文章编号:1004-0609(2013)S1-s0015-05

锻造方法对TA15钛合金组织和性能的影响

张旺峰1, 2,王玉会1,颜孟奇1,张庆玲1

(1. 北京航空材料研究院,北京 100095;

2. 西安交通大学 材料物理系,西安 710049)

摘 要:研究TA15钛合金在等温锻造和普通模锻两种条件下大型锻件组织的性能特征和热处理工艺的影响。结果表明:等温锻件的室温强度和冲击韧性高于普通模锻件的;等温锻件的500 ℃高温拉伸与断裂韧性低于普通模锻件的。两种锻件的热处理工艺有以下特点:在900 ℃以前,随退火温度升高,其室温强度增加,达到900 ℃以后室温强度随退火温度升高而降低。500 ℃下的高温拉伸性能随退火温度升高,表现不同,普通模锻件的随退火温度升高而增加,等温锻件的则在870 ℃出现转折现象。等温锻件比普通模锻的组织更细。

关键词:TA15钛合金;大锻件;等温锻造;普通模锻;热处理

中图分类号:TG 146.23;TG113.25 文献标志码:A

Effect of forging method on microstructure and mechanical properties of TA15 titanium alloy

ZHANG Wang-feng1, 2, WANG Yu-hui1, YAN Meng-qi1, ZHANG Qing-ling1

(1. Beijing Institute of Aeronautical Materials, Beijing 100095, China;

2. Department of Materials Physics, Xi’an Jiaotong University, Xi’an 710049, China)

Abstract: The microstructure and properties of large forgings by isothermal forging and common forging of TA15 titanium alloy before and after heat treatment were studied. The results show that the tensile strength and impact toughness of isothermal forgings at room temperature are higher than those of common forgings, but they are conversed on fracture toughness and tensile strength at 500 ℃. Tensile strength at room temperature increases with increasing annealing temperature before 900 ℃ for large forging, and then decrease with increasing temperature after 900 ℃. Tensile strength at 500 ℃ is different for isothermal forgings and common forgings. The tensile strength at 500 ℃ increases with increasing annealing temperature for common forgings, but increases and then decreases with the temperature increasing for isothermal forgings, and the peak value occurs at 870 ℃. The microstructure of isothermal forgings is finer than that of common forgings.

Key words: TA15 titanium alloy; large forging; isothermal forging; common forging; heat treatment

钛合金锻造最常用的方法有两种,即普通模锻和等温精锻。这两种锻造方法各有优缺点,等温锻造是在恒温低应变速率条件下进行,变形抗力小,可以实现近净成形,锻件加工余量小,组织相对均匀,但对模具的设计与制造要求高,模具成本高,特别是制造大型锻件,更是如此;而普通模锻是在非恒温连续冷却条件下进行,变形抗力较大,锻件加工余量大,对模具设计与制造要求比等温模锻低,模具成本也低。对两种锻造方法均有大量研究[1-9]。但对这两种锻造 方法制造的锻件组织性能及后续热处理工艺的比较研究还很少。本文作者针对这两种锻造方法,比较了TA15钛合金的室温、高温拉伸性能以及冲击性能、损伤容限性能,并研究不同锻造后热处理的影响。

1 实验

实验材料选取在航空航天领域有广泛应用的TA15合金,其主要化学成分(质量分数)为:6.66% Al,1.74% Mo,2.25% V,2.11% Zr,0.01% C,0.06% Fe,0.02% Si,0.083% O,0.01% Cr,2.0% Sn,0.94% W,0.003 8% N,0.001 2% H,其余为 Ti。以飞机隔框大型锻件为研究对象,采用d 350~400 mm棒材制造锻件,所选锻件能够代表大型复杂锻件制造的工艺水 平。等温锻造和普通模锻均在相变点以下20~50 ℃进行,锻件成形后,在850 ℃热处理1~3 h,然后空冷。在下文中,PM代表普通模锻件,DW代表等温精锻件。为了反映锻件组织性能均匀性,在大型锻件的典型部位取样检验,组织观察和定量分析均在Leica DMLM进行。

