DOI: 10.11817/j.issn.1672-7207.2017.03.008

超音速火焰喷涂WC-12Co涂层高温摩擦-磨损性能

王进春1,孔德军1, 2

(1. 常州大学 机械工程学院,江苏 常州,213016)

2. 常州大学 江苏省材料表面科学与技术重点实验室,江苏 常州,213164)

摘要:采用超音速火焰喷涂法在H13钢表面制备WC-12Co涂层,通过扫描显微镜、X线衍射仪和能谱仪分析其表面-界面形貌、物相和化学元素组成。利用球/平面接触方式进行涂层高温磨损试验,通过扫描电镜和能谱仪分析磨痕形貌和化学元素的变化,讨论高温对涂层摩擦因数和磨损性能的影响。研究结果表明:涂层界面致密,与基材紧密结合;在600,700和800 ℃时涂层平均摩擦因数分别为0.395 5,0.327 1和0.266 4;600 ℃时涂层以黏着磨损为主,700 ℃时涂层以氧化磨损为主,并伴有磨粒磨损,800℃时涂层以严重的氧化磨损为主。

关键词:超音速火焰喷涂;WC-12Co涂层;表面;界面;摩擦因数;磨损性能

中图分类号:TG335.86;O354.3 文献标志码:A 文章编号:1672-7207(2017)03-0608-09

Friction-wear properties of HVOF sprayed WC-12Co coatings at high temperatures

WANG Jinchun1, KONG Dejun1, 2

(1. College of Mechanical Engineering, Changzhou University, Changzhou 213016, China;

2. Jiangsu Key Laboratory of Materials Surface Science and Technology, Changzhou University,

Changzhou 213164, China)

Abstract: The WC-12Co coating was sprayed on H13 hot worked die steel by high velocity oxygen fuel (HVOF), and the surface-interface morphologies, phases and chemical element compositions of the obtained coatings were analyzed with SEM (scanning electronic microscope), XRD (X-ray diffractometer), and EDS (energy dispersive spectroscope). And the friction and wear behaviors were investigated at high temperatures by means of ball/plane contact, the worn morphologies and the changes of chemical elements on the coating surface after the wear tests were analyzed with SEM and EDS, and the influences of high temperature on the friction coefficient and wear performance were discussed. The results show that the coating interface is dense and combined closely with the substrate. At the temperatures of 600, 700 and 800 ℃, the average friction coefficients are 0.395 5, 0.327 1 and 0.266 4, respectively. The wear mechanism of WC-12Co coating is an adhesive wear at 600 ℃, and the wear mechanism is the oxidative wear accompanying with abrasive wear at 700 ℃, while the wear mechanism is the serious oxidative wear at 800 ℃.

Key words: high velocity oxygen fuel (HVOF); WC-12Co coating; surface; interface; friction coefficient; wear performance

H13是一种C-Cr-Mo-Si-V型热作模具钢[1],具有良好的韧性、热强性、热稳定性、抗氧化能力和抗热疲劳性能等优点,广泛应用于热锻、热挤压和压铸等模具制造[2]。热作模具的工作温度约为600 ℃,在与金属接触、挤压、摩擦过程中,磨损较常温下更为严重,容易引起模具加工精度降低,甚至失效[3],因此,在热作模具表面制备耐高温磨损的涂层,延长其使用寿命成为材料表面改性研究的热点。热喷涂形成的WC-Co金属陶瓷涂层具有良好的耐磨性和抗高温性,已被广泛应用于许多领域,其中超音速火焰喷涂(HVOF)具有低焰流温度和高焰流速度的优点,可以减少喷涂过程中WC粉末颗粒脱碳和氧化等问题[4],具有硬度高、耐磨性能优异、耐高温性能好等优点,可以应用于热作模具表面改性处理。然而,有关WC-Co涂层的研究主要集中于粉末类型[5-6]、喷涂工艺[7-8]、微观组织[9-11]、力学性能[12]等方面,而对涂层高温下磨损性能的研究甚少。在此,本文作者以热作模具钢H13为基体材料,采用超音速火焰喷涂方法在其表面制备一层WC-12Co涂层,分析其在600,700和800 ℃高温时摩擦-磨损行为,以便为其在热作模具表面改性处理中应用提供实验依据。

