Zn-Al-Cu-TiB2原位复合材料的显微组织、力学性能及耐磨性

来源期刊:中国有色金属学报(英文版)2015年第1期

论文作者:陈 飞 王同敏 陈宗宁 毛 丰 韩 强 曹志强

文章页码:103 - 111

关键词:原位复合材料;TiB2颗粒;摩擦因数;磨损率;力学性能

Key words:in situ composites; TiB2 particles; friction coefficient; wear rate; mechanical properties

摘 要:采用混合盐法(K2TiF6,KBF4)在反应温度875 °C下制备Zn-Al-Cu-TiB2 (ZA27-TiB2)原位复合材料。研究此复合材料的显微组织、力学性能和耐磨性。微观组织分析表明,复合材料中的TiB2颗粒细小,分布均匀。复合材料的力学性能随着颗粒含量的增加而显著增加,相对基体合金,5% TiB2增强复合材料的布氏硬度提高了 HB 18, 抗拉强度提高了49 MPa。磨损实验结果说明复合材料的摩擦因数和磨损量随着颗粒含量的增加而明显降低,当TiB2含量增加到5%时,磨损率由5.9×10-3 mm3/m降低到 1.3×10-3 mm3/m。摩擦因数和磨损表面形貌变化表明,由于TiB2颗粒的引入,材料在磨损初期的磨损机制发生了变化。

Abstract: Zn-Al-Cu-TiB2 (ZA27-TiB2) in situ composites were fabricated via reactions between molten aluminum and mixed halide salts (K2TiF6 and KBF4) at temperature of 875 °C. The microstructure, mechanical properties and wear behavior of the composites were investigated. Microstructure analysis shows that fine and clean TiB2 particles distribute uniformly through the matrix. The mechanical properties of the composites increase with the increase in TiB2 content. As TiB2 content increases to 5% (mass fraction), an improvement of HB 18 in hardness and 49 MPa in ultimate tensile strength (UTS) is achieved. The overall results reveal that the composites possess low friction coefficients and the wear rate is reduced from 5.9×10-3 to 1.3×10-3 mm3/m after incorporating 5% TiB2. Friction coefficient and worn surface analysis indicate that there is a change in the wear mechanism in the initial stage of wear test after introducing in situ TiB2 particles into the matrix.

Trans. Nonferrous Met. Soc. China 25(2015) 103-111

Fei CHEN, Tong-min WANG, Zong-ning CHEN, Feng MAO, Qiang HAN, Zhi-qiang CAO

School of Materials Science and Engineering, Dalian University of Technology, Dalian 116024, China

Received 21 February 2014; accepted 26 May 2014

Abstract: Zn-Al-Cu-TiB2 (ZA27-TiB2) in situ composites were fabricated via reactions between molten aluminum and mixed halide salts (K2TiF6 and KBF4) at temperature of 875 °C. The microstructure, mechanical properties and wear behavior of the composites were investigated. Microstructure analysis shows that fine and clean TiB2 particles distribute uniformly through the matrix. The mechanical properties of the composites increase with the increase in TiB2 content. As TiB2 content increases to 5% (mass fraction), an improvement of HB 18 in hardness and 49 MPa in ultimate tensile strength (UTS) is achieved. The overall results reveal that the composites possess low friction coefficients and the wear rate is reduced from 5.9×10-3 to 1.3×10-3 mm3/m after incorporating 5% TiB2. Friction coefficient and worn surface analysis indicate that there is a change in the wear mechanism in the initial stage of wear test after introducing in situ TiB2 particles into the matrix.

Key words: in situ composites; TiB2 particles; friction coefficient; wear rate; mechanical properties

1 Introduction

The zinc-based alloys containing aluminum, copper and magnesium are characterized by high strength, excellent tribological properties and low melting temperatures, thus having potential for replacing the traditional bronze and iron base foundry alloys to produce wear resistant components [1,2]. In recent years, reinforcing with second phase particles has been noted to substantially improve the mechanical properties and wear response of zinc-based bearing materials. Conventional preparation of zinc-based composites involves the addition of externally synthesized particles, for instance, SiC [3], Al2O3 [4], ZrO2, graphite [5] and TiO2 [6] into molten matrix. Various problems, such as particles segregation and poor adhesion at the interface and inferior thermodynamically instability of the reinforcement frequently arise owing to surface contamination of the reinforcements and poor particle- matrix wettability.

Recently, in situ fabrication techniques have been developed to produce metal matrix composites (MMC). Since the formation and growth of reinforcement take place within the matrix, in situ preparation of composites provides advantages including uniform distribution of finer particles, excellent bond at the interface, thermodynamically stable reinforcements that overwhelm the conventional ex situ processes, yielding better mechanical and tribological properties. Although various in situ techniques have been used to fabricate aluminum [7-9], magnesium [10], copper [11], iron [12] base MMC, fewer studies have been reported regarding the fabrication and properties of zinc-based in situ composites.

