DOI:10.19476/j.ysxb.1004.0609.2019.05.19

基于颗粒分散-电选法细粒黑铝灰中的铝资源回收

曹云霄,王志强,王进君,李国锋

(大连理工大学 电气工程学院,大连 116024)

摘 要:采用喷射气流分散结合高压电晕静电分选手段,对二次铝工业中主要副产物细粒黑铝灰中铝资源进行回收。利用现代图像处理及扫描电镜分析方法验证分散后样品中铝与盐组分的分离状态,设计并采用闭环测试完成单次电选和连续电选,通过X射线荧光光谱(XRF)和X射线衍射(XRD)分析分选产物的铝含量。结果表明:喷射气流分散后的样品颗粒大部分以独立单体状态分布,铝与盐类组分实现有效分离;含铝组分更多存在于样品的大颗粒部分中且能通过电选得到有效分离,三步电选完成后,分选产物中铝含量达到饱和,Al2O3质量分数由50.74%提升至64.93%,其中金属铝含量由8%提升至31%。

关键词:静电分选;气流分散;铝回收;黑铝灰

文章编号:1004-0609(2019)-05-1058-07 中图分类号:TM89 文献标志码:A

铝灰,也称为铝渣灰或铝渣,是工业电解铝或铸造铝行业生产过程中所产生的主要副产物[1]。根据铝灰的来源及组成成分,可将铝灰分为白铝灰和黑铝灰。白铝灰(也称一次铝灰)是一次铝工业的副产物,其可用铝资源(金属铝和氧化铝)含量高达70%~80%(质量分数)。因此,白铝灰通常作为二次铝工业原料直接回收。黑铝灰(也称二次铝灰)是二次铝工业的主要副产物,其可用金属铝含量约为5%~20%(质量分数),氧化铝含量约为20%~50%(质量分数),并含有大量盐类[2-4]。黑铝灰由于可回收铝资源含量低,使得其回收利用率低。黑铝灰中15%~40%(质量分数)为平均粒径低于300 μm的细粒部分,细粒黑铝灰中金属铝含量一般低于10%(质量分数),常被直接废弃处理[5-6]。据估计,我国每年产生的铝灰总量已高达112~180万t,且呈逐年递增趋势[7]。黑铝灰,尤其是细粒黑铝灰的直接废弃不仅造成了铝资源的浪费,同时黑铝灰自身的有毒有害性质也会导致严重的环境问题。因此,对黑铝灰的分离回收和循环利用符合当前我国资源节约和环境保护的要求。

针对黑铝灰的回收处理方法包括熔炼法[8-9]、酸(碱)浸法[10-11]、浮选法[12-13]等。其中,只有浮选法被证明是回收细粒黑铝灰的成熟方法。但浮选法处理的经济成本高,分离过程需要大量水,且容易产生其他有害副产物。相比之下,电选法作为一种干式物理分离方法,其分离过程中不会产生废水、废气及副产物,在经济成本和环境保护两方面都体现其优越性。实现有效电选的前提条件为不同材料之间的电性差异及材料间的有效分离[14]。大量的研究已经证明电选法能有效分离导电性和非导电性材料[15-17]。众所周知,黑铝灰中的盐(NaCl、KCl等)在常温常压条件下为非导电性,这满足了黑铝灰电选的前提条件之一。因此,限制黑铝灰电选的主要因素为铝与盐等其他组分的有效分离[18]。尤其针对细粒黑铝灰,材料粒径的减小导致颗粒间的团聚,也影响细粒黑铝灰的电选分离效果。因此,本文提出采用喷射气流分散结合高压静电分选方法,在保证细粒黑铝灰中铝与盐的有效分离条件下,对其进行电选处理,最终使细粒黑铝灰转变为可回收利用的铝资源。

