In-situ Raman observation on crack tips of Vickers indent in PLZT ceramics

ZHANG Sa, CHENG Xuan, ZHANG Ying

College of Materials, Fujian Key Laboratory of Advanced Materials,

Xiamen University, Xiamen 361005, China

Received 2 December 2010; accepted 6 April 2011

Abstract: Vickers indentation was introduced into the originally in-plane and out-of-plane poled PLZT ceramics. The Raman spectra were in-situ recorded at selected crack tips before and after the indentations, as well as after the applications of external electric field. The results show that the changes in Raman intensities of optical modes could be sensitively related to 90° domain switching around the crack tips which are strongly dependent on the directions of original polarization and geometric locations. When the direction of electric field was perpendicular to the direction of original polarization, the 90° domain switching at crack tips of the Vickers indentation on the originally in-plane poled PLZT ceramics caused most significant change in the Raman intensity, which inhibited the crack growth. However, when the direction of electric field was parallel to the direction of original polarization, the growth of crack tips became predominantly without the 90° domain switching, which led to the crack growth.

Key words: ferroelectric ceramics; domain switching; in-situ Raman spectroscopy; Vickers indentation

1 Introduction

Domain switching under an alternative mechanical and electrical field is considered to be a major cause for degradation and failure of ferroelectric materials [1-3]. It is shown that Raman spectroscopy could be used as a nondestructive, micro-regional and sensitive technique [4-5] for in-situ observations of 90° domain switching [6-8] and domain reorientation [9] of Pb(Zr0.53Ti0.47)O3 (PLZT) polycrystalline ceramics with home-made experimental apparatuses. By assuming that ferroelectric ceramics are homogeneous and thus domain switching takes place only around the small areas of crack tips, YANG [10] proposed a theoretic model for an electric-induced crack tip after the mechanistic studies in electric-induced fracture and fatigue behaviors of ferroelectric/ piezoelectric materials. Based on the theoretic calculations, FANG et al [11] further concluded that the concentration of tensile stress field may lead to 90° domain switching in front of the crack tips of the Vickers indent. Later, through the investigations of indentation-induced cracking and 90° domain switching patterns in BaTiO3 single crystals in the absence of alternative mechanical/electrical fields, FANG and YANG [12] reported preferential cracks along the boundary of two adjacent domain switching zones or from the boundary of domain switching/non-switching zone. DELUCA et al [13-14] and SAKASHITA et al [15] correlated the relative intensity of Raman optical modes of E(TO2) and E(LO2) to the angle between the local orientation of domains and the polarization direction of incident laser light, and reported that both the degree of crystal orientation in PZT-based ceramics and the stress around the Vickers indents contributed to the Raman responses, which supported the occurrence of domain switching induced by stress concentration surrounding crack tips as predicted by FANG et al [11]. Our previous work [8] found that Raman intensities observed at different locations along the crack tips of Vickers indent were affected by the direction of the Raman incidence and scattered lights with respect to the direction of the average polarization direction of the domain in the originally poled PLZT ceramics. When the two directions were parallel, the induced polarizability tensor would be enhanced and give rise to a higher intensity of Raman scattering light. This work was extended to study two pairs of symmetrically distributed crack tips introduced by Vickers indentation with two types of originally poled PLZT ceramic specimens by in-situ Raman spectroscopy in the absence and presence of external electric field. The intensity changes of Raman spectra were related to the geometric positions of Vickers indents.

2 Experimental

Originally in-plane and out-of-plane poled PLZT specimens with a dimension of 8 mm×8 mm×0.8 mm were used. The molar ratio of Zr to Ti was 53:47 with an additional doping of 3% La and Nb (molar fraction). A tetragonal phase was verified by refinement analysis of XRD data with a typical grain size of 3-5 μm. A groove of 0.2 mm wide was etched in the middle of a 8 mm× 8 mm surface on the specimen via lithography. Good abruptness and flatness of the electrodes were ensured for a uniform voltage to be applied between the two electrodes. When a voltage of 200 V was applied, which equals an electric field (E) of 1 000 V/mm, the value of coercing electric field (EC) of the specimen would be produced between the two electrodes.

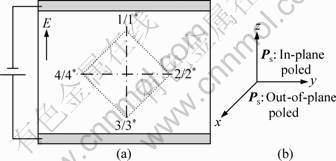

As shown in Fig. 1, a Vickers indent was introduced using a HV-1000 type microsclerometer under a load of 4.90 N and loading time of 20 s on the specimen surface. The crack tips 1 and 3, and crack tips 2 and 4 were mutually symmetrical in terms of location. A DC voltage of 200 V was applied to the in-plane and out-of-plane poled specimens with the direction of electrical field being parallel to z-axis. The Raman spectra before and after the indentations at the four crack tips (marked as 1, 2, 3, 4 and 1*, 2*, 3*, 4*, respectively), as well as the general crack tips (marked as 0 and 0*) which were far away from the indentation and the effect of stress concentration was negligible, were in-situ measured by using a Dilor LabRam-I microspectroscopy system. The 632 nm excitation line from He-Ne laser was focused on a single grain (<3 μm) of the surface in order to eliminate the grain boundary effect.