1 实验

基材为H13热作模具钢成分(质量分数)为:C 0.32%~0.45%,Si 0.80%~1.20%,Mn 0.20%~0.50%,Cr 4.75%~5.50%,Mo 1.10%~1.75%,V 0.80%~1.20%,S,P小于等于0.03%,其余为Fe。喷涂粉末为DG WC-12Co(质量分数,%)。喷涂前先用酒精清洗试样表面,然后用75 μm棕刚玉磨料对试样表面进行喷砂粗化处理。在XM-8000超音速喷涂系统上进行喷涂试验,以航空煤油为燃料,高压O2为助燃气体,N2为送粉气体。其工艺参数为油压1.25 MPa,氧压1.58 MPa,水温40 ℃,喷枪压0.95 MPa。制备的涂层试样经打磨抛光后,采用JSUPRA55型场发射扫描电镜观察涂层表面-界面形貌,通过HV-1000型显微维氏硬度仪测量涂层的显微硬度,在涂层上任取5个点,载荷为300 g,压头保持时间为15 s,取其平均值。磨损试验在HT-1000高温摩擦磨损试验机上进行,摩擦方式为旋转式,对磨副为直径5 mm的Si3N4陶瓷球,高温炉加热温度为600,700和800 ℃,加载载荷为20 N,摩擦副主轴转速为1 000 r/min,摩擦半径为4 mm,试验时间为40 min。高温磨损试验后,摩擦因数由高温摩擦磨损试验机自带软件跟踪获得,并通过扫描电镜和能谱仪分析涂层磨损后形貌和化学元素的面分布,磨损轮廓则通过CFT-I型多功能材料表面综合性能测试仪测量获得。