The present work focuses on the fabrication, microstructure, mechanical properties and wear behaviour of TiB2 particulate reinforced ZA27 in situ composites synthesized by mixed salt route. TiB2 is an advanced reinforcement for zinc-based composites as it possesses a useful combination of physical and mechanical properties, including high melting point (3225 °C), high elastic modulus (534 GPa), high hardness (HV 960) and outstanding wear resistance. More importantly, it does not react with zinc or aluminum to form reaction product at the interface between reinforcement and matrix [13,14]. ZA27 alloy, the nominal composition listed in Table 1, was selected as the matrix alloy because. On one hand, it has been considered for a number of commercial applications due to good mechanical properties, machinability and wear properties [15,16]; on the other hand, aluminum in ZA27 helps to facilitate the salt reaction via aluminothermy reduction in the synthesis process.

Table 1 Chemical composition of ZA27 alloy (ASTM B 240- 2004) (mass fraction, %)

2 Experimental

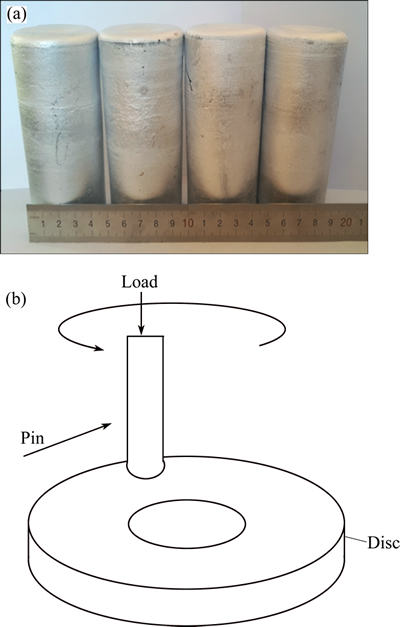

ZA27-TiB2 in situ composites were produced in the laboratory by mixed halide salt reaction. Commercial pure aluminum (99.7%) was melted and heated to 875 °C in a graphite-clay crucible with a resistance furnace. Pre-dried K2TiF6 and KBF4 salts, weighed at a stoichiometric ratio Ti to B of 1:2, were fully blended and wrapped with aluminum foil. A small amount of KCl, CaCl2 and Na3AlF6 salts were added as the reactive assistant and covering agent. The mixed salts were then pressed into the melt and stirred thoroughly for 30 s. The melt was held at 875 °C for 45 min to allow the reaction to reach completion. Cu and Mg were added in the form of Al-Cu and Al-Mg master alloys, whilst Zn was added in the form of molten zinc. After removing the slag and degassing by refining flux and high-purity argon, the melt was poured into a preheated thin-wall permanent mold. A total of three composites (see Fig. 1(a)) were produced with different mass fractions of TiB2 (1%, 3% and 5%). The chemical composition of the composites was determined by atomic absorption analysis.

X-ray diffraction (XRD) test was carried out with a Shimadzu XRD-6000 to identify the various phases in the composites. The microstructures of the composites were examined with a Zeiss Supra 55 scanning electron microscope (SEM). Hardness tests of the composites were carried out by a Brinell hardness tester. The tensile specimens were prepared according to ASTM E8M-04 standard having a gauge length of 30 mm, a gauge diameter of 6 mm. The tensile strength was estimated with a computerized universal testing machine at room temperature and the strain rate for tensile test was 1.25×10-3 s-1. The present values of the hardness and tensile properties are the average of three tests for each composite. The fracture surfaces of the failed tensile specimens were analyzed by SEM.

Fig. 1 Ingots of matrix alloy and composites (a) and schematic diagram of pin-on-disc wear test (b)

Wear tests were carried out at room temperature with a computer-controlled pin-on-disc wear testing machine, and the schematic diagram of the wear test is shown in Fig. 1(b). The pins with 4.8 mm in diameter and 12.7 mm in length were machined from ZA27 alloy and the in situ MMC. The counterpart discs with an external diameter of 54 mm were made of SAE1045 steel (Fe-0.46%C-0.6%Mn-0.035%P-0.03%S) and had a hardness of HRC 50 after induction quenching. Wear tests were performed at a constant load of 90 N, which corresponded to a nominal contact stress of 5 MPa. For each sample, the wear test was carried out at a constant sliding speed of 0.75 m/s for 1 h (corresponding to a sliding distance of 2.7 km). SAE 40 oil was used as the lubricant. Each wear sample was ultrasonically cleaned in acetone and weighed before and after the test by an electronic balance with an accuracy of 0.1 mg to determine the mass loss. The wear rate was calculated by dividing the mass loss by sliding distance and measured density of the sample. The friction coefficients of the samples were recorded simultaneously by the computer. Three tests were carried out for each set of sample to get representative data. The worn surfaces were analyzed by SEM.

