Article ID: 1003-6326(2005)02-0460-04

AlN+MnS inclusions in oriented electrical steels

WANG Jun-an(王均安)1, ZHOU Bang-xin(周邦新)1, LI Qiang(李 强)1,

ZHU Yu-liang(褚于良)1, SUN Huan-de(孙焕德)2

(1. School of Materials Science and Engineering, Shanghai University, Shanghai 200072, China;

2. Research and Development Center, Baoshan Iron and Steel Co Ltd, Shanghai 201900, China)

Abstract: Field emission-scanning electron microscopy(FE-SEM) technique was employed to observe the shape, size and distribution of AlN+MnS inclusions in oriented electrical steels. Specimens used for FE-SEM observation were deeply electrolytic etched at room temperature in non-aqueous acetylacetone(AA) solution. The results indicate that the FE-SEM technique has obvious advantage in specimen preparation. Therefore, it can be easily used to identify the AlN+MnS inclusions and even copper nano-particles in oriented electrical steels with the same analysis accuracy as that by TEM. This technique is a good substitute for TEM and the associated specimen preparation in the observation of inclusions in electrical steels. It will be a powerful technique for routine analysis in the production of grain oriented electrical steels.

Key words: oriented electrical steels; field emission-scanning electron microscopy(FE-SEM); inclusions CLC number: TG115.21

Document code: A

1 INTRODUCTION

It is widely recognized that in order to obtain a sharp (110)[001] texture in oriented electrical steel sheets through a secondary recrystallization process, a variety of inclusions, such as sulfides and nitrides or the combination of them, have been employed[1-3]. The first case application was introduced in late 1960s, Tayuchi et al[3] utilized both MnS and AlN inclusions to provide inhibition to normal grain growth. Based on this, the grain oriented(GO) and Hi-B grain oriented electrical steels were commercially produced later on. Actually, AlN and MnS inclusions also affect the hot-rolling process and the texture formation of electrical steels[4, 5]. The investigation indicates that the population, size, distribution and orientation of these inclusions are significant to the texture formation and magnetic properties of grain oriented electrical steels[5-7]. So characterization of these inclusions draws much attention of the researchers who focus on process control of the production of electrical steels[8-10]. Till now TEM technique is broadly used to characterize the AlN and MnS inclusions in electrical steels[10, 11]. By this technique, the shape and size of AlN and MnS inclusions can be easily observed, while the preparation for TEM specimens is a long-time-consuming process. To simplify the specimen preparation, especially to find a fast approach to examine the inclusions in electrical steels from industrial production process, new observation techniques are badly needed and attempted. In this paper FE-SEM technique was employed to attempt the observation of AlN+MnS inclusions in oriented electrical steels. In comparison with TEM technique, FE-SEM observation shows obvious advantages in characterization of AlN+MnS inclusions in electrical steels.

2 EXPERIMENTAL

Specimens with basic composition of Fe-3%Si containing Al, Mn and Cu cut from the hot-rolled band and metallographically ground and polished with 7μm grade diamond paste for characterization of AlN+MnS inclusions were prepared in the following ways. Specimens used for FE-SEM observation were deeply electrolytic alloy etched at room temperature in non-aqueous AA solution which was composed of 10% acetylacetone, 1% tetramethyl ammonium chloride and methanol[12]. Specimens for TEM observation were prepared by deep electropolishing in the same way as described in specimen preparation for FE-SEM observation and then deposited with 20nm carbon film on the surface in vacuum to attain a carbon extraction replica. The carbon coated specimens were leached in AA solution and the specimens were etched through the carbon. After leaching a period of time, float the replica film directly on to a water surface by lowering the metal specimen into a water bath at a shallow angle and pick up the replica films on copper grids and dry. By this way, the AlN+MnS inclusions as well as nano copper particles can be well collected. JSM-6700F scanning electron microscope equipped with EDAX and JEM-200CX transmission electron microscope were used for observation.