2 分析与讨论

2.1 涂层表面-界面形貌和能谱分析

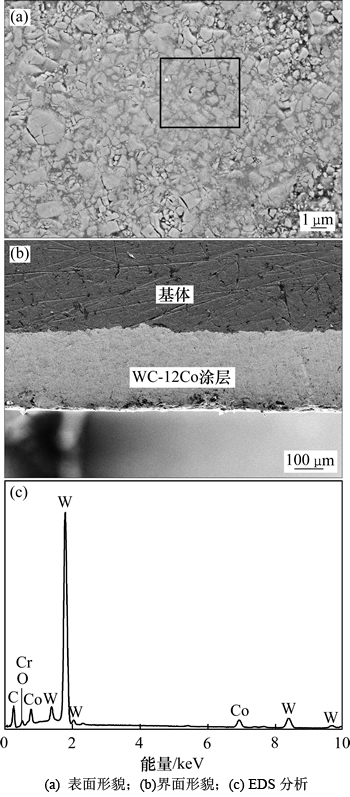

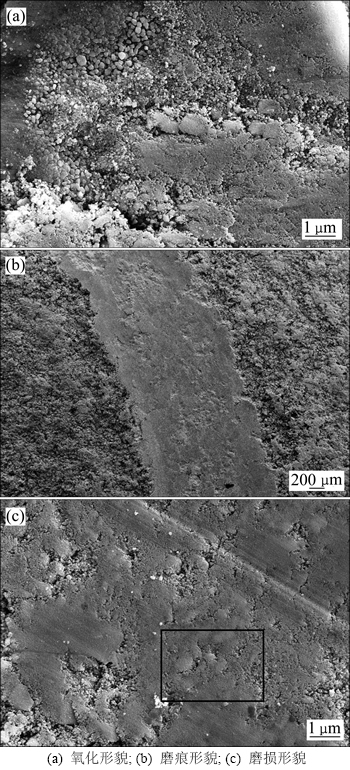

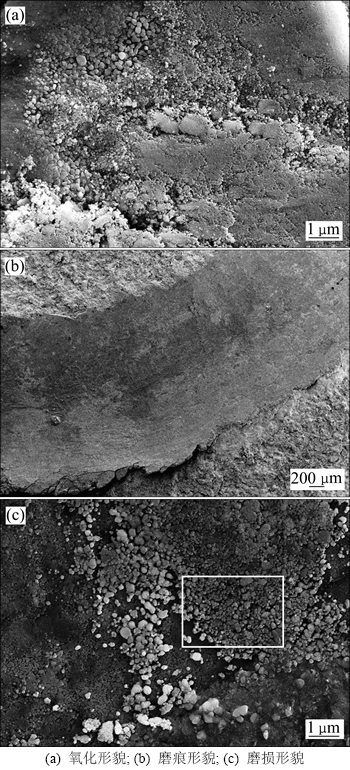

图1(a)所示为WC-12Co涂层表面形貌。可见:颗粒间距明显,这是由于超音速火焰在涂层表面停留时间较短,黏结相金属Co熔化,而陶瓷相WC颗粒没有完全熔化,分散在熔融的金属Co中,整体以半熔融状态进行高速沉积的缘故。图1(b)所示为涂层界面形貌。可见涂层致密,厚度约为l50 μm,与基体结合紧密。在超音速气流冲击作用下喷涂颗粒充分变形,当半熔融状的颗粒流撞击基体时,WC嵌入到基体表面,形成互相咬合状态。同时,熔融态Co具有良好的润湿性,渗透到WC相颗粒撞出的凹坑中,与基体紧密接触后,凝固形成良好互锁状态,减少了在磨损过程中涂层剥落现象。对图1(a)中所示位置进行EDS分析可知,W原子峰线很强,C原子峰线较强,如图1(c)所示,涂层的成分(质量分数)为W 72.93%,C 16.32%,Co 7.90%,Cr 0.45%,O 2.40%,这进一步验证了涂层的主要成分为W和C,同时,涂层表面有Co,Cr和O存在,其中Co是喷涂粉末的组成成分,Cr为基体中元素,O的存在与以高压O2作助燃气体有关。

图1 WC-12Co涂层表面-界面形貌与EDS分析

Fig. 1 Surface-interface morphologies and EDS of WC-12Co coating

2.2 磨损前XRD分析

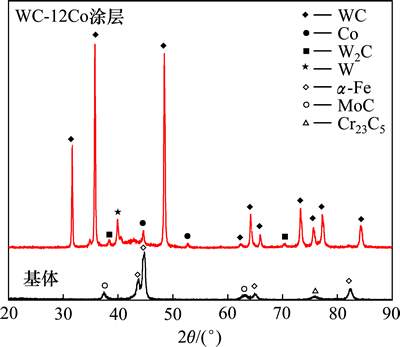

图2所示为喷涂前后试样表面XRD图谱。从图2可见:α-Fe,MoC和Cr23C5相为基体的组成物相,其中α-Fe相的衍射峰很强,是基体的主要组成物相。WC和Co相为WC-12Co涂层的组成物相,且WC相所占的比例较高。同时,XRD还显示涂层中微量W2C和W相的存在,这是由于超音速火焰喷涂(HVOF)过程中出现了轻微的WC氧化、脱碳现象,生成了W2C。涂层中高含量的WC确保了涂层的高硬度,用显微维氏硬度仪测得涂层平均显微硬度(HV0.3)为1 326,有利于提高其耐磨性能。