3 Results and discussion

3.1 Phase composition and microstructure of composites

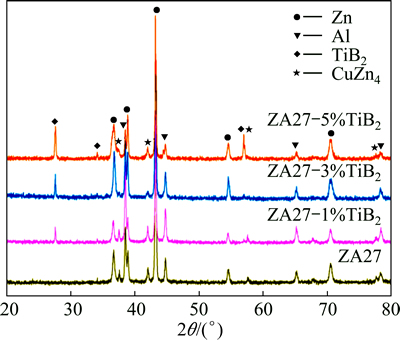

The XRD patterns of the base alloy and the developed in situ composites with different mass fractions of TiB2 are shown in Fig. 2. The main phases of the composite are identified to be α(Al), η-Zn, TiB2 and ε-CuZn4. The presence of TiB2 peaks in all of the three developed composites confirms the formation of TiB2 within the melt. The relative intensity of the TiB2 signals increases with the increase of mass fraction of TiB2, indicating a feasible control of the mass fraction of the TiB2 reinforcement by the in situ route. It was implied that, after the addition of the mixed salts into molten aluminum, the following consecutive reactions were possible to take place [17]:

3K2TiF6+13Al→3KAlF4+K3AlF6+3TiAl3 (1)

2KBF4+3Al→2KAlF4+AlB2 (2)

TiAl3+AlB2→TiB2+4Al (3)

The intermediate product TiAl3 compound is an unfavorable brittle phase. While TiAl3 is always present in TiB2 particulate reinforced composites synthesized by in situ mixed salt routes [18,19], this study did not find any trace of its reflections in the XRD pattern. This is attributed to the presence of Na3AlF6 and KCl which help to finish the above reactions. Also, it is noted that from the XRD analysis, Al2O3, ZnO and other undesirable compounds, are not detected in the composites. It is thus claimed that the present method is a feasible technique to fabricate ZA27-TiB2 in situ composites.

Fig. 2 XRD patterns of ZA27 alloy and developed ZA27-TiB2 in situ composites

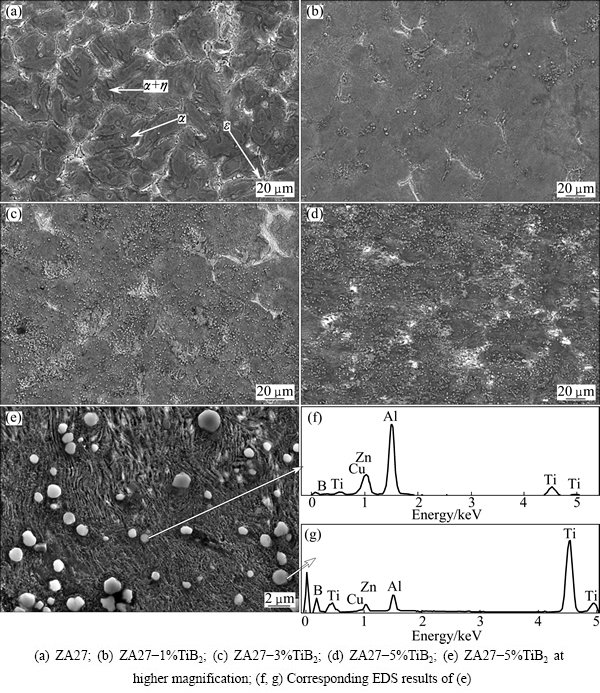

The SEM images of the matrix alloy and the developed in situ composites are shown in Fig. 3. The microstructure of ZA27 alloy (see Fig. 3(a)) reveals a coarse dendritic structure of primary α (Al-rich) dendrites, eutectoid α+η (η is Zn-rich) resulted from α-phase decomposition at 275 °C and intermetallic ε (Cu-rich) phase in the interdendritic regions [6]. The TiB2 particles distribute uniformly and no agglomeration is observed throughout the matrix. Such kind of particulate distribution is an essential requirement to achieve better mechanical properties of the MMC. It is known that the ceramic particle should suspend in the molten matrix for a long time to obtain homogenous distribution [20]. In our present work, the density difference between ZA27 (5.0 g/cm3) and TiB2 particle (4.5 g/cm3) is small. Therefore, the floating or sinking rate of in situ formed TiB2 particles is negligible and TiB2 particles could suspend in the molten ZA27 for a long time. Moreover, the good wettability makes TiB2 readily embed into the solidification front, thus the TiB2 particles are retained inside the grains after solidification. The above said factors lead to more uniform distribution of the reinforcement particles in the final composites.

