体的断口形貌

Fig. 2 Fracture morphology of CIGS bulk prepared by vacuum smelting

2.2 电子束蒸镀法制备CIGS预制薄膜

电子束蒸镀法制备CIGS预制薄膜的XRD谱如图3所示。由图3可知,主要是CuIn0.7Ga0.3Se2相,还有少量In2Se3相。因为蒸镀时电子束集聚于蒸发源的小区域,高能热流使块体蒸发沉积到玻璃衬底上。蒸发时较高的温度使得In和Se蒸气压很高,进而使得In和Se元素结合形成少量的In2Se3。对于薄膜太阳电池来说,In2Se3是一种缺陷,它可以充当载流子复合中心,又会减少少数载流子的寿命,所以要采取措施予以消除[17]。

文献[17,23]表明:玻璃衬底加热至400~600 ℃,电子束蒸镀用球磨方法合成的CIGS粉末,并没有得到单一相的薄膜;另外,玻璃衬底不经预热,直接用电子束蒸镀真空熔炼合成的CIGS块体而制备的CIGS薄膜往往是非晶薄膜。本实验中将玻璃衬底加热至350 ℃,采用电子束蒸镀真空熔炼合成的CIGS块体,反而得到了单一相薄膜,说明衬底加热和真空熔炼对薄膜的单一相结晶和性能均有重要作用。由图3可知,蒸镀后的CIGS薄膜只有(112)、(220)/(204)及(312)/(116)这3个指数的特征峰,可能原因是:该沉积温度时元素扩散能力还不强,其他方向的生长受到抑制而没有显露出来,说明薄膜结晶并不完全。薄膜的(112)晶向择优生长较明显,与CIGS块体表现出的(220)/(204)择优取向明显不同,原因可能是:衬底加热至350 ℃时,Se蒸气压还较小,使得薄膜呈(112)方向择优生长[21]。

真空熔炼合成CIGS块体和电子束蒸镀法制备CIGS预制薄膜的成分分析如表2所列。由表2可知,在玻璃衬底上镀膜时Cu有较严重的损失,与实验过程中观察到的坩埚表面有大量Cu析出的现象相吻合。MEN等[17]研究指出,在较高加速电压下,较高密度的热流可以使原料完全蒸发,沉积元素的比例更接近原始成分,而与元素本身的熔点与蒸气压没有太大的关系;而在较低加速电压下,热流密度较小,沉积过程与其熔点和蒸气压有很大的关系。本实验中采用8 kV的沉积电压相对较小,而Cu的熔点很高且蒸气压较低,导致没有足量的Cu原子沉积到衬底上,从而使得Cu的成分与块体的成分出现很大的偏差。In和Ga的熔点较低,在该沉积电压下,虽然In和Ga元素可以完全蒸发,但是在相同的温度范围内,In的蒸气压比Ga的蒸气压更高,结果使得薄膜中In的含量增加,而Ga的含量减小。Se具有低熔点和高蒸气压的特性,在电子束蒸镀过程中,可以完全蒸发并沉积到玻璃衬底上,又因为在该过程中,Cu元素析出损失较大,结果就使得Se的成分比块体相应成分偏高。栾和新等[3]指出,符合CIGS太阳电池制备要求的弱P型CIGS吸收层的成分(摩尔比)要求为:n(Cu)/n(In+Ga)为0.69~0.98,n(Ga)/n(In+Ga)为0.21~0.38,n(Se)/ n(Cu+In+Ga)为0.95~1.10。由表2可知,n(Cu)/n(In+Ga)和n(Se)/n(Cu+In+Ga)都比所需要的成分偏低,所以还需要后续处理来调整薄膜的成分。

图3 电子束蒸镀法制备CIGS预制薄膜的XRD谱

Fig. 3 XRD pattern of CIGS pre-fabricated thin film deposited by electron-beam evaporation

表2 电子束蒸镀法制备CIGS预制薄膜的成分分析

Table 2 Compositions of CIGS pre-fabricated thin film deposited by electron-beam evaporation