图2 WC-12Co涂层和基体XRD分析

Fig. 2 XRD analysis of WC-12Co coating and substrate

2.3 摩擦因数与磨损轮廓

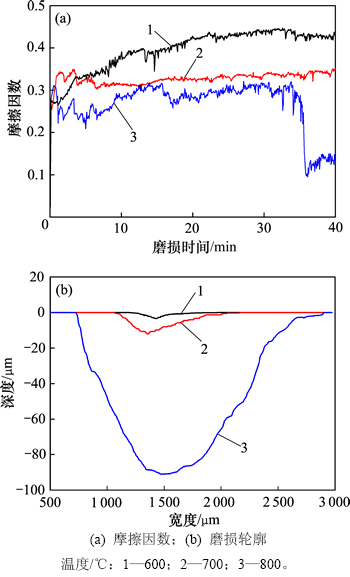

图3(a)所示为摩擦因数与磨损时间的关系曲线。从图3(a)可见:在整个磨损试验阶段(0~40 min),涂层在600,700和800 ℃时平均摩擦因数分别为0.395 5,0.327 1和0.266 4。随着温度的升高,摩擦因数减小,这是由于在高温下涂层表面形成的氧化膜面积增大,降低了涂层的摩擦因数[13]。磨损过程分为磨合和稳定2个阶段,涂层摩擦因数在磨合阶段波动较大,而在稳定阶段则趋于固定值。在600 ℃和700 ℃时,摩擦因数未发生较大的波动现象,这表明磨损后涂层没有发生失效。在800℃时,磨损阶段后期出现了摩擦因数骤降趋势,这与涂层发生剥落、被磨穿和失效等有关。磨痕的轮廓如图3(b)所示,随着温度的升高,涂层磨痕的截面增大。在600,700和800 ℃时磨痕宽度分别为0.76,1.10和2.20 mm,深度分别为3.38,12.11和 91.11 μm,经CFT-I型多功能材料试验机自带软件计算可知,600,700和800 ℃时磨损体积分别为0.04,0.15和2.90 mm3。700 ℃时磨损体积为600 ℃时磨损体积的3.75倍,而800 ℃时磨损体积高达600 ℃时磨损体积的73倍,磨损体积呈数量级增加。由此可见,涂层在低于700 ℃时保持着良好的耐磨性能,而在800 ℃时涂层耐磨性能显著降低。

图3 WC-12Co涂层摩擦因数与磨损轮廓

Fig. 3 Friction coefficients and wear profile of WC-12Co coating

2.4 磨损形貌

600 ℃时涂层表面覆盖了一层由细小氧化物颗粒组成的膜层,表面存在着少量微孔,如图4(a)所示。痕貌深度较浅、宽度较窄(如图4(b)所示),这表明涂层在600 ℃时表现出较好的耐磨性能。磨痕区域有着明显的黏着现象(如图4(c)所示),涂层中Co和W元素发生氧化反应,生成的氧化物在反复磨损过程中极易脱落,对涂层的磨损起着润滑作用,此时,黏着磨损为其主要磨损机制。

700 ℃时涂层磨损后表面氧化膜出现了翘起、开裂和脱落现象(如图5(a)所示),这与涂层表面氧化反应生成的疏松、多孔膜层质量有关。由于磨痕表面生成了大量氧化物,在磨损过程中摩擦因数有所降低,这与图3(a)中结果一致。700 ℃时磨痕深度和宽度与600 ℃时相比增大,如图5(b)所示。磨痕区域存在着轻微的犁沟和剥落坑现象,如图5(c)所示,这是氧化物脱落和对涂层表面磨损所致。在700 ℃时Co和W发生氧化反应,生成的氧化物保护了涂层,因此,磨损机制主要为氧化磨损,并伴随有轻微磨粒磨损。

图4 600 ℃时WC-12Co涂层磨损形貌

Fig. 4 Worn morphologies of WC-12Co coating at 600 ℃

图5 700 ℃时WC-12Co涂层磨损形貌

Fig. 5 Worn morphologies of WC-12Co coating at 700 ℃

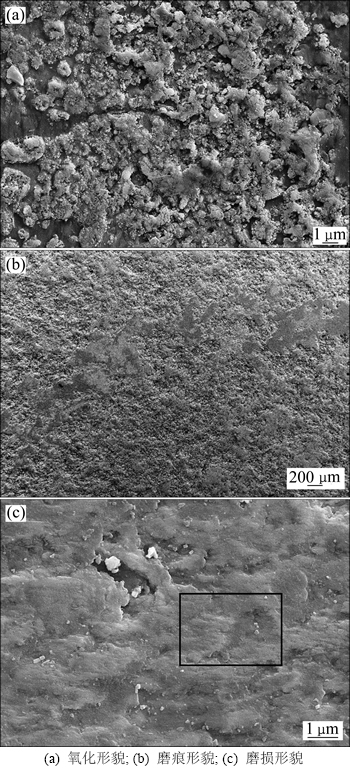

800 ℃时磨损后涂层表面存在大量膜层脱落现象(如图6(a)所示)。800 ℃时磨痕宽度、深度明显增大(如图6(b)所示),这表明该氧化膜疏松、易脆断,由于涂层氧化反应剧烈,WC分解比较严重,使涂层承载能力下降,不足以支持氧化膜抵抗磨损,从而使磨损体积呈量级增加,最终导致涂层失效。磨痕区域存在大量形状各异的片状剥落(如图6(c)所示),这是由于随着温度升高,氧化极其剧烈,生成较厚膜层由于结构疏松,在磨损过程中极易受到剪切,因此,严重的氧化磨损为其主要磨损机制。