1 实验

1.1 实验材料

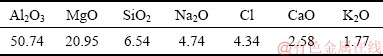

本实验所用黑铝灰原材料来自辽宁营口,实验前将原材料进行筛分,取筛下物原料作为实验样品,以保证其均为细粒黑铝灰,粒径低于300 μm。X射线荧光光谱(XRF)分析得到样品主要化学成分,如表1所示。表中Al2O3中Al元素来源于样品中的金属铝、氧化铝及其他含铝化合物,通过X射线衍射(XRD)基于RIR值的半定量分析[19],得到原始样品中金属铝含量约为8%。

表1 原始黑铝灰样品化学成分

Table 1 Chemical compositions of raw black dross (mass fraction, %)

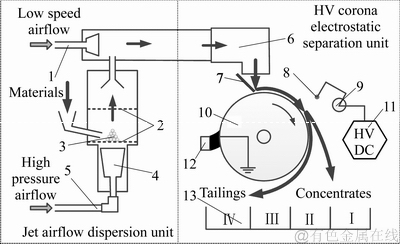

1.2 实验装置

本文采用的实验装置示意图如图1所示,包含两个主要单元,喷射气流分散单元和高压电晕静电分选单元。具体组成包括1—低速气流管、2—筛网、3—样品、4—气流喷嘴、5—高压气流管、6—沉降弯管、7—挡板、8—高压电极、9—静电极、10—接地转鼓、11—高压直流电源、12—毛刷、13—收集盒。

图1 实验装置示意图

Fig. 1 Schematic diagram of experimental set-up

实验首先对细粒黑铝灰样品进行分散处理,气流管5连接高压气泵,高压空气通过气流喷嘴将置于筛网上的样品颗粒吹散。文献[20]研究结果表明气压升至0.3 MPa以后,能够达到良好的颗粒分散效果。基于本文实验装置的耐压强度及样品粒度,也选择0.3 MPa气压提供高压气流进行分散。被分散的样品颗粒进入低速气流管中,低速气流管连接鼓风机,提供低速(约1 m/s)均匀气流,与进入管内的样品颗粒形成均匀气-固两相流,使分散的样品颗粒最终在沉降弯管中依靠重力作用沉降,作为后续电选的材料。在沉降弯管口处设置取样板,利用图像处理及扫描电镜分析方法验证样品中不同组分的分离状态。

转鼓式静电分选单元中,高压电极(直径0.23 mm金属线)和静电极连接负直流高压电源。前期初步实验发现,电源电压为-25 kV时,电晕放电强烈,且不会产生火花击穿。因此,本实验将电源电压固定为 –25 kV。分散后样品进入转鼓式静电分选单元内后,颗粒会因离子轰击作用完成荷电。含导电性颗粒(如金属铝)多的部分由于与接地转鼓接触过程中释放掉电荷,在离心力和重力作用下向收集盒Ⅰ、Ⅱ内运动;对非导电性颗粒(如盐类)而言,表面荷有大量电荷而不能释放,则与金属鼓筒发生感应,产生异极性电荷,从而使非导性颗粒贴附或偏向转鼓表面,最终在毛刷清扫下进入收集盒Ⅲ、Ⅳ中,这种作用力被称为镜像力[14, 21]。由于本文目的在于回收黑铝灰中铝资源,尤其是金属铝,因此,根据选矿工业习惯,将收集于Ⅰ、Ⅱ中的分选产物称为精矿;收集于Ⅲ、Ⅳ中的分选产物称为尾矿。分选产物过筛筛分得到不同粒度分布,通过XRF和XRD分析手段测量其中铝含量。

2 结果与讨论

2.1 颗粒分散状态分析

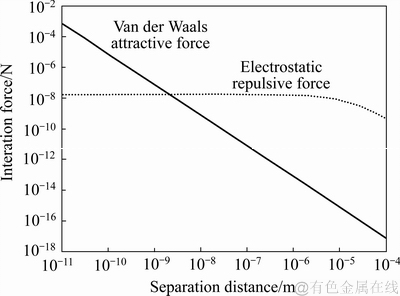

针对干燥颗粒,颗粒间作用力主要为范德华力和静电力,电选机内颗粒间静电力一般由库伦力作用产生。范德华力为颗粒间引力,表达式如式(1)所示[22]:

(1)

(1)

式中:A为颗粒在真空中的Hamaker常数;H为颗粒间间距;d1、d2分别为颗粒直径(假设颗粒为球形)。

静电力与颗粒荷电极性有关,带有同种电荷的颗粒表现为排斥力,带有异种电荷的颗粒表现为吸引力。均匀荷电的同种颗粒间静电力一般表现为排斥力,静电力的表达式如式(2)所示[23]:

(2)

(2)

式中:E为电场强度;ε0为真空介电常数;εr为颗粒介电常数。根据本实验样品与装置的实际参数,依据式(1)和(2)计算得到相同粒级两颗粒间范德华引力与静电斥力的关系如图2所示。

图2中的关系曲线表明,当两颗粒间距减小至接近纳米级(1×10–9 m)时,颗粒间的范德华引力将大于静电斥力,随着间距的减小,引力作用提升明显,造成颗粒的吸引团聚,在理论上解释了颗粒团聚的原因。同时,也表明了增大颗粒间距离能够有效减少颗粒团聚问题,即在理论上证明了喷射气流分散的作用。

图2 两颗粒间作用力与距离关系

Fig. 2 Relation between interaction forces and separation distance of two particles

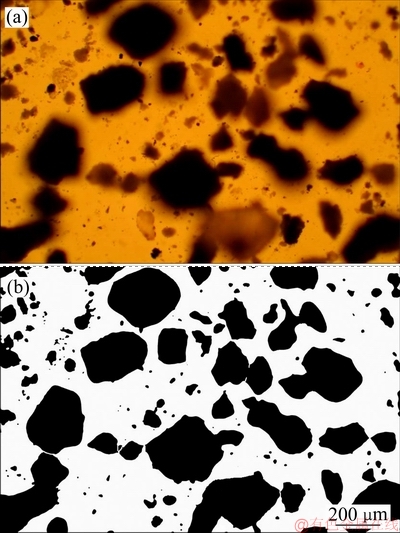

对本文中喷射气流分散的实际分散效果,采用现代图像处理结合扫描电镜能谱(SEM-EDS)分析方法进行验证。在沉降弯管下方设置采样板,对经喷射气流分散后沉降的样品颗粒进行采样。采样颗粒在光学显微镜(奥林巴斯CX41)下进行观测并获取颗粒分布原始图像。依据作者前期研究工作中提出的现代图像识别及处理方法[24],对颗粒分布原始图像进行处理,得到可用于颗粒相关参数分析的二值图像,典型的分散后颗粒分布原始图及其处理后的二值图如图3所示。

图3 分散颗粒分布图及其二值图

Fig. 3 Photograph and binary image of dispersed particle distribution

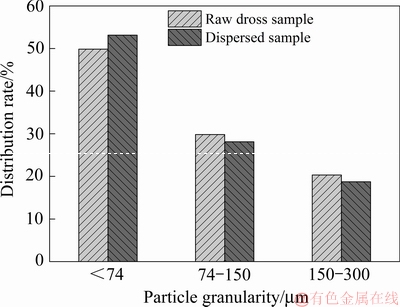

虽然光学显微镜由于景深较浅的原因,导致粒级不同的颗粒不能完全清晰地显示在同一视野中。但图3颗粒分布分析直观表明,经喷射气流分散后的细粒黑铝灰样品,颗粒间已无明显团聚现象,不同粒级的大部分颗粒均以独立单体形式分布于采样板表面。根据处理的颗粒分布二值图,可分析并得到颗粒粒径、粒数等参数。实验前已对细粒黑铝灰原始样品应用300 μm、150 μm和74 μm筛进行筛分,获得3个粒级颗粒分布比率。根据颗粒分布二值图得到的参数,同样以74 μm、150 μm和300 μm为粒级边界,得到分散后颗粒与原始样品颗粒三粒级分布对比,如图4所示。

