文章编号:1004-0609(2013)12-3302-06

重熔工艺对应变诱导熔化激活法制备ZCuSn10铜合金半固态组织的影响

吴龙彪1,肖 寒1,王 佳1, 2,卢德宏1,周 荣1

(1. 昆明理工大学 材料科学与工程学院,昆明 650093;

2. 四川理工学院 机械工程学院,自贡 643000)

摘 要:采用包括锻造与重熔的应变诱导熔化激活(SIMA)法制备ZCuSn10铜合金半固态坯料,分析重熔过程中重熔温度和保温时间对ZCuSn10半固态坯料微观组织的影响。结果表明:在900 ℃保温时,随着保温时间的延长,合金的平均晶粒直径增大,保温时间由5 min延长至50 min时,平均晶粒直径由45.9 μm增大至74.7 μm;晶粒形状因子随保温时间的延长先减小后增大。保温30 min时,随着保温温度的升高,平均晶粒直径减小,当保温温度由850 ℃升高至925 ℃时,平均晶粒直径由72.6 μm减小至64.1 μm;晶粒形状因子随保温温度的升高而增大。900 ℃保温30 min获得的半固态组织均匀、球化效果好,平均晶粒尺寸为64.7 μm,形状因子为1.65。

关键词:ZCuSn10铜合金;半固态;应变诱导熔化激活(SIMA)法;重熔工艺;晶粒尺寸;形状因子

中图分类号:TG146.1+1; TG249.9 文献标志码:A

Effect of remelting process on microstructure of semi-solid ZCuSn10 copper alloy fabricated by strain induced melt activated method

WU Long-biao1, XIAO Han1, WANG Jia1, 2, LU De-hong1, ZHOU Rong1

(1. Faculty of Materials Science and Engineering, Kunming University of Science and Technology, Kunming 650093, China;

2. Faculty of Mechanical Engineering, Sichuan University of Science and Engineering, Zigong 643000, China)

Abstract: Semi-solid ZCuSn10 copper alloy was fabricated by strain induced melt activated (SIMA) method including the forging and remelting process. The effect of remelting temperature and holding time on the microstructure of semi-solid ZCuSn10 copper alloy was investigated. The results indicate that, with the increase of the holding time at 900 ℃, the mean grain diameter of the alloy increases. With the increase of the holding time from 5 min to 50 min, the mean grain diameter increases from 45.9 μm to 74.7 μm, and the shape factor decreases first and then increases. With the increase of the remelting temperature at the holding time of 30 min, the mean grain diameter decreases. With increasing the remelting temperature from 850 ℃ to 925 ℃, the mean grain diameter decreases from 72.6 μm to 64.1 μm, and the shape factor increases. The semi-solid ZCuSn10 copper alloy with uniform and spherical grains can be obtained at remelting temperature of 900 ℃ and the holding time of 30 min, the mean grain diameter of the alloy is 64.7 μm and the shape factor is 1.65.

Key words: ZCuSn10 copper alloy; semi-solid; strain induced melt activated (SIMA) method; remelting parameter; grain size; shape factor

半固态加工技术最先由美国麻省理工学院FLEMINGS等[1-2]提出,该技术具有成形温度较液态成形的低、变形抗力较固态成形的小等优点,能成形复杂形状、高精度零件,并能提高材料利用率,因此。该技术自提出以来得到了迅速发展,特别是在工业发达国家已经开始了工业应用[3-5]。半固态坯制备的主要核心是使其初晶球状化和细晶化[6]。最早的浆料制备方法是机械搅拌法(MS),经过30多年的发展,陆续出现了电磁搅拌(ES)、应变诱导熔化激活(Strain induced melt activated, SIMA)、喷射沉积(SD)、液相线铸造和粉末冶金(PM)等制备方法[7-11]。其中,应变诱导熔化激活(SIMA)法不需要液态金属的搅拌工序,因此制备的半固态坯料致密度高、无污染、适用范围广,尤其对制备较高熔点的非枝晶合金具有独特的优越 性[12]。SIMA法包括预变形[13]和重熔加热[14]两个步骤,首先对合金进行预变形,储备变形能;然后对变形后合金进行重熔加热,将其加热至半固态温度区间并保温,即可得到半固态坯料。目前,国内外科研人员对SIMA法制备半固态坯料开展了大量的研究工作,主要是研究不同预变形工艺以及重熔工艺参数对半固态坯料组织和力学性能的影响,制备了性能较好的半固态坯料,为SIMA法制备半固态坯料以及半固态成形提供了参考[15-18]。但是,这些研究工作大多是针对铝合金和镁合金等低熔点合金,对于铜合金等较高熔点合金的半固态加工研究相对较少。