图6 800 ℃时WC-12Co涂层磨损形貌

Fig. 6 Worn morphologies of WC-12Co coating at 800 ℃

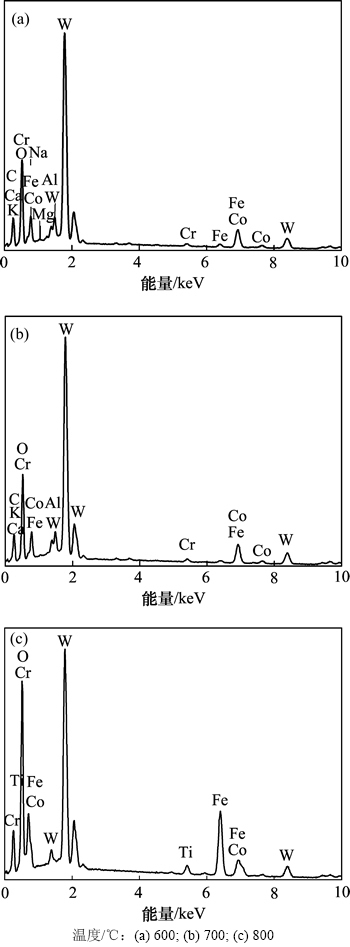

2.5 磨痕区域EDS分析

图4(c)中能谱分析结果如图7(a)所示,600 ℃时磨损后涂层成分(质量分数)为W 37.83%,C 17.76%,Co 9.93%,Cr 0.70%,O 30.39%,Fe 1.21%,Na 0.15%,Mg 0.24%,Al 1.26%,K 0.18%,Ca 0.19%,Ti 0.16%,其中W,C和Co为涂层中元素,占总质量的65.52%;O的质量分数为30.39%,与涂层表面Co和W元素发生氧化反应有关。Cr和Fe为基体中元素,占总质量的1.91%,这表明600℃时磨损后涂层保持着较好的完整性和致密性。图5(c)中能谱分析结果如图7(b)所示,700 ℃时磨损后涂层成分(质量分数)为W 39.79%,C 16.66%,Co 10.27%,Cr 0.77%,O 29.98%,Fe 0.87%,Al 1.25%,K 0.17%,Ca 0.23%,其中W,C和Co为涂层中元素,占总质量的66.72%;O的质量分数为29.98%,与W和Co元素发生氧化反应有关。Cr和Fe为基体中元素,占总质量的1.64%,这表明700℃时磨损后涂层仍保持着较好的完整性和致密性。图6(c)中能谱分析结果如图7(c)所示,800 ℃时磨损后涂层成分(质量分数)为W 24.06%,C 17.95%,Co 5.03%,Cr 1.42%,O 35.02%,Fe 16.52%,其中W,C和Co为涂层中元素,占总质量的47.04%,与图7(a)和(b)对比可知,其质量分数降低了约19%;Cr和Fe为基体中元素,占总质量的17.94%,与图7(a)和(b)对比可知,其质量分数提高了约16%;由此可知,800 ℃时磨损后涂层表面的完整性和致密性被破坏,部分区域基材裸露,与对磨球接触磨损,摩擦因数变化较大。O的质量分数高达35.02%,这是涂层表面W和Co元素氧化反应的结果。