电子束蒸镀法制备CIGS预制薄膜的表面形貌如图4所示。由图4可知,颗粒较小且呈等轴状,基本处于0.3~0.7 μm范围内;表面没有裂纹或者孔洞等缺陷,整体来看结晶性能良好,说明电子束镀膜能得到高质量的预制薄膜。ROCKETT[24]指出,少量Na元素的掺入可以提高CIS/CIGS薄膜太阳电池的转化效率。钠钙玻璃中的Na离子扩散进入吸收层,能增加晶粒的大小,弱化晶粒边界的影响,增加吸收层对光的有效吸收密度,还可以促进薄膜(112)配位的形成。所以,在350 ℃沉积时,Na离子有可能进入吸收层薄膜,促进晶核的进一步长大,使得结晶性变好。由上述分析可知,图3所示薄膜具有(112)方向的择优生长,不仅可能与此时较小的Se蒸气压有关,还可能与渗入的Na离子促进了薄膜(112)配位的生长有关。

图4 电子束蒸镀法制备CIGS预制薄膜的表面形貌

Fig. 4 Surface morphology of CIGS pre-fabricated thin film deposited by electron-beam evaporation

2.3 退火温度对CIGS薄膜性能的影响

不同温度退火薄膜的XRD谱如图5所示。由图5可知,随着退火温度的升高,In-Se二次相逐渐减少、转化以至于完全消失;而CIGS峰则越来越尖锐,表明薄膜的结晶性能越来越好,最后只有结晶性能很好、单一黄铜矿结构、符合化学计量比的CIGS相。退火温度的升高,会使得Se蒸气压升高,但是在300~600 ℃退火并没有因为蒸气压的升高而改变薄膜(112)方向的择优生长。在300 ℃退火时,仍然只存在CIGS和In2Se3两相,与图3结果相比没有太大区别,结晶性能也没有明显改善,表明在300℃退火,对薄膜没有显著的影响。在400 ℃退火,In2Se3相消失,有少量InSe相形成,同时CIGS出现了(332)/(316)特征峰。文献[20]指出:在熔炼合成CIGS过程中,随着温度升高,In-Se二元相的形成顺序是先形成In2Se3,再形成InSe。本实验结果也很好地验证了此前的结论。CIGS新特征峰的出现,表明薄膜发生了再结晶,从而使得薄膜(112)方向择优程度有所减弱。在500、600 ℃退火,形成的InSe二元相消失只剩下单一的CIGS相;在600 ℃退火时,特征峰更加明显、尖锐,表明结晶性能变得更好。

图5 不同温度退火薄膜的XRD谱

Fig. 5 XRD patterns of CIGS annealed films

不同温度退火薄膜的成分分析如表3所列。由表3可知,退火后薄膜n(Se)/n(Cu+Ga+In)相对增加,总的变化规律是退火温度越高,比值越大。但是在400 ℃退火时,n(Se)/n(Cu+Ga+In)却有一定程度的下降。在不大于400 ℃退火时,n(Ga)/n(Ga+In)基本没有变化,但是随着退火温度逐步升高,n(Ga)/n(Ga+In)越来越高,即n(In)/n(Ga+In)呈现逐渐减少的趋势。随着退火温度逐步升高,n(Cu)/n(Ga+In)呈现先降低后升高的趋势,以在400 ℃退火时n(Cu)/n(Ga+In)最低。由图3和图5可知,预制薄膜和300 ℃退火薄膜,都存在In2Se3二元相,而且后者In2Se3的结晶性能相比于前者变差,可能存在In2Se3相的分解,从而导致In和Se摩尔比升高,Ga和Cu摩尔比降低。在400 ℃退火时出现的InSe相,相比于In2Se3,In的含量增加而Se的含量降低,又因为Se蒸气压较高,导致了n(Se)/n(Cu+Ga+In)有很大的改变,而n(In)/n(Ga+In)基本没有发生变化。在500 ℃以上(特别是600 ℃)退火时,InSe相消失,对退火薄膜晶粒生长和补充Se元素发挥了重要作用,促使薄膜成分优化,转变成具有弱P型CIGS成分要求的理想太阳电池吸收层材料[3]。