锡青铜具有较高的强度、优良的弹性、易钎焊和电镀、无磁性、抗蚀性极优、耐磨性优异,被广泛地应用于蒸汽锅炉和船舶工业重要阀件、齿轮和蜗轮等的制备。而在锡青铜传统铸造过程中,锡偏析严重,易导致组织的不均匀,从而导致性能不均匀,影响合金的使用寿命[19]。因此,若能开展锡青铜半固态成形研究,获得组织和性能均匀的锡青铜产品,则会大大提高锡青铜的使用寿命和扩大其应用领域。基于此,本文作者采用结合锻造与重熔工艺的SIMA法制备ZCuSn10铜合金半固态坯料,分析重熔过程中重熔温度和保温时间对ZCuSn10铜合金半固态组织的影响,研究重熔工艺对半固态组织平均晶粒直径和球化效果的影响规律,从而提供一种制备铜合金半固态坯料的方法,并为铜合金半固态成形技术的应用提供理论依据。

1 实验

1.1 实验材料

实验材料为ZCuSn10铜合金,合金的化学成分(质量分数,%)如下:88.25%Cu,10.48%Sn,其他元素含量为1.27%。采用差示扫描量热法测定该合金的固相线温度为830 ℃,液相线温度为1 020 ℃。该合金固液区间宽度达到190 ℃,因此,该合金适合进行半固态成形。

1.2 实验方法

实验流程如图1所示。第一步,浇铸铜合金铸锭,首先按照ZCuSn10铜合金的成分配料并熔化,然后用金属模浇铸为d 34 mm×120 mm的圆柱体铸锭,并将其机加工为d 30 mm×100 mm的圆柱体;第二步,锻造变形,首先将机加工后的试样加热至450 ℃并保温15 min,然后利用空气锤进行锻造变形;第三步,重熔热处理,将锻造后的试样线切割为多个小试样,并放入工频感应加热炉中加热至固液温度区间并保温一定时间,然后快速水淬,获得半固态组织。水淬后的试样先去除氧化皮,并制备金相试样,所用腐蚀剂为FeCl3溶液,利用Leica光学金相显微镜观测金相组织,并借助Image-Pro Plus图形分析软件对半固态组织进行定量分析。最后,分析不同保温时间和保温温度对ZCuSn10铜合金半固态组织的影响。

图1 SIMA法制备ZCuSn10半固态坯料流程图

Fig. 1 Flowchart of semi-solid ZCuSn10 billet fabricated by SIMA method

2 结果与分析

2.1 预变形对ZCuSn10铜合金原始组织的影响

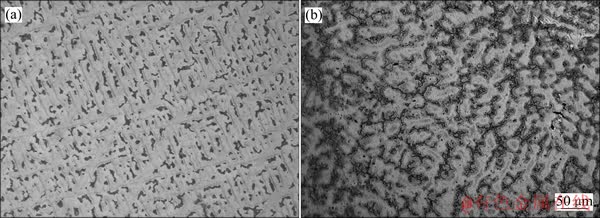

图2所示为ZCuSn10铜合金的铸态组织和预变形组织。由图2可见,ZCuSn10铜合金的组织由α固溶体与(α+δ)共析体组成。α相是锡溶于铜中的置换式固溶体,为面心立方晶格。δ相是以电子化合物(Cu31Sn8)为基体的固溶体,(α+δ)共析体被包围在α树枝状晶体的间隙中。由图2(a)明显可以看出,铸造ZCuSn10铜合金组织由树枝晶组成,且一次枝晶和二次枝晶连接成网状,低熔点的(α+δ)共析体存在于枝晶间隙。由图2(b)可知,ZCuSn10铸锭经过锻造预变形后,原始铸态组织中的一次枝晶和二次枝晶由于形变应力集中而发生碎断,打断了枝晶的连续分布状态,且积累了大量形变产生的形变能,这些形变能在后续的重熔加热过程中使组织发生球化。