图7 不同温度下磨痕区EDS分析

Fig. 7 EDS analysis of wear tracks at different temperatures

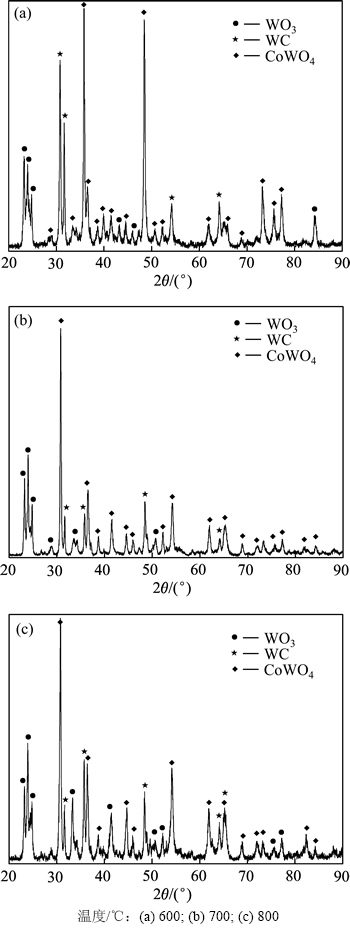

2.6 磨损后XRD分析

图8所示为涂层磨痕的XRD图谱。可见:WO3和CoWO4氧化物的衍射峰表现出较高的强度。在600 ℃时磨损后涂层表面存在着2个较强WC衍射峰,分别出现在衍射角为30.8°和31.66°处。随着试验温度的升高,WO3和CoWO4氧化物衍射峰增强,WC峰强度下降[14-15]。在700 ℃和800 ℃时,WC峰强度显著下降。Co和W发生剧烈氧化反应,生成相应氧化物,导致涂层中硬质相大量分解,降低了涂层磨损的承载能力。同时,大量WO3和CoWO4氧化物衍射峰的存在,验证了图7中所述磨损后涂层表面高含量的O是W和Co元素氧化反应的结果。

2.7 磨痕面能谱分析

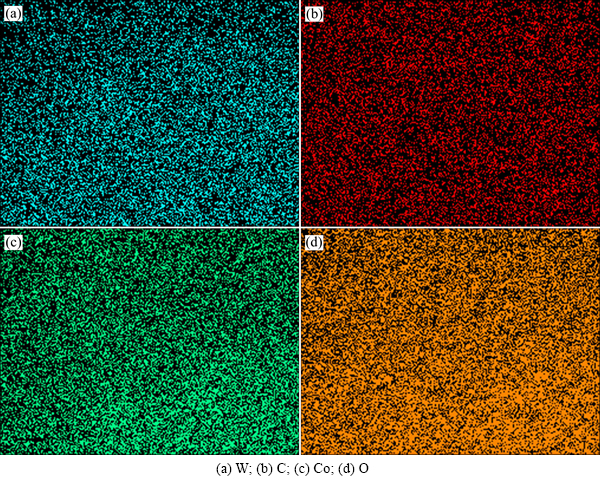

对图4(b)中磨痕形貌进行面扫描分析,其化学元素组成(质量分数)为W 39.95%,C 17.76%,Co 10.20%,O 32.09%。W,C和Co在涂层表面的面分布较为均匀,没有发生富集现象,如图9(a)~(c)所示,其中,W和C在涂层表面的面分布一致,这验证了图7(a)中所述在600 ℃时磨损后涂层保持着较好完整性的结论。O原子在涂层表面的质量分数为32.09%,表现为高含量,且面分布比较均匀,如图9(d)所示。

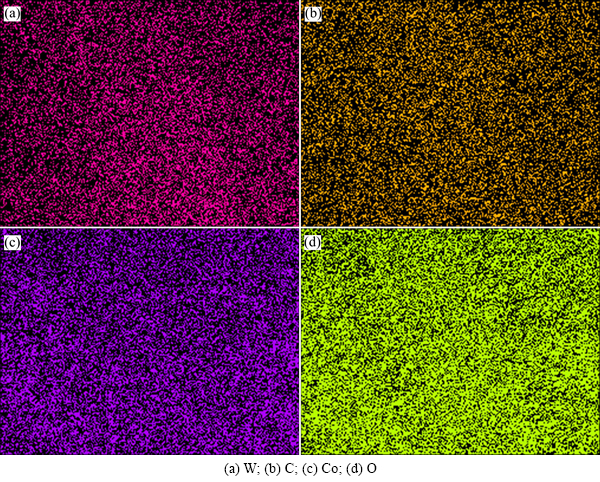

对图5(b)中磨痕形貌进行面扫描分析,其化学元素组成(质量分数)为W 39.79%,C 16.66%,Co 10.27%,O 33.28%。尽管700 ℃时磨损后痕貌深度变大、宽度变宽,然而W,C和Co在涂层表面仍为均匀分布,且W和C的面分布保持一致,如图10(a)~(c)所示,这验证了图7(b)中所述在700 ℃时磨损后涂层仍保持着较好的完整性的结论。O在涂层表面的质量分数为33.28%,表现为高含量,且面分布也较为均匀,如图10(d)所示。