图4对比结果表明,经喷射气流分散的黑铝灰样品在所选3个粒度范围内的颗粒分布与原始样品基本保持一致,表明喷射气流分散处理仅实现了对不同粒度和组分的颗粒进行分离,减少团聚,而并未破坏样品颗粒的原始分布状态和属性。因此,避免了由于实验样品的变化而造成的对后续分选处理的影响。

为进一步验证分散后黑铝灰样品中铝与盐类组分的分离状态,将采样颗粒进行扫描电镜及能谱分析,确定不同颗粒元素成分,其结果如图5所示。

图4 原始样品和分散后样品粒级分布

Fig. 4 Granularity distribution of raw sample and dispersed sample

图5 分散颗粒的SEM像

Fig. 5 SEM image of dispersed particles

SEM结果表明,分散后的单体颗粒主要以4种形式(见图5(a)~(d))存在:Al元素质量分数超过70%的含铝组分颗粒,氧化物(MgO等)颗粒、盐(NaCl等)颗粒及铝镁化合物颗粒。不同单体颗粒间体现出明显的分离状态,再次验证了喷射气流分散对样品中不同组分分离的有效性,使其满足电选的前提条件,保证后续电选的有效进行。

2.2 单次电选结果分析

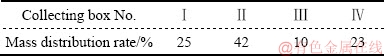

分散后样品进入转鼓式高压静电分选单元中进行电选,在连续进料条件下,设置一次电选时间为2 min。完成单次电选后,4个收集盒内分选产物质量分布率如表2所示。

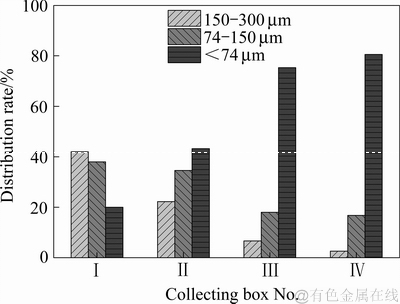

分别利用100 μm和74 μm的筛对四盒内分选产物进行筛分,得到各盒收集的分选产物粒级分布,如图6所示。

表2 单次电选产物质量分布率

Table 2 Mass distribution of products in one separation

图6 单次电选产物粒级分布

Fig. 6 Granularity distribution of products in one separation

图6分选产物粒级分布表明,编号越大的收集盒内收集的分选产物的平均粒径越小。盒Ⅲ、Ⅳ内粒径<74 μm的产物的比率均超过75%,致使其平均粒径明显小于盒Ⅰ、Ⅱ收集的分析产物。根据图1实验装置图内对分选产物的分类,表明精矿的平均粒径较尾矿更大。

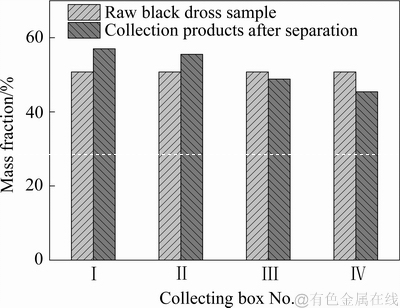

从4个盒收集的产物中取样进行XRF成分分析,得到Al2O3质量分数如图7所示。

图7 单次电选产物Al2O3质量分数

Fig. 7 Al2O3 mass fraction of products in one separation

图7表明,编号越大的收集盒内收集的分选产物含Al2O3质量分数越低,盒I、II内分选产物Al2O3质量分数均超过55%,也高于原始样品(50.74%),证实了电选对黑铝灰中的含铝组分分离的可行性,且分离后含铝组分富集于精矿部分中。同时,结合图6粒级分布结果,表明细粒黑铝灰中含铝组分更多地存在于大颗粒部分内,该结论与已有相关研究相符合[25]。