2.2 重熔处理保温时间对ZCuSn10半固态坯料微观组织的影响

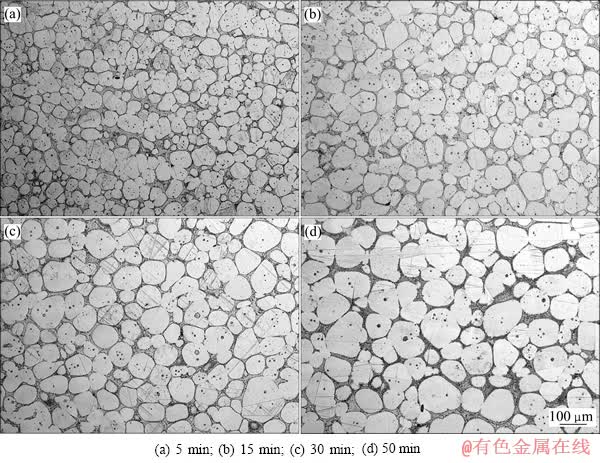

重熔过程中保温时间是影响半固态微观组织的一个重要参数。当重熔处理时保温时间发生变化时,半固态组织也会随之发生变化。经过预变形的铜合金铸锭在工频感应加热炉中加热至900 ℃保温不同时间5、15、30和50 min并水淬获得半固态坯料。图3所示为900 ℃、不同保温时间下ZCuSn10铜合金半固态的微观组织。由图3可知,采用锻造与重熔的应变诱导熔化激活(SIMA)法制备的ZCuSn10半固态坯料组织较好,球化率高且晶粒尺寸比较均匀。当保温温度900 ℃、保温时间5 min时,球状晶粒已经开始出现,且晶粒的直径较小,小于100 μm,但是晶粒尺寸均匀性较差,液相分布不均匀,如图3(a)所示。随着保温时间的延长,如保温15 min后,一部分晶粒合并长大为大晶粒;一部分小晶粒堆积到大晶粒上,使晶粒进一步长大,此时,晶粒尺寸相对均匀,小晶粒大量减少,固相晶粒内部出现小熔池,如图3(b)所示。随着保温时间增加至30 min,晶粒尺寸进一步增大,晶粒尺寸分布更加均匀,球化效果更好,且液相增多,如图3(c)所示。当保温时间增加至50 min时,晶粒尺寸显著增大,液相明显增加,球化效果变差,如图3(d)所示。

图2 ZCuSn10铜合金的铸态组织和预变形组织

Fig. 2 As-cast (a) and pre-deformation (b) microstructures of ZCuSn10 copper alloy

图3 900 ℃不同保温时间下半固态ZCuSn10铜合金的微观组织

Fig. 3 Microstructures of semi-solid ZCuSn10 alloys at 900 ℃ for different holding times

为了定量分析ZCuSn10铜合金半固态组织,采用Image-Pro Plus软件对图3所示金相组织进行统计分析,并计算平均晶粒直径和形状因子,平均晶粒直径和形状因子的计算公式分别如式(1)和(2)所示:

(1)

(1)

式中:dm为平均晶粒直径;S1,S2,…,Sn分别为第1,2,…,n个晶粒的面积。

(2)

(2)

式中:zm为晶粒平均形状因子;l1,l2,…,ln分别为第1,2,…,n个晶粒的周长。

图4所示为900 ℃、不同保温时间下ZCuSn10铜合金半固态坯料的平均晶粒直径和形状因子。由图4可知,当保温温度为900 ℃、保温时间从5 min增加到50 min时,晶粒的平均直径随着保温时间的延长而增大,由5 min的45.9 μm增大至50 min的74.7 μm,晶粒的长大趋势同Ostwald熟化机理很相似。在重熔过程中,晶粒的合并长大过程与熔化过程同时存在,当晶粒的长大速度大于熔化速度时,晶粒表现出长大的趋势。由于曲率半径的差别,不同曲率半径的颗粒之间形成扩散偶,小颗粒沉积在大颗粒上,使大颗粒粗化。由式(2)可知,晶粒为球形时,形状因子为1;若晶粒不是球形,则形状因子大于1,越接近于1,则表明球化效果越好。由图4可知,随着保温时间的延长,平均形状因子先快速减小,然后又有所增大。其原因是在保温5 min时,液相量相对较少,且晶粒之间呈相互粘连状态,这将不利于半固态触变成型,在用有效直径表征晶粒尺寸时,计算的是多个粘连小晶粒的平均直径,所以在保温时间较短时晶粒的平均形状因子较大。但是,随着保温时间的延长,液相量增加,将固相分隔开和小晶粒的合并长大,使晶粒平均形状因子减小,保温30 min时,晶粒的平均形状因子最小,其值为1.65。当继续延长保温时间至50 min,已经粗化晶粒再次合并长大使晶粒的平均形状因子有所增大。