Fig. 3 SEM images of composites

It is evident from Fig. 3 that grain size of the reinforced composite (Figs. 1(b) and (c)) is smaller than that of the particle-free matrix and decreases with the increase in TiB2 content. The grain refinement can be attributed to the following two causes: the α-phase solidified on TiB2 particles which acted as heterogeneous nucleation sites in the initial state of solidification; growing α-phase was surrounded by hard TiB2 particles region, which acted as hard restrictive obstacles against grain growth [20]. Figure 3(e) reveals that the in situ synthesized TiB2 particles, evidenced by EDS analysis and the comparison among low magnified images (see Figs. 3(a)-(d)), are hexagonal and spherical in shape, with size distribution ranging from 0.2 to 1.5 μm. This is in agreement with the reports in the available literatures [7,10,20]. These fine particles are much smaller than the ex situ particles in conventional composites, contributing to yielding higher mechanical properties according to the Orowan looping strengthening mechanism. It can also be seen that the interface between TiB2 particles and ZA27 matrix is clean. This can be ascribed to two facts: 1) in situ formation of TiB2 within the melt reduced the opportunity for oxidation of the particle surface [19]; 2) the heat of reaction and cryolite slag (Na3AlF6) improved the interfacial conditions for bonding and wetting between the particles and the matrix [21].

3.2 Mechanical properties of composites

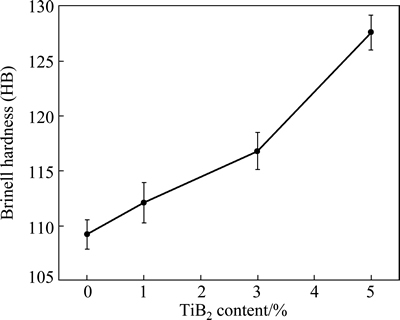

Figure 4 shows the Brinell hardness of the matrix alloy and the experimental composites. It is evident that, as the mass fraction of TiB2 particles increases, a significant improvement in the hardness of the developed in situ composites is noticed. An improvement of 3.2%, 7.8% and 16.8% in hardness was observed for 1%, 3% and 5%TiB2 reinforced ZA27 composites respectively compared with the matrix alloy. The improved hardness was favored by the fine, hard and dispersed TiB2 particulates. The strong interface bond, which can efficiently transfer load from the matrix to the particles, may also be responsible for this improvement.

Fig. 4 Influence of TiB2 content on hardness of ZA27-TiB2 in situ composites

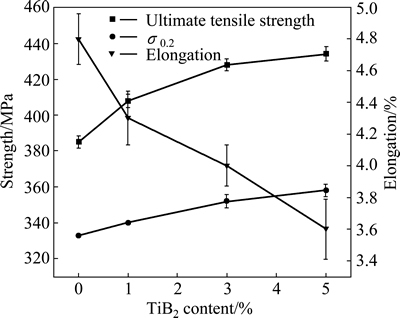

The variation of ultimate tensile strength (UTS), yield strength (σ0.2) and elongation of the developed composites as a function of TiB2 content is depicted in Fig. 5. It can be found that UTS and σ0.2 increase with the increase of mass fraction of TiB2 particles. In contrast, the elongation decreases continuously with the reinforcement content. The UTS of the composite increases from 385 to 434 MPa while the elongation decreases from 4.8% to 3.6% after incorporating 5% in situ TiB2 particulates. The experimental results in terms of UTS and ductility are compared with those reported for SiC, TiO2, or ZrO2 reinforced ZA27-based MMCs available in literatures [5,6,22]. It is found that, in spite of lower content of reinforcement is incorporated, the developed composites exhibit superior tensile properties.

Fig. 5 Effect of TiB2 content on tensile strength and elongation of ZA27-TiB2 in situ composites

The strengthening of ZA27 by in situ formed TiB2 particles can be explained as follows: 1) a large amount of fine TiB2 particles well distributed in the matrix act as obstacles to the movement of dislocations during the loading of the composites, it is likely for the dislocation line to loop around the fine TiB2 particles by the Orowan looping rather than to cut through them owing to the high elastic modulus (534 GPa) of the particles, thus enhancing the strength of the composites according to the Orowan strengthen mechanism [23,24]; 2) during solidification of the MMCs, appending dislocations are created around TiB2 particles due to the difference of the thermal expansion coefficient between the base alloy (26×10-6 K-1) and TiB2 particle (8×10-6 K-1), the interaction of different dislocation areas also contributed to the higher UTS [25]; 3) grain boundaries can act as obstacles for dislocation slip as well as dislocation source, TiB2 particle refines the grains of matrix, which provides more area to resist the dislocation movement.