2.3 连续电选结果分析

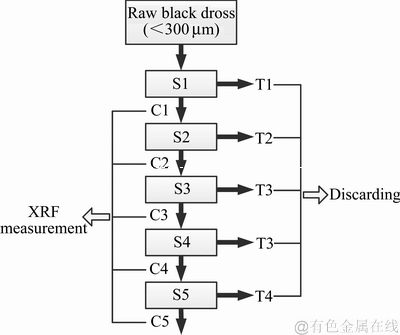

虽然单次电选实验结果验证了电选对含铝组分分离的可行性,但并未使原始黑铝灰样品达到可回收的经济等级(铝含量超过60%),其分离的精矿具有继续提高铝含量的潜力。因此设计并进行了连续电选实验,进一步使分选产物中的含铝组分进行富集。本文连续电选实验基于矿物工业的闭环测试(Locked cycle test),即在高压电晕静电分选单元内重复进行分选,在第一环测试完成完整分选实验后,即单次电选完成后,以第一环测试中获得的精矿作为第二环测试的原料完成第二环测试[26]。本文设计的闭环测试流程如图8所示。

图8 闭环测试流程

Fig. 8 Procedure for locked cycle test

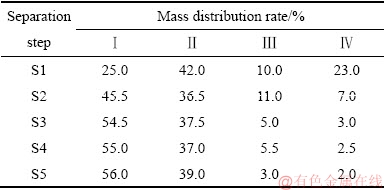

图8中闭环测试包含5次电选步骤,S1、S2、S3、S4和S5,每一步电选代表每一环测试,S1即为单次电选。其中“C”表示每环测试中电选分离得到的精矿,“T”表示尾矿,上一步电选分离的精矿被投入下一步电选中,每步电选中分离的尾矿被排除。五次电选步骤中的分选产物在各收集盒的质量分布比率如表3所示。

表3 闭环测试产物质量分布

Table 3 Mass distribution rate of products in locked cycle test

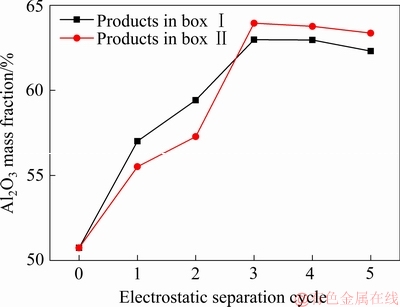

表3表明,在闭环测试中,第一步电选收集产物质量分布异于其余四步电选,是分离得到细粒产物最多的一步电选。第三至第五步电选,四盒内分选产物质量分布相对稳定,表明电选的分离效果逐渐微弱,精矿与尾矿的含量已基本达到饱和。对每步电选分离的精矿取样,完成XRF成分分析,得到每步分离的精矿中的铝含量(以Al2O3质量分数表示),结果如图9所示。由于精矿是分别收集于盒Ⅰ和Ⅱ中,故包含两组数据。

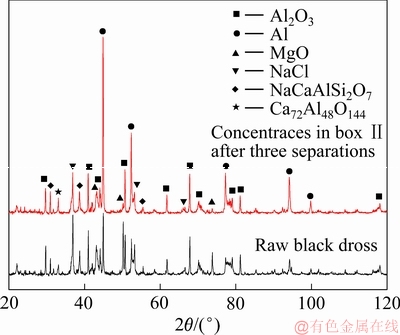

图9表明,分离的精矿中Al2O3质量分数随电选次数增加而逐渐增大,在第三步电选时,其值达到最大,分别为63.98%(盒Ⅰ)和64.93%(盒Ⅱ),XRD分析表明盒Ⅱ内精矿中金属铝含量达到31%,衍射峰曲线如图10所示。

图9 连续电选中产物Al2O3质量分数变化

Fig. 9 Dependence of Al2O3 mass fraction on separation cycles

图10 三步电选后精矿的XRD谱

Fig. 10 XRD patterns of concentrates after three separation cycles

第四、第五步电选分离的精矿中,Al2O3质量分数相对保持稳定,并微有下降。这表明基于当前实验装置及实验条件,三步电选完成后,原始细粒黑铝灰样品分离已达到极限,分选产物中含铝组分已达到最高,再次添加后续分选步骤也难以继续实现含铝组分的进一步富集。该结果也与表3中所示连续电选中各盒内收集产物质量分布变化一致。而后续电选中出现的Al2O3质量分数微有下降的原因可能是由于多次电选过程中,少部分样品吸附于电选装置内壁导致的。