2 结果与分析

2.1 材料性能

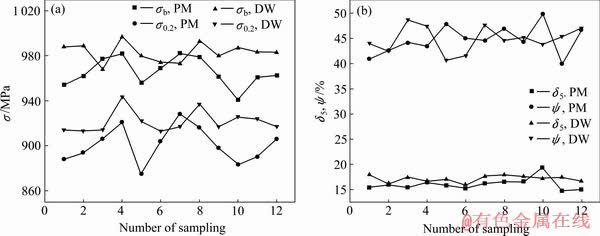

图1所示是从大型锻件不同部位取样得到的室温拉伸性能数据。可以看出,除个别数据点以外,整体而言,等温锻件的室温屈服强度和抗拉强度均高于普通锻件的。塑性指标中的伸长率d5为等温锻件的比普通模 锻件的略高,而断面收缩率ψ有波动,水平基本相当。

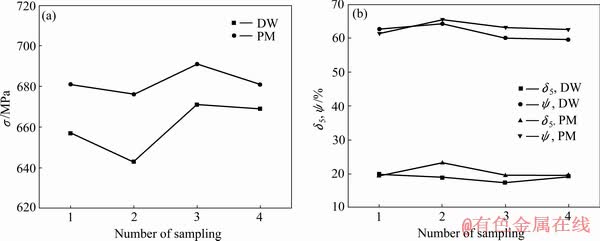

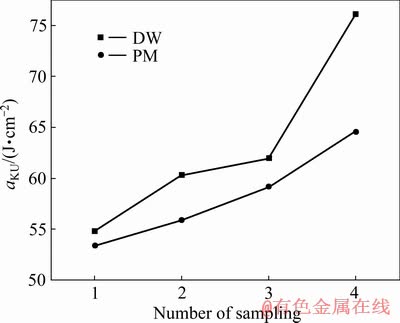

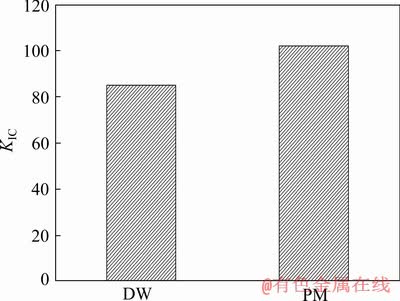

对500 ℃高温拉伸性能,普通锻件的强度和塑性均高于等温锻件的,见图2;等温锻件的冲击韧性aKU高于普通模锻件的,见图3;普通模锻件的断裂韧性KIC明显高于等温锻件的, 见图4。

图1 TA15两种锻件的室温拉伸性能

Fig. 1 Tensile properties of isothermal and common forgings at room temperature for TA15 alloy

图2 TA15两种锻件的500 ℃高温拉伸性能

Fig. 2 Tensile properties of isothermal and common forgings at 500 ℃ for TA15 alloy

图3 两种锻件的室温冲击性能

Fig. 3 Impact toughness of isothermal and common forgings at room temperature for TA15 alloy

2.2 显微组织

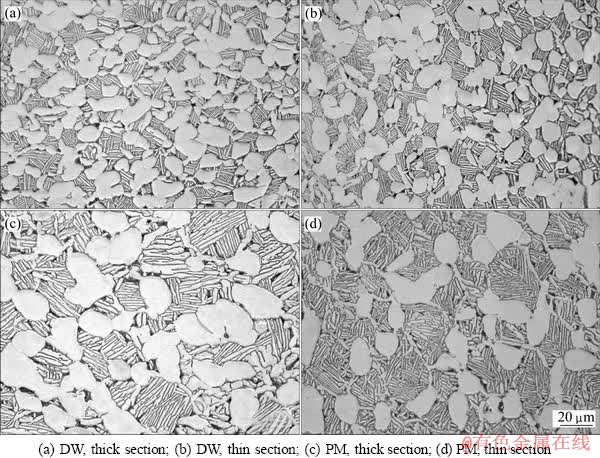

为了比较两种锻造方法的组织形貌,分别选取锻件的两个典型截面进行组织观察,即厚截面和薄截面。这种选取方法,除了可比较两种锻造方法的组织特点外,还可反映大型锻件的组织均匀性问题。厚截面处冷却速率小,薄截面处冷却速率大。从两种锻件的显微组织(图5)可以看出,等温锻件厚薄截面组织相差不大,比较均匀。普通模锻件在厚截面处的初生α相较大,β转变组织中片较厚,而薄截面处组织初生α相含量低,β转变组织中片较细。总体而言,等温锻件晶粒更细小,初生α相也较小。

