Effect of sputtering pressure and rapid thermal annealing on optical properties of Ta2O5 thin films

ZHOU Ji-cheng(周继承), LUO Di-tian(罗迪恬), LI You-zhen(李幼真), LIU Zheng(刘 正)

School of Physics Science and Technology, Central South University, Changsha 410083, China

Received 6 December 2007; accepted 4 March 2008

Abstract: Ta2O5 thin films were deposited by DC reactive magnetron sputtering followed by rapid thermal annealing(RTA). Influence of sputtering pressure and annealing temperature on surface characteristics, microstructure and optical property of Ta2O5 thin films were investigated. As-deposited Ta2O5 thin films are amorphous. It takes hexagonal structure (δ-Ta2O5) after being annealed at 800 ℃. A transition from δ-Ta2O5 to orthorhombic structure (L-Ta2O5) occurs at 900-1 000 ℃. Surface roughness is decreased after annealing at low temperature. Refractive index and extinction coefficient are decreased when annealing temperature is increased.

Key words: Ta2O5 thin films; DC reactive magnetron sputtering; sputtering pressure; rapid thermal annealing(RTA)

1 Introduction

Because of good chemical and thermal stability, high refractive index, high transmission and low extinction coefficient in visible spectrum, Ta2O5 thin films are used in optical applications[1-2], such as anti-reflecting coatings, optical waveguides, interference coatings and photoelectric conversion. Ta2O5 thin films have a large dielectric constant (20-26) and are considered as the potential candidates for high k gate dielectrics[3-4].

Methods and conditions of deposition affect optical and structural properties of Ta2O5 thin films. Various techniques have been used to deposit Ta2O5 thin films, such as chemical vapor deposition[5-6], sol-gel[7], electron beam evaporation[8], thermal oxidation[9], ion beam sputtering[10] and RF sputtering[11]. GHODSI and TEPEHAN[12] studied the effect of heat treatment on optical properties of sol-gel Ta2O5 thin films. SPASSOV et al [13] prepared Ta2O5-Si structures by RF sputtering and discussed effects of rapid thermal annealing(RTA) on electrical properties of Ta2O5 thin films. Compared with other methods, DC reactive magnetron sputtering has lots of advantages[14], such as low deposition temperature and better adhesion. The thickness and stoichiometric composition of the films can be easily controlled. The complexity and expense of RF systems can be avoided since metallic targets are electrically conductive, which allows DC power to be applied. Studying the effect of sputtering pressure and annealing on optical properties of Ta2O5 thin films prepared by DC reactive magnetron sputtering is helpful to understanding and optimizing the fabrication processing.

In this work, Ta2O5 thin films were prepared by DC reactive magnetron sputtering and annealed at different temperatures. The material properties were investigated by X-ray diffractometer, atom force microscope, ultraviolet and visible spectrophotometer. The refractive index and extinction coefficient were calculated by the envelop method. Effects of sputtering pressure and annealing on properties of Ta2O5 thin films were also discussed.

2 Experimental

Ta2O5 thin films were deposited by DC reactive magnetron sputtering. Target was pure Ta metal (99.9%). Glass slide and Si(111) substrates were placed under the targets (60 mm in distance) in the chamber. The base pressure was 1×10-3 Pa. Mixture of argon (99.99%) and oxygen (99.99%) was used as sputtering gas. The oxygen volume fraction was kept constant at 30%, with working pressure changed between 0.1 and 0.9 Pa. The magnetron sputter source was supplied by a constant DC power of 200 W. To remove compound layer from the target surface, the target was sputter etched in pure argon for 10 min before deposition. HT-600 was performed for rapid thermal annealing. Ta2O5 thin films were annealed at 300, 500, 700, 800, 900 and 1 000 ℃ in pure nitrogen (99.99%) for 5 min, respectively, and the heating rate used was 70 ℃/s.

Mean deposition rate was calculated by deposition time and film thickness. Ta2O5 thin film thickness ranging from 300 to 450 nm, was measured by Alpha-Step IQ surface profiler (KLA-Tencor). A y2000 X-ray diffraction measurement (Cu Kα 40 kV, 20 mA) was performed to obtain the phase composition. The diffraction angle 2θ was scanned in 10?-90? with step of 0.05?. Solver P47 AFM was used to exam surface morphology, and the scan area was 1 000 nm×1 000 nm. Transmitted spectrum of selected samples was measured by Tu-1800PC ultraviolet and visible spectrophotometer with resolution of 0.3 nm. Optical constants were calculated from optical transmission measurements using envelop method[15-17].