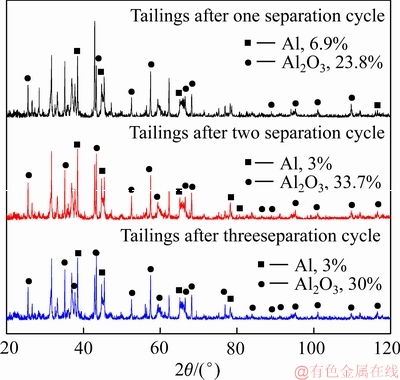

此外,根据精矿中铝资源含量随电选次数的变化规律,对一至三步电选后产生的尾矿进行了XRD分析,其XRD谱如图11所示。结果表明,随电选步骤的增加,尾矿中铝资源,尤其是金属铝含量逐渐降低(低至3%),难以达到可回收利用的经济等级,因此做排除处理。

图11 一至三步电选后尾矿的XRD谱

Fig. 11 XRD patterns of tailings after one to three separation cycles

3 结论

1) 通过喷射气流分散后的黑铝灰样品颗粒间距明显增大,使产生颗粒团聚的范德华力减弱,样品颗粒大部分以独立单体状态分布。

2) 颗粒分布的二值图分析结果表明,喷射气流分散处理并未改变原始样品组成,避免了其对电选结果的干扰;扫描电镜结果进一步验证样品中不同组分已实现有效分离,保证后续电选有效进行。

3) 电选后的分选产物分为含铝组分多的精矿和含盐类组分多的尾矿两类,验证了细粒黑铝灰电选的有效性;精矿的平均粒径明显大于尾矿,证明含铝组分更多地存在于样品的大颗粒部分中;基于闭环测试的连续电选结果表明,在完成第三步电选后,精矿中Al2O3的质量分数达到最高,可达64.93%。

4) 后续电选中精矿的质量分布及铝含量均保持相对稳定,表明电选效果逐渐微弱,精矿量已基本达到饱和。

5) 针对其他实验条件对细粒黑铝灰样品电选结果的影响以及其他不同来源铝灰样品的分离验证,有待后续进一步深入研究。

REFERENCES

[1] 高振朋, 王 芳, 李钢林, 周在常. 铝灰处理工艺研究[J]. 铸造设备与工艺, 2011, 3: 41-42.

GAO Zhen-peng, WANG Fang, LI Gang-lin, ZHOU Zai- chang. Study on the aluminum dross treatment process[J]. Foundry Equipment and Technology, 2011, 3: 41-42.

[2] 李远兵, 孙 莉, 赵 雷, 常 娜, 周 胜, 李亚伟. 铝灰的综合利用[J]. 中国有色冶金, 2008, 6: 63-67.

LI Yuan-bing, SUN Li, ZHAO Lei, CHANG Na, ZHOU Sheng, LI Ya-wei. Utilization of aluminum ash[J]. China Nonferrous Metallurgy, 2008, 6: 63-67.

[3] 王宝庆, 王 丹, 廖耀华, 刘振锋, 任保增. 铝灰回收工艺研究进展[J]. 河南化工, 2015, 32(3): 12-15.

WANG Bao-qing, WANG Dan, LIAO Yao-hua, LIU Zhen-feng, REN Bao-zeng. Research progress of recovery technology for aluminum dross[J]. Henan Chemical Industry, 2015, 32(3): 12-15.

[4] HWANG J Y, HUANG X, XU Z. Recovery of metals from aluminum dross and saltcake[J]. Journal of Minerals and Materials Characterization and Engineering, 2006, 5(1): 47.