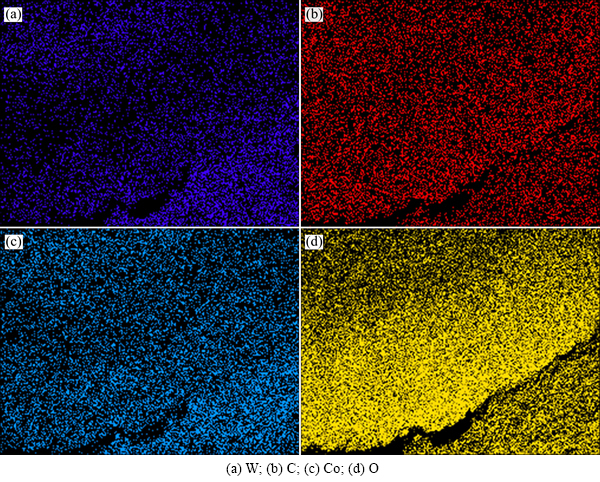

对图6(b)中磨痕形貌进行面扫描分析,其化学元素组成(质量分数)为W 24.06%,C 17.95%,Co 5.03%,O 52.96%。W,C和Co在涂层表面的面分布不均匀,出现了贫集区,如图11(a)~(c)所示。这是由于在800 ℃时WC分解比较严重,涂层的承载能力下降,出现片状剥落现象所致。O在涂层表面的质量分数高达52.96%,表现为高含量,如图11(d)所示,这是高温下涂层发生了氧化反应的缘故。

图8 不同温度下WC-12Co涂层磨痕的XRD分析

Fig. 8 XRD analysis of wear tracks on WC-12Co coating at different temperatures

由上述分析可知,涂层在低于700 ℃时磨损后可以保持较好完整性,表现出较好的耐磨性能。而在800 ℃时涂层的完整性被破坏,其耐磨性能显著降低。

图9 600 ℃时WC-12Co涂层磨痕面扫描分析

Fig. 9 Plane scans of wear track on WC-12Co coating at 600 ℃

图10 700 ℃时WC-12Co涂层磨痕面扫描分析

Fig. 10 Plane scans of wear track on WC-12Co coating at 700 ℃

图11 800 ℃时WC-12Co涂层磨痕面扫描分析

Fig. 11 Plane scans of wear track on WC-12Co coating at 800 ℃

3 结论

1) WC-12Co涂层表面粒子间距明显,界面致密,且与基材紧密结合,高含量的WC相比例确保其高硬度,有利于提高其耐磨性能。

2) 在600,700和800 ℃时涂层平均摩擦因数分别为0.395 5,0.327 1和0.266 4,随着温度升高,涂层的磨损体积呈数量级增加。

3) 在600 ℃时涂层主要发生黏着磨损,700 ℃时涂层以氧化磨损为主,并伴随着轻微的磨粒磨损,800 ℃时涂层发生严重的氧化磨损。

4) 涂层在低于700 ℃时磨损后保持较好完整性,表现出较好的耐磨性能,而在800 ℃时其完整性被破坏,其耐磨性能显著降低。

参考文献:

[1] GE P L, BAO M D, ZHANG H J, et al. Effect of plasma nitriding on adhesion strength of CrTiAlN coatings on H13 steels by closed field unbalanced magnetron sputter ion plating[J]. Surface and Coatings Technology, 2013, 229: 146-150.

[2] 李士战, 王雷刚, 黄瑶. 稀土元素在H13热作模具钢表面强化中的应用综述[J]. 稀土, 2007, 28(6): 88-91.

LI Shizhan, WANG Leigang, HUANG Yao. Summary of application of RE elements in surface strengthening of H13 hot die steel[J]. Chinese Rare Earths, 2007, 28(6): 88-91.

[3] WANG Dan, LI Heng, YANG He, et al. Tribological evaluation of surface modified H13 tool steel in warm forming of Ti-6Al-4V titanium alloy sheet[J]. Chinese Journal of Aeronautics, 2014, 27(4): 1002-1009.

[4] MA Ning, GUO Lei, CHENG Zhenxiong, et al. Improvement on mechanical properties and wear resistance of HVOF sprayed WC-12Co coatings by optimizing feedstock structure[J]. Applied Surface Science, 201, 320: 364-371.