不同温度退火CIGS薄膜的表面形貌如图6所示。由图6可知,相比于图4,随着退火温度的升高,薄膜不断发生再结晶,晶粒逐渐增大,由低温退火时的颗粒状,渐渐转变成晶界清晰,晶粒较大的光滑薄膜。在300 ℃退火时,薄膜晶粒大小相对均匀,分布在0.3~0.8 μm范围内,相比预制薄膜,晶粒有所长大。这说明300 ℃退火虽然没有改变薄膜的物相组成,但是也促进了原子扩散,使得晶粒呈长大的趋势。在400 ℃退火时,薄膜晶粒再结晶明显,生成粒径0.5~1.2 μm的较大晶粒,说明此时薄膜的结晶性能得到改善。由图5可知,此时薄膜中有InSe相出现,在图6(b)中较亮的小颗粒认为是析出来的InSe相。在500 ℃退火时,薄膜晶粒结构欠清晰,只能看到一些模糊的晶粒边缘形貌。原因可能是薄膜处在一种过渡状态,还没有再结晶完全;另外InSe二元相的分解弥合了晶粒边界的缺陷而使得边界模糊不清。在600 ℃退火时,晶粒结晶完全,粒径较大,分布在1.0~3.5 μm范围内。较大晶粒的吸收层薄膜,光电转化效率可能更高。所以600 ℃退火薄膜可能会有较好的转化效率。

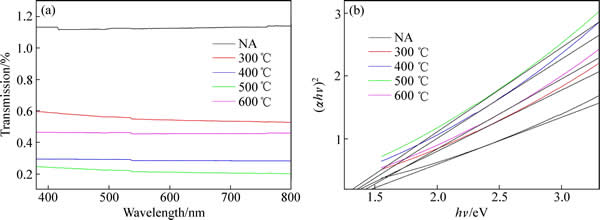

图7(a)所示为不同温度退火薄膜透射光谱。由图7(a)可知,在波长380~800 mm的可见光范围内,薄膜的透射率均很低,低于1.2%,说明薄膜的光吸收性能很好。随着波长的增长,薄膜的透射率呈现小幅度降低的趋势,预制薄膜(NA薄膜)透射率基本维持在1.1%左右,没有太大的变化;退火使薄膜的透射率进一步降低,在300~500 ℃范围内,退火温度越高透射率越低,这可能是与退火使得薄膜晶粒增大有关。在600 ℃退火时,薄膜的透射率有所增加,但仍维持在较低水平,这可能是和600 ℃退火时薄膜晶粒粗大以及晶界过于明显有关。

表3 不同温度退火薄膜的成分分析

Table 3 Compositions of CIGS annealed films

图6 不同温度退火薄膜的表面形貌

Fig. 6 Surface morphologies of CIGS annealed thin films at different temperatures

图7 不同温度退火薄膜的透射光谱和(αhν)2-hν关系曲线

Fig. 7 Transmittance spectra curve (a) and (αhν)2-hν curve (b) of annealed films

图7(b)所示为不同温度退火薄膜的(αhν)与hν关系曲线。依据曲线斜率可以推断不同温度下薄膜的禁带宽度(Eg)[25]。由图7(b)可知,NA薄膜、300 ℃退火薄膜、400 ℃退火薄膜、500 ℃退火薄膜及600 ℃退火薄膜所对应的禁带宽度分别为1.48、1.39、1.36、1.33和1.44 eV。MADHURI等[26]研究指出:薄膜的吸收系数、膜厚与透射率的关系如式(2)所示,吸收系数与禁带宽度的关系如式(3)所示:

(2)

(2)

(3)

(3)

式中:α为薄膜的吸收系数;d为薄膜厚度;T为透射率;R为反射系数;Eg为禁带宽度;hν为光子能量。

根据式(2)和(3)可知,随着退火温度升高,T减小,α增加,使得(αhν)2-hν的关系曲线上移,切线与hν的交点的数值变小,这与上述禁带宽度的变化一致。在600 ℃退火时,由于透射率有稍微的升高,使得禁带宽度增加。文献[27]研究表明:当CIGS薄膜的禁带宽度在1.4~1.5 eV范围时,能与太阳光谱更好匹配,可以更有效地吸收太阳光,产生较高的开路电压,从而提高薄膜电池的光电转化效率。在600 ℃退火时,薄膜禁带宽度处于该范围,所以很可能制备出高效的太阳电池。

3 结论

1) 在1200 ℃、保温2 h条件下,4种单质真空熔炼得到了具有(220)/(204)择优取向的CuIn0.7Ga0.3Se2块体。CIGS块体相比原始成分,In和Se的含量均有所降低,而Ga和Cu的含量有所升高。块体内部存在很多不规则的孔洞,表面并没有典型的晶粒形貌,呈连续蔓延生长,以孔洞为分界,形成一种结晶完整的材料。