3 Results and discussion

3.1 Deposition rate

Fig.1 shows the relationship between deposition rate and sputtering pressure. At φ(O2)=10% and p=0.9 Pa, the deposition rate is 79.35 nm/min, which is much higher than that at φ(O2)=30%. When oxygen content increases from 10% to 30%, the process changes from metallic mode to reactive mode, leading to so-called target poisoning. The deposition rate reaches a maximum (32.9 nm/min) at 0.3 Pa, and starts to decrease with the increase of sputtering pressure. At a low sputtering pressure, less particles present in the plasma, which permits low deposition rate. Consequently, the deposition rate increases with sputtering pressure. But at a high sputtering pressure, mean free path of gas molecules is very short, whereas the collision of particles becomes frequent in the chamber. Due to collision, particles lost energy, and cannot reach the substrate or do not have enough energy to form films. As the result, the deposition rate decreases.

Fig.1 Deposition rate as function of sputtering pressure

3.2 Structural analyses

Fig.2 presents XRD patterns of Ta2O5 thin film as a function of annealing temperature. As-deposited Ta2O5 thin film is amorphous, and exhibits no diffraction peaks but a typical noncrystalline diffraction package at 2θ=23? for glass substrates. Ta2O5 thin film is crystallized at 700-800 ℃, and takes hexagonal structure(δ-Ta2O5) [18]. New diffraction peaks appear at the diffraction angle range of 45?-60?. After being annealed at 900 ℃, the structure of Ta2O5 thin films is transformed from hexagonal structure to low temperature orthorhombic structure (L-Ta2O5) [18]. δ-Ta2O5 and L-Ta2O5 are two likely phases, and their three major X-ray diffraction peaks are very closely located. It is to be noted that diffraction patterns in the case of orthorhombic polymorphs of the stoichiometric pentoxide should contain two or more peaks, instead of one for the hexagonal phase, close to 28.3?, 36.7? and 50? [19]. Indeed, displacement and broadening of those peaks are observed in Fig.2, which are attributed to new contributions from orthorhombic structure.

Fig.2 XRD patterns of Ta2O5 films annealed at different temperature (θ<700 ℃, glass substrate; θ≥700 ℃, Si(111) substrate)

3.3 AFM analysis

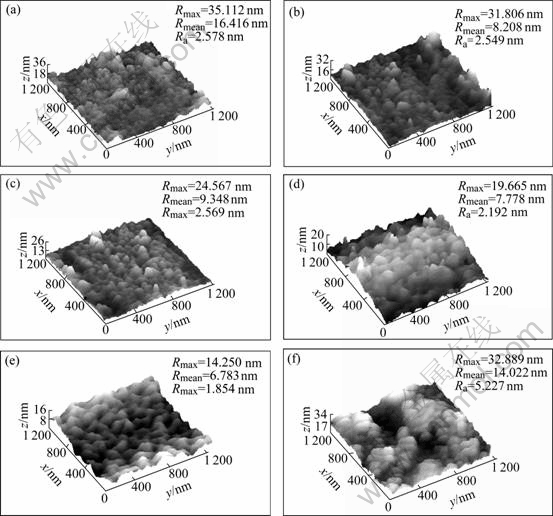

In order to discover the effects of sputtering pressure and annealing temperature on the surface properties of Ta2O5 thin films, AFM was performed. Figs.3(a)-(c) show AFM images of Ta2O5 thin films deposited at different sputtering pressure. All surfaces are constructed by evenly dispersed islands without any visible defects or holes. With the increase of sputtering pressure, the maximum roughness(Rmax) and root mean square roughness(Ra) are decreased. At higher deposition rate, the particles have less time to diffuse and are covered instantly by incoming particles, leading to larger roughness. With the decrease of sputtering pressure, the deposition rate decreases, so the formed islands have enough time to diffuse, which makes the roughness of the thin films decrease.

Sample deposited at 0.6 Pa was annealed at 300, 500 and 800 ℃, respectively. Figs.3(c)-(d) show that the surface morphologies of Ta2O5 thin films is improved after being annealed at low temperature, and the surface roughness decreases. With the increase of annealing temperature, the diffusion of particles is increased, which causes the decrease of roughness. When the annealing temperature is higher than 800 ℃, Ta2O5 thin films are transformed from amorphous to crystalline. Fig.3(f) presents large grains on surface of sample after annealing at 800 ℃, and the roughness increases significantly.