The decrease in the elongation of the composites with TiB2 content may be related to the prevented plastic deformation of the matrix by the particles and the reduction of ductile matrix content when the mass fraction of TiB2 particles is increased. Moreover, the residual stresses generated due to the large difference in thermal expansion coefficient between the matrix and particles would probably contribute to the brittle nature of the composites [5].

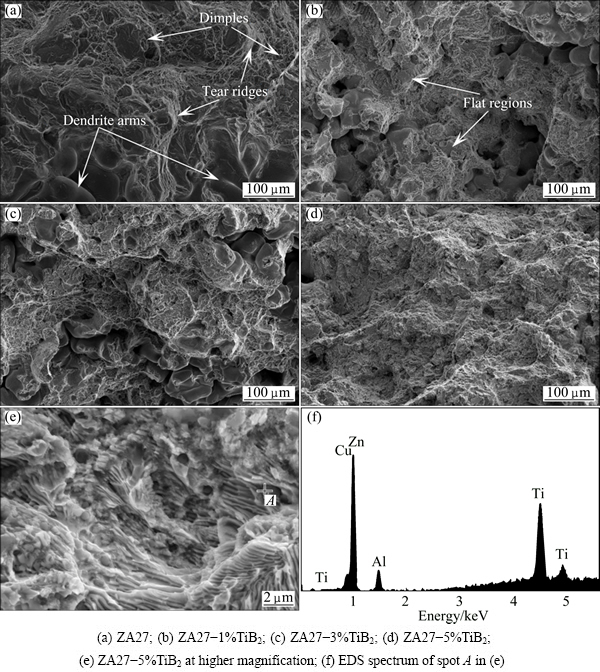

The fracture morphologies of the ZA27-TiB2 composites are presented in Fig. 6. The presence of small dimples and tearing ridge in the unreinforced matrix (see Fig. 6(a)) indicates that the fracture mechanism of the base alloy is principally ductile fracture containing some brittle failure. It can be seen that dimples decrease with the increase of TiB2 content while the flat regions exhibit an opposite tendency. Flat regions coupled with tearing ridge indicate that the fracture of composites contains quasi-cleavage fracture, which is consistent with the low elongation of the composites. It is worth noting that, in addition to above said fracture features, shrinkage cavities also present on the fracture surfaces of the matrix, 1% and 3%TiB2 reinforced composites. This can be attributed to the dendrite segregation in non-equilibrium solidification process. The continuous enrichment of solute in interdendrite residual liquid and subsequent solidification without effective feeding results in weakened grain boundary, which is verified by the exposed dendrite arms inside the cavities. As the TiB2 content increases, the grain size reduces and the dendrite segregation becomes insignificant, for ZA27-5%TiB2 (see Fig. 6(d)), which shows a brittle fracture, and no obvious shrinkage cavities are observed. The presence of titanium in EDS spectrum (see Fig. 6(f)) of spot A (see Fig. 6(e) combined with the foregoing XRD analysis confirms that the particles on fracture surface are TiB2. Although debonding at some places can be detected, bonding between particles and matrix is generally good, and the majority of particles are well encompassed by the matrix, providing firm evidence of excellent bonding between the matrix and in situ formed TiB2 particles.

Fig. 6 SEM images showing fracture surface of composites

3.3 Wear behaviour of composites

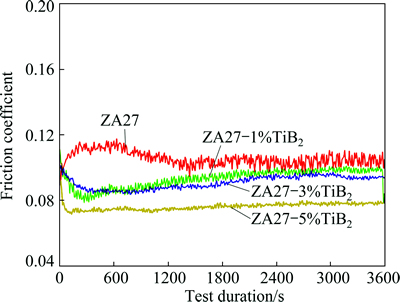

The variation of friction coefficient as a function of test duration for the base alloy and in situ composites is plotted in Fig. 7. It is evident that the friction coefficient is decreased by incorporating in situ TiB2 particles into the matrix. Increasing content of TiB2 results in a further decrease. This could be attributed to good bonding at the interface and uniform distribution of the particles as evidenced by the SEM images shown in Fig. 3. It has been demonstrated that a uniform particle distribution and a clean matrix/particle interface both lead to a lower friction coefficient [26]. Similar trends have also been reported by other researchers [18,27]. During the sliding process, the matrix surrounding the TiB2 particles was worn away and all the contacts were provided between the particles and the steel counter face. The gap between the contact surfaces could store oil and help to improve the lubricating condition.