2) 电子束蒸镀法制备的CIGS预制薄膜,主要得到(112)方向择优生长的CuIn0.7Ga0.3Se2相,还有少量的In2Se3杂质相。相比CIGS块体预制薄膜中,Cu含量有较严重的损失,Ga也有少量损失,使得薄膜中In和Se的成分相应升高。预制薄膜晶粒呈现等轴状,晶粒较小,表面并没有裂纹或者孔洞等缺陷。

3) 随着退火温度升高,CIGS薄膜的单相性能越来越好。在300 ℃退火,薄膜物相并没有改变,仍然存在In2Se3杂质相;在400 ℃退火,有少量的InSe相出现;在500 ℃和600 ℃退火,形成的InSe相消失,只剩下单一的CIGS相,相比500 ℃,在600 ℃退火时获得的薄膜特征峰更加明显、尖锐,结晶性能也更好。退火温度越高,薄膜中Se的含量越高。但是400 ℃退火时,薄膜中Se的含量有所降低;随着退火温度升高,Cu的含量连续增加,Ga的含量有所增加,而In的含量有所降低,使得贫铜成分的薄膜更接近于理想的太阳电池吸收层材料的要求。随着退火温度的升高,薄膜不断发生再结晶,晶粒逐渐增大,由低温退火时的颗粒状逐渐转变成晶界清晰、晶粒较大的薄膜。

4) 在可见光的光谱范围内,不同温度退火薄膜的透射率都很低,而且随波长变化没有明显波动;相对应的禁带宽度,分别为1.48、1.39、1.36、1.33和1.44 eV,可知1.44 eV与太阳光谱有更好的匹配,很可能得到转化效率较高的薄膜太阳电池。

REFERENCES

[1] 田 力, 张晓勇, 毛启楠, 李学耕, 于平荣, 王 东.真空快速退火对CIGS太阳电池性能的影响[J]. 无机材料学报, 2015, 30(1): 35-40.

TIAN Li, ZHANG Xiao-yong, MAO Qi-nan, LI Xue-geng, YU Ping-rong, WANG Dong. Effect of vacuum rapid annealing treatment on performance of CIGS solar cells[J]. Journal of Inorganic Materials, 2015, 30(1): 35-40.

[2] JACKSON P, HARISKOS D, WUERZ R, KIOWSKI O, BAUER A, FRIEDLMEIER T M, POWALLA M. Properties of Cu(In,Ga)Se2 solar cells with new record efficiencies up to 21.7%[J]. Physica Status Solidi-Rapid Research Litters, 2015, 9(1): 28-31.

[3] 栾和新, 庄大明, 曹明杰, 刘 江. 磁控溅射法制备CIGS薄膜太阳电池的工艺及性能研究[J]. 真空科学与技术学报, 2012, 32(8): 661-668.

LUAN He-xin, ZHUANG Da-ming, CAO Ming-jie, LIU Jiang. Growth and characterization of copper indium gallium diselenide films for solar cells fabrication[J]. Chinese Journal of Vacuum Science and Technology, 2012, 32(8): 661-668.

[4] 张秀清, 李艳红, 张 超. 太阳电池研究进展[J]. 中国材料进展, 2014, 33(7): 436-441.

ZHANG Xiu-qing, LI Yan-hong, ZHANG Chao. Research progress on solar cell[J]. Materials China, 2014, 33(7): 436-441.

[5] 朱晓晶, 马建华, 姚娘娟, 梁 艳, 江锦春, 王善力, 褚君浩. CuInSe2薄膜的化学溶液制备方法[J]. 红外与毫米波学报, 2014, 33(3): 231-236.

ZHU Xiao-jing, MA Jian-hua, YAO Niang-juan, LIANG Yan, JIANG Jin-chun, WANG Shan-li, CHU Jun-hao. Preparation of CuInSe2 thin films by chemical solution method[J]. J Infrared Millim & Waves, 2014, 33(3): 231-236.

[6] PARK J W, CHOI Y W, LEE E, JOO O S, YOON S, MIN B K. Synthesis of CIGS absorber layers via a paste coating[J]. Journal of Crystal Growth, 2009, 311: 2621-2625.

[7] XIA Dong-lin, LI Jang-zhuang, XU Man, ZHAO Xiu-jian. Electrodeposited and selenized CIGS thin films for solar cells[J]. Journal of Non-Crystalline Solids, 2008, 354: 1447-1450.