3 RESULTS AND DISCUSSION

3.1 Direct observation of AlN+MnS inclusions by FE-SEM

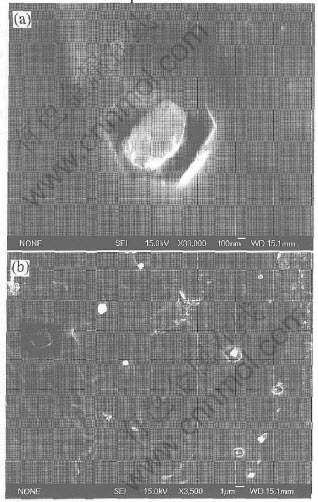

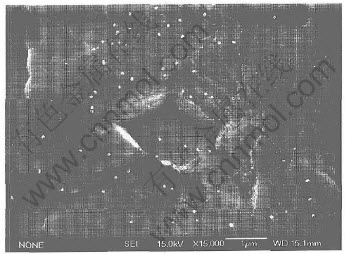

The characterization of AlN+MnS inclusions in electrical steels was ordinarily performed by TEM technique and the specimens must be carefully prepared. To make the characterization process easier, the FE-SEM technique was employed and the results attained are shown in Figs.1 and 2. It can be clearly seen that under lower magnification pits together with inclusions disperse on the surface of the electropolished specimen via etching in non-aqueous AA solution. Most of the inclusions are hexagon, as shown in Fig.1(a). It is confirmed to be the composite of AlN and MnS which can be inducted from Table 1 where the composition was obtained by energy spectrum analysis. The other elements except Al, Mn, N and S appear due to the penetration depth of electron beam which is apparently larger than the thickness of the inclusions. Therefore the information of the matrix composition below the inclusions is also collected. The size of most inhibitor composites is 300nm to 500nm, which is in the suitable size range for pinning effects in the manufacture of electrical steels and in practice the corresponding process results in good secondary recrystallization of electrical steels[13]. Under high magnification(Fig.2), the uniformly distributed white particles are clearly observed and those particles are about 50nm in size and verified as copper. It should be noted that the distribution of copper particles along the etched profile can also be well observed by FE-SEM. All these observation results fit the designed composition very well, and interestingly, they are consistent with the results obtained by other analytical methods.

Fig.1 Morphology of AlN+MnS inclusions(a) and their distribution(b)

Fig.2 Copper particles distribution in specimen

Table 1 Composition of inclusion as that in Fig.1(a)

(all elements analyzed and normalized) (mass fraction, %)

It can be concluded that when the specimens are deeply etched by electrolytic etching, the AlN and MnS composite inclusions and copper particles expose at the fresh surface. These exposed particles can be easily observed and identified by FE-SEM. Based on the observation results, it is apparent that the corresponding process and composition are suitable for the production of oriented electrical steel sheets because the dimension of most composite inclusions is in the range that the inclusions have effective inhibition to the normal grain growth.

3.2 Comparison of FE-SEM and TEM technique in observation of inclusions in electrical steels

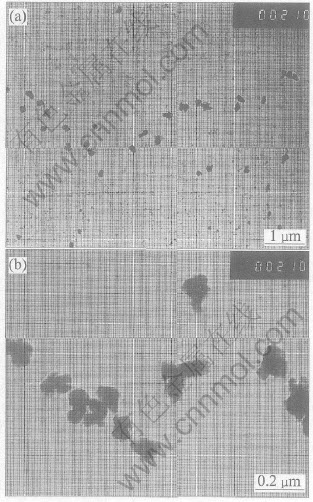

Carbon extraction replica combined with TEM technique is usually used to characterize carbides, sulfides and nitrides in steels[14, 15]. Although this combination can successfully show the morphology of the inclusions and sometimes characterize their crystal structures as well, it is complicated and long-time-consuming. As a comparison to FE-SEM, the replica obtained from the surface of the same specimens was observed by TEM and the results are shown in Fig.3. The large composite inclusions of AlN and MnS appeared almost the same form as that seen by FE-SEM. The small particles which were identified to be copper by selected area diffraction are much more in population than that observed by FE-SEM technique. The copper distribution difference largely comes from the carbon extraction process. In this process, a thick layer of materials on the specimens was etched by the non-aqueous AA solution in order to detach the carbon films from the specimen, therefore, much more copper particles were probably extracted from the specimens. While in the FE-SEM technique, the exposed and attached copper particles located at the out surface of the

Fig.3 Distribution of inclusions(a) and morphology of large particles(b)

specimens were detected as that seen in Fig.2. The results indicate that the non-aqueous AA solution is a very suitable solution for the replica making in electrical steels. With this solution all particles can be effectively extracted from the specimens. Usually, by selected area diffraction the inclusions can be characterized in structure, while for this case the inclusions of AlN and MnS composites are not easily identified as the thickness of them is beyond the diffraction depth of electron beam, which results in ambiguous diffraction patterns. The shortage of the technique could be supplemented by FE-SEM technique where the composition of inclusions can be identified by the coupled EDAX.