Fig. 7 Variation of friction coefficient with test duration for alloy and composites

It should be noted that the friction coefficients of the composites initiated with a sharp decrease and then reached a constant level while the base alloy showed a contrary trend during the early stage of wear test, indicating that there was a change in the wear mechanism after introducing the TiB2 particles into the matrix. It is well known that at the beginning of the test run, contact between the sliding surfaces occurs at only a few highly protruding asperities and the oil film is unstable [3]. As the test proceeds, the area of contact increases and a more stable lubricating layer forms, thereby leading to the decrease of the friction coefficient. In the case of the base alloy, asperity junction took place in the initial stage due to the low hardness and inferior strength. As a consequence, local tearing occurred in the vicinity of the asperities and gave rise to coarse debris which got clogged between the rubbing surfaces (confirmed by the following wear surfaces analysis) and coupled with the rough worn surface, resulting in the initial increase of the curve.

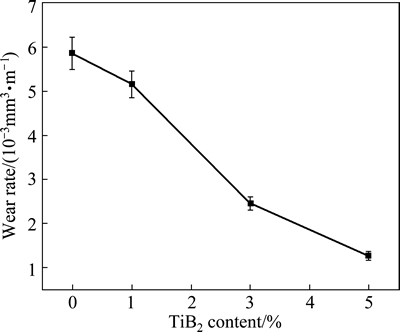

The variation of the wear rate of ZA27-TiB2 in situ composites as a function of TiB2 content is depicted in Fig. 8. It is observed that the wear rate decreases dramatically with the increase of TiB2 content. Incorporating 5% TiB2 reduces the wear rate of the composite from 5.9×10-3 to 1.3×10-3 mm3/m. This can be attributed to higher hardness of the composites and good interfacial bonding between the matrix and reinforcement, both of which enhance the bearing capacity of the final composite [27]. Furthermore, TiB2 particles reduce the extent of direct metal-to-metal contact and play the role of bearing load for protecting the matrix during the sliding process.

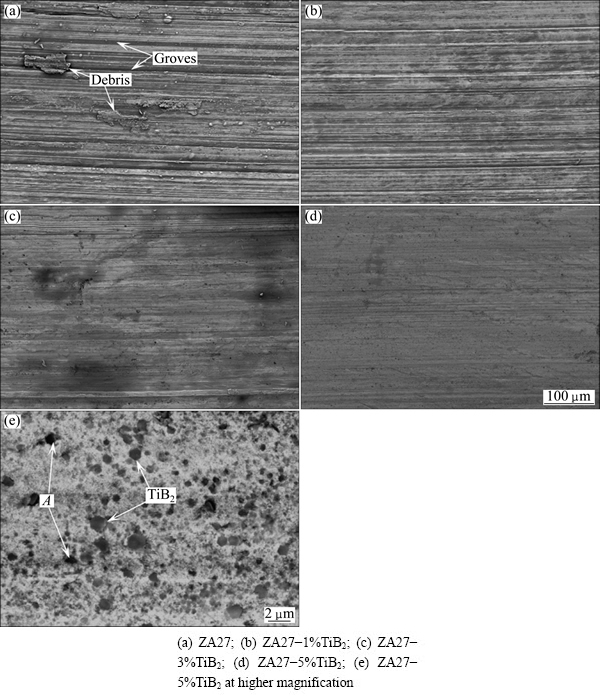

SEM images of the worn surfaces of ZA27 and the developed in situ composites are shown in Fig. 9.

Fig. 8 Influence of TiB2 content on wear rate of ZA27-TiB2 in situ composites

Fig. 9 SEM images showing worn surface of ZA27 and developed in situ composites

The worn surface of the ZA27 matrix alloy exhibits deep and wide grooves running parallel to one another along the sliding direction. Some coarse debris were worn out and reattached onto the worn surface due to the contact pressure. The composites, to the contrary, revealed narrow grooves and almost flat surfaces. These observations support the lower friction coefficients and wear rates of the composites. Figure 9(e) clearly shows that particles with well-developed hexagonal morphology distributed evenly throughout the surface in spite of a few particles damaged during sliding (region A).

Grooves were formed due to the ploughing of the steel counterpart on the sample surface. The smooth worn surfaces of the in situ composites were attributed to the following factors: 1) verified by the dispersed TiB2 particles on the worn surface, the strong interfacial bonding between the TiB2 particles and the matrix minimized the debonding trend of TiB2 from the matrix alloy, ensuring that these stiff TiB2 particles effectively resist the ploughing of the counterpart; 2) compared with the matrix alloy, the developed in situ composites have higher hardness, thus leading to narrow and shallow grooves; 3) the TiB2 fragments damaged off from individual particles were entrapped in the oil and rolled across the wear surfaces, resulting in three-body abrasive wear [28], in general, three-body abrasion results in a lower wear rate than that of the two-body abrasion [18,28], which was just the case in the wear test of the ZA27 base alloy.