[8] REPINS I, CONTRERAS M A, EGAAS B, DEHART C, SCHARF J, PERKINS C L, TO B, NOUFI R. 19.9%-efficient ZnO/CdS/CuInGaSe2 solar cell with 81.2% fill factor[J]. Progress in Photovoltaics: Research and Applications, 2008, 16: 235-239.

[9] SHI J H, LI Z Q, ZHANG D W, LIU Q Q, SUN Z, HUANG S M. Fabrication of Cu(In,Ga)Se2 thin films by sputtering from a single quaternary chalcogenide target[J]. Progress in Photovoltaics: Research and Applications, 2011, 19: 160-164.

[10] 张晓科, 王 可, 解晶莹. CIGS太阳电池的低成本制备工艺[J]. 电源技术, 2005, 29(12): 849-852.

ZHANG Xiao-ke, WANG Ke, XIE Jing-ying. Low cost processing of CIGS solar cells[J]. Chinese Journal of Power Sources, 2005, 29(12): 849-852.

[11] 李 伟, 刘 平, 王卫兵, 马凤仓, 刘新宽, 陈勤妙, 韩朝霞. CIGS薄膜太阳电池吸收层的非真空制备工艺研究进展[J]. 材料导报A, 2012, 26(5): 134-137.

LI Wei, LIU Ping, WANG Wei-bing, MA Feng-cang, LIU Xin-kuan, CHEN Qin-miao, HAN Zhao-xia. Research progress in non-vacuum processing for absorber layer of CIGS thin film solar cell[J]. Material Review A, 2012, 26(5): 134-137.

[12] 郭杏元, 许 生, 曾鹏举, 范垂祯. CIGS薄膜太阳电池吸收层制备工艺综述[J]. 真空与低温, 2008, 14(3): 125-132.

GUO Xing-yuan, XU Sheng, ZENG Peng-ju, FAN Chui-zhen. Review on fabrication process of the absorber layer of the CIGS thin-film solar cell[J]. Vacuum & Cryogenics, 2008, 14(3): 125-132.

[13] ZHANG Li, XUE Yu-ming, XU Chuan-ming, HE Qing, LIU Fang-fang, LI Chang-jian, SUN Yun. Microstructural characterization of Cu-poor Cu(In,Ga)Se2 surface layer[J]. Thin Solid Films, 2012, 520: 2873-2877.

[14] LIU Jiang, ZHUANG Da-ming, LUAN He-xin, CAO Ming-jie, XIE Min, LI Xiao-long. Preparation of Cu(In,Ga)Se2 thin film by sputtering from Cu(In,Ga)Se2 quaternary target[J]. Progress in Natural Science: Materials International, 2013, 23(2): 133-138.

[15] 耿魁伟, 曾 飞, 谷 宇, 李晓伟, 宋 成, 潘 峰. 超高真空电子束蒸镀Fe/Ru多层膜的结构和磁性[J]. 中国有色金属学报, 2005, 15(11): 1833-1837.

GENG Kui-wei, ZENG Fei, GU Yu, LI Xiao-wei, SONG Chen, PAN Feng. Structural and magnetic properties of Fe/Ru multilayers prepared by ultra-high vacuum electron-gun evaporation[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(11): 1833-1837.

[16] 郝安林. 电子束蒸发法制备Co/Ru多层膜的微观结构与磁电阻[J]. 粉末冶金材料科学与工程, 2014, 19(5): 832-838.

HAO An-lin. Microstructure and magneto-resistor of Co/Ru multimembranes fabricated by electron beam vapor deposition method[J]. Materials Science and Engineering of Powder Metallurgy, 2014, 19(5): 832-838.

[17] MEN Chuan-ling, TIAN Ziao, SHAO Qiu-ping, ZHANG Hua, AN Zheng-hua. Characterization of Cu(In,Ga)Se2 films deposited by single-step electron beam evaporation for solar cell applications[J]. Applied Surface Science, 2012, 258: 10195-10198.

[18] VENKATACHALAMA M, KANNANA M D, JAYAKUMARA S, BALASUNDARAPRABHUA R, NANDAKUMARA A K, MUTHUKUMARASAMY N. CuInxGa1-xSe2 thin films prepared by electron beam evaporation[J]. Solar Energy Materials and Solar Cells, 2008, 92: 571-575.