The external E was then applied to the in-plane poled specimen after the Vickers indentation and the in-situ Raman spectra at tip 1* were recorded with the E values in the sequence order of 0→0.4EC→0.6EC→ 0.8EC→1.0EC→1.2EC→1.4EC→1.6EC→1.8EC→2.0ECfor 5 min at each E value. The corresponding image was also obtained with the optical microscope.

Fig. 1 Schematic diagrams of Vickers indents introduced as crack tips (1, 2, 3 and 4) for in-situ Raman measurements with specimen being subjected to electrical field (a) and directions of in-plane poled and out-of-plane poled specimens (b)

3 Results and discussion

Figure 2 presents the typical in-situ Raman spectra of two optical modes, E(2TO) and E(3TO+2LO)+B1, obtained before and after the Vickers indentation for the in-plane and out-of-plane poled PLZT specimens. As can be seen in Figs. 2(a) and (b), before the indentation, the Raman spectra near tips 1-4 and tip 0 for both in-plane and out-of-plane poled specimens are essentially identical except the magnitude of Raman intensity is slightly larger for the in-plane poled PLZT specimen. However, after the indentation, the Raman intensities of tips 1*-4* increase noticeably, while those around tip 0* slightly increase (Figs. 2(c) and (d)). In particular, the Raman spectra observed at tips 1*-3* jump more pronouncedly than those at tips 2*, 4* and 0*. A comparison of the Raman intensities for the in-plane and out-of-plane poled specimens at tips 1-4 and tip 0 is shown in Fig. 3. The relative changes in Raman intensities before and after the indentations (DI) is calculated as:

(1)

(1)

where I0 and Ii are the Raman intensities before and after the Vickers indentations. DI values of 513% and 512% at tip 1*, 509% and 498% at tip 3*, 301% and 177% at tip 2*, as well as 288% and 189% at tip 4*, while only 34% and 38% at tip 0*, for the in-plane and out-of-plane poled specimens, respectively, are obtained before and after the indentations. The significant changes in Raman intensities at tips 1* and 3* might be associated with the domain tensile stress at the tips and the 90° domain switching induced through the indentation due to the average polarization direction being parallel to y-axis. This observation confirms the dependence of domain switching on stress concentration at the tips.

Figure 4 shows the normalized results from the Raman spectra measured for the in-plane poled specimen at tip 1* (i.e. the original polarization direction is along y-axis as illustrated in Fig. 1) after applying a series of E values. Here I0 and IE are the Raman intensities before and after the E applications. A nearly linear decrease in IE/I0 with the increase of E/EC is observed for both Raman optical modes up to E/EC?1.6. R1 and R2 are the linear correlation coefficients for fitting E(2TO) and E(3TO+2LO)+B1, respectively. However, the IE/I0 values become virtually unchanged when the value of E/EC gets ger than 1.6. This indicates that the saturation of 90° domain switching might be reached at E>>EC.

Fig. 2 In-situ Raman spectra of four selected crack tips and general tip obtained before and after Vickers indentations: (a) Out-of-plane poled sample before indentation; (b) In-plane poled sample indentation; (c) Out-of-plane poled sample indentation; (d) In-plane poled sample after indentation

Fig. 3 Comparison of Raman intensities of optical modes obtained at general tip and four crack tips before and after indentations: (a) Out-of-plane poled specimen; (b) In-plane poled specimen

The built-in optical microscope image for the same specimen is present in Fig. 5. The growth of crack tips during the E applications varies due to the differences in polarization direction and electric field direction. For the geometry of the crack tips and the polarization orientation direction shown in Fig. 1, the original polarization direction of tips 1* and 3* is along y-axis direction, which is perpendicular to the applied E direction (z-axis direction). Such a rearrangement movement of the ions would turn the original dipole Ps (or polarization direction) from y-axis to the new direction along z-axis and thus result in a 90° domain switching near tips 1* and 3*, which would effectively inhibit the extension of indentation crack, showing a crack blunting effect. On the other hand, the E direction is parallel to the original polarization direction of specimen, the E-induced tensile stress field in front of tips 2* and 4* would not be able to induce such a 90° domain switching, which leads to the crack growths of tips 2* and 4* and eventually dominant cracks. Future work is undergoing to perform more systematical studies for quantitative analyses in the amount of domain switching and the extent of crack growth at the Vickers indents in the absence and presence of electric field.

Fig. 4 Normalized Raman intensity of optical modes as function of relative intensity of electric field for in-plane poled specimen at crack tip 1*

Fig. 5 Optical image showing growth of crack tips for in-plane poled specimen

4 Conclusions

1) The changes in Raman intensity of optical modes are sensitive to the geometric location of crack tips in ferroelectric ceramics and directions of original polarization and applied electric field. When the direction of electric field is perpendicular to the direction of original polarization, the 90° domain switching at the crack tips of the Vickers indents on originally in-plane poled PLZT ceramics causes the most significant change in the Raman intensity of optical modes, which inhibits the crack growth.