图4 900 ℃、不同保温时间下半固态ZCuSn10铜合金的平均晶粒直径和形状因子

Fig. 4 Mean grain diameter and shape factor of semi-solid ZCuSn10 alloys at 900 ℃ for different holding times

2.3 重熔处理保温温度对ZCuSn10半固态坯料微观组织的影响

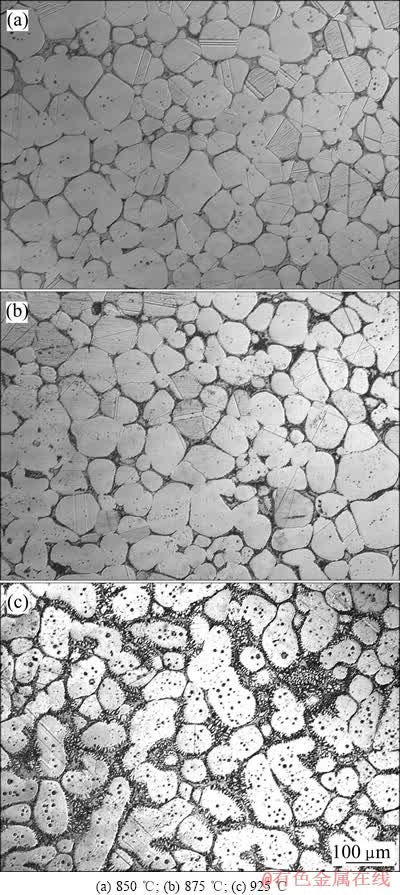

当ZCuSn10铜合金重熔保温30 min时,不同保温温度的微观组织如图5所示。由图5以及图3(c)可知,当保温时间为30 min、保温温度从850 ℃升高至925 ℃时,在850 ℃就已经开始出现液相,如图5(a)所示,并且可以明显地看出,850 ℃时晶粒的球化效果已经比较好。但随着保温温度的升高,平均晶粒直径减小,晶粒尺寸分布不均匀,如图5(b)和3(c)所示。随着保温温度升高至925 ℃,晶粒尺寸继续减小,球化效果变差,半固态组织中出现大量的条状晶粒,晶界轮廓不圆滑且出现大量锯齿状,晶粒内部出现大量小熔池,液相明显增加。

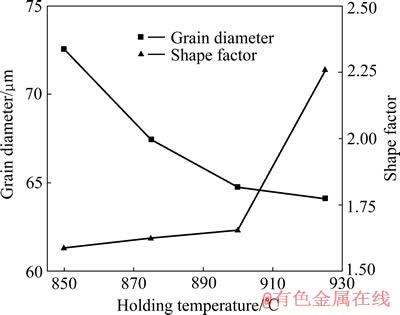

重熔保温温度对半固态组织的平均晶粒直径和形状因子的影响如图6所示。由图6可知,在保温30 min时,随着保温温度的升高,平均晶粒直径减小。当保温温度由850 ℃升高至925 ℃,平均晶粒直径由72.6 μm减小至64.1 μm。平均晶粒直径随着保温温度的升高呈现减小趋势的原因如下:晶粒的合并长大和熔化在重熔过程中同时存在,铜合金铸锭在锻造变形后积累了形变能,随后在保温温度为850~925 ℃时重熔,此时,晶粒熔化速度大于晶粒合并长大速度,最终导致平均晶粒直径随保温温度的升高而减小。

图5 不同保温温度下保温30 min时半固态ZCuSn10铜合金的微观组织

Fig. 5 Microstructures of semi-solid ZCuSn10 alloys at different holding temperatures for 30 min

图6 不同保温温度下保温30 min时ZCuSn10半固态铜合金的平均晶粒直径和形状因子

Fig. 6 Mean grain diameter and shape factor of semi-solid ZCuSn10 alloys at different holding temperatures for 30 min