[19] LEI C, LI C M, ROCKETT A, ROBERTSON I M. Grain boundary compositions in Cu(In,Ga)Se2[J]. Journal of Applied Physics, 2007, 101: 024909–1-7.

[20] BAEK E R, ASTINI V, TIRTA A, KIM B. Phase evolution of CIGS alloyed compound synthesis by direct melting method[J]. Current Applied Physics, 2011, 11: S76-S80.

[21] CONTRERAS M A, ROMERO M J, NOUFI R. Characterization of Cu(In,Ga)Se2 materials used in record performance solar cells[J]. Thin Solid Films, 2006, 511/512: 51-54.

[22] 戴永年, 杨 斌. 有色金属材料的真空冶金[M]. 北京: 冶金工业出版社, 2000: 24-28.

DAI Yong-nian, YANG Bin. Vacuum metallurgy of nonferrous metal materials[M]. Beijing: Metallurgical Industry Press, 2000: 24-28.

[23] VENKATACHALAM M, KANNAN M D, MUTHUKUMARASAMY N, PRASANNA S, JAYAKUMAR S, BALASUNDARAPRABHU R, SAROJA M. Investigations on electron beam evaporated Cu(In0.85Ga0.15)Se2 thin film solar cells[J]. Solar Energy, 2009, 83: 1652-1655.

[24] ROCKETT A. The effect of Na in polycrystalline and epitaxial single-crystal CuIn1-xGaxSe2[J]. Thin Solid Films, 2005, 480/481: 2-7.

[25] LI Z H, CHO E S, KWON S J. Properties of the Cu(In,Ga)Se2 absorbers deposited by electron-beam evaporation method for solar cells[J]. Current Applied Physics, 2011, 11: 28-33.

[26] MADHURI K V, NAIDU B S, HUSSAIN O M, EDDRIEF M, JULIEN C. Physical investigations on electron beam evaporated V2O5-MoO3 thin films[J]. Materials Science and Engineering B, 2001, 86: 165-171.

[27] 周丽梅, 高 宏, 薛钰芝. 铜铟铝硒(CIAS)薄膜太阳电池关键材料–制备和性能[M]. 北京: 化学工业出版社, 2014: 11-14.

ZHOU Li-mei, GAO Hong, XUE Yu-zhi. The preparation and properties research of copper indium aluminum selenium for key material of thin film solar cells[M]. Beijing: Chemical Industry Press, 2014: 11-14.

Characterization of CuIn0.7Ga0.3Se2 films prepared by electron-beam evaporation for thin film solar cell

WANG Xing-xing1, ZHANG Fu-qin1, ZHOU Jun1, ZHENG Ji-xiang1, LI Bing-qian2, LIU Yi2

(1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The CuIn0.7Ga0.3Se2 (CIGS) thin films used as absorber layers of solar cell were deposited by electron-beam evaporation utilizing CIGS bulk synthesized by quartz-tube vacuum smelting, followed by annealing treatment in vacuum atmosphere at different temperatures. The performances of CIGS bulk and annealed films on the surface morphology, compositions, crystal microstructure and photoelectric property were studied by X-ray diffractometry (XRD), scanning electron microscopy (SEM), energy dispersive spectrometry (EDS) or spectroscopic analysis, respectively. The results show that ideal CuIn0.7Ga0.3Se2 bulk with good crystallization property and single chalcopyrite structure is obtained by vacuum smelting at 1200 ℃for 120 min. With the increase of annealing temperature, single phase CIGS presents, accompanying by decomposition of In-Se impurity phase. Meanwhile, the grain size continuously grows up to 1.0-3.5 μm, and the composition and optical band gap are gradually optimized. Therefore, the as-annealed film at 600 ℃ is in much more consistent with the absorber layers material of ideal solar cell.

Key words: solar cell; CuIn0.7Ga0.3Se2; vacuum melting; electron-beam evaporation; annealing treatment

Foundation item: Project (2011CB605803) supported by the National Key Basic Research Development Program of China

Received date:2015-05-06;Accepted date:2015-09-23

Corresponding author: ZHANG Fu-qin; Tel: +86-13873129106; E-mail: zhangfuqin@csu.edu.cn

(编辑 龙怀中)

基金项目:国家重点基础研究发展规划资助项目(2011CB605803)

收稿日期:2015-05-06;修订日期:2015-09-23

通信作者:张福勤,教授,博士;电话:13873129106;E-mail:zhangfuqin@csu.edu.cn