图4 两种锻件的断裂韧性

Fig. 4 Fracture toughness of isothermal and common forgings for TA15 alloy

2.3 大型锻件热处理工艺

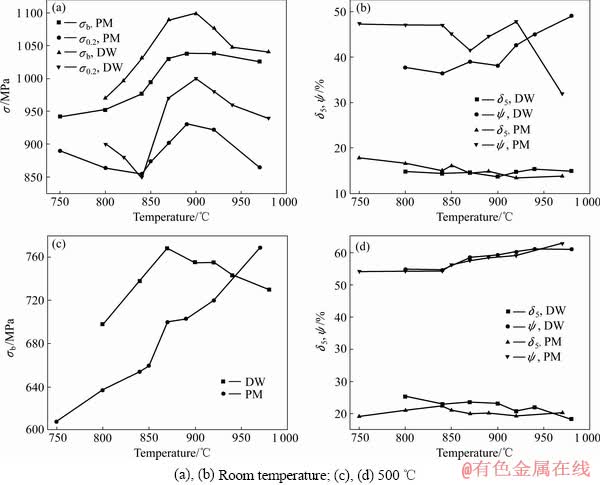

图6给出了在750~980 ℃范围内、不同温度退火时普通模锻件和等温精锻件的力学性能的变化规律。

图5 TA15钛合金两种锻件的显微组织

Fig. 5 Microstructures of isothermal and common forgings for TA15 alloy

图6 退火温度对普通模锻件和等温模锻件拉伸性能的影响

Fig. 6 Effect of annealing temperature on room and high temperature tensile properties of common and isothermal forgings

图6所示为在750~980 ℃热处理1 h,空气冷却,退火后等温精锻件及普通模锻件的拉伸性能随退火温度的变化规律。由图6(a)可知,在750~900 ℃退火,两种锻件的室温抗拉强度随退火温度升高而提高;900 ℃以后,室温强度随退火温度增加呈现下降趋势。而在840~870 ℃范围内,两种锻件的抗拉强度随退火温度变化的曲线斜率最大,即抗拉强度随退火温度的增加增幅最大。对于等温精锻件,从840 ℃到870 ℃,温度增加30 ℃,强度增加约60 MPa;而对普通模锻件,从840 ℃到870 ℃,温度增加30 ℃,强度增加约53 MPa。两者在强度增加的同时,塑性变化均不大(见图6(b))。对于500 ℃下高温拉伸性能,随温度升高,表现各不同,普通模锻件,随温度升高而增加,等温锻件则在870 ℃出现转折现象,见图6(c)、(d)。

2.4 分析讨论

等温锻件由于加工余量小,变形量大以及恒温下变形,组织均匀细小,初生α相形态细小,因此,室温强度、塑性和冲击韧性高;而普通模锻件由于加工余量大,变形量较小以及非恒温下变形,组织没有等温锻件均匀细小,室温强度、塑性和冲击韧性低于等温锻件的,但其500 ℃下的高温拉伸性能、断裂韧性高于等温锻件的。

钛合金的普通退火是建立在回复和再结晶的基础之上的,其目的是消除内应力,使合金的组织和性能均匀。而两相钛合金在退火时除了再结晶过程外,还可能发生与相变有关的组织和性能变化。经过热变形的TA15半成品在退火过程中,不仅发生回复、多边形化和再结晶过程,而且还会发生亚稳定β相的分解。回复和再结晶是一个软化过程,亚稳定β相分解析出弥散的α相是强化过程[10]。所以退火半成品的性能在很大程度上取决于退火温度下这两种因素中那种因素起主导作用。随着退火温度的变化,这两种因素不是一成不变的,在某个温度下是强化起主导作用,在另一个温度下可能是软化起主导作用。大型锻件的热处理工艺结果就是如此。

3 结论

1) 等温锻件由于变形量大,晶粒组织更细,其室温强度、冲击韧性高于普通模锻的,而500 ℃下高温拉伸与断裂韧性低于普通模锻件的。

2) 等温锻件和普通模锻件的热处理工艺研究表明,在900 ℃以前,随退火温度升高,室温强度增加,900 ℃以后室温强度随温度升高而降低,等温锻件降低更明显。500 ℃下的高温拉伸性能,随退火温度升高,表现不同,普通模锻件随温度升高而增加,等温锻件则在870 ℃出现转折现象。

3) 等温锻件比普通模锻件的组织更细。

REFERENCES

[1] FILIP R, KUBIAK K, ZIAJIA W. The effect of microstructure on the mechanical properties of two-phase titanium alloys[J]. Journal of Materials Processing Technology, 2003, 133: 84-88.