由图6可知,随着保温温度的升高,晶粒的形状因子呈现上升趋势。当保温温度由850 ℃升高至925 ℃,形状因子由1.58增加至2.26,表明半固态组织的球化效果越来越差。保温温度在900 ℃以下,晶粒的球化主要靠Ostwald熟化机制和未被液相润湿的晶粒合并,积累了形变能,致使在温度相对较低情况下,晶粒球化速度较快,也相对圆整。当保温温度为925 ℃时,晶粒的形状因子增大,圆整度下降,球化效果变差。主要原因如下:925 ℃保温时,半固态坯料的升温速度快且保温温度高,在保温时间相同条件下析出的液相量较多且析出液相速度较快,液相进入晶界将形变后的枝晶组织较快分隔,使粘连团聚的晶粒数减少,从而抑制晶粒合并长大,这不利于重熔处理时晶粒的球化。而且已经析出的液相加快了对晶界的熔化,晶界呈不平滑的锯齿状,导致晶粒被液相包围,从图5(c)中明显能看到,由于液相对固相的侵蚀较快,在液相中仍然有未完全熔化的固相小颗粒,晶粒的球化主要靠Ostwald熟化机制。

3 结论

1) 采用包括锻造与重熔的应变诱导熔化激活(SIMA)法能够制备出组织较好的ZCuSn10铜合金半固态坯料,在900 ℃保温30 min条件下获得的半固态组织最好,此时,其平均晶粒直径为64.7 μm,形状因子为1.65。

2) 在保温温度为900 ℃时,保温时间从5 min延长至50 min,ZCuSn10铜合金半固态组织的平均晶粒直径由45.9 μm增大至74.7 μm,形状因子则是先减小后增大,在30 min时半固态组织形状因子最小,表明圆整度最好。

3) 在保温时间为30 min时,当保温温度从850 ℃增加到925 ℃,ZCuSn10铜合金半固态组织的平均晶粒直径由72.6 μm减小到64.1 μm。晶粒的形状因子呈现增大趋势,半固态组织球化效果越来越差。

REFERENCES

[1] SPENCER D B, MEHRABIAN R, FLEMINGS M C. Rheological behavior of Sn-15 Pct Pb in the crystallization range[J]. Metallurgical Transactions, 1972, 3(7): 1925-1932.

[2] FLEMINGS M C. Behavior of metal alloys in the semi-solid state[J]. Metallurgical Transactions A, 1991, 22(5): 957-981.

[3] 孙国强. 半固态加工技术及其应用[J]. 稀有金属, 2003, 27(3): 382-384.

SUN Guo-qiang. Technology and application of semi-solid processing[J]. Chinese Journal of Rare Metals, 2003, 27(3): 382-384.

[4] 罗守靖, 姜巨福, 杜之明. 半固态金属成形研究的新进展、工业应用及其思考[J]. 机械工程学报, 2003, 39(11): 52-60.

LUO Shou-jing, JIANG Ju-fu, DU Zhi-ming. New research development, industrial application and some thinking of semi-solid metal forming[J]. Chinese Journal of Mechanical Engineering, 2003, 39(11): 52-60.

[5] 罗守靖, 田文彤, 谢水生, 毛卫民. 半固态加工技术及应用[J]. 中国有色金属学报, 2000, 10(6): 765-773.

LUO Shou-jing, TIAN Wen-tong, XIE Shui-sheng, MAO Wei-min. Technology and applications of semi-solid forming[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(6): 765-773.

[6] KIRKWOOD D H. Semi-solid metal processing[J]. International Materials Reviews, 1994, 39(5): 173-189.

[7] LIN H Q, WANG J G, WANG H Y, JIANG Q C. Effect of predeformation on the globular grains in AZ91D alloy during strain induced melt activation (SIMA) process[J]. Journal of Alloys and Compounds, 2007, 431(1/2): 141-147.

[8] 张小立, 凌向军, 李廷举, 谢水生, 金云学. 电磁搅拌过程中镁合金半固态浆料初生相颗粒的团簇行为[J]. 中国有色金属学报, 2012, 22(3): 2448-2453.

ZHANG Xiao-li, LING Xiang-jun, LI Ting-ju, XIE Shui-sheng, JIN Yun-xue. Agglomerating behavior of primary solid particles in magnesium alloy semi-solid slurry during electromagnetic stirring[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(3): 2448-2453.