2) The growths of crack tips during the application of electric field vary due to the differences in polarization direction and electric field direction. The electric-induced crack tips with the direction of electric field being parallel to the direction of original polarization would grow predominantly without 900 domain switching.

References

[1] YANG Wei. Mechatronic reliability [M]. Beijing: Tsinghua University Press, 2001: 21-128. (in Chinese)

[2] HWANG H J, TAJINM K, SANDO M, TORIYAMA M. Fatigue behavior of PZT-based Nanocomposites with fine platinum particles [J]. Journal of the American Ceramic Society, 1998, 81(12): 3325-3328.

[3] ZHONG Wei-lie. Electrical physics [M]. Beijing: Science Press, 1996: 155-169. (in Chinese)

[4] ZHANG Guang-yan, LAN Guo-xiang, WANG Yu-fan. The spectroscopy of crystal lattice liberation [M]. Beijing: Higher Education Press, 2001: 195-255. (in Chinese)

[5] FANG Rong-chuan. The spectroscopy of solid [M]. Beijing: Science Press, 2001: 282-294. (in Chinese)

[6] ZHANG Sa, CHENG Xuan, ZHANG Ying. In situ Raman spectroscopy observation for domain switching of ferroelectric ceramics [J]. Acta Metallurgica Sinica, 2005, 41(6): 663-668. (in Chinese)

[7] ZHANG Ying, CHENG Xuan, ZHANG Sa. In-situ Raman spectroscopic study of domain switching of PLZT ceramics [J]. Applied Physics A: Materials Science & Processing, 2007, 89(3): 685-693.

[8] ZHANG Sa, CHENG Xuan, ZHANG Ying. In-situ observation on domain switching of PLZT via Raman spectroscopy [J]. Transactions of Nonferrous Metals Society of China, 2006, 16(3): 638-642.

[9] YANG Feng-juan, CHENG Xuan, ZHOU Zhi-dong, ZHANG Ying. An analysis of domain reorientation in PLZT ceramics by in situ Raman spectroscopy [J]. Journal of Applied Physics, 2009, 106(11): 114115(1-5).

[10] YANG Wei. Mechtronic failure analysis [J]. Advances in Mechanics, 1996, 26(3): 338-352. (in Chinese)

[11] FANG Fei, YANG Wei, ZHU Ting. Fatigue crack growth in ferroelectric ceramics below the coercive field [J]. Journal of Materials Research, 1999, 14(7): 2940-2944.

[12] FANG Fei, YANG Wei. Indentation-induced cracking and 90° domain switching pattern in barium titanate ferroelectric single crystals under different poling[J]. Materials Letters, 2002, 57(1): 198-202.

[13] DELUCA M, SAKASHITA T, GALASSI C, PEZZOTTIL G. Investigation of local orientation and stress analysis of PZT-based materials using micro-probe polarized Raman spectroscopy [J]. Journal of the European Ceramic Society, 2006, 26(12): 2337-2344.

[14] DELUCA M, SAKASHITA T, PEZZOTTI G. Polarized Raman scattering of domain structures in polycrystalline lead zirconate titanate [J]. Applied Physics Letters, 2007, 90(5): 051919-051913.

[15] SAKASHITA T, CHAZONO H, PEZZOTTI G. Quantitative analysis of domain texture in polycrystalline barium titanate by polarized Raman microprobe spectroscopy [J]. Journal of Applied Physics, 2007, 102(12): 124106-124107.

PLZT铁电陶瓷维氏压痕裂纹尖端的原位Raman观测

张 飒, 程 璇, 张 颍

厦门大学 材料学院,福建省特种先进材料重点实验室,厦门 361005

摘 要:通过对预先切向极化和纵向极化的PLZT铁电陶瓷试样表面引入维氏压痕,在压痕引入前后以及外加电场作用下原位记录维氏压痕裂纹尖端处的Raman光谱变化。结果表明:裂纹尖端的Raman光学模的强度与90°畴变、试样的预先极化方向以及裂纹尖端的空间分布位置密切相关。当试样的极化方向与外加电场方向垂直时,极化试样的维氏压痕裂纹尖端发生90°畴变,抑制裂纹的生长,此时观测到的Raman光谱强度变化最显著。当试样的极化方向与外加电场方向平行时,几乎不发生90°畴变,将导致裂纹尖端的裂纹生长。

关键词:铁电陶瓷;畴变;原位Raman技术;维氏压痕

(Edited by FANG Jing-hua)

Foundation item: Project (2006L2003) supported by the Fujian Key Laboratory of Advanced Materials, China; Project (10802070) supported by the National Natural Science Foundation of China

Corresponding author: ZHANG Ying; Tel: +86-592-2180999; Fax: +86-592-2185599; E-mail: yzh@xmu.edu.cn

DOI: 10.1016/S1003-6326(11)61005-4