Fig.3 AFM images of Ta2O5 films: (a) 0.4 Pa; (b) 0.6 Pa; (c) 0.8 Pa; (d) 300 ℃; (e) 500 ℃; (f) 800 ℃ (Samples (a)-(e): glass substrate; sample (f): Si(111) substrate)

3.4 Optical characteristic

Ta2O5 thin films are transparent, and have color of light green. From the transmittance of samples (Fig.4), Ta2O5 thin films exhibit a good visible optical transmission of 75%-85%. The maximum transmittance is very close to the bare glass, revealing that there are few impurities and defects in the films. With the increase of sputtering pressure, the absorption of visible light of the films decreases, mainly due to the following reasons. 1) The surface roughness decreases with the increase of sputtering pressure, which reduces the scattering of visible light. So the transmittance of samples increases. 2) The growth process of Ta2O5 thin films includes absorption, diffusion and re-evaporation. In general, the

equilibrium pressure of O is considered to be higher than that of Ta. Hence, O atoms easily break away from Ta2O5 films, leading to the formation of oxygen vacancies. With the increase of sputtering pressure, oxygen partial pressure increases, which enhances the combination of Ta and O, thereby reducing oxygen vacancies and improving the transparence of Ta2O5 thin films. Fig.5 shows the transmittance of Ta2O5 films deposited at 0.6 Pa, which decreases with increase of annealing temperature.

Fig.4 Transmittance of as-deposited Ta2O5 films

Fig.5 Transmittance of as-deposited and annealed Ta2O5 films

The optical constant of films is calculated from the transmittance curve by using envelop method. Fig.6 presents the variation of refractive index with sputtering pressure. At λ=550 nm, refractive index of Ta2O5 thin films ranges from 2.04 to 2.16, and decreases with the increase of sputtering pressure. Because at lower sputtering pressure, Ta2O5 thin films are formed by particles with higher energy, the density of the films is greater. The refractive index of thin films varies inversely with the density, therefore, refractive index of Ta2O5 thin films decreases with the increase of sputtering pressure.

Fig.6 Refractive index of as-deposited Ta2O5 films (λ=50 nm)

In Fig.7 refractive index and extinction coefficient of Ta2O5 thin films deposited at 0.6 Pa are simulated by CAUCHY model. Refractive indexes of 2.091, 2.063 and 2.049 are obtained at 550 nm for as-deposited, 300 ℃and 500 ℃ annealed films, respectively. Extinction coefficients of 2.37×10-4, 1.03×10-4 and 7.40×10-5 are obtained at 550 nm. Because crystallization temperature of Ta2O5 thin films is higher than 700 ℃, the films maintain amorphous after annealing at low temperature. Internal stress of Ta2O5 thin films is released after annealing, so the density of the films decreases. Thus, refractive index of Ta2O5 thin films decreases with increase of annealing temperature. Furthermore, defects inside the films are reduced after annealing, which is helpful to decreasing the absorption of visible light of Ta2O5 thin films.

Fig.7 Refractive index and extinction coefficient of Ta2O5 films simulated by CAUCHY model

4 Conclusions

1) As sputtering pressure increases, the deposition rate of Ta2O5 thin films reaches the maximum at 0.3 Pa.

2) It is shown that as-deposited Ta2O5 thin films are amorphous, and a hexagonal structure (δ-Ta2O5) is identified after annealing at 800 ℃. A transition from δ-Ta2O5 to low temperature orthorhombic structure (L-Ta2O5) occurs at 900-1 000 ℃.

3) The roughness of Ta2O5 thin films decreases with the increase of sputtering pressure. At 550 nm, refractive index of Ta2O5 thin films ranges from 2.04 to 2.16.

4) While maintaining amorphous state, roughness, refractive index and extinction coefficient of Ta2O5 thin films decrease with the increase of annealing temperature.

References

[1] FARHD E G, FATMA Z, T, GALIP G. T. Optical properties of Ta2O5 thin films deposited using the spin coating process [J]. Thin Solid Films, 1997, 295: 11-15.

[2] LIU W J, GUO X J, CHEN C H. The study of optical and microstructural evolution of Ta2O5 and SiO2 thin films by plasma ion assisted deposition method [J]. Surface & Coatings Technology, 2005, 196: 69-75.