4 Conclusions

1) ZA27-TiB2 in situ composites were successfully fabricated via in situ mixed salt reaction. The undesirable phases such as brittle compound TiAl3, have been completely suppressed. The formation of hexagonal and spherical shaped in situ TiB2 particles with clean particle-matrix interface and sizes ranging from 0.2 to 1.5 μm was confirmed by XRD and SEM analyses.

2) The composites exhibit a significant improvement in hardness and tensile strength, while a reduction in elongation, in comparison to the base alloy. The Brinell hardness and UTS of the composites containing 5% TiB2 are up to HB 128 and 434 MPa, respectively.

3) In situ TiB2 particles significantly improve wear response of the zinc-based matrix alloy. Both friction coefficient and wear rate decrease dramatically with the increase in TiB2 content. Friction coefficient and worn surface analyses indicate that there is a change in the wear mechanism in the initial stage of wear test.

References

[1] LO S H J, DIONNE S, SAHOO M, HAWTHORNE H M. Mechanical and tribological properties of zinc-aluminium metal-matrix composites [J]. Journal of Materials Science, 1992, 27(21): 5681-5691.

[2] XU Xiao-qing, LI Dr-fu, GUO Sheng-li, WU Xiao-ping. Microstructure evolution of Zn-8Cu-0.3Ti alloy during hot deformation [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(7): 1606-1612.

[3] PRASAD B K. Sliding wear response of a zinc-based alloy and its composite and comparison with a gray cast iron: Influence of external lubrication and microstructural features [J]. Materials Science and Engineering A, 2005, 392: 427-439.

[4] MODI O P, PRASAD B K, JHA A K. Influence of alumina dispersoid and test parameters on erosive wear behaviour of a cast zinc–aluminium alloy [J]. Wear, 2006, 260: 895-902.

[5] ABOU El-KHAIR M T, LOTF A, DAOUD A, EL-SHEIKH A M. Microstructure, thermal behavior and mechanical properties of squeeze cast SiC, ZrO2 or C reinforced ZA27 composites [J]. Materials Science and Engineering A, 2011, 528: 2353-2362.

[6] RANGANATH G, SHARMA S C, KRISHNA M, MURULI M S. A Study of mechanical properties and fractography of ZA-27/titanium- dioxide metal matrix composites [J]. Journal of Materials Engineering and Performance, 2002, 11(4): 408-413.

[7] WANG T M, CHEN Z N, ZHENG Y P, ZHAO Y F, KANG H J, GAO L. Development of TiB2 reinforced aluminum foundry alloy based in situ composites—Part I. An improved halide salt route to fabricate Al-5wt%TiB2 master composite [J]. Materials Science and Engineering A, 2014, 605: 301-309.

[8] WANG T M, CHEN Z N, ZHENG Y P, ZHAO Y F, KANG H J, GAO L. Development of TiB2 reinforced aluminum foundry alloy based in situ composites—Part II. Enhancing the practical aluminum foundry alloys using the improved Al-5wt%TiB2 master composite upon dilution [J]. Materials Science and Engineering A, 2014, 605: 22-32.

[9] YI Hong-zhan, MA Nai-heng, LI Xian-feng, ZHANG Yi-jie, WANG Hao-wei. Heat treating behaviors of in-situ TiB2/ZL109 composites [J]. The Chinese Journal of Nonferrous Metals, 2005, 15(8): 1184-1188. (in Chinese)

[10] ZHANG S L, ZHAO Y T, CHEN G, CHNEG X N, SHE C J, WANG X Y, WU D N. Effects of in situ TiB2 particle on microstructures and mechanical properties of AZ91 alloy [J]. Journal of Alloys and Compounds, 2010, 494: 94-97.

[11] LEE J S, KIM N J, JUNG J Y, LEE E S, AHN S. The influence of reinforced particle fracture on strengthening of spray formed Cu-TiB2 composite [J]. Scripta Materialia, 1998, 39(8): 1063-1069.

[12] LI B H, LIU Y, LI J, GAO S J, CAO H, HE L. Effect of tungsten addition on the microstructure and tensile properties of in situ TiB2/Fe composite produced by vacuum induction melting [J]. Materials and Design, 2010, 31(2): 877-883.

[13] GUO M X, SHEN K, WANG M P. Relationship between microstructure, properties and reaction conditions for Cu-TiB2 alloys prepared by in situ reaction [J]. Acta Materialia, 2009, 57(15): 4568-4579.

[14] XUE J, WANG J, HAN Y F, LI P, SUN B D. Effects of CeO2 additive on the microstructure and mechanical properties of in situ TiB2/Al composite [J]. Journal of Alloys and Compounds, 2011, 509(5): 1573-1578.