For the observation of inclusions in electrical steels, both TEM and FE-SEM techniques are powerful and effective. In the case of fast examination of AlN and MnS composite inclusions, FE-SEM technique shows obvious advantage in specimen preparation and therefore it would be more useful in the process control.

4 CONCLUSIONS

By comparing the observation results obtained from different specimen preparation methods and analysis techniques, FE-SEM observation on the deeply electrolytic etched specimens is considerably simple and effective for the morphological analysis of AlN and MnS composite inclusions even the copper particles in nano size in electrical steels. The advantage of FE-SEM technique is that it obviously simplifies the specimen preparation, which has special significance to the routine analysis. It is a good substitute for TEM and the associated specimen preparation in the observation of inclusions in electrical steels.

REFERENCES

[1]Fiedler H C. Grain oriented silicon-iron with a unique inhibition system for texture development [J]. Metall Trans A, 1977, 8A: 1307-1312.

[2]Yoshitomi Y, Iwayama K, Nagahima T, et al. Role of inhibitor for secondary recrystallization texture evolution in Fe-3%Si-alloy [J]. Materials Science Forum, 1993, 113-115: 281-286.

[3]Taguchi S, Sakaura A, Takashima H. Process for Producing Single-Oriented Silicon Steel Sheets Having a High Magnetic Induction [P]. US 3287183, 1966.

[4]Rodrigues V A, Monteiro W A, Silva A M S, et al. Comparison between precipitation kinetics of manganese sulfide during hot compression process with one and two holding time in grain-oriented electrical steel [J]. Journal De Physique Ⅳ, 1998, 8(2): 527-530.

[5]Kang Y L, Yu H, Fu J, et al. Morphology and precipitation kinetics of AlN in hot strip of low carbon steel produced by compact strip production [J]. Mater Sci Eng A, 2003, 351(1-2)A: 265-271.

[6]Sakai T, Shiozaki M, Takashima K. A study on AlN in high permeability grain-oriented silicon steel [J]. Journal of Applied Physics, 1979, 50 (B3): 2369-2371.

[7]Zaveryukha A, Davis C. An investigation into the cause of inhomogeneous distributions of aluminium nitrides in silicon steels [J]. Mater Sci Eng A, 2003, 345(1-2)A: 23-27.

[8]Research Group of Silicon Iron, Peking Institute of Iron and Steel Research. Effects of aluminium on commercial grain-oriented 3% Si-iron with MnS as the main second phase [J]. Acta Metallurgica Sinica, 1977, 13(1-2): 80-92. (in Chinese)

[9]Petrovic D S, Jenko M. A HRAES study of the morphology of non-metallic inclusions in non-oriented electrical steel containing Cu and Se [J]. Vacuum, 2003, 71(1-2): 33-40.

[10]Shen T H. Study of desulfurization kinetics in grain oriented 3 percent silicon iron [J]. Metall Trans A, 1986, 17A(8): 1347-1351.

[11]Park J Y, Han K S, Woo J S, et al. Influence of primary annealing condition on texture development in grain oriented electrical steels [J]. Acta Mater, 2002, 50(7): 1825-1834.

[12]Kurosawa F, Taguchi I, Matsumoto R. Observation of precipitates and metallographic grain orientation in steel by a non-aqueous electrolyte-potentiostatic etching method [J]. Journal of the Japan Institute of Metals, 1979, 43 (11): 1068-1077.

[13]Nakayama T, Honjou N. Effect of aluminum and nitrogen on the magnetic properties of non-oriented semi-processed electrical steel sheet [J]. Journal of Magnetism and Magnetic Materials, 2000, 213(1-2): 87-94.

[14]Sennour M, Esnouf C. Contribution of advanced microscopy techniques to nano-precipitates characterization: case of AlN precipitation in low-carbon steel [J]. Acta Mater, 2003, 51: 943-957.

[15]Garbarz B, Marcisz J, Wojtas J. TEM analysis of fine sulphides dissolution and precipitation in steel [J]. Materials Chemistry and Physics, 2003, 81(2-3): 486-489.

Foundation item: Project(50471104) supported by the National Natural Science Foundation of China

Received date: 2004-12-06; Accepted date: 2005-01-18

Correspondence: WANG Jun-an, Associate Professor, PhD; Tel: +86-21-56338634; E-mail: jawang@staff.shu.edu.cn

(Edited by LI Xiang-qun)