[5] TSAKIRIDIS P E, OUSTADAKIS P, AGATZINI- LEONARDOU S. Aluminium recovery during black dross hydrothermal treatment[J]. Journal of Environmental Chemical Engineering, 2013, 1(1/2): 23-32.

[6] TSAKIRIDIS P E. Aluminium salt slag characterization and utilization—A review[J]. Journal of hazardous materials, 2012, 217: 1-10.

[7] 李 菲, 郑 磊, 冀树军, 苏 鹏, 郭学益. 铝灰中铝资源回收工艺现状与展望[J]. 轻金属, 2009(12): 3-8.

LI Fei, ZHENG Lei, JI Shu-jun, SUN Peng, GUO Xue-yi. The status quo and prospects of the techniques of aluminium dross resources recycling[J]. Light Metals, 2009(12): 3-8.

[8] DROUET M G, MEUNIER J, LAFLAMME C B. Dross treatment in a rotary arc furnace with graphite electrodes[J]. JOM, 1994, 46(5): 26-27.

[9] üNLü N, DROUET M G. Comparison of salt-free aluminum dross treatment processes[J]. Resources, Conservation and Recycling, 2002, 36(1): 61-72.

[10] DASH B, DAS B R, TRIPATHY B C, BHATTACHARYA I N, DAS S C. Acid dissolution of alumina from waste aluminium dross[J]. Hydrometallurgy, 2008, 92(1/2): 48-53.

[11] 吴 艳, 辛海霞, 陈若平, 牟文宁, 翟玉春. 铝灰碱浸提取铝工艺研究[J]. 中国稀土学报, 2010, 28(s): 752-754.

WU Yan, XIN Hai-xia, CHEN Ruo-ping, MO Wen-ning, ZHAI Yu-chu. Study of extracting alumina from aluminum dross[J]. Journal of the Chinese Rare Earth Society, 2010, 28(s): 752-754.

[12] SOTO H, TOGURI J M. Aluminum recovery from dross by flotation[J]. Conservation & Recycling, 1986, 9(1): 45-54.

[13] BRUCKARD W J, WOODCOCK J T. Recovery of valuable materials from aluminium salt cakes[J]. International Journal of Mineral Processing, 2009, 93(1): 1-5.

[14] KELLY E G, SPOTTISWOOD D J. The theory of electrostatic separations: A review Part Ⅰ. Fundamentals[J]. Minerals Engineering, 1989, 2(1): 33-46.

[15] 马俊伟, 王真真, 李金惠. 电选法回收废印刷线路板中金属Cu的研究[J]. 环境科学, 2006, 27(9): 1895-1900.

MA Jun-wei, WANG Zhen-zhen, LI Jin-hui. Study on recovery of copper from waste printed wiring boards by electrostatic separation[J]. Environmental Science, 2006, 27(9): 1895-1900.

[16] CHEN J, HONAKER R. Dry separation on coal–silica mixture using rotary triboelectrostatic separator[J]. Fuel Processing Technology, 2015, 131: 317-324.

[17] REGUIG A, BENDAOUD A, DORDIZADEH P, SALAMA A R, MESSAL S, DASCALESCV L. Experimental study of a modified dual-type high-voltage electrode for electrostatic separation applications[J]. Journal of Electrostatics, 2017, 88: 232-235.

[18] 柴登鹏, 周云峰, 李昌林, 汪艳芳, 刘 卓. 铝灰综合回收利用的国内外技术现状及趋势[J]. 轻金属, 2015(6): 1-4.

CHAI Deng-peng, ZHOU Yun-feng, LI Chang-lin, WANG Yan-fang, LIU Zhuo. The technology status and trends of comprehensive recovery and utilization of aluminum dross both at home and abroad[J]. Light Metals, 2015(6): 1-4.

[19] 夏秀文, 张新琴, 曹春燕. 利用参比强度法半定量相分析标定磁性样品金相物相[J]. 井冈山大学学报(自然科学版), 2010, 31(5): 35-37.