[9] DONG J, CUI J Z, LE Q C, LU G M. Liquidus semi-continuous casting, reheating and thixoforming of a wrought aluminum alloy 7075[J]. Materials Science and Engineering A, 2003, 345(1/2): 234-242.

[10] GAN Gui-sheng, ZHANG Lei, BEI Shu-yu, LU Yi, YANG Bin. Effect of TiB2 addition on microstructure of spray-formed Si-30Al composite[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(10): 2242-2247.

[11] JIANG Ju-fu, LIN Xin, WANG Ying, QU Jian-jun, LUO Shou-jing. Microstructural evolution of AZ61 magnesium alloy predeformed by ECAE during semi-solid isothermal treatment[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(3): 555-563.

[12] YOUNG K P, KYONKA C P, COURTOIS J A. Fine grained metal composition: US, 4415374[P]. 1983-11-15.

[13] 夏明许, 郑红星, 袁 森, 李建国. 大挤压形变AZ91D镁合金半固态等温组织演变[J]. 材料科学与工艺, 2005, 13(3): 287-290.

XIA Ming-xu, ZHENG Hong-xing, YUAN Sen, LI Jian-guo. Microstructural evolution of highly extruded AZ91D magnesium alloys[J]. Material Science and Technology, 2005, 13(3): 287-290.

[14] 曹富荣, 管仁国, 陈礼清, 赵占勇, 任 勇. 二次加热过程中半固态AZ31镁合金的显微组织演变[J]. 中国有色金属学报, 2012, 22(1): 7-14.

CAO Fu-rong, GUAN Ren-guo, CHEN Li-qing, ZHAO Zhan-yong, REN Yong. Microstructure evolution of semi-solid AZ31 magnesium alloy during reheating process[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(1): 7-14.

[15] 翟秋亚, 袁 森, 蒋百灵. AZ91镁合金的SIMA法半固态组织特征[J]. 中国有色金属学报, 2005, 15(1): 123-128.

ZHAI Qiu-ya, YUAN Sen, JIANG Bai-ling. Microstructural characteristics of semi-solid AZ91 magnesium alloy based on SIMA process[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(1): 123-128.

[16] 姚亮宇, 袁 森, 王武孝, 蒋百灵, 唐文亭. SIMA法处理AZ91D镁合金压缩形变及半固态等温组织的特征[J]. 中国有色金属学报, 2004, 14(4): 660-664.

YAO Liang-yu, YUAN Sen, WANG Wu-xiao, JIANG Bai-ling, TANG Wen-ting. Characterization of deformation and semi-solid isothermal microstructures of AZ91D alloy for upsetting in SIMA process[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(4): 660-664.

[17] JIANG Ju-fu, WANG Ying, LIU Jun, QU Jian-jun, DU Zhi-ming, LUO Shou-jing. Microstructure and mechanical properties of AZ61 magnesium alloy parts achieved by thixo-extruding semi-solid billets prepared by new SIMA[J]. Transactions of Nonferrous Metals Society of China, 2013, 23 (3): 576-585.

[18] 张倩倩, 曹占义, 刘勇兵. 铝含量对应变诱发法半固态镁合金的影响[J]. 材料热处理学报, 2010, 31(4): 24-28.

ZHANG Qian-qian, CAO Zhan-yi, LIU Yong-bing. Effect of aluminum content on the semi-solid magnesium alloy produced by strain induced melt activation process[J]. Transactions of Materials and Heat Treatment, 2010, 31(4): 24-28.

[19] 耿浩然, 王守仁, 王 艳. 铸造锌、铜合金[M]. 北京: 化学工业出版社, 2006.

GENG Hao-ran, WANG Shou-ren, WANG Yan. Cast zinc, copper alloy[M]. Beijing: Chemical Industry Press, 2006.

(编辑 陈卫萍)

基金项目:高等学校博士点专项科研基金资助项目(20125314120013);云南省应用基础研究重点项目(2011FA007);云南省教育厅科学研究基金资助项目(2012Y543);四川理工学院培育项目(2013PY05)

收稿日期:2013-02-02;修订日期:2013-07-20

通信作者:卢德宏,教授,博士;电话:13888324279;E-mail: ldhongkust@126.com