[15] CHEN T J, HAO Y, LI Y D, MA Y. Effect of solid solution treatment on semisolid microstructure of dendritic zinc alloy ZA27 [J]. Materials Science and Technology, 2008, 24(11): 1313-1320.

[16] LIU Yang, LI Hong-ying, JIANG Hao-fan, LU Xiao-chao. Effects of heat treatment on microstructure and mechanical properties of ZA27 alloy [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(3): 642-649.

[17] BARTELS C, RAABE D, GOTTSTEIN G, HUBER U. Investigation of the precipitation kinetics in an Al6061/TiB2 metal matrix composites [J]. Materials Science and Engineering A, 1997, 237: 12-23.

[18] KUMAR S, CHAKRABORTH M, SUBRAMANYA SARMA V, MURTY B S. Tensile and wear behaviour of in situ Al-7Si/TiB2 particulate composites [J]. Wear, 2008, 265: 134-142.

[19]  L, LAI M O, SU Y, TEO H L, FENG C F. In situ TiB2 reinforced Al alloy composites [J]. Scripta Materialia, 2001, 45(9): 1017-1023.

L, LAI M O, SU Y, TEO H L, FENG C F. In situ TiB2 reinforced Al alloy composites [J]. Scripta Materialia, 2001, 45(9): 1017-1023.

[20] MICHAEL RAJANA H B, RAMABALAN S, DINAHARAN I, VIJAY S J. Synthesis and characterization of in situ formed titanium diboride particulate reinforced AA7075 aluminum alloy cast composites [J]. Material and Design, 2013, 44: 438-445.

[21] LAKSHMI S, LU L, GUPTA M. In situ preparation of TiB2 reinforced Al based composites [J]. Journal of Materials Processing Technology, 1998, 73: 160-166.

[22] PAN Lei, TAO Jie, LIU Zi-li, CHEN Zhao-feng. Zinc matrix composites prepared by ultrasonic assisted casting method [J]. Transactions of Nonferrous Metals Society of China, 2005, 15(S3): 104-109.

[23] LU L, LAI M O, CHEN F L. Al-4 wt% Cu composite reinforced with in-situ TiB2 particles [J]. Acta Materialia, 1997, 45(10): 4297-4309.

[24] LEE J S, JUNG J Y, LEE E S, PARK W J, AHN S, KIM N J. Microstructure and properties of titanium boride dispersed Cu alloys fabricated by spray forming [J]. Materials Science and Engineering A, 2000, 277: 274-283.

[25] ZHAO D G, LIU X F, PAN Y C, BIAN X F, LIU X J. Microstructure and mechanical properties of in situ synthesized (TiB2+Al2O3)/ Al-Cu composites [J]. Journal of Materials Processing Technology, 2007, 189: 237-241.

[26] THAKUR S K, DHINDAW B K. The influence of interfacial characteristics between SiCp and Mg/Al metal matrix on wear, coefficient of friction and microhardness [J]. Wear, 2001, 247: 191-201.

[27] RAMESH C S, AHAMED A. Friction and wear behaviour of cast Al 6063 based in situ metal matrix composites [J]. Wear, 2011, 271: 1928-1939.

[28] GATES J D. Two-body and three-body abrasion: A critical discussion [J]. Wear, 1998, 214: 139-146.

陈 飞,王同敏,陈宗宁,毛 丰,韩 强,曹志强

大连理工大学 材料科学与工程学院,大连 116024

摘 要:采用混合盐法(K2TiF6,KBF4)在反应温度875 °C下制备Zn-Al-Cu-TiB2 (ZA27-TiB2)原位复合材料。研究此复合材料的显微组织、力学性能和耐磨性。微观组织分析表明,复合材料中的TiB2颗粒细小,分布均匀。复合材料的力学性能随着颗粒含量的增加而显著增加,相对基体合金,5% TiB2增强复合材料的布氏硬度提高了HB 18, 抗拉强度提高了49 MPa。磨损实验结果说明复合材料的摩擦因数和磨损量随着颗粒含量的增加而明显降低,当TiB2含量增加到5%时,磨损率由5.9×10-3 mm3/m降低到 1.3×10-3 mm3/m。摩擦因数和磨损表面形貌变化表明,由于TiB2颗粒的引入,材料在磨损初期的磨损机制发生了变化。

关键词:原位复合材料;TiB2颗粒;摩擦因数;磨损率;力学性能

(Edited by Xiang-qun LI)

Foundation item: Projects (51071035, 51274054, 51375070) supported by the National Natural Science Foundation of China; Project (313011) supported by the Key Project of Ministry of Education of China

Corresponding author: Zhi-qiang CAO; Tel: +86-411-84706169; E-mail: caozq@dlut.edu.cn

DOI: 10.1016/S1003-6326(15)63584-1