[3] ATANASSOVA E, PASKALEVA A. Challenges of Ta2O5 as high-k dielectric for nanoscale DRAMs [J]. Microelectronics Reliability, 2007, 47(6): 913-923.

[4] CHANELIERE C, AUTRAN J L, DEVINE R A B, BALLAND B. Tantalum pentoxide (Ta2O5) thin solid films for advanced dielectric applications [J]. Materials Science and Engineering R, 1998, R22: 269-322.

[5] PORPORATI A, ROITTI S, SBAIZERO O. Metallorganic chemical vapor deposition of Ta2O5 films [J]. Journal of the European Ceramic Society, 2003, 23(2): 247-251.

[6] YAN Zhi-qiao, XIONG Xiang, XIAO Peng, HUANG Bai-yun. Advances in Ta2O5 film growth with chemical vapor deposition [J]. Journal of Functional Material, 2006, 36(4): 511-514. (in Chinese)

[7] YIDIRIM S, ULUTAS K, DEGER D, ZAYIM E O, TURHAN I. Dielectric properties of sol-gel derived Ta2O5 thin films [J]. Vacuum, 2005, 77(3): 329-335.

[8] GUO Pei-tao, XUE Yi-yu, ZHANG Guang-yong, WANG Han-hua, MA Zhong-jie. Surface morphology and optical property of Ta2O5 thin film [J]. Vacuum, 2007, 44(5): 32-35. (in Chinese)

[9] ATANASSOVA E, SPASOV D. Thermal Ta2O5—alternative to SiO2 for storage capacitor application [J]. Microelectronics Reliability, 2002, 42(8): 1171-1177.

[10] MARIUS G, WILHELM H, MARKUS K T. Near-interfacial delamination failures observed in ion-beam-sputtered Ta2O5/SiO2 multi-layer stacks [J]. Thin Solid Films, 2007, 516(2/4): 136-140.

[11] GRUGER H, KUNATH Ch, KURTH E, SORGE S, PUFE W, PECHSTEIN T. High quality r.f. sputtered metal oxides (Ta2O5, HfO2) and their properties after annealing [J].Thin Solid Films, 2004, 447/448: 509-515.

[12] GHODSI F E, TEPEHAN F Z. Heat treatment effects on the optical properties of sol-gel Ta2O5 thin films [J]. Solar Energy Materials & Solar Cell, 1999, 59: 367-375.

[13] SPASSOV D, ATANASSOVA E, BESHKOV G. Effects of rapid thermal annealing in vacuum on electrical properties of thin Ta2O5-Si structures [J]. Microelectronics Journal, 2000, 31(8): 653-661.

[14] ZHOU J C, CHEN H B, LI Y Z. Diffusion barrier performance of nanoscale TaNx [J]. Trans Nonferrous Me Soc China, 2007, 17(4): 733-738.

[15] MANIFACIER J C, GASIOT J, FILLARD J P. A simple method for the determination of the optical constants n, k and the thickness of a weekly absorbing thin-film [J]. Journal of Physics E: Scientific Instruments, 1976, 9: 1002-1004.

[16] SWANEPOEL R. Determination of the thickness and optical constants of amorphous silicon [J]. Journal of Physics E: Scientific Instruments, 1983, 16: 1214-1222.

[17] MARQUEZ E, RAMIREZ M J, VILLARES P. Calculation of the thickness and optical constants of amorphous arsenic sulphide films from their transmission spectra [J]. Journal of Physics D: Applied Physics, 1992, 25: 535-541.

[18] Joint Committee on Powder Diffraction Standards. Powder Diffraction File [S]. ASTM, Philadelphia, PA, 1967.

[19] MASSE J P, SZYMANOWSKI H, ZABEIDA O, AMASSIAN A, KLEMBERG-SAPIEHA J E, MARTINU L. Stability and effect of annealing on the optical properties of plasma-deposited Ta2O5 and Nb2O5 films [J]. Thin Solid Films, 2006, 515(4/5): 1674-1682.

Foundation item: Project(60371046) supported by the National Natural Science Foundation of China

Corresponding author: ZHOU Ji-cheng; Tel: +86-731-8877805; E-mail: jicheng08@yahoo.cn

DOI: 10.1016/S1003-6326(08)60278-2

(Edited by YANG Bing)