XIA Xiu-wen, ZHANG Xin-qin, CAO Chun-yan. Magnetic alloy micrograph indication based on semi-quantitative component analysis by RIR method[J]. Journal of Jinggangshan University (Natural Science), 2010, 31(5): 35- 37.

[20] ENDO Y, HASEBE S, KOUSAKA Y. Dispersion of aggregates of fine powder by acceleration in an air stream and its application to the evaluation of adhesion between particles[J]. Powder Technology, 1997, 91(1): 25-30.

[21] 谢广元, 张明旭, 边炳鑫, 樊民强. 选矿学[M]. 徐州: 中国矿业大学出版社, 2001: 372-373.

XIE Guang-yuan, ZHANG Ming-xu, BIAN Bing-xin, FAN Min-qiang. Mineral concentration[M]. Xuzhou: China University of Mining and Technology Press, 2001: 372-373.

[22] 任 俊, 沈 健, 卢寿慈. 颗粒分散科学与技术[M]. 北京: 化学工业出版社, 2005: 66-67.

REN Jun, SHEN Jian, LU Shou-ci. Particle dispersion science and technology[M]. Beijing: Chemical Industry Press, 2005: 66-67.

[23] REN J, LU S, SHEN J, YU C. Electrostatic dispersion of fine particles in the air[J]. Powder Technology, 2001, 120(3): 187-193.

[24] 曹云霄, 王志强, 王进君, 李国锋. 基于图像识别的微细粒子静电捕集效率评价方法[J]. 高电压技术, 2016, 42(5): 1455-1462.

CAO Yun-xiao, WANG Zhi-qiang, WANG Jin-jun, LI Guo-feng. Evaluation method of fine particle electrostatic collection efficiency based on image identification[J]. High Voltage Technology, 2016, 42(5): 1455-1462.

[25] MAH K, TOGURI J M, SMITH H W. Electrostatic separation of aluminum from dross[J]. Conservation & Recycling, 1986, 9(4): 325-334.

[26] AGAR G E. Calculation of locked cycle flotation test results[J]. Minerals Engineering, 2000, 13(14/15): 1533- 1542.

Recovery of aluminum from fine black dross by particle dispersion coupled with electrostatic separation

CAO Yun-xiao, WANG Zhi-qiang, WANG Jin-jun, LI Guo-feng

(School of Electrical Engineering, Dalian University of Technology, Dalian 116024, China)

Abstract: The recovery of aluminum resource from fine black dross, which is a waste by-product in secondary aluminum production, was investigated by high-voltage corona electrostatic separation combined with jet airflow dispersion. The modern image processing and scanning electron microscope were used to analyze the separation status between aluminum and salt components after jet airflow dispersion. A locked cycle test was designed and used to complete single step and continuous electrostatic separation. The aluminum content of separated products was measured by X-ray Fluorescence (XRF) and X-ray diffraction (XRD). The dispersion results indicate that, most of sample particles are distributed individually after dispersion. The aluminum is separated effectively from salt components. The separation results indicate that, the larger size fraction of sample contains more aluminum and can be separated by electrostatic separation. When the third separation step is completed, the aluminum content of separated products reaches saturation. Al2O3 mass fraction increases from 50.74% to 64.93%, and the metallic aluminum content increases from 8% to 31%.

key words: electrostatic separation; airflow dispersion; aluminum recovery; black dross

Foundation item: Project(51607023) supported by the National Natural Science Foundation of China; Project (DUT16QY36) supported by the Fundamental Research Funds for the Central Universities, China

Received date: 2018-06-22; Accepted date: 2018-10-10

Corresponding author: LI Guo-feng; Tel: +86-411-84706489; E-mail: guofenli@dlut.edu.dn

(编辑 李艳红)

基金项目:国家自然科学基金青年科学基金项目(51607023);中央高校基本科研业务费专项资金项目(DUT16QY36)

收稿日期:2018-06-22;修订日期:2018-10-10

通信作者:李国锋,教授,博士;电话:0411-84706489;E-mail:guofenli@dlut.edu.dn