[5] WANG Q, CHEN Z H, DING Z X. Performance of abrasive wear of WC-12Co coatings sprayed by HVOF[J]. Tribology International, 2009, 42(7): 1046-1051.

[6] QIAO Y F, LIU Y R, FISCHER T E. Sliding and abrasive wear resistance of thermal-sprayed WC-Co coatings[J]. Journal of Thermal Spray Technology, 2001, 10(1): 118-125.

[7] SAHRAOUI T, GUESSASMA S, ALI J M, et al. HVOF sprayed WC-Co coatings: Microstructure, mechanical properties and friction moment prediction[J]. Materials & Design, 2010, 31(3): 1431-1437.

[8] 王铁钢, 宋丙红, 华伟刚, 等. 工艺参数对爆炸喷涂WC-Co涂层性能均匀性的影响[J]. 金属学报, 2011, 47(1): 115-122.

WANG Tiegang, SONG Binghong, HUA Weigang, et al. Influence of process parameters on the performance uniformity of detonation gun sprayed WC-Co coatings[J]. Acta Metallurgica Sinica, 2011, 47(1): 115-122.

[9] 李博宇, 董星龙, 刘圆圆, 等. 等离子喷涂法纳米结构WC-12Co涂层的微结构与形成机理的研究[J]. 材料工程, 2006(6): 40-45.

LI Boyu, DONG Xinglong, LIU Yuanyuan, et al. Microstructure and format ion mechanism of nanostructured WC-12Co coatings deposited by plasma flame spray[J]. Materials Engineering, 2006(6): 40-45.

[10] 傅迎庆, 周锋, 高阳, 等. 等离子喷涂WC-Co涂层的微观组织及硬度[J]. 稀有金属材料与工程, 2007, 36(S2): 731-734.

FU Yingqing, ZHOU Feng, GAO Yang, et al. Microstructure and hardness properties of low power plasma sprayed WC-Co cermet coatings[J]. Rare Metal Materials and Engineering, 2007, 36(S2): 731-734.

[11] 崔永静, 王长亮, 汤智慧, 等. 超音速火焰喷涂WC-17Co涂层微观结构与性能研究[J]. 材料工程, 2011(11): 85-88, 96.

CUI Yongjing, WANG Changliang, TANG Zhihui, et al. Microstructure and performance of WC-17Co coatings fabricated by high velocity oxy-fuel spraying[J]. Materials Engineering, 2011(11): 85-88, 96.

[12] FACTOR M, ROMAN I. Use of microhardness as a simple means of estimating relative wear resistance of carbide thermal spray coatings, Part 2: wear resistance of cemented carbide coatings[J]. Journal of Thermal Spray Technology, 2002, 11(4): 482-495.

[13] 张群莉, 徐卫仙, 姚建华, 等. Co/介孔WC激光复合涂层的显微结构与高温磨损性能研究[J]. 中国激光, 2014, 41(5): 1-6.

ZHANG Qunli, XU Weixian, YAO Jianhua, et al. Microstructure and high temperature wear resistance performance of Co/mesoporous WC laser composite coating[J]. Chinese Journal of Lasers, 2014, 41(5): 1-6.

[14] MINDIVAN H. Wear behavior of plasma and HVOF sprayed WC-12Co+6%ETFE coatings on AA2024-T6 aluminum alloy[J]. Surface and Coatings Technology, 2010, 204(12/13): 1870-1874.

[15]  W. The microstructure and tribological properties of liquid-fuel HVOF sprayed nanostructured WC-12Co coatings[J]. Surface and Coatings Technology, 2013, 220: 276-281.

W. The microstructure and tribological properties of liquid-fuel HVOF sprayed nanostructured WC-12Co coatings[J]. Surface and Coatings Technology, 2013, 220: 276-281.

(编辑 赵俊)

收稿日期:2016-03-04;修回日期:2016-04-02

基金项目(Foundation item):江苏省科技支撑计划(工业)项目(BE2014818) (Project(BE2014818) supported by the Science and Technology Pillar Program of Jiangsu Province)

通信作者:孔德军,博士,教授,从事材料表面改性处理研究;E-mail: kong-dejun@163.com