[2]  G. Influence of processing on microstructure and mechanical properties of (α+β) titanium alloys[J]. Materials Science and Engineering A, 1998, 243: 32-36.

G. Influence of processing on microstructure and mechanical properties of (α+β) titanium alloys[J]. Materials Science and Engineering A, 1998, 243: 32-36.

[3] 罗 皎, 李淼泉, 于卫新. TC4钛合金高温变形时微观组织演变[J]. 稀有金属材料与工程, 2010, 29(8): 1323-1328.

LUO Jiao, LI Miao-quan, YU Wei-xin. Microstructure evolution during high temperature deformation of Ti-6Al-4V alloy[J]. Rare Metal Materials and Engineering, 2010, 39(8): 1323-1328.

[4] SUN Z C, YANG H. Microstructure and mechanical properties of TA15 titanium alloy under multi-step local loading forming[J]. Materials Science and Engineering A, 2009, 523: 184-192.

[5] 张行健, 吕宏军, 王 琪, 陈永来, 周晓建. 钛合金模锻工艺的研究进展[J]. 材料导报, 2007, 21(11): 95-98.

ZHANG Xing-jian,  Hong-jun, WANG Qi, CHEN Yong-lai, ZHOU Xiao-jian. Research progress in die forging technology of titanium alloy[J]. Materials Review, 2007, 21(11): 95-98.

Hong-jun, WANG Qi, CHEN Yong-lai, ZHOU Xiao-jian. Research progress in die forging technology of titanium alloy[J]. Materials Review, 2007, 21(11): 95-98.

[6] 郭拉凤, 朱艳春, 孔虎星, 原梅妮, 吴伏家. 钛合金复杂构件等温锻造工艺研究[J]. 稀有金属, 2012, 36(3): 357-362.

GUO La-feng, ZHU Yan-chun, KONG Hu-xin, YUAN Mei-ni, WU Fu-jia. Isothermal forging process of titanium alloy complex components[J]. Chinese Journal of Rare Metals, 2012, 36(3): 357-362.

[7] 曲银化, 孙建科, 孟祥军. 钛合金等温锻造技术研究进展[J]. 钛工业进展, 2006, 23(1): 6-9.

QU Yin-hua, SUN Jian-ke, MENG Xiang-jun. Research and development of isothermal forging of titanium alloys[J]. Titanium Industry Progress, 2006, 23(1): 6-9.

[8] 孙念光, 杨 合, 孙志超. 大型钛合金隔框等温闭式模锻成形工艺优化[J]. 稀有金属材料与工程, 2009, 38(7): 1296-1300.

SUN Nian-guang, YANG He, SUN Zhi-chao. Optimization on the process of large titanium bulkhead isothermal closed-die forging[J]. Rare Metals Materials and Engineering, 2009, 38(7): 1296-1300.

[9] WANG K L, LU S Q, FU M W, LI X, DONG X J. Identification of the optimal (α+β) forging process parameters of Ti-6.5Al-3.5Mo-1.5Zr-0.3Si based on processing-maps[J]. Materials Science and Engineering A, 2010, 527: 7279-7285.

[10] 张旺峰, 王玉会, 马济民. TA15钛合金大锻件热处理强化及机制[J]. 稀有金属, 2010, 34(1): 1-5.

ZHANG Wang-feng, WANG Yu-hui, MA Ji-min. Heat treatment strengthening and its mechanism of large forging for TA15 titanium alloy[J]. Chinese Journal of Rare Metals, 2010, 34(1): 1-5.

(编辑 袁赛前)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:张旺峰,研究员,博士;电话:010-62496632;E-mail: wfzbiam@126.com